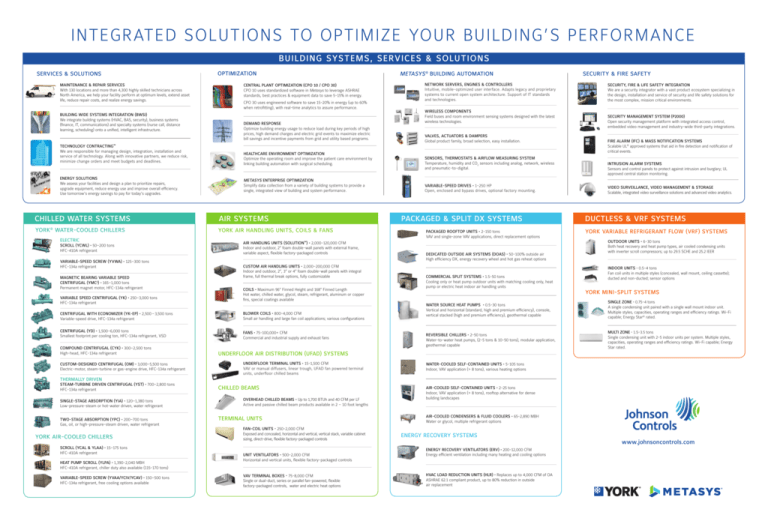

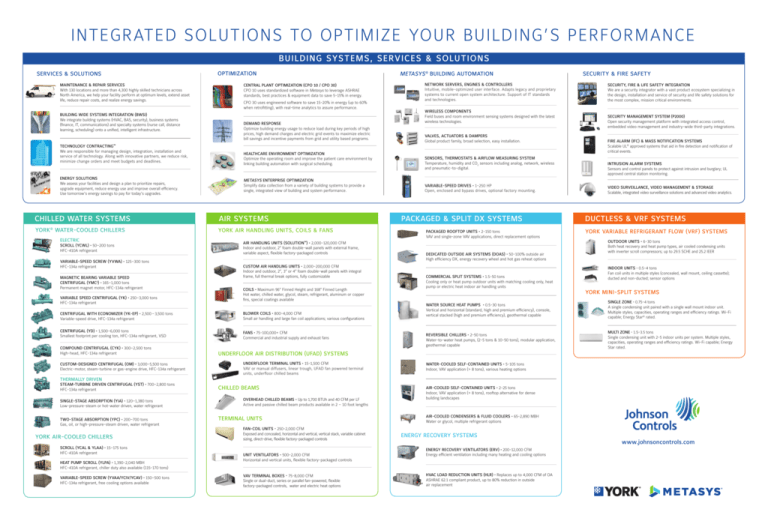

INTEGRATED SOLUTIONS TO OPTIMIZE YOUR BUILDING’S PERFORMANCE

BUI LD I NG SYS TE M S , S E RV I C E S & S O LUTI O NS

SERVICES & SOLUTIONS

MAINTENANCE & REPAIR SERVICES

With 130 locations and more than 4,300 highly skilled technicians across

North America, we help your facility perform at optimum levels, extend asset

life, reduce repair costs, and realize energy savings.

BUILDING WIDE SYSTEMS INTEGRATION (BWSI)

We integrate building systems (HVAC, BAS, security), business systems

(finance, IT, communications) and specialty systems (nurse call, distance

learning, scheduling) onto a unified, intelligent infrastructure.

TECHNOLOGY CONTRACTING™

We are responsible for managing design, integration, installation and

service of all technology. Along with innovative partners, we reduce risk,

minimize change orders and meet budgets and deadlines.

ENERGY SOLUTIONS

We assess your facilities and design a plan to prioritize repairs,

upgrade equipment, reduce energy use and improve overall efficiency.

Use tomorrow’s energy savings to pay for today’s upgrades.

OPTIMIZATION

CENTRAL PLANT OPTIMIZATION (CPO 10 / CPO 30)

CPO 10 uses standardized software in Metasys to leverage ASHRAE

standards, best practices & equipment data to save 5-15% in energy.

CPO 30 uses engineered software to save 15-20% in energy (up to 60%

when retrofitting), with real-time analytics to assure performance.

DEMAND RESPONSE

Optimize building energy usage to reduce load during key periods of high

prices, high demand charges and electric grid events to maximize electric

bill savings and incentive payments from grid and utility based programs.

HEALTHCARE ENVIRONMENT OPTIMIZATION

Optimize the operating room and improve the patient care environment by

linking building automation with surgical scheduling.

METASYS ENTERPRISE OPTIMIZATION

Simplify data collection from a variety of building systems to provide a

single, integrated view of building and system performance.

CHILLED WATER SYSTEMS

AIR SYSTEMS

YORK® WATER-COOLED CHILLERS

YORK AIR HANDLING UNITS, COILS & FANS

ELECTRIC

SCROLL (YCWL) • 50–200 tons

HFC-410A refrigerant

VARIABLE-SPEED SCREW (YVWA) • 125–300 tons

HFC-134a refrigerant

MAGNETIC BEARING VARIABLE SPEED

CENTRIFUGAL (YMC2) • 165–1,000 tons

Permanent magnet motor, HFC-134a refrigerant

VARIABLE SPEED CENTRIFUGAL (YK) • 250–3,000 tons

HFC-134a refrigerant

AIR HANDLING UNITS (SOLUTION™) • 2,000-120,000 CFM

Indoor and outdoor, 2” foam double-wall panels with external frame,

variable aspect, flexible factory-packaged controls

CUSTOM AIR HANDLING UNITS • 2,000–200,000 CFM

Indoor and outdoor, 2”, 3” or 4” foam double-wall panels with integral

frame, full thermal break options, fully customizable

COILS • Maximum 96” Finned Height and 168” Finned Length

Hot water, chilled water, glycol, steam, refrigerant, aluminum or copper

fins, special coatings available

CENTRIFUGAL WITH ECONOMIZER (YK-EP) • 2,500 – 3,500 tons

Variable-speed drive, HFC-134a refrigerant

BLOWER COILS • 800-4,000 CFM

Small air handling and large fan coil applications; various configurations

CENTRIFUGAL (YD) • 1,500–6,000 tons

Smallest footprint per cooling ton, HFC-134a refrigerant, VSD

FANS • 75-100,000+ CFM

Commercial and industrial supply and exhaust fans

COMPOUND CENTRIFUGAL (CYK) • 300–2,500 tons

High-head, HFC-134a refrigerant

CUSTOM-DESIGNED CENTRIFUGAL (OM) • 3,000–5,500 tons

Electric-motor, steam-turbine or gas-engine drive, HFC-134a refrigerant

METASYS® BUILDING AUTOMATION

NETWORK SERVERS, ENGINES & CONTROLLERS

Intuitive, mobile-optimized user interface. Adapts legacy and proprietary

systems to current open system architecture. Support of IT standards

and technologies.

WIRELESS COMPONENTS

Field buses and room environment sensing systems designed with the latest

wireless technologies.

VALVES, ACTUATORS & DAMPERS

Global product family, broad selection, easy installation.

SENSORS, THERMOSTATS & AIRFLOW MEASURING SYSTEM

Temperature, humidity and CO2 sensors including analog, network, wireless

and pneumatic-to-digital.

VARIABLE-SPEED DRIVES • 1-250 HP

Open, enclosed and bypass drives, optional factory mounting.

PACKAGED & SPLIT DX SYSTEMS

PACKAGED ROOFTOP UNITS • 2-150 tons

VAV and single-zone VAV applications, direct replacement options

DEDICATED OUTSIDE AIR SYSTEMS (DOAS) • 50-100% outside air

High efficiency DX, energy recovery wheel and hot gas reheat options

COMMERCIAL SPLIT SYSTEMS • 1.5-50 tons

Cooling only or heat pump outdoor units with matching cooling only, heat

pump or electric heat indoor air handling units

SECURITY & FIRE SAFETY

SECURITY, FIRE & LIFE SAFETY INTEGRATION

We are a security integrator with a vast product ecosystem specializing in

the design, installation and service of security and life safety solutions for

the most complex, mission critical environments.

SECURITY MANAGEMENT SYSTEM (P2000)

Open security management platform with integrated access control,

embedded video management and industry-wide third-party integrations.

FIRE ALARM (IFC) & MASS NOTIFICATION SYSTEMS

Scalable UL® approved systems that aid in fire detection and notification of

critical events.

INTRUSION ALARM SYSTEMS

Sensors and control panels to protect against intrusion and burglary; UL

approved central station monitoring.

VIDEO SURVEILLANCE, VIDEO MANAGEMENT & STORAGE

Scalable, integrated video surveillance solutions and advanced video analytics.

DUCTLESS & VRF SYSTEMS

YORK VARIABLE REFRIGERANT FLOW (VRF) SYSTEMS

OUTDOOR UNITS • 6-30 tons

Both heat recovery and heat pump types, air cooled condensing units

with inverter scroll compressors; up to 29.5 SCHE and 25.2 IEER

INDOOR UNITS • 0.5-4 tons

Fan coil units in multiple styles (concealed, wall mount, ceiling cassette);

ducted and non-ducted; sensor options

YORK MINI-SPLIT SYSTEMS

WATER SOURCE HEAT PUMPS • 0.5-30 tons

Vertical and horizontal (standard, high and premium efficiency), console,

vertical stacked (high and premium efficiency), geothermal capable

SINGLE ZONE • 0.75-4 tons

A single condensing unit paired with a single wall mount indoor unit.

Multiple styles, capacities, operating ranges and efficiency ratings. Wi-Fi

capable; Energy Star® rated.

REVERSIBLE CHILLERS • 2-50 tons

Water-to-water heat pumps, (2-5 tons & 10-50 tons), modular application,

geothermal capable

MULTI ZONE • 1.5-3.5 tons

Single condensing unit with 2-5 indoor units per system. Multiple styles,

capacities, operating ranges and efficiency ratings. Wi-Fi capable; Energy

Star rated.

UNDERFLOOR AIR DISTRIBUTION (UFAD) SYSTEMS

UNDERFLOOR TERMINAL UNITS • 15-1,500 CFM

VAV or manual diffusers, linear trough, UFAD fan powered terminal

units, underfloor chilled beams

WATER-COOLED SELF-CONTAINED UNITS • 5-105 tons

Indoor, VAV application (> 8 tons), various heating options

THERMALLY DRIVEN

STEAM-TURBINE DRIVEN CENTRIFUGAL (YST) • 700–2,800 tons

HFC-134a refrigerant

SINGLE-STAGE ABSORPTION (YIA) • 120–1,380 tons

Low-pressure-steam or hot-water driven, water refrigerant

TWO-STAGE ABSORPTION (YPC) • 200–700 tons

Gas, oil, or high-pressure-steam driven, water refrigerant

YORK AIR-COOLED CHILLERS

SCROLL (YCAL & YLAA) • 15–175 tons

HFC-410A refrigerant

HEAT PUMP SCROLL (YLPA) • 1,390-2,040 MBH

HFC-410A refrigerant, chiller duty also available (115-170 tons)

VARIABLE-SPEED SCREW (YVAA/YCIV/YCAV) • 150–500 tons

HFC-134a refrigerant, free cooling options available

CHILLED BEAMS

OVERHEAD CHILLED BEAMS • Up to 1,700 BTUh and 40 CFM per LF

Active and passive chilled beam products available in 2 – 10 foot lengths

TERMINAL UNITS

FAN-COIL UNITS • 250-2,000 CFM

Exposed and concealed, horizontal and vertical, vertical stack, variable cabinet

sizing, direct-drive, flexible factory-packaged controls

UNIT VENTILATORS • 500-2,000 CFM

Horizontal and vertical units, flexible factory-packaged controls

VAV TERMINAL BOXES • 75-8,000 CFM

Single or dual-duct, series or parallel fan-powered, flexible

factory-packaged controls, water and electric heat options

AIR-COOLED SELF-CONTAINED UNITS • 2-25 tons

Indoor, VAV application (> 8 tons), rooftop alternative for dense

building landscapes

AIR-COOLED CONDENSERS & FLUID COOLERS • 65-2,890 MBH

Water or glycol, multiple refrigerant options

ENERGY RECOVERY SYSTEMS

ENERGY RECOVERY VENTILATORS (ERV) • 200-12,000 CFM

Energy efficient ventilation including many heating and cooling options

HVAC LOAD REDUCTION UNITS (HLR) • Replaces up to 4,000 CFM of OA

ASHRAE 62.1 compliant product, up to 80% reduction in outside

air replacement

www.johnsoncontrols.com

Psychrometric Chart for HVAC Analysis

1 BTU = A

mount of heat required to raise (or lower)

the temperature of one pound of water 1°F

2000 ft

0.930

4000 ft

0.864

1 ton of refrigeration = 12,000 Btu/hr = 200 Btu/min

6000 ft

0.801

1 watt = 3.414 Btu/hr

8000 ft

0.743

50

1 5 .5

Air changes per hour (N) in a space

N = (60 x CFM) / space ft3

CFM = airflow rate (ft3/min)

Latent cooling (Btu/hr) = CFM x 4840 x Δw

45

85

CFM = airflow rate (ft3/min)

h = enthalpy (Btu/lb)

t = dry bulb air temperature (°F)

w = humidity ratio (lb water / lb dry air)

Water quantity (GPM) required for heating and cooling

GPM = q / (500 x Δt)

q = load in Btu/hr

t = water temperature

40

FD

RY

AIR

ER

P

-B

TU

P

density of air

density of standard air

.021

-°

F

65

%

60

70

%

T.

CU.F

0

35

5

Chart by: HANDS DOWN SOFTWARE, www.handsdownsoftware.com

%

%

30

20%

10

15

.9

75

0.65

.8

50

0.70

70

20

115

110

100

95

90

105

25

.7

.014

.012

65

.6

60

.5

.010

40

40

.005

35

.004

ENTHALPY - BTU PER POUND OF DRY AIR

50

45

.006

30

1.00

.4

.008

.002

0.95

55

.009

.003

0.85

0.90

45

.011

.007

0.75

0.80

.013

.001

85

80

75

60

55

50

70

MIDITY

IVE HU

T

A

L

E

10% R

45

25

40

25

15

40

30

30

20

20

10

5

15

5

0

10

10

5

0

-5

-5

0

15

1 2 .0

© 2015 Johnson Controls, Inc.

P.O. Box 423, Milwaukee, WI 53201

All rights reserved worldwide.

Printed in USA

MISC-692 (Rev. 10/15)

www.johnsoncontrols.com

0

40

1 2 .5

Technology Contracting™ and Solution™ are trademarks of Johnson Controls, Inc. in

the United States of America and other countries. Other trademarks used herein may

be trademarks or registered trademarks of other companies.

20

45

%

65

25

Johnson Controls, the Johnson Controls logo, Metasys and YORK are registered

trademarks of Johnson Controls, Inc. in the United States of America and other countries.

35

5

50

1 3 .0

30

®

%

60

40

50

1 3 .5

45

35

®

IR

RY A

LB. D

PER

55

50

DRY BULB TEMPERATURE - °F

55

120

80

%

MEVOLU

90

1 4 .0

60

10

0.60

.015

25

15

55

.017

70

20

1

.018

.016

65

0.55

.020

70

EN

TH

AL

PY

x

UR

E

75

30

80

.019

OU

ND

O

1 = initial; 2 = desired

1.1

.022

75

35

0.50

.023

80

GPM x ft head

Pump hp =

x specific gravity

3960 x efficiency

CFM x static pressure (in. W.G.)

6356 x efficiency

TE

M

PE

RA

T

1.2

60

.024

BU

LB

1 4 .5

W

ET

80

Fan Laws

CFM2 = CFM1 x (RPM2 / RPM1)

SP2 = SP1 x (RPM2 / RPM1)2

HP2 = HP1 x (RPM2 / RPM1)3

capacity (Tons)

Tons = (GPM x Δt) / 24

GPM = gallons per minute of chilled water

t = water temperature

.025

HUMIDITY RATIO - POUNDS MOISTURE PER POUND DRY AIR

Sensible cooling (Btu/hr) = CFM x 1.085 x Δt

85

.026

125

1 boiler horsepower = 33,475 Btu/hr

1 5 .0

Total cooling (Btu/hr) = CFM x 4.5 x Δh

Fan hp =

.027

85

1 ft (head) = 0.433 psi (at 62°F)

1.3 0.45

.028

1 horsepower = 2545.6 Btu/hr

Chiller

.029

90

30

35

25

20

10

0

.3

.2

.1

SENSIBLE HEAT RATIO = Qs / Qt

Air Density Ratio at 70˚F

DEW POINT TEMPERATURE - °F

Altitude

130

Atmospheric pressure = 29.921" Hg. at sea level

60

55

VAPOR PRESSURE - INCHES OF MERCURY

Air-Conditioning Formulas and Conversion Factors