Behavior of oxyanions forming heavy metals in municipal solid

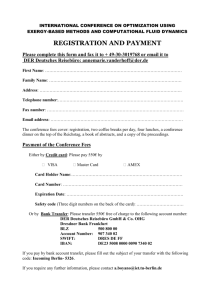

advertisement