Joseph M. Juran Joseph M. Juran's Quality Trilogy

advertisement

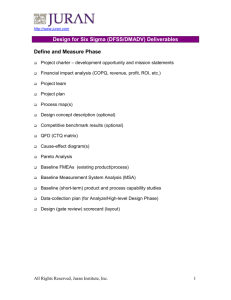

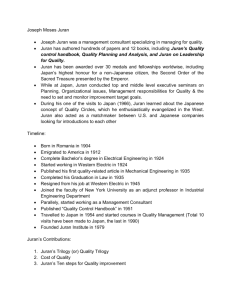

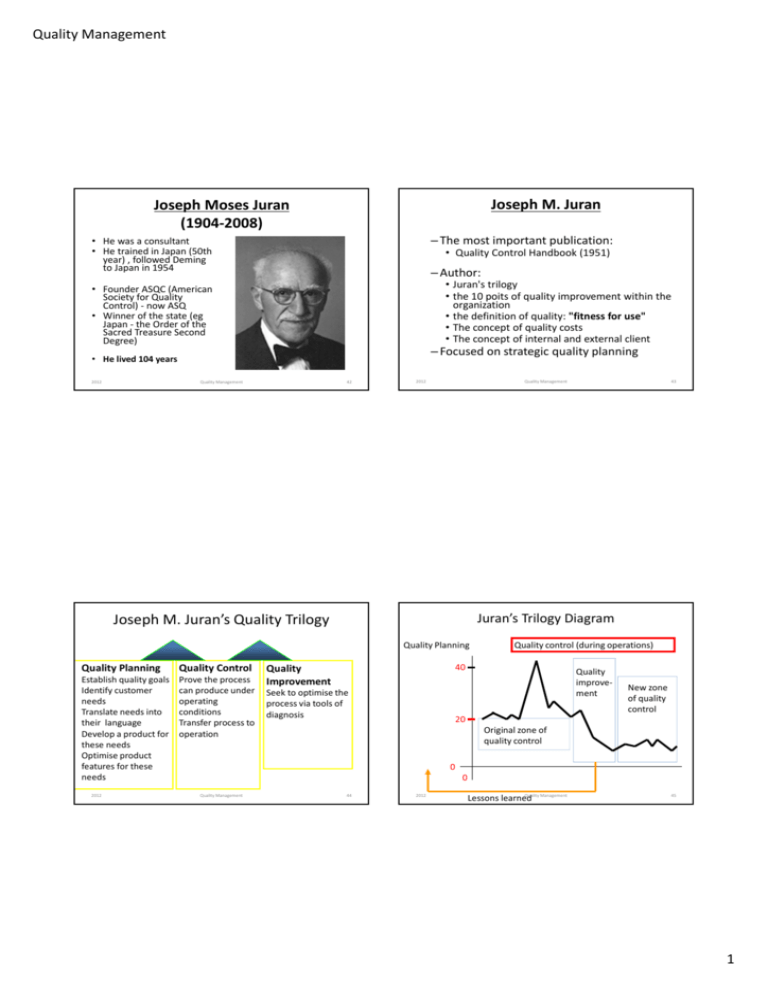

Quality Management Joseph M. Juran Joseph Moses Juran (1904-2008) – The most important publication: • He was a consultant • He trained in Japan (50th year) , followed Deming to Japan in 1954 • Quality Control Handbook (1951) – Author: • Juran's trilogy • the 10 poits of quality improvement within the organization • the definition of quality: "fitness for use" • The concept of quality costs • The concept of internal and external client • Founder ASQC (American Society for Quality Control) - now ASQ • Winner of the state (eg Japan - the Order of the Sacred Treasure Second Degree) – Focused on strategic quality planning • He lived 104 years 2012 Quality Management 42 2012 Quality Management Juran’s Trilogy Diagram Joseph M. Juran’s Quality Trilogy Quality Planning Quality Planning Quality Control Establish quality goals Identify customer needs Translate needs into their language Develop a product for these needs Optimise product features for these needs Prove the process can produce under operating conditions Transfer process to operation 2012 43 Quality control (during operations) 40 Quality Improvement Seek to optimise the process via tools of diagnosis Cost of Poor Quality Quality improvement New zone of quality control 20 Original zone of quality control 0 0 Quality Management 44 2012 TIME Quality Management Lessons learned 45 1 Quality Management Juran’s Quality Planning Road Map Joseph M.Juran and the Cost Of Quality 2 types of costs 1) Identify who are the customers 2) Determine the customer’s needs 3) Translate the needs into their language 4) Develop a product to meet those needs 5) Optimise a product so as to meets our needs as well as the customer’s. 6) Develop a process which is able to produce the product 7) Optimise the process 8) Prove the process can make the product under operating conditions 2012 Quality Management • Unavoidable Costs: • preventing defects (inspection, sampling, sorting, QC) • Avoidable Costs: • defects and product failures (scrapped materials, labour for re-work, complaint processing, losses from unhappy customers) 46 Joseph M.Juran and the Cost Of Quality Costs Total Costs Unavoidable costs Avoidable costs 100% defective 2012 Point of “Enough quality” Quality Management 100% good 48 2012 Quality Management 47 Joseph M. Juran’s 10 Points 1. Build awareness of the need and opportunity for improvement. 2. Set goals for improvement. 3. Organise to reach the goals (establish a quality council, identify problems, select projects, appoint teams, designate facilitators) 4. Provide the training. 5. Carry out projects to solve problems. 2012 Quality Management 49 2 Quality Management Armand Vallin Feigenbaum (1922-?) Joseph M. Juran’s 10 Points In 1951, introduced concepts of total quality control and continuous quality improvement Books: 1945, Quality control: principles, practice and administration; an industrial management tool for improving product quality and design and for reducing operating costs and losses, McGraw-Hill industrial organization and management series, New York, McGraw-Hill, 1961, Total Quality Control, McGraw-Hill 6. Report progress. 7. Give recognition. 8. Communicate results. 9. Keep score. 10.Institionalize the improvement process (Maintain momentum by making annual improvement part of the regular systems and process of the company.) 2012 Quality Management 50 2012 A.V. Faigenbaum 1. 2. 3. 4. 5. – Term: QUALITY COST (1943) – Term: TOTAL QUALITY MANAGEMENT (1961) Quality Management 51 Japanese quality gurus • Author: 2012 Quality Management 52 2012 Kaoru Ishikawa Shigeo Shingo Taiichi Ohno Genichi Taguchi Masaaki Imai Quality Management 53 3 Quality Management Kaoru Ishikawa (1915-1989) Kaoru Ishikawa Shigeo Shingo (1909 - 1990) • Industrial engineer • Shingo method = Pokayoke method ("foolproofing" or "idiotproofing") Dr Promoted use of quality circles Developed “fishbone” diagram (Ishikawa Diagram) Emphasized importance of internal customer 2012 Quality Management – A poka-yoke is any mechanism in a lean manufacturing process that helps an equipment operator avoid mistakes 54 2012 Taiichi Ohno (1912 – 1990) 55 Genichi Taguchi (1924-2012) • an engineer and statistician. • From the 1950s onwards, Taguchi developed a methodology for applying statistics to improve the quality of manufactured goods. • Taguchi methods • He was a Toyota executive and one of the chief architects of the Toyota Production System (kaizen). • He wrote several books about Toyota, f.e: – Toyota Production System: Beyond Large-Scale Production – Workplace Management. Quality Management Quality Management – Taguchi loss function – design of experiments 56 2012 Quality Management 57 4 Quality Management Masaaki Imai (1930-…) • Leader in spreading the Kaizen philosophy (Kaizen Institut) • Books: – 1986: Kaizen: The Key to Japan’s Competitive Success – 1997: Gemba Kaizen: A Commonsense, Low-cost Approach to Management 2012 Quality Management 58 5