Untitled - MSME Development Institute, Mumbai

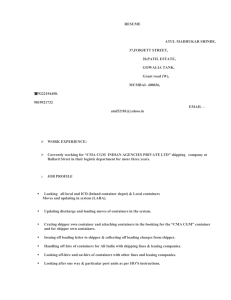

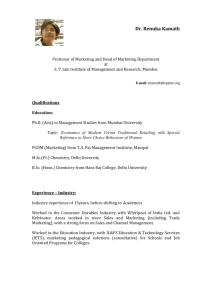

advertisement