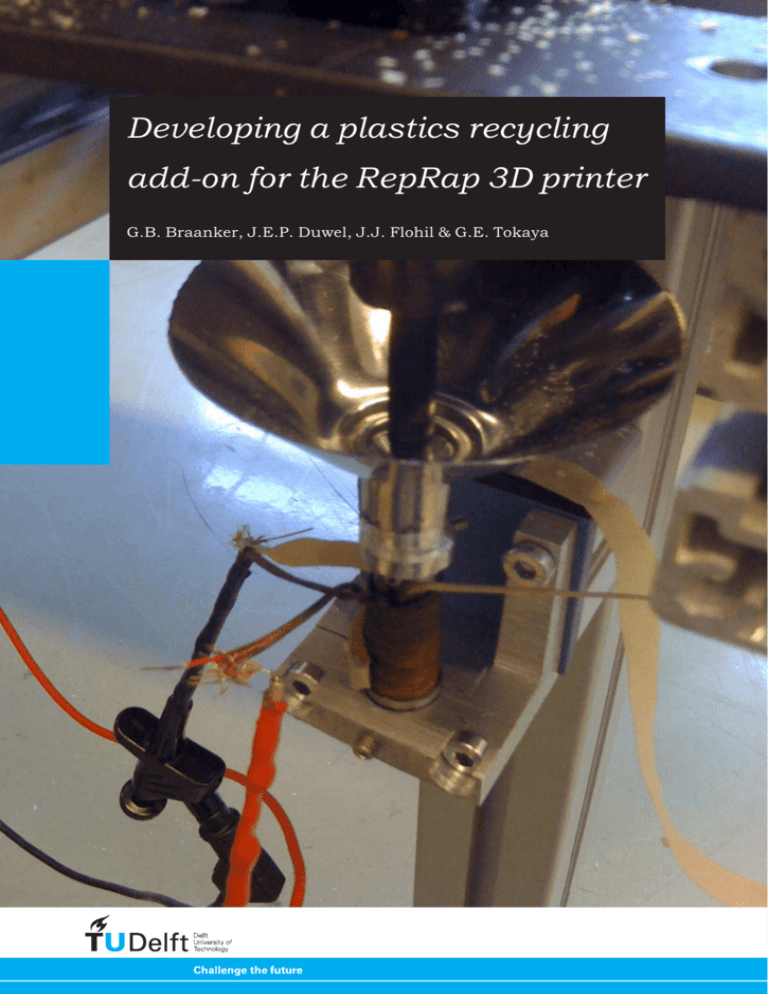

RepRap granule extruder - RepRap Recycling

advertisement