sEcTtoN 15281

sEcTtoN

15281

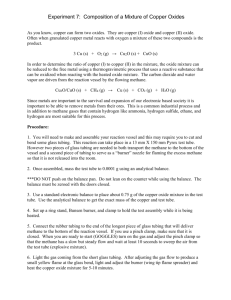

SEAMLESS ASTM B 88 COPPER WATER TUBE

PART

1

GENERAL

I.OI

SUMMARY

A.

Section lncludes: Seamless copper water tube.

B.

Related Sections:

1.

Section 15061 - Pipe Supports.

2.

Section 15062 - Preformed Channel Pipe Support System.

1.02

REFERENCES

A.

American Society for Testing and Materials (ASTM):

1.

B 32 - Standard Specification for Solder Metal.

2.

B 88 - Standard Specificatíon for Seamless Copper Water Tube.

3.

B 813 - Standard Specification for Liquíd and Paste Fluxes for Soldering of

Copper and Copper Alloy Tube.

4.

B 828 - Standard Practice for Making Capillary Joints by Soldering of Copper and Copper Alloy Tube and Fitting.

B. lnternational Association of Plumbing and Mechanical Officials (IAPMO):

1. lS 3 - lnstallation Standard for Copper Plumbing Tube, Pipe and Fíttings.

PART

2

PRODUGTS

2.01

MATERIALS

A.

Seamless Copper Water Tube:

1.

Type: ASTM B 88: a.

Exposed Copper Piping or Tubing: Type L hard-drawn, rigid.

b.

Copper Tubing Buried in the Ground or in Plastic Conduit: Type K soft-annealed.

2.

Fittings: Manufacturers: Solder type forged, or wrought copper. One of the following or equal: a.

Hoke, Gyrolok.

b.

Crawford Fitting Company, Swagelok.

c.

Parker.

3.

Solder: ASTM B 32, Alloy Grade Sb5.

4.

Flux

ASTM B 813.

5.

Dielectric lnsulating Unions or Fittings: Manufacturers: One of the following or equal: a.

PatrolValveCompany.

b.

Mueller Company.

6.

Special Thread to Tube Adapters: Manufacturers: One of the following or equal: a.

Crawford Fitting Company, Swagelok.

APRTL 2010 -

FTNAL 15281-1 pwl/Carollo/Documents/ClienUTXFort Worth/820541 0/Specifications/1 5281 (Final (clean))

8205A10

b.

Hoke, Gyrolok.

c.

Parker.

PART

3

EXECUTION

3.01

INSTALLATION

A.

General:

1.

Support copper piping and tubing as specified in Sections 15061 and 15062.

2.

Clean copper lines with high-pressure air after first dlsconnecting pipíng at instruments, filters, pressure reducers, valve operators, and other special devices.

3. lnstall copper pipe in accordance with IAPMO lS 3.

B. lnstallation of Copper Piping:

1.

Connect copper pipe connected to fenous pipe or valves, or other non-copper items, by means of dielectric insulating unions or fittings.

2.

Where connections are made to meters or other devices having iron pipe size threaded fittings, provide specialthread to tube adapters.

C. lnstallation of Copper Tubing:

1. lnstall copper tubing in accordance with ASTM B 828 and IAPMO lS 3.

2- lnstall copper tubing in straight runs, supported at intervals close enough to avoid sagging.

3.

Make cuts square with a tubing cutter or with a 32-tooth hacksaw. Provide a sizing tool to correct distortions.

4.

Ream the inside of the tubing and remove buns from the outside, holding the end of the tubing downward and preventing chips and fillings from entering the tubing.

5.

Perform Flaring With a Flare Block and Yoke Type Screw Feed Flaring Tool: a.

After removing the tubing from the flare block, inspect both surfaces of the flare for splits, cracks, or other imperfections.

b.

Where there are imperfections, cut off the imperfect flare, and prepare a new flare.

3.02

FIELD QUAL]TY CONTROL

A.

Testing: Test copper lines in the same manner as the piping system to which they connect.

END OF SECTION

APRTL 2010 -

F¡NAL 15281-2 pw://Carollo/Documenls/Client/IXFort

Worth/8205A1 0/Specificalions/1 5281 (Final (clean))

8205A10