PLASTIC ANALYSIS Bending beyond the elastic limit

advertisement

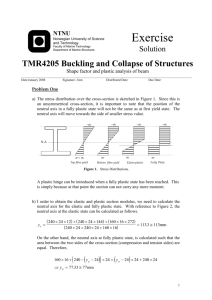

PLASTIC ANALYSIS Reading – Megson I, Sections 9.10, Megson II, Chapter 18. Neal, B.G., ‘The plastic methods of structural analysis’, 3rd (S.I.) Ed., Chapman & Hall, 1977. Horne, M.R., ‘Plastic theory of structures’, Nelson, London, 1971. Bending beyond the elastic limit Limit state design of structures requires the prediction of the ultimate strength or collapse load of a structure. Safe loads are then determined as a suitable fraction of the collapse load. As bending of a beam proceeds, strains increase steadily, but the corresponding stress values depend on the material’s stress-strain relationship. Some materials will fail suddenly in a brittle fashion when the strain reaches a certain value (e.g. timber, cast iron, glass, etc). Others will yield and flow in a plastic fashion (e.g. many types of steel). Although some structures may fail whilst still in a fully elastic state (by buckling, for example), most will exhibit stresses that exceed the elastic limit before failing. We consider now the behaviour of a beam under steadily increasing bending moment and assume it is made from an elasto-plastic material with an idealised stress-strain relationship as shown in the plot on the right (not to scale). σ yield ‘plateau’ yield stress, σy yield strain onset of strain hardening -εy We further assume that the beam crosssection has at least one axis of symmetry which lies in the plane of bending. εy ε -σy plane of loading and bending coincides with plane of symmetry examples of symmetric sections M M neutral axis εy σy elastic neutral axis ε σy strain (linear) plastic neutral axis σ σy σy σy M = Mp ‘Fully Plastic Moment’ M = My ‘Yield Moment’ maximum stress has just reached σ y for the first time Plastic_Analysis_Notes.doc σy increasing ymax y σy p1 as strain increases yielding penetrates further into the beam yield stress penetrates entire cross-section Yield moment, My When the stress at the extreme fibre most distant from the neutral axis just reaches yield stress. This defines the maximum moment the beam can resist whilst still fully elastic. It follows that σy = My y max I where ZE = , or My = ZE σ y I y max (the elastic section modulus) Plastic Neutral axis Under elastic conditions the neutral axis (zero strain locus) passes through the centroid of the crosssection. As parts of the cross-section yield and the stress distribution becomes nonlinear, the need for the tension and compression forces to remain equal causes the position of the neutral axis to move away from the centroid (except in the case of a doubly symmetric section). σy A1 G1 _ y1 _ y2 C plastic neutral axis MP G2 A2 σy T Let the plastic neutral axis divide the section such that the areas above and below are A1 and A2 respectively. For zero resultant axial force: A1 σ y = A2 σ y ∴ A1 = A2 = A / 2 Thus the plastic neutral axis divides the section into equal areas. Fully plastic moment, MP When entire cross-section has reached yield stress, attempting to further increase the applied bending moment will simply result in the beam rotating without further increase in resisting moment. A plastic hinge is said to have formed. A plastic hinge could perhaps be likened to a ‘rusty’ hinge in that it displays a constant resisting moment. MP is the maximum or ‘ultimate’ moment the beam can resist. The condition of full plasticity associated with the fully plastic moment theoretically requires infinite curvature (finite change in slope over a zero length of the beam – i.e. a ‘kink’) implying infinite strain – which is unattainable. In practice strains near the neutral axis will be below yield strain, but will be compensated for by extreme fibre strains reaching strain-hardening levels with consequent small increases in stress above σy. Let y1 and y2 denote the distance of the centroids of areas A1 and A2 from the PNA. Let C denote the compressive force due to σ y acting on A1, and T the tensile force on A2 – C = σ y A1 = σ y A / 2 T = C = σ yA / 2 Taking moments about the PNA – MP = Cy1 + Ty2 = σ yA( y1 + y2 ) Plastic_Analysis_Notes.doc 2 p2 Copyright © J.W.Butterworth, July 2005 or MP = Z P σ y where ZP is the plastic section modulus. Plastic section modulus It follows from the preceding relationship that ZP = A(y1 + y 2 ) 2 or, more strictly Z P = ( A y1 + y 2 ) 2 (taking absolute values of y1 and y2 ). More generally we could write ZP = ∫ y dA A where y denotes the distance of each element of area, dA, from the PNA. Shape factor Maximum elastic moment, My = ZE σ y , where ZE = I y max (the elastic section modulus). Ultimate (fully plastic) moment, MP = Z P σ y . The ratio of the fully plastic moment to the yield moment depends on the shape of the cross-section and is known as the shape factor, f (Megson’s notation, but also called S and sometimes, v). f= MP My = ZP Zy f is a measure of the ‘reserve strength’ in a beam that has reached its maximum elastic moment, My. Some sample values: f = 1.5 f ≅ 1.7 f ≅ 1.27 f ≅ 1.15 to 1.6 Example – rectangular beam b bd ⎛ d d ⎞ bd 2 ZP = ⎜ + ⎟= 2 ⎝4 4⎠ 4 ZE = f= I bd / 12 bd = = y max d/2 6 ZP ZE 3 = d/2 2 ( - should know this….) d/2 6 = 1.5 4 If b=40mm, d=120mm and σ y = 250,000 kPa, the fully plastic moment will be MP = Z P σ y = 0.04 × 0.12 2 × 250,000 = 36 kNm 4 Example – collapse load of a steel T-beam Plastic_Analysis_Notes.doc p3 Copyright © J.W.Butterworth, July 2005 10 W yP plastic neutral axis 140 2m 10 100 σ y = 280 MPa γ steel = 76 kN / m 3 The problem is to determine the load W that will cause collapse of the steel cantilever T-beam. It is obvious that the maximum bending moment occurs at the left hand end. When this peak moment reaches the fully plastic value MP, a plastic hinge will form at the left hand end and the beam will collapse. Plastic neutral axis If yP denotes the position of the PNA, the area above must = A/2. A (140 + 100)10 = 2 2 yP = 120mm 10 yP = Plastic section modulus ZP = ∑Ay i i (summing the area moments of each rectangle about the PNA) = 120 × 10 × 60 + 20 × 10 × 10 + 100 × 10 × 25 = 99,000 mm3 = 99 × 10 −6 m3 Fully plastic moment MP = ZP σ y yielded material Wcollapse = 99 × 10 × 280,000 −6 = 27.72 kN − m Collapse load Ignoring self-weight, the maximum bm is 2W kN-m at the left hand end. Equating this to MP : plastic hinge Collapse mechanism 2Wcollapse = 27.72 Wcollapse = 13.86 kN Show also that PNA is 18.75 mm from the elastic neutral axis, ZE = 55.1 × 10 −6 m3 , f = 1.798, My = 15.42 kNm, and load at first yield, Wy = 7.71 kN. What value of W would cause collapse if self-weight was included? (13.68 kN) Plastic_Analysis_Notes.doc p4 Copyright © J.W.Butterworth, July 2005 Spread of plasticity in the plastic hinge vicinity [Megson I p.244, Megson II p.602] material at σy b c My MP σy σy yielded elastic under point load at b at c STRESS DISTRIBUTION at selected points along beam COLLAPSE MECHANISM The form of the yielded zone will vary according to the bending moment diagram and the shape of the crosssection. Once sufficient plastic hinges have formed to create a mechanism there will be no further increase in stress or load. However, strains and displacements will continue to increase as plastic flow proceeds in the plastic hinge zones. Suitability for plastic analysis Note that not all structural members are capable the ductile behaviour needed to form stable plastic hinges. Timber, for example tends to fail in a brittle fashion but can achieve ductile performance by means of steel connectors (but ductility is necessarily confined to the connector locations). Similarly unreinforced concrete fails in a brittle manner, but when suitable reinforced with steel becomes satisfactorily ductile. Structural steel is probably the pre-eminent ductile material, but care is still needed to ensure that undesirable buckling doesn’t occur prior to the establishment of to be suitably proportioned and intervene before the formation of plastic hinges. Plastic_Analysis_Notes.doc p5 Copyright © J.W.Butterworth, July 2005 Plastic Analysis Role in Design When designing for the strength limit state, the objective is to satisfy the inequality S * ≤ φ Sn . S* denotes the structural action(s) caused by the characteristic or factored loads, and φSn denotes the reliable strength of the structure based on nominal strength Sn and strength reduction factor φ. The characteristic loads are normally obtained by reference to Standards (NZS 1170 for example) which present basic loads together with appropriate factors. The intention is to define loadings that typically have a 5% probability of exceedance in 50 years (in other words a value that is unlikely to underestimate the maximum load encountered by the structure during its intended design life). You will be familiar with loadings such as 1.2G + 1.6Q where G and Q represent the intensity of dead and live loads on a timber deck. The reliable strength is intended to represent a value with a 95% probability of exceedance (in other words a value that is unlikely to over-estimate the strength). The structural actions S* and strengths Sn are normally replaced by specific actions such as bending moment in the case of flexural (beam and frame) structures, or axial forces in the case of truss-type structures. Flexural structures: M * ≤ φ Mn (where Mn may be replaced by MP, the fully plastic moment). Truss structures: N * ≤ φ Nn (where N* denotes the axial force in a truss member) Plastic analysis provides the means of determining the design actions M*, throughout the structure resulting from the application of the factored loads. Plastic analysis can also be used to determine the magnitude of applied loads that would bring about the collapse of a given structure. Example – Required strength of a simply supported beam A simply supported beam of 8m span is to carry a uniform spread load of 12.5kN/m (factored). Determine the required fully plastic strength of the beam. w collapse mechanism 2 wL /8 Maximum bm, wL2/8 occurs at mid-span with a value = 12.5 x 82/8 = 100kNm. Collapse will ensue if the beam has a fully plastic moment of φMp = 100kNm. Hence the required beam strength, Mp = 100/φ = 100/0.9 = 111kNm. (taking φ = 0.9, the value for a normal steel beam) Plastic_Analysis_Notes.doc p6 Copyright © J.W.Butterworth, July 2005 Example – Collapse load of a simply supported (determinate) beam with overhang (from Megson) The beam ABC has span AB = L and overhang BC = L/2. Point loads of 4W and W act at mid-span AB and C respectively. 4W W B A C D L/2 L/2 L/2 WL/2 3WL/4 collapse mechanism The bm diagram is readily obtained revealing a maximum bm of 3WL/4 at D. If is gradually increased a plastic hinge will eventually form at D creating the collapse mechanism shown. The value of W is determined from the knowledge that 3WL = MP 4 4MP Wcollapse = 3L The formation of a plastic hinge immediately created a mechanism, allowing collapse to occur. This will always be the case for determinate structures, but not necessarily for indeterminate structures as the next example shows. W Example – collapse load of an indeterminate beam Consider the propped cantilever with central point load, W. An elastic analysis (e.g. by using integration, momentarea or similar) gives the bms shown, with maximum moment of 3WL/16 at the support. As W increases the 1st plastic hinge forms when 3WL/16 = MP (i.e. when W = 16MP/3L). However, this does not create a mechanism and W may be further increased until eventually the bm at mid-span also reaches MP. At this stage a 2nd plastic hinge forms and this time a mechanism is created and collapse ensues. L/2 L/2 bm, elastic analysis 3WL/16 = MP 5WL/32 1st plastic hinge forms here bm increases with W MP bm at collapse Finally we carry out a static equilibrium analysis of the beam at the instant of collapse to determine the value of W. MP But hold on, this is an indeterminate structure isn’t it? How can we use just static equilibrium to analyse it? Wcollapse Answer is that each plastic hinge provides the value of Plastic_Analysis_Notes.doc p7 collapse mechanism Copyright © J.W.Butterworth, July 2005 the bm at its location. This additional information allows the analysis to be completed. W A C MP B MP VA VC Taking moments about B for segment BC: L , 2P 2MP VC = L MP = VC C MP B VC Taking moments about A for AC: L − VC L, 2 2MP ⎞ 2⎛ W = ⎜⎜ MP + L ⎟⎟ L⎝ L ⎠ 6MP = L MP = W Giving the required collapse load in terms of the beam’s fully plastic strength. Alternative equilibrium calculation using virtual work principle Virtual work (Megson Section 15.2) provides powerful alternative principles that are widely used in theoretical mechanics. Here we will apply the principle of virtual displacements which is an alternative equilibrium criterion to Newton’s Laws. It states that if a structure in equilibrium is given a virtual displacement the sum of the internal and external virtual work done will be zero. To illustrate the principle we apply it first to the simply supported beam ABC: W Apply a vertical virtual displacement ∆ to whole: A B VW done = W∆ − VA ∆ − VC ∆ = 0, VA + VC = W ∆ Next apply a rotational virtual displacement δθ about A: VW done = W VC = W 2 C VA VC δθ L δθ − VC Lδθ = 0, 2 Lδθ VC Giving us the expected results. Plastic_Analysis_Notes.doc p8 Copyright © J.W.Butterworth, July 2005 In applying the principle the displacements are referred to as virtual to distinguish them from real displacements that result from things such as applied loads. The application of a virtual displacement is not permitted to alter any external or internal forces (or stresses) that may be present. Forces are effectively “frozen” during the process. Virtual work is computed as the product of the real forces acting through virtual displacements, or as real moments acting through virtual rotations. We now apply the principle to the beam ABC at the instant of collapse, using the collapse mechanism as the virtual displacement: Denoting the rotations of the beam segments AB and BC by θ (assumed small, since we need only consider the initial movement of collapse), we deduce from the geometry that the rotation at the mid-span hinge is 2θ. W θ MP θ 2θ MP L θ 2 Internal VW = MP θ + MP 2θ External VW = W collapse mechanism as virtual displacement where the internal work is obtained as the product of moment x rotation. Equating the internal and external VW gives L θ = 3MP θ 2 6MP W= L W The same result as before. However, the virtual work approach avoids the need to calculate the intermediate result VC and provides a consistent (and very simple) approach to the equilibrium calculation. Note that it was not necessary to carry out an elastic analysis. Plastic analysis requires us to consider only the final plastic collapse state, not the elastic state that precedes it. Example – Guessing collapse mechanisms W L/3 2L/3 For the fixed end beam shown we guess a collapse mechanism (A) as shown below: W θ θ 2θ L/3 L/2 Denoting the rotations as shown, we proceed directly to the calculation of the collapse load using virtual work principle: Plastic_Analysis_Notes.doc p9 Copyright © J.W.Butterworth, July 2005 L θ, 3 Internal VW = MP (θ + 2θ + θ) External VW = W and equating, W= 12MP L Repeating for the mechanism (B) below: W θ 2θ 3θ L/3 L/3 L θ, 3 Internal VW = MP (θ + 2θ + 3θ) External VW = W and equating, W= 18MP L Not surprisingly we see that the result depends on the choice of the collapse mechanism. Trying one more, (C): W 2θ θ 3θ L/3 2L/3 L External VW = W 2θ, 3 Internal VW = MP (θ + 2θ + 3θ) and equating, W= 9MP L Each mechanism results in a different value of collapse load, W. Which one, if any, is correct? If we draw the bm diagram for each collapse mechanism we obtain the results shown in the next figure. Note that for mechanisms (A) and (B) the resulting bms (that satisfy equilibrium) exceed MP over the shaded part of the diagram. This is impossible of course, as MP is by definition the maximum bm that the beam can resist, and indicates that the resulting value of W must be wrong. Mechanism (C) however gives a distribution of bm that nowhere exceeds MP. It also gives the lowest value of collapse load, W = 9MP/L. Obviously if the beam was able to collapse at this load, it would not continue on to carry the higher loads calculated for mechanisms (A) and (B). We conclude that the mechanism which gives the lowest collapse load is probably the correct one. Plastic_Analysis_Notes.doc p10 Copyright © J.W.Butterworth, July 2005 W=12MP/L MP MP (A) MP W=18MP/L MP MP (B) MP W=9MP/L MP MP (C) MP Cases (A) and (B) are said to violate the Yield Condition, i.e. they have M > MP. Hypothesis A collapse load calculated on the basis of an assumed mechanism is greater than or equal to the true collapse load. (Later we show that this is correct.) Example – collapse? load based on satisfaction of equilibrium and yield We attempt to salvage some useful information from the previous analyses using guessed mechanisms. Taking mechanism (A) we observe that the calculated collapse load is 12MP/L. The maximum apparent bm occurs under the point load and from the bm diagram can be seen to have a value of Mmax = 5MP/3. If load W is reduced, internal actions such as bms will be reduced proportionately. To reduce the largest bm to MP, we need to reduce W by the ratio of MP/Mmax = 3/5. This will give the following load and bms: W=36MP/5L (A) 3MP/5 3MP /5 no plastic hinges at supports now MP original bm This leaves just a single plastic hinge under the point load. Plastic_Analysis_Notes.doc p11 Copyright © J.W.Butterworth, July 2005 We now have a load, 36MP/5L, that is in equilibrium with a set of internal moments that nowhere exceed MP. However, there are not enough plastic hinges left to create a mechanism, so we conclude that the applied load is less than the collapse load. Hypothesis If a bm distribution can be found that is (1) in equilibrium with the applied load(s), and (2) ≤ MP everywhere, then the applied load is ≤ true collapse load. (Later we show that this is correct.) Thus by considering just one mechanism, (A), we have been able to show that the true collapse load lies in the range 12MP 36MP ≤W≤ L 5L 7.2MP 12MP ≤W≤ L L With the true collapse load of 9MP lying close to the mean of the upper and lower bounds. L Example – beam with distributed loading Examples so far have all carried point loads, making it easy to guess the likely location of plastic hinges (since the bm diagram consists of straight line segments peak values must occur at the loads or at fixed ends). With distributed loads it is not so easy to identify the plastic hinge locations. The approach used in this example is to treat the hinge location as a variable, calculate the collapse load and then change the variable until the collapse load is minimised. For the propped cantilever we assume plastic hinges form at the fixed end and at a point distant x from the fixed end. w The geometry of the resulting mechanism has the angles shown in the figure. x L−x + w( L − x ) x θ 2 2 Internal VW = MP θ(L − x + L) External VW = wx(L − x)θ Equating: (L-x)θ xθ Lθ x 2MP (2L − x) w= Lx(L − x) Correct value of x will minimise the collapse load. Hence seek x such that L-x dW = 0 , leading to dx x 2 − 4Lx + 2L2 = 0 x = (2 − 2 )L = 0.586L w = (6 + 4 2 ) = 11.657 Plastic_Analysis_Notes.doc MP L2 MP L2 p12 Copyright © J.W.Butterworth, July 2005 Reduction of MP due to axial load (Megson I p.250Megson II p.611) When a structural member is subjected to axial load (tension or compression) in addition to moment, the fully plastic moment will be reduced (since some strength is used up in resisting the axial force). The reduced plastic moment is known as MRP or, (Megson) MP,R. The amount by which MP is reduced depends on the shape of the cross-section and the magnitude of the axial force. We examine the case of a beam with a rectangular cross-section. σy σy b σy stress resisting M M d/2-a d/2+a P a stress resisting M σy σ = P/A M=0 small M compressive yield tensile yield d/2 a stress resisting P d/2 σy fully plastic cross-section Assume the axial force is applied first followed by gradually increasing moment until the cross-section reaches its fully yielded state as illustrated above. Yield stress is eventually reached over the entire crosssection, with equal areas of tensile and compressive stress at the top and bottom resisting the moment, and a central area of compressive stress resisting the axial force. MRP = σ y b( d d d2 − a)( + a) = σ y b( − a2 ) 2 2 4 (1) (2) P = σ y b(2a) substituting for a in equation 1: MRP = σ y b( MRP = d2 P2 ) − 4 4σ 2y b 2 bd2 P2 σy − 4 4σ y b (3) Now let Py = squash load (axial load that will fully yield cross-section). Thus Py = bdσ y also MP = we get MRP = MP − bd2 σ y , and since P = 2abσ y , 4 P2d , or 4Py ⎛P MRP = MP − MP ⎜ ⎜ Py ⎝ = MP (1 − n 2 ) where n = ⎞ ⎟ ⎟ ⎠ MRP MP 2 P Py Plastic_Analysis_Notes.doc 1.0 P Py p13 1.0 Copyright © J.W.Butterworth, July 2005 Reduction of MP due to shear force The presence of shear force will also cause a reduction in MP, although the effect is less serious than in the case of axial force. As detailed analysis is more complicated discussion is deferred until later courses. Moment-curvature relationship (Megson II, p.600) Consider a beam of rectangular cross-section under the action of a bm M (<MP). Let de denote the depth of the elastic core, then yielded zone σy 2 bde d − de d + de M= ⋅ σy + b ⋅ ⋅ ⋅ σy 6 2 2 (d-de)/2 where (d+de)/2 de 1st term = bm resisted by the elastic core, and 2nd term = bm resisted by the yielded (plastic) zones. i.e. M= σy elastic core bde 2 b 2 + (d − de2 )σ y 6 4 cross-section stress distribution ⎛ d2 de2 ⎞ ⎟σ y M = b⎜⎜ − 12 ⎟⎠ ⎝ 4 (1) The curvature of the elastic core (and of the beam), M 1 =κ= e R EIe where Me = resisting moment of elastic core = Ze σ y Ie = moment of inertia of elastic core bde2 σy Ze σ y ∴κ = = 6 3 EIe bd E e 12 i.e. κ= M 1.0 MP a b Behaviour Model 2/3 oac = rigid plastic 2σ y (2)plastic obc = elastic-perfectly Ede Equations (1) and (2) define bm and curvature in terms of de, where de ranges from d down to zero. when de = d, M = bd2 σ y = My , the yield moment. 6 2 bd σ y = MP , the fully plastic moment 4 and κ → ∞ . when de = 0, M = c oc = elasto-plastic 1/3 0 1 2 3 κ κy The figure shows the relationship for a rectangular section. Similar plots can be obtained for sections of other shapes, such as I-beams. Simplifying assumptions about the moment-curvature relationship are often made. Three of these are shown in the figure above. Plastic_Analysis_Notes.doc p14 Copyright © J.W.Butterworth, July 2005 Residual stress resulting from removal of load after MP achieved We consider what happens if, after applying increasing load to a beam until the maximum moment reaches MP, we then remove the load, causing the bending moment to return to zero. σ σy c σy b unloading MP MP (elastic) a ε εy -σy d When the moment reaches MP, the entire cross-section is assumed to have reached either the tensile or compressive yield stress. stress under MP Reducing the moment to zero is equivalent to applying a bm of MP in the reverse direction. Referring to the stress-strain diagram, note that as strain is reduced, stress reduces according to the straight line cd – i.e. a linear elastic response. Thus applying reverse MP results in a stress distribution of the form: σmax MP MP σmax change in stress due to reverse MP MP . ZE Where σ max = But as MP = ZP σ y , σ max = ZP σ y = fσ y ZE = 1.5σ y for a rectangular section Superimposing the stress distributions reveals the final state of residual stress following the removal of the load. Note that the final stresses are self-equilibrating (i.e. zero bending moment and axial force). σy M=0 1.5σy 0.5σy M=0 + σy 1.5σy MP Plastic_Analysis_Notes.doc = p15 -MP σy σy 0.5σy residual stress when M=0 Copyright © J.W.Butterworth, July 2005 PLASTIC ANALYSIS THEOREMS (Megson II, 18.1) Three conditions that must be satisfied by a structure on the point of collapse are: 1. EQUILIBRIUM CONDITION 2. MECHANISM CONDITION 3. YIELD CONDITION At collapse the bending moments must everywhere be ≤ MP. At collapse, the bending moments must correspond to a state of equilibrium between the external loads and the internal actions. At collapse there must be sufficient plastic hinges to create a partial or complete collapse mechanism. Using these conditions we can now state three fundamental theorems of plastic analysis – LOWER BOUND THEOREM If the bending moments are in equilibrium with the external load and M ≤ MP everywhere, the load is a lower bound (i.e. load is ≤ collapse load). UPPER BOUND THEOREM For an assumed mechanism in which the virtual work done in the plastic hinges equals the virtual work done by the external loads, the load is an upper bound (i.e. load is ≥ collapse load). UNIQUENESS THEOREM If a bending moment distribution can be found that satisfies the three conditions of equilibrium, mechanism and yield, then the corresponding load is the collapse load. Proofs of the theorems are straightforward, but rather unexciting. See Horne, 1971 or Neal, 1977. The three theorems are summarised diagrammatically below: . MECHANISM UNIQUENESS UPPER BOUND load ≥ true collapse load EQUILIBRIUM LOWER BOUND load ≤ true collapse load load = true collapse load YIELD There are a number of corollaries (easily proved consequences) of the theorems: 1. The collapse load of a structure cannot be decreased by increasing the strength of any part of it (corollary of lower bound theorem). 2. If the collapse loads are determined for all possible mechanisms, the actual collapse load will be the smallest of these (corollary of upper bound theorem). 3. The collapse load of a structure cannot be increased by decreasing the strength of any part of it (corollary of upper bound theorem). 4. The initial state of stress has no effect on the collapse load (excluding elastic stability effects) (from uniqueness theorem). Plastic_Analysis_Notes.doc p16 Copyright © J.W.Butterworth, July 2005 5. If a structure is subjected to any programme of proportional or non-proportional loading, collapse will occur at the first combination of loads for which a bm distribution satisfying the conditions of equilibrium, mechanism and yield can be found (from uniqueness theorem). Note 1. The uniqueness theorem does not assert that the bm distribution at collapse is unique. The bm distribution at collapse may depend on factors such as initial state of stress and loading history. Nor does it assert that the collapse mechanism is unique. There may be alternative mechanisms, but they will lead to the same collapse load. 2. An assumed plastic mechanism leading to a collapse load need not imply that a bm distribution in equilibrium with the external loads can exist for such a mechanism – as shown below: Example – assumed mechanism, equilibrium not satisfied W L/2 W/4 L/2 L/4 W/4 W θ W θ MP 3θ = W W= 48MP 7 θ θ Correct mechanism W/4 θ Assumed mechanism L W L θ− θ 2 4 4 MP 4θ = W W= 7W/48 8MP L L θ 2 WL/8 WL/8 WL/16 7W/48 WL/8 Assumed mechanism - bm diagram (doesn’t satisfy equilibrium, but the calculated collapse load is still a valid upper bound) True collapse bm diagram (satisfies equilibrium) Plastic_Analysis_Notes.doc not in equilibrium p17 Copyright © J.W.Butterworth, July 2005 Mechanism Method of Analysis This method of analysis is based directly on the upper bound theorem. The basic idea is to try all the likely collapse mechanisms and select the one which gives the lowest collapse load. The steps involved are as follows: 1. Identify the likely plastic hinge locations (under point loads, at supports, at joints, at zero shear positions under spread loads). 2. Sketch all the likely collapse mechanisms. 3. For each mechanism use virtual work to calculate the collapse load factor. 4. Select the mechanism which gives the lowest load. 5. For this chosen case check that M ≤ MP (this is just to check that the selected mechanism is indeed the correct one). If this condition is not satisfied the correct mechanism has been overlooked. Example – Fixed end beam with point loads 2W A 3.5W MP = 120kNm B 2m D C 3m 1m 3.5W 1) 4θ 2θ 2W 6θ 2) θ 2W 5θ 3.5W 6θ Mechanism 1: 2W(4 θ)2 + 3.5W(2θ)1 = MP (4 + 6 + 2) θ W= 12MP = 62.61kN 23 ← lowest Mechanism 2: 2W(θ)2 + 3.5W(5θ)1+ = MP (1 + 6 + 5) θ W= 12MP = 66.98kN 21.5 Plastic_Analysis_Notes.doc p18 Copyright © J.W.Butterworth, July 2005 Yield check on mechanism giving lowest load: We only need to find the moment at C, MC, since we know the bm at A, B and D is MP. Using virtual work again, we take the known bms and load from the chosen mechanism (1) and use mechanism (2) as a virtual displacement to determine MC: MP 2(62.61) θ 5θ MP 3.5(62.61) 6θ MC (unknown) MP (θ + 5θ) + MC (6θ) = 2(62.61)(θ)2 + 3.5(62.61)(5θ)1 MC = 104.35kNm (≤ MP , OK) giving the collapse bm diagram below: 120 120 104.35 120 The same result could be found by ‘conventional’ methods: 3.5W Consider segment BD and take moments about B: MP + 3.5 × 62.61 × 3 + MP − 4VD = 0 VD = 224.35kN MP D B C 3m VD 1m Summing moments about C for segment CD: MC + MP = VD × 1 MC = 224.35 × 1 − 120 = 104.35kNm. (≤ MP , OK ) MC C D VD 1m Plastic_Analysis_Notes.doc p19 Copyright © J.W.Butterworth, July 2005 Example – Fixed base rectangular frame, varying MP, point loads (examples of frame analyses can be found in Megson II from p.613) 8W kN 6W kN 4 3 2 MP (beam) = 60kNm 4m MP (both columns) = 40kNm 1 5 6m 1. 6m Likely plastic hinge positions identified at points 1, 2, 3, 4, and 5. Note: At the joints between beam and columns, a plastic hinge will form in the weaker member (the column) as soon as the moment reaches 40kNM. 2. Sketch candidate collapse mechanisms: 8W 6W 6W θ 8W 6W θ 2θ θ θ θ θ θ ‘SWAY’ mechanism ‘BEAM’ mechanism (example of partial collapse mechanism) θ 90° θ θ 8W θ ‘COMBINED’ mechanism Note that the ‘combined’ mechanism is obtained by combining (adding) the ‘sway’ and ‘beam’ mechanisms. In the process the plastic hinge rotations at hinge location 2 cancel each other, removing the plastic hinge and leaving the beam and column meeting at right angles. 3. Calculate collapse load factor (W) for each mechanism using virtual work equation: SWAY MP (column) (4θ) = 6W.4.θ W = 6.67 BEAM MP ( column) (2θ) + MP (beam) (2θ) = 8W.6.θ 40 × 2 + 60 × 2 8×6 = 4.167 W= Plastic_Analysis_Notes.doc p20 Copyright © J.W.Butterworth, July 2005 COMBINED MP ( column) (4θ) + MP (beam) (2θ) = 6W.4.θ + 8W.6.θ 31.11kN 23.33 kN 40 × 4 + 60 × 2 24 + 48 = 3.889 W= 4. Conclude collapse load, W = 3.889 (upper bound theorem) 5. Check yield condition to ensure M ≤ MP for selected mechanism: Need to find the moments at points 1 to 5. However, we know that the moments at 1, 3, 4 and 5 are the MP values for those locations. This leaves just M2 to find. 3 2 4 1 5 M 4 = 40 (M P(column) ) M2 31.11 θ θ 2θ M 3 = 60 (M P(beam) ) Using the beam mechanism as a virtual displacement to find M2: M2 (θ) + 60(2θ) + 40(θ) = 31.11 × 6 × θ M2 = 26.7kNm Hence collapse bm diagram as shown with M ≤ MP everywhere proving solution is correct (uniqueness theorem). 40 26.7 60 40 40 Example – Frame with sloping member Sloping members complicate the mechanism geometry, and we introduce the concept of instantaneous centre of rotation. Otherwise it is business as usual. 3W 2W 2 3 L 4 all members have same MP 1 5 L 1. L Diagram above shows frame details and 5 possible plastic hinge locations. Plastic_Analysis_Notes.doc p21 Copyright © J.W.Butterworth, July 2005 ic θ θ 3W θ 3W θ 2W 2θ 2W 3W Mechanism A Mechanism B θ 4θ θ θ 4θ θ 2θ 2θ 2. θ plastic hinge cancels θ θ Mechanism C = 2A + B Sketches above show three likely mechanisms. Mechanism A – familiar beam mechanism. Mechanism B – a ‘sway’ type mechanism. Note: Joint 2 can only rotate about joint 1 and so moves in a direction perpendicular to 1-2. Joint 4 likewise moves perpendicular to 4-5. As joints 2 and 4 also belong to member 2-4 they must rotate about a common instantaneous centre of rotation. Since 2 moves perpendicular to 1-2 its centre of rotation must lie on 1-2, and similarly the centre of rotation of 4 must lie on 4-5. Member 4-5 must therefore rotate about the intersection of 1-2 and 4-5, marked as ‘ic’ in the diagram. From the geometry of the diagram it can be seen that 2-4 rotates through an angle θ. Mechanism C – a ‘combined’ mechanism. We seek to combine mechanisms A and B such that plastic hinge cancellation occurs. Noting that the hinge at 2 has a negative rotation of θ in mechanism A (causing tensile stress on outside of frame) and a positive rotation of 2θ in mechanism B, we use the combination 2A + B to eliminate the plastic hinge at 2. 3. Collapse loads for each mechanism. A: L 3W. .θ = MP .4Gq 2 8MP W= 3L B: L 3W. .θ + 2W.L.θ = MP .6θ 2 12MP W= 7L C: L 3W. .3θ + 2W.L.θ = MP .10θ 2 20MP W= ← lowest 13L Plastic_Analysis_Notes.doc p22 Copyright © J.W.Butterworth, July 2005 2W 4. Mechanism C gives the lowest collapse load, providing us with our answer (according to the lower bound theorem). 5. To prove that our solution is correct we need to demonstrate that for the chosen collapse mechanism M ≤ MP throughout the frame. Since there are plastic hinges at locations 1, 3, 4 and 5, we only need to show that M2 ≤ MP. Using mechanism A as a virtual displacement in a similar way to the previous example we obtain the virtual work (equilibrium) equation as: L 3W. .θ = M2 .θ + MP .3θ 2 M2 3W θ 20MP subst. W = 13L θ 2θ MP MP 60 − 3)MP 26 = − 0.692MP M2 = ( MP 0.69M P The negative value for M2 simply indicates that it acts in the opposite direction to that assumed in the diagram. Thus M2 ≤ MP and the final bm diagram will be as shown. MP MP MP Example – Beam design 5m 8m 2kPa (dead) 3m 5kPa (live) 3m A reinforced concrete floor in an industrial building is to be supported by steel universal beams spaced 3m apart. Each beam is 13m long and supported at three points creating spans of 5m and 8m. The floor is 150mm thick and is attached to the top surface of the beam, providing restraint against lateral buckling. Partitions, etc, result in an additional dead load of 2kPa over the floor area. A live load of 5kPa is also specified. Determine the required size of UB for strength limit state loading of 1.2G+1.5Q. Use grade 300 steel and take the weight of reinforced concrete as 24kN/m3. Plastic_Analysis_Notes.doc p23 Copyright © J.W.Butterworth, July 2005 Objective To select a beam size such that M* < φMn, where φ = 0.9, M* is the design bending moment for the factored (strength limit state) loading and Mn is the nominal (in this case fully plastic) moment capacity of the selected beam. Loading Dead: Concrete slab: 24 x 0.15 x 3 10.8kN/m Partitions, etc. 2x3 6.0 Self weight UB 60kg/m 0.6 (guess) Total Live: G = 17.4kN/m Specified Factored 5x3 Q = 15kN/m 1.2G+1.5Q 43.4kN/m Analysis Longest span will collapse first with a mechanism identical to a propped cantilever (see p.12 of these notes). 0.586L (4.7m) 5m 3.3m We’ve already worked out the collapse load for this case (see p.12) and obtained w = 11.657 MP . L2 Hence the maximum design action (bending moment) imposed by the factored loads will be w.L2 11.657 43.4 × 82 = 11.657 = 238 kNM M* = Selection of beam with adequate strength We require a beam with φMn ≥ M*, and since Mn = ZPσy, ZP ≥ 238 0.9 × σ y ≥. 238 0.9 × 300,000 ≥ 0.00088 m 3 ≥ 881 × 10 3 mm 3 Select 360UB51 from table of UB section properties (next page). It has a plastic section modulus of 897x103 mm3, giving φZPσy = 242kNM (>238). Finally check that self-weight of chosen beam is in agreement with initially guessed value. 360UB51: self weight = 51kg/m, compared with guessed value of 60kg/m – OK. Plastic_Analysis_Notes.doc p24 Copyright © J.W.Butterworth, July 2005 Alternative design based on linear elastic analysis Designers frequently opt to determine the design actions by means of a linear elastic analysis – e.g. by moment distribution or more likely by computer analysis, rather than by plastic analysis. The loading, 43.4kN/m is the same but the analysis will give the bms shown below. The beam section is then selected such that M* < φMn as in the design based on plastic analysis. The maximum design bm M*, now occurs only at the interior support. 265.8 Thus, M * = 266kNm , requiring ZP ≥ 266 φσ y 34.3 ≥ 985 × 10 3 mm 3 225.8 Select 410UB53.7 from table of UB section properties (next page). It has a plastic section modulus of 1060x103 mm3, giving φZPσy = 286kNM (>266). The design is effectively based on the lower bound theorem in that only one plastic hinge is allowed to form (at the point of maximum bm) and so there is no mechanism. The approach is more conservative and leads to a less economical choice of beam. However, there are advantages in that the structure does not have to satisfy such stringent ductility conditions as that designed using plastic analysis. Providing sufficient restraint to ensure satisfactory plastic hinge rotation can increase the cost of a plastic-based design making it less economic. Plastic_Analysis_Notes.doc p25 Copyright © J.W.Butterworth, July 2005 Flange Overall depth Root radius Depth between flanges Web slenderness Flange outstand Gross area d1 t B−t 2 Ag Width Thickness d B T t r d1 mm mm mm mm mm mm Designation kg/m Web thickness About x-axis Ix 2 mm 6 10 mm Zx 4 3 10 mm 3 Warping constant ry J Iw mm 10 mm About y-axis ZPx 3 Torsion constant 3 10 mm rx Iy mm 10 mm 6 Zy 4 3 10 mm ZPy 3 3 10 mm 3 3 4 9 10 mm 6 610UB 125 113 101 612 607 602 229 228 228 19.6 17.3 14.8 11.9 11.2 10.6 14. 14.0 14.0 572 572 572 48.1 51.1 54.0 5.54 6.27 7.34 16000 14500 13000 986 875 761 3230 2880 2530 3680 3290 2900 249 246 242 39.3 34.3 29.3 343 300 257 536 469 402 49.6 48.7 47.5 1560 1140 790 3450 2980 2530 530UB 92.4 82 533 528 209 209 15.6 13.2 10.2 9.6 14.0 14.0 502 502 49.2 52.3 6.37 7.55 11800 10500 554 477 2080 1810 2370 2070 217 213 23.8 20.1 228 193 355 301 44.9 43.8 775 526 1590 1330 460UB 82.1 74.6 67.1 460 457 454 191 190 190 16.0 14.5 12.7 9.9 9.1 8.5 14.0 11.4 11.4 428 428 428 43.3 47.1 50.4 5.66 6.24 7.15 10500 9520 8580 372 335 296 1610 1460 1300 1840 1660 1480 188 188 186 18.6 16.6 14.5 195 175 153 303 271 238 42.2 41.8 41.2 701 530 378 919 815 708 410UB 59.7 53.7 406 403 178 178 12.8 10.9 7.8 7.6 11.4 11.4 381 381 48.8 50.1 6.65 7.82 7640 6890 216 188 1060 933 1200 1060 168 165 12.1 10.3 135 115 209 179 39.7 38.6 337 234 467 394 360UB 56.7 50.7 44.7 359 356 352 172 171 171 13.0 11.5 9.7 8.0 7.3 6.9 11.4 11.4 11.4 333 333 333 41.6 45.6 48.2 6.31 7.12 8.46 7240 6470 5720 161 142 121 899 798 689 1010 897 777 149 148 146 11.0 9.60 8.10 128 112 94.7 198 173 146 39.0 38.5 37.6 338 241 161 330 284 237 310UB 46.2 40.4 32.0 307 304 298 166 165 149 11.8 10.2 8.0 6.7 6.1 5.5 11.4 11.4 13.0 284 284 282 42.3 46.5 51.3 6.75 7.79 8.97 5930 5210 4080 100 86.4 63.2 654 569 424 729 633 475 130 129 124 9.01 7.65 4.42 109 92.7 59.3 166 142 91.8 39.0 38.3 32.9 233 157 86.5 197 165 92.9 250UB 37.3 31.4 25.7 256 252 248 146 146 124 10.9 8.6 8.0 6.4 6.1 5.0 8.9 8.9 12 234 234 232 36.6 38.4 46.4 6.40 8.13 7.44 4750 4010 3270 55.7 44.5 35.4 435 354 285 486 397 319 108 105 104 5.66 4.47 2.55 77.5 61.2 41.1 119 94.2 63.6 34.5 33.4 27.9 158 89.3 67.4 85.2 65.9 36.7 200UB 29.8 25.4 22.3 18.2 207 203 202 198 134 133 133 99 9.6 7.8 7.0 7.0 6.3 5.8 5.0 4.5 8.9 8.9 8.9 11.0 188 188 188 184 29.8 32.3 37.5 40.9 6.65 8.15 9.14 6.75 3820 3230 2870 2320 29.1 23.6 21.0 15.8 281 232 208 160 316 260 231 180 87.3 85.4 85.5 82.6 3.86 3.06 2.75 1.14 57.5 46.1 41.3 23.0 88.4 70.9 63.4 35.7 31.8 30.8 31.0 22.1 105 62.7 45.0 38.6 37.6 29.2 26.0 10.4 180UB 22.2 18.1 16.1 179 175 173 90 90 90 10.0 8.0 7.0 6.0 5.0 4.5 8.9 8.9 8.9 159 159 159 26.5 31.8 35.3 4.20 5.31 6.11 2820 2300 2040 15.3 12.1 10.6 171 139 123 195 157 138 73.6 72.6 72.0 1.22 0.975 0.853 27.1 21.7 19.0 42.3 33.7 29.4 20.8 20.6 20.4 81.6 44.8 31.5 8.71 6.80 5.88 150UB 18.0 14.0 155 150 75 75 9.5 7.0 6.0 5.0 8.0 8.0 136 136 22.7 27.2 3.63 5.00 2300 1780 9.05 6.66 117 88.8 135 102 62.8 61.1. 0.672 0.495 17.9 13.2 28.2 20.8 17.1 16.6 60.5 28.1 3.56 2.53 UNIVERSAL BEAMS – Dimensions and Properties Plastic_Analysis_Notes.doc p26 Copyright © J.W.Butterworth, July 2005