BP / Valhall A 08B - Petroleum Safety Authority Norway

advertisement

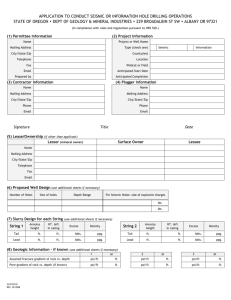

ODBP.doc Casing Design – Review of Design Methodology Review performed for PSA at BP by Rock-Well Consultants 2004 Report No. RWC 5/04, rev. 1. 1 Contents: Page: Summary 3 1. Project description 4 2. Review of BP casing design procedures 2.1 BP’s governing documentation 2.2 Discussion of BP Casing and Tubing Design Manual. 5 3. Well failure on Valhall 3.1 Description of incident 3.2 Operational summary of 2/8-A-08 10 4. Design of well 2/8-A8B 4.1 Valhall general casing design 4.2 Well 2/8-A8B 4.3 Worst case considerations 4.4 Summary of incident 21 5. Summary of review 30 6. Recommendations 31 Abbreviations 32 References 33 Appendix A: Design factors for well 2/8-A8B 34 2 Summary: The design documentation used by BP is reviewed. The casing design manuals are of high quality. This report also presents an evaluation of BP methodology for well construction using a well incident of well 2/8-A5B at Valhall as a case. Severe circulation losses led to pumping of a gunk pill. This plugged the drill string leading to a shut-in wellhead pressure. A well control operation stabilized the well, which was eventually sidetracked. The review found that the casings had sufficient strength in burst and tension and collapse. It is, however, recommended to consider more realistic design scenario. Severe losses indicate that a gas filled casing scenario should be appliad rather than a kick margin for burst design. This will require a higher casing test pressure. Likewise, circulation losses gives more severe loading than base-oil filled casing for collapse design. However, in the subsequent sidetrack (A-08 C9 more severe design scenario were used. The risk worksheet cover normal losses, but does not identify total losses in the reservoir as a potential risk. A strategy for combating lost circulation in the reservoir should be developed. The decision to continue to circulate the well after a positive flow check, and the unsuccessful pumping of a gunk pill should be re-visited, with a view to clarifying what procedures would be applicable in a future similar situation. 3 1. Project Description The objective of the project is to investigate the methodology for casing design for several operating companies in Norway. The present report focuses on BP. The project will evaluate the design manuals, the methodology for data collection, the quality and the use of these in the course of the well design. The background for the project is that the PSA has observed cases where the casing design was the limiting factor for the well at several operating companies. Because one expects a number of HPHT wells in the near future, the design basis each operator uses is identified to search for improvements. This project uses a well control incident of well 2/8-A8B as a case to search for improvements. A review of the operational aspects of the incident has also been performed. 4 2. Review of BP’s casing design procedures 2.1 BP’s governing documentation After the merger a few years ago between BP and Amoco, the documentation has been revised. References 1 through 5 identify the manuals related to well construction. The overall impression is a set of manuals that are modern, updated and of high quality. The manuals are in electronic format, allowing for yearly updates. In the following we will review ref. 3 which is the Casing Design Manual. This manual contains the following chapters: Authorisation for Issue Amendment Summary Distribution List Preface List of Abbreviations Part 1: Overview and Policies Part 2: Quick Guide Part 3: Detailed Manual Part 4: Design Example Part 5: Useful Information Addendum References Part 1 contains the following subchapters: 1. Overview 2. Changes to This Manual 3. Policy Statement for casing Design 4. Pressure Test Requirements 5. Contravention of policy Statements Under Policy Statement the following policies are defined: - All wells require casing design, checked and approved - Pore and frac pressure design basis required - Setting depth selected to provide safety margin. - Kick tolerance calculations required - Burst loading design required, with less risk of casing failure than of exposed formation. - Tubing leak design required for production casing - Tri-axial design recommended - Exploration and appraisal wells require gas filled casing design, whilst development wells reservoir fluid should be used. - Recommended to run leak-off-tests. 5 It is implied in these policy statements that the importance of design criteria (pore and frac pressure) and, the assessment of risk (setting depth-safety margin) are key factors in the design of a well. Part 2: Quick Guide contains the following subchapters: 1. Introduction 2. Data needed before design 3. Design summary 4. Casing setting depths 5. Collapse design 6. Burst design 7. Tension design 8. Tri-axial design 9. Buckling and compression 10. Casing wear 11. Temperature 12. Special design cases 13. Reliability 14. Connection selection 15. Materials selection 16. Kick tolerance This part is a compact reference for well designers familiar with the remainder of the manual. References are provided to details defined in other chapters. The Quick Guide provides a good summary. We will not discuss this further, but provide comments to the chapters to follow. Part 3: Detailed Manual contains the following subchapters: 1. Introduction 2. Data needed before design 3. Casing design software in BP Amoco 4. Casing setting depth guidelines 5. Collapse design criteria 6. Burst design criteria 7. Tensile design criteria 8. Tri-axial design analysis 9. Buckling and compression design considerations 10. Casing wear 11. Temperature considerations 12. Special design cases 13. Casing design reliability 14. Connections 15. Corrosion 16. Kick tolerance Part 3 is the major part of the manual and contains a lot of information. Although different design criteria can be applied, the manual reflects current industry understanding. A few comments will be tied to certain subchapters. 6 Under 1. Introduction it is stated: "While this manual identifies minimum requirements it must be recognized that government regulations and/or local considerations may require that casing designs be carried out to standards exceeding those in the manual." Under 3. Casing Design Software in BP Amoco, the software packages are defined. Most of these are used by many other operating companies and are considered industry standard. A discussion about each program is also presented, addressing limitations and giving practical advice. Subchapter 4: Casing Setting Depth Guidelines is a key chapter in the design process. The initial setting depth based on pore and frac pressures is the start of the design. The chapter further addresses mud weight, hole inclination and other important factors. The chapter gives a good overview over the well design process. The following statement is reproduced from this chapter: “Sensitivity studies should be considered to identify the contingency provisions required to accommodate pore or fracture pressures during drilling which differ from those assumed during design. Kick tolerances which may be acceptable for seat selection are not an acceptable basis for mechanical burst design.” Subchapter 4 further presents methods to derive fracture gradient and overburden prognosis. Methods by Daines, Hubbert and Willis, Mathew and Kelly, Pennebaker, Eaton, MacPherson and Berry and Zamora are recommended. These are all correlation methods from the 1970’s and 1980’s. Daines method has in particular been popular to establish fracture prognosis in vertical wells. Most wells today are deviated. Also, in-situ stress analysis has proven useful. It is recommended to consider these newer approaches for fracture gradient predictions. The inversion method derived by Aadnøy(ref. 6) has in particular provided good results. Reference 7 presents alternative modeling methods. Subchapter 6 covers burst design. It is stated that: “Local regulatory agencies, e.g. MMS in the Gulf of Mexico, may impose specific local criteria which differ from those in the manual. Nevertheless wherever possible, casing design in BP Amoco should: - Provide casing stronger in burst than the fracture pressure of exposed formation beneath the shoe. - Take account of the possibility of a hydrocarbon column to the wellhead.” The first condition implies that a weak point in the well should never be beneath the wellhead, but below the casing shoe, a sound approach. Reference 7 discusses this requirement in 7 detail. The second comment about gas(oil) filled casing will be addressed in the discussion of well A8B later in this report. Also the burst design chapter discusses the external pressure profiles for burst load design. In summary, the following conditions are given(our short version of the conditions): -External pressure equal to pore pressure in cemented intervals. -External pressure equal to mud mix fluids (i.e. hydrostatic of water for waterbased mud and hydrostatic of base oil for oil based mud). -Mud density for short time applications. The classical back-pressure used in the oil industry is the pressure caused by water. Because water is the only mobile phase, and particles settles out over time, this very conservative criterion is used by many operators. However, for critical wells the mud weight is used as a short time scenario. It should be stated that the back-pressure issue is not fully resolved throughout the industry. Subchapter 10 covers casing wear. Their treatment includes practical experience, experimental tests on casing, tool joints and mud. They also state the well known fact that the theoretical solutions for wear are not particularly good. Casing wear reduces the burst and collapse strength of the casing strings. Equations are presented to perform these calculations. Additional comments that could be included are: 1) Tools that measure casing wear have a given resolution, and may not give a correct picture, and, 2) in critical wells it may be advisable to pressure test casings if there is uncertainty about the degree of casing wear. Subchapter 13 covers casing design reliability. It is interesting to observe the following statement: “The most important parameter in determining the reliability and success of a casing design is the pore pressure. This means drilling engineers must work closely with all supporting groups to determine pore pressure confidence levels and ensure that all parameters impacting pore pressure predictions have been addressed.” This demonstrates the fundamental coupling between various elements of the well design. Part 5 presents a design example. This worked example serves well as a guide as many important elements are included. 2.2 Discussion of BP’s Casing and Tubing Design Manual. The manual is modern and a document of high quality. The manual reflects the understanding and emphasize the four key parameters: -the pore pressure -the fracture pressure -the density of the formation fluid 8 -the back pressure on the casing We did not find any errors in the manual, but have supplied a few comments as seen from an outside observer. BP Amoco may consider including these. The manual is very comprehensive and well organized. Such a manual should also be accompanied by a competence requirement for the personnel using it. The quality of the design still depends on the competency of the well designer and the quality of the design verification. One difficulty with such governing documentation is to impose the policies at all levels, well design, procurement and the actual well operations. 9 3. Well failure on Valhall 3.1 Description of Incident The second task is to investigate the well problems on well 2/8-A-8 B. The summary from the Incident Investigation Report (ref. 8) will be reproduced below to give the overview. Quote from Reference 8: 2. Summary Well 2/8-A B was spudded in October 2003. The A-8 slot was reclaimed and the A-8 B bore was drilled out of the 13 3/8” casing of the mother-bore. During November and December 2003 the well was drilled according to plan with setting an 11 ¾” liner and then drilling a 9 ½” x 12 ¼” section. After setting and cementing the 9 5/8” drill-in liner in the top of the reservoir, the shoe was drilled out and a 10.5 ppg equivalent FIT was performed. The 13 3/8” liner/11 ¾” liner was tested to 1500 psi. An inflow test was performed on the 9 5/8” liner. The test showed no flow. Drilling ahead approximately 62 m from the shoe, total losses were encountered. Loss rates up to 600 bbl/hr were experienced with the 8.3 ppg oil base mud originally in the hole. The loss rate was gradually reduced as the rig attempted to keep the hole full by filling it with premix and base oil and then eventually seawater. The well was then stabilized by placing a total of 65 bbls LCM in the open hole section. The drill string was round-tripped to lay down the radioactive source. As the string washed down from the top of the 9 5/8” liner, dynamic losses were again induced. At the shoe a flow check gave 10 bbls gain in 25 min, suspected to be ballooning. The well was circulated for 15 min before a new flow check gave 2 bbls gain in 5 min. Circulation with the well open was performed for 1 hour until a sharp increase in returns was observed. The well was shut in on the annular preventer with SIDPP of 0 psi and SICP of 200 psi. Attempts were made to stabilize the well by circulating out gas through the choke. Returns were again lost and then two annular volumes of seawater were bullheaded on the annulus side while the losses increasing up to 100 bbl/hr. Two LCM pills were displaced in attempt to cure the losses without success. Casing pressure was still rising slowly. It was then attempted to kill the well using 9.0 ppg water based mud. During the circulation, dynamic losses were experienced and the returns contained crude oil. After circulating the full well, the casing pressure was 534 psi while the drill pipe pressure was 450 psi. Another LCM pill was displaced down and squeezed to cure the losses, but unsuccessful. It was then attempted to kill the well by circulating 10 ppg mud around through the choke. Due to high gas peaks and unstable returns the well was shut in and it was attempted bullhead the gas on annulus side by seawater and 10 ppg mud. Gas readings were still high and a gunk pill was pumped through the drill pipe to plug off the open hole. The gunk pill plugged off the drill pipe and the ability to circulate the well was lost. The casing pressure continued to rise leveling off at 800 psi. An attempt to pressure test the annulus broke down the formation and gave injectivity at 850 psi. The casing pressure 10 Quote from ref. 8, continued: was still rising so the annulus was bullheaded with 2 annulus volumes of seawater making the casing pressure to drop to 0 psi. When circulating 4 bpm across the BOP the loss rate was 55 bbl/hour. To stem the losses, a 54 bbl LCM pill was bullheaded down and squeezed into the formation. The well was then shut in and monitored showing a rapid pressure build-up on the casing side. The pressure was bled off and kept at max 1400 psi to be below the 13 3/8” casing test pressure at 1500 psi. At the same time it was started to lubricate in 15.0 ppg mud to increase the hydrostatic head on the annulus side, and a mix of free gas and 9-11 ppg mud was bled off. While continuing to bleed off and lubricate on the annulus side, wireline equipment was rigged up on top of the drill string. After a wireline drift run, and a tubing perforator mis-run, the drill string was successfully perforated at 2700 m. The surface pressure was then allowed to stabilize, giving a SIDPP of 1530 psi and a SICP of 1900 psi (the outer annulus was backed up with 500 psi to stay within the 13 3/8” test pressure). Preparations were then made to kill the well with 14.0 ppg mud. After circulated the well to even mud through the choke, the annular was opened and the well circulated conventionally. A flow check was performed and the well was static. 3. Conclusions Root cause of lost circulation. The most likely explanation for the losses is that within the reservoir there are several hard ground units – on centimeter scale. These fractured hard grounds, likely to be found in the crestal area, may act as flow units and free gas may accumulate in the fractures, which will allow for easy flow of drill fluid even at low-pressure differentials. Cores from the hard grounds in a similar well (F-11) prove large voids, which support the current failure explanation. (see details in appendix 3) The subsurface team will use some more time to look at other possible causes. They will check details on the plot (appendix 4) to see if there are other reasons for the loss problem. This information will be used for future planning on similar wells on Valhall Crest. Well Control root cause The well control incident initially developed on the trip to lay down the radioactive source, but escalated when gunk plugged the drill string and circulation was no longer possible. This investigation has not been able to establish the root cause for the incident, but the preliminary results from the A-8B influx study seems to confirm that we most likely got the influx of oil&gas from the Tor reservoir and not the Mid Miocene “reservoir”. 3 possible root cause scenarios has been identified. Ref. Section 7. 4. Recommendations -If new wells are planned to be drilled into areas with a combination of hard beds and free gas into such areas, make sure a rigorous risk assessment and a plan for how to mitigate the high risks are in place. 11 Quote from ref. 8, continued: -Evaluate to utilize a more robust port collar design to avoid possible leaks. -Evaluate improved isolation around the shoe of the casing/liner entering the reservoir. For additional recommendations see chapter 8 – Recommended Corrective Action. Quote from Ref. 8 ended. 12 3.2 Operational summary 2/1-A-08 Conclusions from operational summary 1. Well control response offshore as would be expected apart from the decision to circulate the well open after a positive flow check. The background for this decision should be evaluated to give guidelines for the future. 2. The risk of lost circulation in the Tor reservoir does not appear to be identified in the risk worksheet and an agreed strategy may not have been in place. 3. Activities that should be instigated should include investigation into the best loss circulation combating strategy, with identification of applicable LCM materials (including gunk) and combination of same, together with procedures for use of them. 4. The procedures used to place the gunk pill need to be investigated and improved to avoid blocking the drill string, possibly in the form of a ‘best practice’ procedure to ensure optimal execution. Discussions The actions taken during the lost circulation problems on Valhall well 2/1-A-08A were, as far as can be seen from the daily drilling reports, as would be expected. It can also be seen that they took time to agree with a ‘Management of Change‘ process with the BP land organisation. From the actions taken in the initial phases of the incident, BP seem to have lacked a plan for dealing with lost circulation. Total losses were first encountered at 0315 hrs 9.12.2003, but the first lost circulation pill was pumped at 1000 hrs on the same day, after losing over 4000 bbl of fluid (oil based mud, base oil, and sea water). This observation appears to be confirmed by the risk worksheet listing potential risks with the well. Several similar aspects were addressed: Risk #13. Destabilise natural fractured rock (around faults and in potential problem area) with the risk description including ballooning with losses while drilling and flow back with the pumps off. The mitigation strategy was to limit the maximum ECD and to follow the mud weight increase set out in the drilling fluid BOD (basis of design). Combating losses was not addressed Risk 3601. Unexpected faults. Poor seismics in the upper 1000 m may make it difficult to identify faults, leading to the possibility of drilling unexpectedly through a fault. The mitigation here was to specify in detail how to weigh up, and to avoid weighing up too quickly. Combating losses was not addressed Please note that the two risks above refer to the overburden section, not the reservoir. The incident described in this report is the first time breathing in the reservoir has been seen. 13 Risk 3610. Loss of circulation during running casing and cementing. Consequences were indicated as poor zonal isolation behind casing and mitigation was ‘good drilling practices … and Opticem cement job calculation’. This does not address total losses while drilling Risk 3625. Run out of active mud while drilling down the 9 5/8” liner if major losses occur. The mitigation strategy was to ensure sufficient mud reserves available by storage on boats so that drilling without returns would be possible. This risk is addressed at the 12 ¼” hole section and, as such, does not cover the 8 ½” hole section. The mitigation strategy certainly does not seem to have been in place for this incident. Risk 77. Mud losses penetrating the Tor with drilling string. This again addresses losses in the 12 ¼” section with the mitigating strategy to have a gunk system ready for use. Gunk was first pumped on this incident about 5 days after losses were seen. Losses did in fact come in the Tor formation, but not while drilling down the liner, and 62 m below the shoe after the mud weight had been cut back. It appears that total losses in the 8 ½” section were not expected/considered as a risk, and a mitigating strategy had not been considered. Although the internal BP report indicate that the reservoir drilling risk evaluation identified losses was a risk, and contingency plans made, the risk worksheet does not confirm this. Although the losses were stopped and a trip to change the BHA and remove the radioactive source was made successfully, well integrity was not sufficient, and losses were again induced, finally leading to an influx being taken. Activities that should be instigated should include investigation into the best total loss circulation combating strategy, with identification of applicable LCM materials (including gunk) and combination of same, together with procedures for use of them. The gain seen during the flow check after the trip to change the BHA was interpreted as ballooning, which in this case may have been erroneous. In hindsight, a full circulation over the choke at constant bottom hole pressure would have been advisable to confirm the gain was, in fact, ballooning. Most well control policies demand the well be shut in if a gain is seen at a flow check. Due to the loss problem, it is perhaps understandable that circulating over the choke was not done. This again goes back to evaluation of applicable strategies for combating loss circulation. The strategy chosen led to the use of the gunk pill, which was identified as a mitigating strategy in the 12 ¼” section. The result of this action, was possibly the worst possible. The drill string was blocked during this process, and the losses were not cured. This worsened the situation significantly. The procedures used in this case need to be investigated and improved to avoid blocking the drill string, possibly in the form of a ‘best practice’ procedure to ensure optimal execution. We are in agreement with the need to focus on both temperature differences to ‘normal’ gunk pill jobs on Valhall, and the base fluid type (sea water). 14 2/8-A-08B Daily Operations Summary Date Description Comments 5.12.03 Repaired annular preventer on BOP Retrieved wear bushing, jet washed wellhead and BOP Ran wear bushing 13 3/8 casing set at 1297 m MD 12 ¼” hole drilled to 2994 m MD/2437 m TVD 9 5/8” liner run to TD 6.12.03 Changed wash pipe on top drive Picked up 12 ¼” BHA (6 ¾” bent housing mud motor w/LWD, float sub, SDC + HWDP RIH P/U 5” DP from deck RIH w/5” DP to 1407 m. RIH w/5 ½” DP Washed down to landing collar at 2983 m. Hung up in Tam collar at 2932 m Displaced well from 14.6 ppg to 8.5 ppg OBM mud Inflow tested well for 15 m – well stable Milled landing collar, drilled shoe track. Tagged shoe at 2993 m. Drilled shoe Drilled out shoe. String stalled out several times, got stuck, pulled free with 70K lbs O/P. Broke through shoe at 2995.5 m MD. Flow checked well – stable Drilled 8.5” hole 2995.5 to 3001 m in rotary mode (11 m/hr ave ROP) Drilled 8.5” hole 3001 to 3013 m in oriented mode (4.5 m/hr ROP) Pulled into shoe and circulated BU Took FIT to 10.5 ppg – OK Drilled in oriented mode from 3013 m to 3036 m. ECD 8.78 ppg. Unable to slide, sticky formation (50 klbs O/P) Reduced mud weight to 8.3 ppg Rotary drilled from 3036 to 3037 m – (8 m/hr) ECD 8.59 ppg Drilled 8 ½” hole from 3037 m to 3056 m. ROP 8-10 m/hr. When sliding at 3056 m pressure increased from 1600 psi to 2200 psi Well went into total losses Started filling annulus with 7.6 ppg base oil, pulled into shoe Annulus full with 700 bbls of base oil pumped. Total losses 1050 bbls mud Kept annulus full with base oil, loss rate 250 bbl/hr. Annulus entirely full with base oil. No decrease in loss rate. Total losses 1412 bbl mud, 341 bbl base oil 7.12.03 8.12.03 9.12.03 Problems with Hitec Cyberbase system. Lost 2.5 hrs plus more problems off the critical path FIT 900 psi at 2437 m TVD with 8.4 ppg mud (Check!!) 7 hrs downtime with Cyberbase system Differential sticking indications Mud motor stall out? Packed off annulus? Base oil to formation 15 Date 10.12.03 11.12.03 Description Comments Switched to filling annulus with sea water. Pumped 1265 bbl SW, loss rate increased to 600 bbl/hr, decreased when SW hit TOR formation. Total losses 1412 bbl mud, 1191 bbl base oil, 415 bbl SW Pumped 65 bbl LCM pill into annulus, kept LC lube, Mica F, Ultraseal, annulus full of SW Venfyber, CaCo3, nut plug fine, nut plug medium Loss rate slowed down before LCM plug reached loss zone at 3056 m. 130 bbl early. Losses stopped – Total losses 2603 bbl mud + base oil, 1135 bbl SW Pumped slug and POOH POOH P/U new BHA (negative pulse MWD) Similar BHA to previous RIH. Took kick drill. RIH to 2176 m and broke circulation – no losses Washed down from 2076 m to 2132 m with 200 gpm. Losses increased gradually to 4 bbl/stand. At 2132 m losses suddenly increased. Flow Got LCM in returns over checked well – losses stopped after 20 min. Lost shaker. 15 bbl in 15 min. Washed down from 2132 to 2475 m. Losses – 2 Again, LCM seen in returns bbl/stand from 2475 m to 2562 m. Flow checked over shaker. well – no static losses. Washed down to 2736 m. Washed down to casing shoe at 2994 m. Got LCM in returns over shaker. Flow checked well – Gained 10 bbl in 25 min Flow back after losses? This was what was assumed Circulated with 200 gpm – open well. 15 minutes Flow checked well – 2 bbl gain in 5 min Circulated with 450 gpm – open well. 1 hour. SICP 200 psi (9 min) Well shut in after sudden increase in returns. SIDPP 0 (ported float) Start drillers kill method – DP pressure held constant (brought up pumps correctly) 120 gpm No losses Shut in well to check pressures SICP 70 psi SIDPP 0 psi Resumed circulation thru’ choke. After 640 bbl gas increased. Gas up to 12%. Shut in well. Circulated gas out from BOP. Resumed circulating over choke, 120 gpm, DP constant 180 psi, CP 40 psi. Circulated across BOP to monitor losses. Auto choke leaking, switched over to manual choke Resumed circulating over choke, 70 gpm DP 270, CP 350/400 psi 16 Date Description Comments Lost returns while circulating shut in well. SIDPP 0 SICP 236 psi Performed injection test: 4 bbl/min 1175, 9.5 bbl/min 1125 psi Bullheaded 1050 bbl at 9.5 bbl/min, 1100 – 850 psi Observed annulus pressure. Pressure dropped to 0 psi in 8 min Circulated over BOP to monitor losses. Bullheaded 1050 bbl at 1100 psi Circulated over BOP to monitor losses. Pumped 65 bbl of LCM down the string. Losses reduced while pumping LCM out of string. Lost 17 bbl under displacement Flow checked well. Gained 2 bbl in 4 min. 12.12.03 Hesitation squeezed 60 bbl LCM pill Observed pressures. Level in DP dropping Injectivity test. Bullheaded 1700 bbl SW at 16 bbl/min Monitored losses Bullheaded annulus with LCM pill. Pumped down string with cement unit to keep string open. Hesitation squeezed LCM pill into loss zone. Squeezed 5.1 bbl Monitored well. Gained 4.3 bbl in 20 min Shut in well Correct pressure development indicating influx removed from annulus Indicating well killed 78 bbl/hr 100 bbl/hr SIDPP 0 SICP 155 psi Slowly pumped down string to avoid plugging DP 0 CP 160 psi 112 bbl/hr Some rig power problems in connection with ESD SIDPP 675 psi SICP 750 psi Pumped down string2.6 bbl SIDPP 896 psi Pumped down both DP and annulus DP 940 psi CP 913 psi Pumped down string 190 gpm.. DP pressure 1070 Formation fracturing? ->800 psi. Pumped 5.5 bbl down annulus. LCM outside 9 5/8” shoe Shut in well SIDPP 511 psi SICP 544 psi Displaced LCM out into open hole. Observed SIDPP 780 psi-> 570 psi well. SICP 870 psi->930 psi W&W – circulated in 9 ppg polymer mud ICP 750 FCP 600 psi Circulated gas out from below BOP. Crude oil CP 1050 psi seen in returns 17 Date Description Comments 13.12.03 Circulated in 9 ppg WBM (W&W) 50 bbl crude oil, 70 bbl, crude oil + water ICP 750 psi FCP 600 psi Max gas after poor boy 56.8% Traces of LCM in returns Gas in returns 10 -16% No decrease SIDPP 450 psi SICP 534 psi Losses 10 bbl/hr Gas 14 – 16% SIDPP 603 psi SICP 700 psi Circulated annulus to 9 ppg mud. Losses 0-18 bl/hr Shut in well Circulated over choke to bring down gas levels, circ in LC Lube LCM Shut in well Pumped LCM pill down string. Hesitation squeeze 8 bbl into loss zone Circulated over choke at 3 bbl/min Shut in well (over 15 min) 14.12.03 Circulated well to 10 ppg mud. No losses Circulated well to 10 ppg mud. Gas 10-18% 38% at BU Shut in well Attempted to circ over choke – no returns Shut in well Attempted to circ over choke – regained returns Shut in well due to high gas levels – 70% Bullheaded sea water into annulus – 1723 bbl 15.12.03 DP 652 psi CP 630 psi Gas peak 25% SIDPP 475 –> 537 psi SICP 548 -> 605 psi Gas migration SIDPP 56 psi ->229 psi SICP 199 psi -> 350 psi SIDPP 82 psi SICP 200 psi SIDPP 56 psi SICP 240 psi Pumped down string to avoid plugging nozzles Verified string free by shutting in well on annular preventer – OK PU 273 klbs w/900 psi closing pressure Bullheaded annulus with 10 ppg mud Monitored losses 100 bbls ->80 bbls/hr Pumped gunk pill down string (base oil spacer 10 bbls, 20 bbl gunk, 10 bbl base oil) Shut in annulus and squeezed gunk out of string at 2 bbl/min. 200 psi – 2000 psi at end. Meanwhile pumped down annulus at 0.5 bbl/min w/cement unit. Pulled one stand – string blocked Shut in well. Reciprocated/rotated pipe SIDPP 0 (blocked) SICP 840 psi Pumped 16 bbl SW into annulus SICP 899 psi 18 Date 16.12.03 17.12.03 18.12.03 19.12.03 20.12.03 Description Comments Bled off annulus to 851 psi. Gas/water in returns Observe well Bullheaded annulus with 917 bbl SW. Shut in well Bullheaded annulus with 920 bbl SW. Shut in well Circ over BOP to monitor losses RIH to shoe – no gunk tag (wt). No circ possible Observe shut in well SICP 851 -> 854 psi SICP 1000 psi CP 1312 -> 960 psi SICP 830 psi -> 319 psi CP 1051 ->850 psi SICP 645 psi -> 0 Losses 55 bbl/hr Bullheaded annulus volume with SW, 60 bbls hivis mud, second annulus volume, 64,5 bbls hi-vis mud, SW, 30 bbl hi-vis mud, 52.4 bbl LCM pill, 30 bbl hi-vis behind, SW Squeezed LCM pill in gently in stages Observed pressure Allow to build to 1300 psi, bleed back to ca. 1200 psi continually Allowed pressure to build to 1450 psi, bled off to 1300 psi Lubricate 15 ppg WBM into annulus SICP-> 550 psi migration velocity 39 m/hr SICP 1310 psi Gas started to increase, crude oil bled off. Free gas bled off Surface pressure kept at 1400 psi R/U W/L. Continue lubricating mud into hole RIH with W/L drift. Problems coming out of pipe Gunk in pipe? Continue lubricating mud into hole M/U JRC perforating string, attempt to fire – no go. Wait on JRC (out of hours) Continue lubricating mud into hole POOH w/JRC tool. Re-ran same. Perforated and confirmed communication. Continue lubricating mud into hole Allowed SICP to increase to 1900 psi. Increased pressure on 20” x 13 3/8” annulus to 500 psi SIDPP 1530 psi Bled off dry gas tp keep SICP <1900 psi, SIDPP 1570 – 1520 psi W&W – pumped 14 ppg kill weight mud. Crude in returns Shut in well SIDPP 0 Removed gas from BOP’s. SICP 40 Opened annular – well static Circulated long way with open well with 14 ppg Gas 8% - 0.9% kill mud. 19 Well Schematic Valhall 2/8 A-08A TOC at 270 m 20” at 370 m 13 3/8” window at 1296.8/1251 m 9 5/8” TOL at 2092 m 11 ¾” TOL at 1223.4m 11 ¾” liner at 2292/2103 m 9 5/8” liner at 2994/2437 m Influx Losses TD at 3056 m Figure 3.1: Details of incident. 20 4. Design of well 2/8-A8B 4.1 Valhall general casing design We will review the initial design of the Valhall wells. Reference 9 presents the general design for all Valhall wells. Quote: “…..The generic casing design in this section will cover most of design conditions on Valhall and it should not be required to do individual casing design for each well. A well/section specific casing design will be required if the design criteria is outside this generic design. Special design cases and/or cases with “low” safety factor should be checked by running Amoco’s Tube program or equivalent recognized industry casing design program.” We will, in the following, briefly summarize the most important design criteria from ref. 9. The following general design formulas are recommended: Casing collapse uses API recommended procedure and considers the following 4 collapse modes: yield, plastic, transition and elastic. For burst pressure API is not recommended, but the 3-dimensional von Mises approach. Increase in burst pressure due to axial tension is not recommended. Bending stresses are included. Joint strength is also included, as well as casing wear. The following main criteria are listed for each casing size: The 20”/18-5/8” casing: Collapse: Lost circulation at max. 13-3/8” setting depth. Mud weight 12.5 ppg (frac grad. at shoe) Mud level drop to 10.5 ppg at bottom, that is to 216 m TVD. Burst: 800 psi surface pressure, for 12.5 ppg frac gradient. Tension: Buoyed weight of casing, bending and a test/bump pressure of 700 psi The 13-3/8” production casing: Collapse: During drilling: Lost circulation at max. 9-5/8” setting depth (maximum 2600 mTVD). Mud weight 15.8 ppg (frac grad. at 13-3/8” shoe) Mud level drop to 10.5 ppg at bottom, that is to 872 m TVD. Collapse: During production: Collapse at 9-5/8” liner lap. 5.0 ppg inside, 12.5 ppg outside(frac press. at 20” shoe). Both collapse scenario corrected for wear. Burst: P-110 casing. 21 5000 psi surface pressure. Brine both inside/outside casing. N-80 casing. Critical at KOP because of bending. Max. inside pressure equal to frac. press. at 13-3/8” shoe., i.e. 15.8 ppg at 1350 m. Assume empty casing, with brine outside. Tension: Buoyed weight of casing, bending and a test/bump pressure of 2500 psi. Wear included for P-110 casing. The 11-3/4” production casing: Collapse: During drilling: Lost circulation at max. 9-5/8” setting depth (maximum 2600 mTVD). Mud weight 15.8 ppg (frac grad. at 13-3/8” shoe) Mud level drop to 10.5 ppg at bottom, that is to 872 m TVD. Collapse: During drilling, loss zone, reservoir pressure below 6 ppg.: 8.6 ppg inside, 15.8 ppg outside pressure. Depth 2250 or 2450 mTVD. Burst: Kick with max frac. Grad at casing shoe equal to 16.4 ppg. Reservoir fluid density is 5.0 ppg. External pressure equal to pore pressure at 133/8” shoe equal to 10.5 ppg. Tension: Buoyed weight of casing, bending and a test/bump pressure of 2500 psi. The 9-5/8” production casing: Collapse: Inside 5.0 ppg, outside 15.8 ppg mud, plus temperature induced pressure behind of 2000 psi. Design depth at 13-3/8” shoe at 1360 mTVD, alternatively at 2600 mTVD Burst: Maximum surface pressure of 5000 psi. Design point at 400 m, just below the 20” shoe. Tension: Buoyed weight of casing, bending and a test/bump pressure of 2500 psi. Critical point at 180 m. The 7-5/8” liner (Q 125): Collapse: Inside 5.0 ppg, outside 15.8 ppg mud, plus temperature induced pressure behind of 2000 psi. Design depth at 13-3/8” shoe at 1360 mTVD, alternatively at 2600 mTVD 22 Burst: Maximum surface pressure of 5000 psi. Inside/outside fluids are brines. Tension: Buoyed weight of liner, bending and a test/bump pressure of 2500 psi. Critical point at 180 m. The 7” liner (29 ppf): Same design conditions as for the 7-5/8” liner above The reservoir liner (Q 125): Collapse: Inside 5.0 ppg, outside 15.8 ppg mud. Design depth 2800 mTVD. Burst: Maximum surface pressure of 9000 psi during well stimulation jobs. Outside pressure 8.6 ppg, inside 5 ppg. Design depth 2800 mTVD. Tension: Weight of liner, bending and a test/bump pressure of 3500 psi. Critical point at 180 m. The table below summarizes the results of the generic design that gives lowest design factor. Casing size(in, grade, Depth ppf): (mTVD): 20, K55, 94 13-3/8, P110, 13-3/8. N80 11-3/4, 9-5/8, NT95HS, 47 7-5/8, Q125, 7, , 29 5, Q125, 18 Design factor, Collapse 1.97 1.10 1.36 1.00 1.26 1.42 1.19 1.56 Design factor, Burst 2.64 1.33 1.59 2.49 1.63 2.47 1.63 1.48 Design factor, Tension 2.68 2.93 2.54 2.85 1.81 4.37 3.21 4.88 Design factor, Coupling: 1.55 1.62 3.27 2.37 3.60 It is observed from the table above that casing collapse is the most critical parameter except for the 5 in. liner. All safety factors are well above minimum, except for the 11-3/4 in. casing. For burst design, all strings except the production casing, are based on a limited fracture gradient. This implies that a kick margin defines the safe pressure levels. Full well integrity is obtained if the influx to the borehole is less than the kick margin. Reference 7 discusses in detail the aspects of full or reduced well integrity. Because of the fracture criterion, the strings are not designed for gas filled casing. 23 4.2 Design of well 2/8-A8B Well Schematic (Planned) Valhall 2/8 A-8B RKB-MSL: 43.5 m Water depth: 69.2 m NPD PERMIT NR Casing Depths Prognosed (except 20”) P er Survey revision 2.2.8 RIG Valhall DP TOTAL DEP TH 4071 m MD / 2495.50 m TVD RISK BASED DURATION DAYS 106 TOC ~ 270m ACP 352 m SIZE (in) 20” 20” csg @ 370 m MD, 370 m TVD FIT to 12.3 ppg (Actual) PRESET 13-3/8” 11-¾” 9-5/8” 6-5/8” WT (ppf) 203 x 94.00 72.00 65.00 53.50 65.8 GRADE CONNECTION TYPE Buttress ID (inches) Drift ID K-55 P-110 Q-125 Q-125/C-95 Q-125 New Vam H-SLX / H-511 H-523 Hydril MAC - II 12.347 10.682 8.535 4.375 12.25 10.625 8.50 4.250 11 ¾” TOL @ 1270 m MD 13 3/8” window 1300 m MD, 1270 m TVD 13-3/8” casing is preset 9 5/8” Planned tied-back to surface 9 5/8” TOL @2193 m MD 14” Hole to 2284 m MD, 2100 m TVD 11 3/4" liner @ 2284 m MD, 2100 m TVD 62° inclination 6-5/8” TOL approx. 2424 m MD (300 m TVD above top Tor) 8-1/2” X 12-1/4” hole to 3040 m, 2459.5 m TVD 9-5/8” Drilling Liner w/drilling shoe 68° inclination 9 5/8" casing shoe @3055 m MD, 2465 m TVD 6-5/8” Liner @ ~ 4044 m MD, 2495 m TVD * 8-1/2” x 9-1/4” hole to 4071m MD, 2495 m TVD •6-5/8” liner will have 5” shoe track Note: Error in Table above. 13-3/8 csg. is N80 quality , not P110. After the well control incident, BP performed a casing design evaluation for well 2/8 A8B, which is given reference 10. In the following the main criteria from ref. 10 will be listed. 24 The 13-3/8” production casing: Collapse: Lost returns filling up annulus with base oil. Burst: Pressure tested to 1500 psi, with a 12 ppg mud. Gas kick. Circulating out 100 bbls gas from 3030 m asuming a pore pressure of 14.6 ppg. The 11-3/4” production casing: Collapse: Lost returns filling up annulus with base oil, and cementing phase. Burst: Pressure tested to 900 psi, with a 14.6 ppg mud. While setting the liner hanger the casing was subjected to 2800 psi over 2 minutes. Tension: 100 000lbs over pull, pre- and post-cementing static loads, running in hole loads and service loads. The 9-5/8” production casing: Collapse: Lost returns filling up annulus with base oil, and cementing phase. Burst: Pressure tested to 2500 psi, with 14.6 ppg mud.(Equivalent to 4500 psi surface pressure). Tension: 100 000lbs over pull, pre- and post-cementing static loads, running in hole loads and service loads. 4.3 Worst case considerations In the following we will perform an evaluation of the design factors reported by BP. Because there is significant reservoir pressure depletion we will not use virgin conditions, but will suggest alternative scenarios for BP’s considerations. As stated later, the exact pressures are not known. Burst design. It is clear from the summary above that the well was designed for a limited kick scenario. During the well control event, the well was exposed to a more severe condition, approaching full gas filled casing. The following case is presented to compare these two scenarios. 25 We assume that the well is completely gas filled. It is difficult to determine the actual pore pressure from the documentation received, as the reservoir is depleted to a low pressure. However, the overburden just above the reservoir has a pore pressure gradient of about 14 ppg at 2400 mTVD (ref. 11). If we assume that this formation has a kick potential (permeability), the following parameters are used: Depth: Reservoir pressure grad: Reservoir fluid density: Density behind casings: 2400 mTVD 14 ppg (1.68 s.g.) 5.0 ppg (0.60 s.g.) 8.6 ppg (1.03 s.g.) Reservoir pressure: 0.098 x 1.68 x 2400 = 395 bar Weight of reservoir fluid: 0.098 x 0.6 x 2400 = 141 bar Surface pressure if shut-in gas-filled casing: 395 – 141 = 254 bar = 3683 psi At surface, there is no back pressure. Worst case scenario is therefore that the 13-3/8 in. casing is exposed to the surface pressure above. The burst strength of the casing is 510 bar. Worst case burst design factor, 13-3/8 in. P110, 72 lbs/ft casing: 510 = 2.01 254 If we assume that the reservoir fluid is nearly weightless gas, the design factor would become: 510 = 1.29 395 which exceeds a minimum requirement of 1.10. In Appendix A this calculation is also performed for a fully 3-dimensional design. The result of this calculation is a design factor of 2.17, exceeding the minimum requirement of 1.25 for 3-D. The top of the exposed 11-3/4 in. Q125 65 lbs/ft casing is at 1296 mTVD. Repeating the computation for this casing: Weight of reservoir fluid to 1296 mTVD: 0.098 x 0.6 x (2400 - 1296) = 65 bar Pressure at 1296 m if shut-in gas-filled casing: 395 - 65 = 330 bar With a wellhead elevation of 40 m above the sea level, the back pressure becomes: 0.098 x 1.03 x (1296 - 40) = 127 bar The burst load is: 330 - 127 = 203 bar The burst strength of the casing is 685 bar. Worst case burst design factor, 11-3/4 in. casing: 26 685 = 3.37 203 For completeness, this evaluation is also performed for the 9-5/8 in. Q125 53,5 lbs/ft production casing which starts at 2292 mTVD. Weight of reservoir fluid to 2292 mTVD: 0.098 x 0.6 x (2400 - 2292) = 6.4 bar Pressure at 2292 m if shut-in gas-filled casing: 395 – 6.4 = 388.6 bar Assuming a wellhead elevation of 40 m above the sea level, the back pressure becomes: 0.098 x 1.03 x (2292 - 40) = 227.3 bar The burst load is: 388.6 – 227.3 = 161.3 bar The burst strength of the casing is 854 bar. Worst case burst design factor, 9-5/8 in. casing: 854 = 35.29 161.3 Below is a comparison between the two design approaches: Casing, BP limited kick Worst case, gas in: margin: filled casing: 13-3/8 2.11 2.0/1.29* 11-3/4 2.48 3.37 9-5/8 2.15 5.29 Table 3.1.: Comparison of burst design factors, not corrected for wear. *Assuming weightless gas The exposed 13-3/8 in casing has highest load. All design factors are considerable higher than the minimum requirements The well has sufficient burst resistance. Please observe that the reason for difference in design factors is different design assumptions. This will be further discussed in the following. Casing test pressure. Assumes virgin pore pressure, the wellhead pressure would be 4680 psi. However, the field is depleted. According to ref. 11, the expected pressure in the Tor formation was 2760 psi at reservoir level. This leads to a surface pressure of: 2760 – 2552 = 218 psi assuming reservoir fluid of 0.6 s.g. density or: 2760 psi assuming methane (weightless) gas The well control incident measured a casing pressure of 1900 psi, as opposed to the test pressure of 1500 psi. The casing should have been tested to a higher pressure for three 27 reasons: 1) there is uncertainty about the pore pressure. The reservoir is highly depleted, but it is uncertain if a formation above has sufficient permeability to produce a kick, and 2) it is uncertain what density this formation fluid has. For future wells methane gas may be assumed as it is the gas with lowest density, and 3) a gas filled casing scenario probably applies rather than the limited kick size used. We will not define an exact test pressure in this report, but it should for future wells exceed 1900 psi. BP should base the on analysis on realistic scenarios. Collapse design: The basic design criterion from ref. 10 is lost returns filling up annulus with base oil. A more severe, but realistic scenario is lost returns with 14.6 ppg mud in the hole. Assuming that the annulus level stabilizes at a bottom-hole-pressure equal to normal pore pressure, the depth of the annulus fluid level becomes: 0.098 x 1.03 x (2495 - 40) = 0.098 x 1.75 x (2495 – H) H = 1445 m This is near the shoe of the 13-3/8 in. casing. We will perform a collapse evaluation at this position. The well is empty (zero inside pressure) down to this depth. Assume that the back-pressure is caused by 13.3 ppg (1.60 s.g.) mud, as used by ref. 10. The collapse load then becomes: 0.098 x 1.6 x 1445 = 226 bar With a collapse rating of 323 bar, the design factor in collapse for the 11-3/4 in casing becomes: 323 = 1.43 226 Wear and bi-axial derating is not included in the calculation above. Ref. 10 operates with a design factor of 2.03 in collapse. The discrepancy is caused by their assumption of a base-oil-filled casing. It appears that this condition is not creating the most severe collapse loading. The casing back-pressure is the most important factor for the low design factor above. The two extreme conditions are (from ref. 7): -A short time scenario using mud weight above the cemented interval. -A long time scenario assuming that particles settles out leaving only water as the mobile phase creating pressure. There is not yet full consensus in the oil industry about the application of these criteria. For the above analysis we will conclude that the well have not been exposed to a loading exceeding the collapse strength of the casing. It has been difficult to determine the bottom-hole pressures when circulation losses arose. It is possible that a sub-normal loss pressure exists due to reservoir depletion. The above collapse calculation would become more critical for this case. 28 4.4 Summary of incident The well is designed with a tie-back production casing. This was not in place during the well control incident, so both the 13-3/8 in, the 11-3/4 in and the 9-5/8 in casing string were simultaneously exposed to the reservoir pressure. Each of the two largest casings were designed for the drilling phase, and not for reservoir penetration. The well was not designed for full a gas filled casing scenario, but for a reduced integrity case with the casing shoe fracture pressure as the weak point in the well. However, the casing strings used are of sufficient strength. This brings up a general problem. If we assume a kick entering the well at the bottom, we can base the design on circulating this out. This implies a pressure distribution throughout the well caused by the pore pressure, the gas column and the mud column on top. If we on the other hand assume completely gas filled well, a totally different pressure distribution arise, with a surface pressure equal to the pore pressure minus the weight of the gas column. In the present case it appears that BP based the design on a limited gas kick, whereas the kick control incident approached a gas filled casing scenario. Please also note BP’s philosophy as quoted on page 7 in this report. The well was designed for drilling with a casing test pressure of 1500 psi. However, during the well control incident a surface pressure of 1900 psi was recorded. Clearly, the well was not exposed to a limited gas kick situation. For future wells gas filled casing should be considered. The collapse evaluation was based on a base-oil filled casing. Circulation loss with drop in fluid level is in some instances a more severe 29 5. Summary of review The review concludes that BP’s casing design manual is a document of high quality. It addresses the many factors of importance for a good well design. The lost circulation/kick problem of well 2/8-A8B has also been reviewed. The following conclusions came out of this investigation: -The 13-3/8 in. casing was the weakest exposed casing string. It was sufficiently strong for burst and collapse. -The well section was designed for a limited gas kick scenario. However, due to circulation losses, a gas filled casing may be a more realistic scenario. This will require a casing test pressure exceeding 1900 psi. (1500 psi was used). -There is uncertainty about the depth of the kick, the pore pressure and the fluid density. A revised analysis of this and a risk analysis is required to determine the magnitude of the casing test pressure. -The assumption of base oil filled annulus may not be the most severe collapse scenario. Circulation losses with drop in fluid level is in some instances more severe than base oil filled annulus and should be considered as a design criterion. -Risk evaluation of the incident appears to be incomplete. It should also include the risk of losses in the Tor formation. -After a positive flow check, the well was circulated with an open well. This procedure should be clarified. -Well design of the particular well is missing, as BP uses a common design used many well. The contingency solution for lost circulation should be reviewed. Operational procedures for setting the gunk pill should be evaluated. 30 6. Recommendations It is recommended to perform a casing design for each well, and to accurately address changes in design conditions. The increasing reservoir pressure depletion, and also the subsidence, increase the likelihood of lost circulation during drilling. For this reason BP may consider a stronger burst criterion, that is designing for full gas filled casing instead of assuming a maximum kick margin. It is advisable that all reservoir penetration is designed for gas filled casing as this scenario is realistic during production of the well. Furthermore, loss zones, formation pressures and formation fluid densities should be reviewed to obtain improved design conditions for future wells. The results of this evaluation will define the required casing test pressures. In the event of considering circulation losses as a future challenge, it is recommended to initiate a separate program to handle these. One example of such a program is to set up a task force to follow up all operations. This group may measure mud properties systematically before, during and after the loss events to derive a data base. In this way the drilling fluids can be tailored to Valhall. Such a program can be developed using Stavanger University’s unique fracturing lab. Risk evaluation should include lost circulation potential in the Tor formation. It is advisable to develop a strategy for use of gunk material and LCM, and also a ‘best practice’ document to help ensure efficient lost circulation procedures. 31 Abbreviations BOP BHA BU CP DP ECD FCP FIT ICP LCM LOT LWD MD M/U MT OBM POOH P/U PBR R/T RIH RT RWC ROP SW SICP SIDPP TD TRSCSSSV TVD W&W WL WBM Blow out preventer Bottom hole assembly Bottom up casing pressure Drill pipe, drill pipe pressure Equivalent circulating density Final casing pressure Formation integrity test Initial casing pressure Lost circulation materials Leak-off test Logging while drilling tool Measured depth Make up Metric tons Oil based mud Pull out of hole Pull up Polished bore receptable Running tool Run in hole Rotary table Rock-Well Consultants Rate of penetration Sea water Shut in casing pressure Shut in drill pipe pressure Total depth, m Tubing safety valve Total vertical depth Wait and weigh method Wire line Water based mud 32 References 1. BPA-D-001 BP Drilling and Well Operations Policy 2. BPA-D-002 Well Control Manual 3. BPA-D-003 Casing Design Manual 4. BPA-D-004 Directional Survey Handbook 5. BPA-D-005 Offshore Site Investigation Manual 6. B.S.Aadnøy (1990): Inversion Technique to Determine the In-Situ Stress Field from Fracturing Data. Journal of Petroleum Science and Engineering, ¤(1990); 127-141. 7. Modern Well Design by B. S. Aadnøy. A.A.Balkema Publishers Rotterdam/Brookfield, 1996, ISBN 90 5410 633 6. 8. Valhall A-8 B Investigation of Lost Circulation and Wellcontrol Incident. Internal BP report of 01.02.04, rev.1 of 17.03.04. Authors: E.Braune/S.Samuelsen. 9. Valhall General Drilling Plan, DRL-M-002: 6.0 Casing Design. Amoco Document of 09/23/98. 10. Valhall well A-08B Casing Evaluation. T.J. Tjøstheim 06.02.2004. 11. Valhall Field Well 2/8-A-8 B Drilling Program. Date: 1/23-2004. 33 Appendix A: Design factors for well 2/8-A8B 34 Casing Wizard The Casing Wizard software is developed by Well Experts for casing planning and design. The Casing Wizard software presents both 1D standard analyses and exact 3D analyses for burst and collapse design. © Well Experts Casing Wizard Select units of input data Metric units (default) Oilfield units Burst Design Criteria Assume gas filled casing for burst design. Fluid density 0.6 s.g. inside and seawater of 1.03 s.g. outside casing. Highest load at top of casing string. Design parameters* Formation depth Casing shoe depth Casing top depth Depth to seabed Depth to sealevel Depth to top of cement Formation pressure gradient Formation/influx fluid density Mud density Cement density Density behind casing Bouancy factor 2400,0 m 1251,0 m 0,0 m m 40,0 m m 1,68 s.g. 0,6 s.g. s.g. s.g. 1,03 s.g. 0,87 7874,0 ft 4104,3 ft 0,0 ft ft 131,2 ft ft 14,0 ppg 5,0 ppg ppg ppg 8,6 ppg 0,87 * All depths are true vertical depth (TVD) Casing data** Casing OD Casing ID Specific weight Crossectional area Wall thickness (API) OD-thickness ratio (API) Geometry factor, β (API) Yield strength Burst strength Collapse resistance Pipe body yield strength 33,97 31,36 107,20 133,92 1,14 29,75 15,39 7584,24 510 199,3 1,016 cm cm kg/m cm2 cm bar bar bar kdaN 13,37 12,35 71,97 20,76 0,45 29,75 15,39 110000 7396,92 2890 2284 inch inch ppf inch2 inch psi psi psi klbf ** Note that a API 12.5% reduced wall thickness is applied for 3D analysis Casing burst loading* Inside pressure, bottom Inside pressure, top Outside pressure, bottom Outside pressure, top Axial load, top Axial stress, top Inside stress ratio, x Pressure differential ratio, y 395,1 254,0 126,3 0 114,2 852,7 0,1459 0,5155 Design Factor (3D model) 2,17 2,17 Design Factor (1D model) 2,01 2,01 bar bar bar bar kdaN bar 5731,0 3684,2 1831,5 0 256702 12367 0,1459 0,5155 psi psi psi psi klbf psi