Basic history and theory Ch 8 - Ch 14 e.g. pull, level out

advertisement

Lean historic background

Lean philosophy

Lean and stable processes

Exercise presentations

Companies for VSM

2013-09-12

Anders Hellström Competitive Productions System KPP202

A historic development

Craft production

• Make what the customer wants

=> Mass production

• Large demand for products with large scale manufacturing - Henry

Ford

=> Lean production

• The challenge of producing customized products with

efficient manufacturing - Taiichi Ohno

VCE history 6 min

https://www.youtube.com/wa

tch?v=h1pzB0LppyE

=> Flexibility

• A business environment dominated by

change and uncertainty

Craft production

Knowledge to develop, manufacture and fit

The apprentice system

Decentralized workshops – own companies

Low production volume

General purpose machines

A historic development

Craft production

• Make what the customer wants

=> Mass production

• Large demand for products with large scale manufacturing - Henry

Ford

=> Lean production

• The challenge of producing customized products with

efficient manufacturing - Taiichi Ohno

=> Flexibility

• A business environment dominated by

change and uncertainty

Mass production

• Henry Ford is often said to be one of the

persons behind the development of mass

production

– it was in Detroit that the first real mass-productive

production system for cars was born - Ford’s

model T began to be produced in 1908

5

FORD

Mass production – Model T (1908)

Manufacturer

Ford Motor Company

Production

Predecessor

1908-1927

Ford Model S

Successor

Ford Model A

Body style(s)

Touring,, roadster, ton, closed cab ton truck, coupé, two door, center

door, station wagon (SUV), convertible

Engine(s)

Transmission(s)

177 in³ (2.9 L) straight-4, 20 hp

Rear wheel drive, planetary gear, 2 forward speeds

Curb weight

1,200 pounds (540 kg)

Henry Ford, Childe Harold Wills, Joseph A. Galamb and Eugene

Farkas

Designer

7

Mass production, how?

– The key to

automotives:

mass

production

of

•

•

•

•

precision manufacturing

interchangeability of components

the simplicity of attaching them together

division of labor - the demand for versatile labor

was not important when the assembly operations

were broken down so that anyone could perform

them

• the human being became interchangeable and in

some cases eliminated by automation

• later - the moving or continuous assembly line

8

A historic development

Mass Production – on it’s peak 1955

7 000 000 cars sold in USA

Ford, GM, Chrysler - 95% of sales

6 models accounted for 80% of all cars sold

A historic development

Craft production

• Make what the customer wants

=> Mass production

• Large demand for products with large scale manufacturing - Henry

Ford

=> Lean production

• The challenge of producing customized products with

efficient manufacturing - Taiichi Ohno

=> Flexibility

• A business environment dominated by

change and uncertainty

Lean production

Mass Production did not work in Japan

A tiny domestic market – demanded a wide range of vehicles

Strong tradition in craftmanship – not interchangable

humans

War – starved for capital

Competition in mainly the USA

Lean production

Toyota 1950-1951

Toyota had produced in total 2 685 cars in 1950

7000 cars per day in Rouge

Eiji Toyoda and Taiichi Ohno visits Detroit

Creative Idea Suggestion System started in 1951

Toyota 1960, about as large as Volvo Car the

same year

The fundamental principle for

Toyota

”All we do is focused on reducing

waste in the time line from order to

delivery”

- Taiichi Ohno

Order in

Production

Money in

time

13

Lean Production

The term “lean” comes from using less of everything compared

to mass production. This means using less human effort in the

factory with less manufacturing space, less investments in tools,

less engineering hours to develop a new product in shorter time,

keeping less inventory, fewer defects in production, and

production of a greater and ever growing variety of products

Lean Tools

•

•

•

•

•

•

•

•

•

•

•

•

•

5S

TPM (Total Productive Maintenance)

Andon

Standardized processes

Flexible staffing

Kanban

One-piece Flow

Pareto/Gannt/Ishikawa-diagrams etc

Pokayoke

SMED (Single Minute Exchange of Dies)

SPC (Statistical Process Control)

Takt

...

15

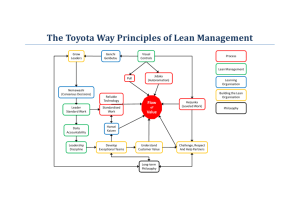

The House – Toyota Production System,

see Liker TTW Ch 3

Toyota Way Philosophy

16

A historic development

Craft production

• Make what the customer wants

=> Mass production

• Large demand for products with large scale manufacturing - Henry

Ford

=> Lean production

• The challenge of producing customized products with

efficient manufacturing - Taiichi Ohno

=> Flexibility

• A business environment dominated by

change and uncertainty

Trends and challenges?

1. A global and turbulent market

Globalization

Growing/new markets

International competition

Demanding customers

18

Trends and challenges?

1. A global and turbulent market

CONSEQUENCES

=> TTM

=> Demand variation

=> Continuous improvements

19

Trends and challenges?

2. Demographic development

Difficult to recruit people to industry?

Importance of:

- Values/branding/policy

- Organization and working conditions

CONSEQUENCES

=> Industrial work in the future

=> Organization

20

Trends and challenges?

3. Technology development –

increased knowledge content

New products

More then a physical product – service, software

Shorter product lifecycles

Complexity in work

Complex products give complex processes

21

Trends and challenges?

3. Technology development –

increased knowledge content

CONSEQUENCES

=> Cooperation product and production development

=> Continuous process development

22

Trends and challenges?

4. Environment

Global warming / CO2-emissions

More transport by truck

Longer transportation

More transports

CONSEQUENCES

Taxes and regulations?

Alternative modes of transport

23

Important to handle changes!

The ability to robustly handle short-term changes

quickly and at a low cost in an existing system

The ability to robustly handle long-term changes

quickly and at a low cost which effects and transforms

the actual system

Flexibility and

reconfiguarbility

• Flexibility is defined as the ability to robustly handle

short-term changes quickly and at a low cost in an

existing production system

• Reconfigurability is defined as the ability to robustly

handle long-term changes quickly and at a low cost,

effecting and transforming the production system

25

Production Development

Productivity

Kaizen - Kaikaku - Kaizen

Time

New product or process?

26

Production Development

New technology

Development of products and processes

Analysis and working methods

Tools and equipment

Change management

Organization

Cooperation

People, knowledge, and creativity

27

Collaboration between actors

28

The need for competence in

industry

Managing change

Creativity

New ideas

Cooperation

Holistic view

Involvement

Project managment

Product development

Production development

Analaysis and evaluation

Design

Product- and process development

Change agents

29

TOYOTA Motor Corporation

The

Way

Basis of TPS according to Liker, focus stable processes

Adoption to KPP202 fall 2013 Anders Hellström MDH, stable processes, preparing for improvement

Mainly based on Patricia Grah presentation visiting PhD 2009 at MDH from RheinAhrCampus Remagen

Jeffrey K. Liker

Professor of the Michigan University

Studied 20 years long the specialities of Toyota

Wrote many books about the key elements of Toyota`s

success

This presentation has its roots on the descriptions

of Jeffrey K. Liker

31

Source: Jeffrey K. Liker

The number of car models and variants increases, Audi 80 and

Audi 100 platforms already 2005, increasing need to meet

customer demands for tailoring, for example Volvo web 2013:

http://www.volvocars.com/intl/top/corporate/volvo-sustainability/Pages/default.aspx

32

But:

How is success defined?

What do you know about the Toyota`s success?

33

Source: Jeffrey K. Liker

Some Evidence – GM versus Toyota

•

Toyota’s selling prices are much higher than GM’s due to

refinement, delivered quality, and durability.

•

Toyota is able to get new designs to market vastly faster than GM

as market conditions change

12 months

•

Toyota needs fewer hours of engineering and less capital to launch

products with a given capacity.

•

Toyota’s suppliers have higher margins and lower selling prices,

better quality & fresher technology.

•

As a result of weak policy management, GM has been very slow to

change.

34

The Age of Brilliant Objects

•

Most striking achievement of lean production has been the

introduction of truly superlative objects, with few defects, high

refinement & great durability.

•

But is this all consumers want today?

•

As we look ahead we can see that the consumer’s most precious

asset is not money but time.

•

Today’s brilliant objects often squander consumer time because

consumption – better called problem solving -- is a complex process

of searching for, obtaining, installing, maintaining, repairing,

upgrading & recycling brilliant objects.

•

Toyota in Japan addresses this problem.

35

The Age of Lean Solutions

•

•

•

•

•

•

•

•

If consumption is a problem-solving process, it follows that there

should be principles of lean solutions similar to the principles of lean

thinking (value, value stream, flow, pull and perfection.)

Dan Jones and James Womack propose the following:

Solve my problem completely

Don’t waste my time

Provide exactly what I want

Exactly where I want

Exactly when I want

Continually reduce my total cost (time, money and hassle) to solve

my problem.

36

What exactly is lean enterprise?

James Womack and Daniels Jones: Book “Lean Thinking”

5-step-process:

- Defining Customer Value

- Defining the Value Stream

- Making it “flow”

- “Pulling” from the Customer back

- Striving for Excellence

37

Source: Jeffrey K. Liker

Which are the wishes of customers in the future?

Convenience/simplicity

Flexibility and speed

Improvement

Respect for men

Pursuit of excellence

38

Some of these wishes are already considered by Toyota

Shaping of value, long term

planning…

Stepwise improvement,

lean systems, learning org.

Personal involvement, goal

orientation…

Respect to stakeholders, suppliers, own staff, community

Develop exceptional employees

and teams, mutual respect

39

So: What is the secret of Toyota`s success?

= direct result of operational excellence

Toyota turned operational excellence into a strategic weapon

This operational excellence is based on tools and quality improvement

methods

Just-in-time

Kaizen

One-piece-flow

Jidoka

Heijunka

“lean manufacturing” revolution

40

Source: Jeffrey K. Liker

“4 P” Model of the

Toyota Way

Problem

Solving

Toyota`s

terms:

(Continuous

Improvement and Learning)

Kaizen

Continual organizational learning through Kaizen

Go see for yourself to thoroughly understand the

situation. (Genchi Genbutsu)

Make decisions slowly by consensus, thoroughly

considering all options; implement rapidly

(Nemawashi)

Respect +

People and Partners

teamwork

(Respect, Challenge and Grow Them)

Process

(Eliminate Waste)

challenge

Grow leaders who live the philosophy

Respect, develop and challenge your

people and teams

Respect, challenge, and help your

suppliers

Create process “flow” to surface

problems

Level out the workload (Heijunka)

Stop when there is a quality problem

(Jidoka)

Use pull systems to avoid overproduction

Standardize tasks for continuous

improvement

Use visual control so no problems are

hidden

Use only reliable, thoroughly tested

technology

Philosophy

(Long-term Thinking)

Source: Jeffrey K. Liker

Base management

decisions on a long-term

philosophy, even41

at the

expense of short-term

financial goals

Example of application of TPS, Volvo Production System VPS

42

Example of application of TPS, SCANIA

Core values -> Principles -> Practical methodes -> Results

43

The Toyota Way

Verhältnis Zulieferer-Hersteller

Klicken Sie, um das Titelformat zu bearbeiten

• Klicken Sie, um die Formate des

Vorlagentextes zu bearbeiten

• Zweite Ebene

• Dritte Ebene

• Vierte Ebene

• Fünfte Ebene

Patricia Grah, RheinAhrCampus Remagen

September 2009

44

“4 P” Model of the

Toyota Way

Problem

Solving

(Continuous

Improvement and Learning)

Continual organizational learning through Kaizen

Go see for yourself to thoroughly understand the

situation. (Genchi Genbutsu)

Make decisions slowly by consensus, thoroughly

considering all options; implement rapidly

(Nemawashi)

People and Partners

(Respect, Challenge and Grow Them)

Grow leaders who live the philosophy

Respect, develop and challenge your

people and teams

Respect, challenge, and help your

suppliers

Adding Value to Customers &

Process

Society

(Eliminate Waste)

Philosophy

Create process “flow” to surface

problems

Level out the workload (Heijunka)

Stop when there is a quality problem

(Jidoka)

Use pull systems to avoid overproduction

Standardize tasks for continuous

improvement

Use visual control so no problems are

hidden

Use only reliable, thoroughly tested

technology

(Long-term Thinking)

Source: Jeffrey K. Liker

Base management

decisions on a long-term

philosophy, even at45

the

expense of short-term

financial goals

Base management decisions on a long term philosophy, even at the expense of

short-term financial goals, principle 1

1

Toyota mission:

•

Contribute to the economic growth of the

country in which it is located (external

stakeholders)

•

Contribute to the stability and well being of

team members and partners (internal

stakeholders)

•

Contribute to the overall growth of Toyota

46

Source: Jeffrey K. Liker

“The most important factors for success

are patience, a focus on long term rather

than short-term results, reinvestment in

people, product, and plant, and an

unforgiving commitment to quality.”

- Robert B. McCurry, former Executive V.P., Toyota Motor Sales

47

Source: Jeffrey K. Liker

Base your management decisions on a long-term philosophy, even

at the expense of short-term financial goals

- Work, grow and align the whole organization

toward a common purpose that is bigger than

making money

- Create value for the customer, society, and the

economy

- Be responsible

48

Source: Jeffrey K. Liker

“4 P” Model of the

Toyota Way

Problem

Solving

Continual organizational learning through Kaizen

Go see for yourself to thoroughly understand the

situation. (Genchi Genbutsu)

Make decisions slowly by consensus, thoroughly

considering all options; implement rapidly

(Nemawashi)

(Continuous

Improvement and Learning)

Eliminate Waste through Flow

People and Partners& Standardization

(Respect, Challenge and Grow Them)

Grow leaders who live the philosophy

Respect, develop and challenge your

people and teams

Respect, challenge, and help your

suppliers

Process

(Eliminate Waste)

Philosophy

Create process “flow” to surface

problems

Level out the workload (Heijunka)

Stop when there is a quality problem

(Jidoka)

Use pull systems to avoid overproduction

Standardize tasks for continuous

improvement

Use visual control so no problems are

hidden

Use only reliable, thoroughly tested

technology

(Long-term Thinking)

Source: Jeffrey K. Liker

Base management

decisions on a long-term

philosophy, even49

at the

expense of short-term

financial goals

Principle 3

Use “pull” systems to avoid overproduction

-

Minimize inventory and work in process by stocking

small amounts and restocking regularly

-

Consumption => Production

-

Respond to shifts in customer demand, not on

computer systems to track schedule and inventory

-

3

Questions: What do our customers want, when and in

what amount

50

Source: Jeffrey K. Liker

Defined: „Pull-Principle”, „Just-in-Time” and „Kanban”

in the 1950:s

51

Source: Jeffrey K. Liker

Heijunka

The main purpose is to balance demand and capacity

Heijunka is then set to produce at the takt rate

Time frame is an interval

Interval deals with mix

52

Principle 5

Build a culture of stopping to fix problems, to get quality right the

first time

5

- Build a culture of stopping or slowing down to get quality

right the first time

- Automate problem detection (“Jidoka”)

- Notify leaders of problems (“Andon”)

- Develop a visual system to alert team or project leaders

that a machine or process needs assistance

53

Source: Jeffrey K. Liker

1

2

8

9 10 11 12 13 14

STOP BUTTON

(STOP THE L INE AUTHOR ITY )

3

4

5

6

7

STOP BUTTON

(STOP THE L INE AUTHOR ITY )

5

4

Abnormality

Station 5

Team Leader

54

Source: Jeffrey K. Liker

Principle 8

Use only reliable, thouroughly tested technology that serves your

people and processes

-

-

8

Technology to support people, not to replace them

Often it is better to work out a process manually before

adding technology to support the process

A proven process is better than new technology

Encourage people to consider new technology.

Quickly adopt if the technology has proven itself.

55

Source: Jeffrey K. Liker

Product Lead Time

Casting

Waiting

Assembly

Machining

Transportation

Raw

Material

Staging

Inventory

Time

= Value

Added Time

= Non-Value

Added Time

(WASTE)

Staging

(Materialbereitstellung)

Finished

Parts

Value Added Time is only a very small

percentage of the Lead time.

Traditional Cost Savings only focused

on Value Added Items.

LEAN FOCUSES ON NON-VALUE

ADDING ITEMS.

56

Source: Jeffrey K. Liker

Casting

Waiting

Assembly

Machining

Transportation

Raw

Material

Staging

Inventory

Time

= Value

Added Time

= Non-Value

Added Time

(WASTE)

Staging

Finished

Parts

This figure shows the waste through a

simple time line for the process of

casting, machining, and assembling.

From a lean perspective, the first thing

you should do in approaching any

process is to map the value stream

following the circuitous path of material

(paper or information) through your

process.

It is necessary to walk the actual path

to get the full experience.

57

Source: Jeffrey K. Liker

Casting

Waiting

Assembly

Machining

Transportation

Raw

Material

Staging

Inventory

Time

Staging

Finished

Parts

Wasted time:

= Value

Added Time

= Non-Value

Added Time

(WASTE)

Reaching, walking, picking

up, removing, pulling,…

Value added time:

Positioning the component on the chassis

Placing the bolts in the component

Tightening the bolts to the chassis with the power tool

58

Source: Jeffrey K. Liker

Why Focus on Flow?

“If some problem occurs in one-piece-flow manufacturing then

the whole production line stops. In this sense it is a very bad

system of manufacturing. But when production stops everyone

is forced to solve the problem immediately. So team members

have to think, and through thinking, team members grow and

become better team members and people.”

-Teruyuki Minoura, former President,

Toyota Motor Manufacturing, North America

59

Source: Jeffrey K. Liker

5 S is more than housekeeping

Basis of safety; reduces accidents

Cuts waste, particularly wast of motion

Reduces variation

Improves efficiency

60

Difference in

average

inventory level

with more

changeovers

Why Quick Change Over?

Inventory

level

Change Over

Average inventory level

Time

The more often we changeover, the more our inventory

levels decrease. This helps accomplish our goal of

waste elimination.

Makes e.g. capital available for other possibilities.

61

Source: Jeffrey K. Liker

Leveled production, example

Need per variant/ month

Important!

The smaller

batch size the

higher need for

shorter change

over time

62

What is a Visual Workplace?

When anyone can walk into a

workplace and visually

understand the current

situation.

63

Source: Jeffrey K. Liker

What is a Visual Workplace?

Example after use of 5S

Before

Source Produktionslyftet

After

64

What is a Visual Workplace?

Example after use of 5S, to feel wellcommed to work!

Before

Source Produktionslyftet

After

65

Standard Work Tools

Standardized

Work Chart

Detail of each

Process Step

Takt

90s

1

Work Element Sheet

Detail of the Elements

of each Process Step

2

3

4

Assembly Process #

5

Stack Chart

(Yamazumi)

A Visual Tool for

Balancing Processes

66

Source: Jeffrey K. Liker

Standard Work Tools, A3 tool for improvement work

Source Produktionslyftet

67

“4 P” Model of the

Toyota Way

Problem

Solving

The heart & soul of

The Toyota Way

(Continuous

Improvement and Learning)

Continual organizational learning through Kaizen

Go see for yourself to thoroughly understand the

situation. (Genchi Genbutsu)

Make decisions slowly by consensus, thoroughly

considering all options; implement rapidly

(Nemawashi)

People and Partners

(Respect, Challenge and Grow Them)

Grow leaders who live the philosophy

Respect, develop and challenge your

people and teams

Respect, challenge, and help your

suppliers

Process

(Eliminate Waste)

Philosophy

Create process “flow” to surface

problems

Level out the workload (Heijunka)

Stop when there is a quality problem

(Jidoka)

Use pull systems to avoid overproduction

Standardize tasks for continuous

improvement

Use visual control so no problems are

hidden

Use only reliable, thoroughly tested

technology

(Long-term Thinking)

Source: Jeffrey K. Liker

Base management

decisions on a long-term

philosophy, even at68

the

expense of short-term

financial goals

Principle 9

Grow leaders who thoroughly understand the work, live the

philosophy, and teach it to others

-

9

Grow leaders rather than “buy” them from outside

Leaders must be role models

A good leader understands the daily work

e.g. Coaching, promote from within the team

69

Source: Jeffrey K. Liker

Principle 11

Respect your extended network of partners and suppliers by challenging

them and helping them improve

-

11

Treat partners as an extension of your team

Challenge partners to grow and develop.

Set challenging targets and assist in achieving them

e.g. Collaboration with users, customers, other teams

70

Source: Jeffrey K. Liker

Take care of the people?

But what about assembly line work?

Is assembly line work really stupid work?

71

Source: Jeffrey K. Liker

In the sense of Toyota: NO!

Reasons:

Toyota challenges people to use their initiative and

creativity to experiment and learn

Workers should grow in their jobs by constantly

solving problems

They should improve their processes and find

innovative ways to satisfy their customers

72

Source: Jeffrey K. Liker

So for People and Partners:

Respect, Challenge, and Grow Them:

Grow leaders who thoroughly understand the work,

live the philosophy, and teach it to others

Develop exceptional people and teams who follow

your company’s philosophy

Respect your extended network of partners and

suppliers by challenging them and helping them

improve

73

Source: Jeffrey K. Liker

One-Piece Flow Demands Team Work!

x

x

x

x x

Station B

Traditional Western

Team

x

x

x

x

x

x

x

x

x

Station A

Station C

Need

help?

x

x

x

Need

help?

X

Toyota Way Team

Workcell

74

Source: Jeffrey K. Liker

Typical Toyota Organization to support Continuous Improvement

Team Size

Team Member

{5-8}

Kaizen

Team Leader

{3-4}

Group Leader

{5-8}

Asst. Manager

{ 4 - 10 }

Manager

Source: Bill Costantino, former group leader, Toyota, Georgetown.

Source: Jeffrey K. Liker

75

76

Source: Jeffrey K. Liker

The dynamic of

The Toyota Way

Toyota Way Principles

in 4P Model

Problem

Solving

(Continuous

Improvement and Learning)

Continual organizational learning through Kaizen

Go see for yourself to thoroughly understand the

situation. (Genchi Genbutsu)

Make decisions slowly by consensus, thoroughly

considering all options; implement rapidly

(Nemawashi)

People and Partners

(Respect, Challenge and Grow Them)

Grow leaders who live the philosophy

Respect, develop and challenge your

people and teams

Respect, challenge, and help your

suppliers

Process

(Eliminate Waste)

Philosophy

Create process “flow” to surface

problems

Level out the workload (Heijunka)

Stop when there is a quality problem

(Jidoka)

Use pull systems to avoid overproduction

Standardize tasks for continuous

improvement

Use visual control so no problems are

hidden

Use only reliable, thoroughly tested

technology

(Long-term Thinking)

Source: Jeffrey K. Liker

Base management

decisions on a long-term

philosophy, even at77

the

expense of short-term

financial goals

Principle 12

Go and see for yourself to thoroughly understand

the situation (genchi genbutsu)

-

12

Go to the source to observe and verify data

Don’t theorize on the basis of what people and

computers tell you

Even high-level managers should do this

78

Source: Jeffrey K. Liker

Principle 13

Make decisions slowly by consensus, thoroughly

considering all options, implement decisions rapidly.

-

13

Do not pick a single solution but consider

alternatives

Discuss problems and potential solutions with all

involved

79

Source: Jeffrey K. Liker

Value Stream Perspective

Get away from isolated perspective / improvements

Process 1

Process 2

Kaizen

Process 3

Kaizen

Kaizen

See the whole of the process

80

Source: Jeffrey K. Liker

5-Why - example

What is the problem?

Employees are frustrated and complaining about

the new e-mail system

Why?

Employees do not understand how to use the

functions of the system

Why?

The employees didn`t receive adequate training on

the new system, a manual they can use, and didn`t

give input on their needs for the new system

functions

81

Source: Jeffrey K. Liker

5-Why - example

Why?

The I.S. manager had a poor planning process:

didn`t ask employees about their needs on system

functions, didn`t plan for training, didn`t notify

employees using multiple communication

channels, didn`t review the manual with employees

(pilot group)

Why?

The manager didn`t get direction and support from

his boss, or received planning process training.

82

Source: Jeffrey K. Liker

5-Why - example

Why?

The company as a whole does not have effective

internal processes in place, nor is it disciplined in

using good process.

Why?

Senior management hasn`t worked to create a

work culture that encourages and reinforces

effective internal processes

83

Source: Jeffrey K. Liker

How Do we Develop People?

Research in occupational training

shows that individuals retain about:

• 10 % of what they read

• 20 % of what they hear

• 30% of what they see

• 50% of what they hear and use

• 70% of what they say

• 90% of what they say and do

84

Source: Jeffrey K. Liker

• Job Instruction Training is designed to teach

people how to do a particular job by:

Hearing (what to do)

Seeing (how it is done)

Using (what was learned)

Saying (what was learned)

Doing (the task)

REPEATEDLY !!

85

Source: Jeffrey K. Liker

Toyota is a learning organization

that has learned nearly through

a whole century

86

Source: Jeffrey K. Liker

“No Problem” is problem!

• Problems are opportunities to learn

• Hiding problems undermines the system

87

Source: Jeffrey K. Liker

Characteristics of Effective Lean

Transformation – How to Do It

• Top Down Directive that this is the new way.

• Bottom-up involvement in concrete projects with clear

results. Lean Pilots.

• Develop internal experts through learning by doing.

• Experts to guide the process and teach.

• Learning philosophy: every project, activity, is a

chance to learn.

• Start with value stream transformation projects.

• Build on successes to transform broader organization

and culture over time - - - YEARS!

88

Source: Jeffrey K. Liker

Why is this hard to do?

•

•

•

•

•

Traditional organizations used to “fire fighting”

No clear vision of the future state

Culture change is hard

Organizational change is disruptive

Management has to change its role from

managing from the office to deeply

understanding processes!

89

Source: Jeffrey K. Liker

Keep in mind (you as future managers):

“There will never be enough managers

for total quality”

90

Source: Jeffrey K. Liker

91

Source: Jeffrey K. Liker

Conclusion

92

Source: Jeffrey K. Liker

Lean is…

“A long journey that needs commitment, patience,

long-term thinking, positive mindset and attitude,

and continuous improvement which are merged

together as operational excellence and as a

strategic weapon.”

Train for Your journey and Do Your Best !

93

Source: Jeffrey K. Liker

A whole system:

Many good (American) companies have respect for

individuals, and practice kaizen and other TPS

tools.

But what is important is having all the elements

together as a system.

It must be practiced every day in a very consistent

manner – not in spurts – in a concrete way on the

shop floor.

Fujio Cho, President, Toyota Motor Corporation

94

Source: Jeffrey K. Liker

Words of Wisdom

“It is

not the strongest nor the most intelligent of

the species that survives,

but the one that is most adaptable to

change”

-Charles Darwin-

95

Source: Jeffrey K. Liker

Thanks a lot for listening and for your interest!

96

Company

Contact at company, primary

MDH backing for assistants

Process

Remarks

Project Name

Grp

Volvo GTO, Köping

Ulf Larsson

Tel: 0221-373 56

ulf.larsson.2@consultant.volvo.com

Mats Ahlskog,MDH Innofacture

Produktion, TBD

Pref. Contact

already 12/9 or

13/9

GTO

V1?

Volvo CE, Eskilstuna

Mats Jackson + TBD

Anders Hellström

Together with internal VCE

course project grp

VCE1

3?

Volvo CE, Eskilstuna

Mats Jackson + TBD

Anders Hellström

Together with internal VCE

course project grp

VCE2

6?

Scania, Södertälje

Marcus Gustavsson, 070-795 21 36

Magnus "Z" Zetterberg

Manager | SPS Office Chassi | Scania CV AB

Boxintag

ASAP, 3 full

days at line sugg.

ScaniaBox

5?

Scania, Södertälje

Ola Fransson, 070-768 09 14

Magnus "Z" Zetterberg

Manager | SPS Office Chassi | Scania CV AB

C-artikel flöde

ASAP, 3 full

days at line sugg.

Scania Cartikel

2?

Alfa Laval

Eskilstuna

Rebecca Nilsson

Lean Six Sigma Black Belt, Quality & Environment

Mobile: +46 708 575940

rebecca.nilsson@alfalaval.com

Daniel Gåsvaer

Delivery and inspection of

incoming goods to production

RN available at

first from 16/9

Delivery and

inspection of

incoming

goods to

production

7?

Calix AB, Eskilstuna

Prel Joachim Schmidt

Joachim Schmidt ProduktionschefPostal address:

Box 5026, SE 630 05 Eskilstuna, Sweden

Visiting address: Filargatan 14, SE 632 29 Eskilstuna,

Sweden

Phone: +46 (0)16-10 80 40 Fax: +46 (0)16-10 80

60 Mobile: +46 (0)722-41 80 40 Mail:

joachim.schmidt@calix.se

Internet: www.calix.se

TBD

Calix

8?

Bonaj, Eskilstuna

Grp 4

Mobile: +46 (0)73 558 78 50

E-mail: mats.ahlskog@volvo.com

TBD

4?

97