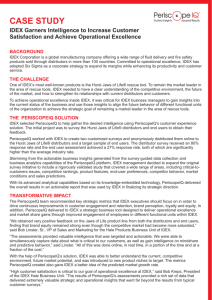

DISCIPLINED - IDEX Corporation

advertisement