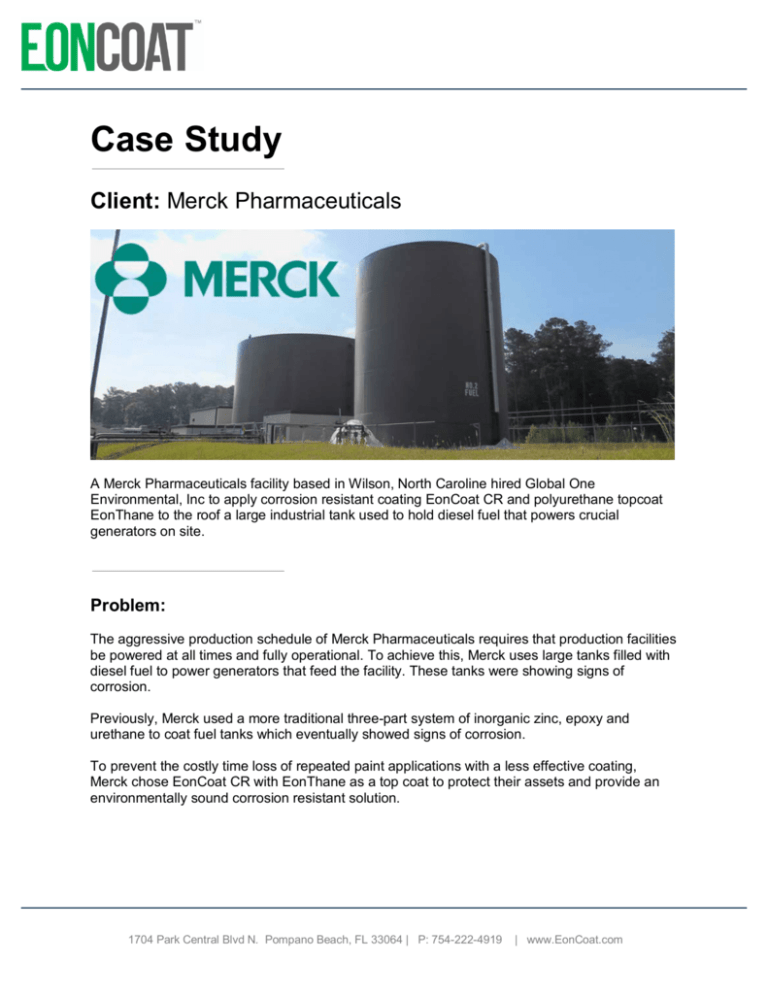

Merck Pharmaceuticals EonCoat Case Study

advertisement

Case Study Client: Merck Pharmaceuticals A Merck Pharmaceuticals facility based in Wilson, North Caroline hired Global One Environmental, Inc to apply corrosion resistant coating EonCoat CR and polyurethane topcoat EonThane to the roof a large industrial tank used to hold diesel fuel that powers crucial generators on site. Problem: The aggressive production schedule of Merck Pharmaceuticals requires that production facilities be powered at all times and fully operational. To achieve this, Merck uses large tanks filled with diesel fuel to power generators that feed the facility. These tanks were showing signs of corrosion. Previously, Merck used a more traditional three-part system of inorganic zinc, epoxy and urethane to coat fuel tanks which eventually showed signs of corrosion. To prevent the costly time loss of repeated paint applications with a less effective coating, Merck chose EonCoat CR with EonThane as a top coat to protect their assets and provide an environmentally sound corrosion resistant solution. 1704 Park Central Blvd N. Pompano Beach, FL 33064 | P: 754-222-4919 | www.EonCoat.com Prep & Application: Global One Environmental, Inc prepped the surface to a 2-4mil profile, with a dustless blaster using water and a mix of garnet and soluble media. Once the surface achieved a NACE 2, it was allowed to flash rust before the coating was applied. They then applied EonCoat CR and companion top coat EonThane to one exterior rook tank. 1704 Park Central Blvd N. Pompano Beach, FL 33064 | P: 754-222-4919 | www.EonCoat.com Results: What is typically a 2 week job was shortened to 5 days, as the prep was less time consuming, flash rust did not need to be removed, and there was no need to wait for EonCoat CR to dry overnight prior to top-coating with EonThane. The application occurred in June 2014 when temperatures exceeded 95 degrees Fahrenheit in direct sunlight. 1704 Park Central Blvd N. Pompano Beach, FL 33064 | P: 754-222-4919 | www.EonCoat.com