10 Years of “Green” Projects at NC State

advertisement

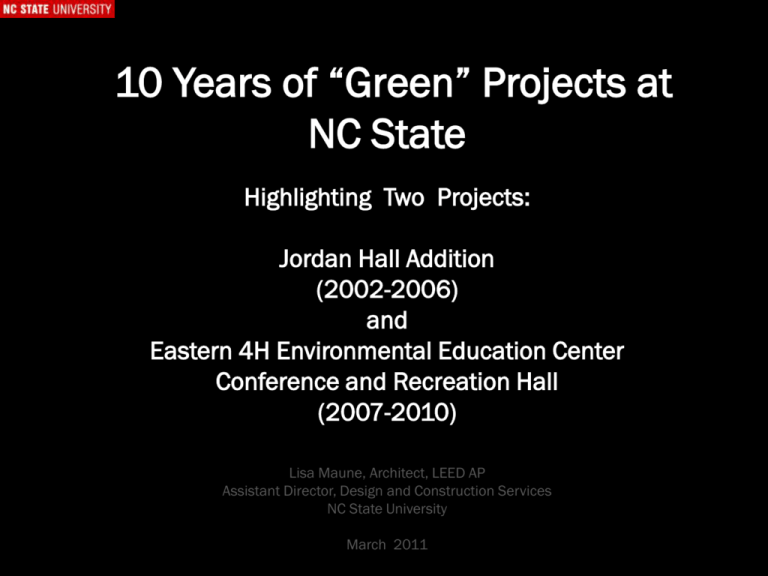

10 Years of “Green” Projects at NC State Highlighting Two Projects: Jordan Hall Addition (2002-2006) and Eastern 4H Environmental Education Center Conference and Recreation Hall (2007-2010) a Lisa Maune, Architect, LEED AP Assistant Director, Design and Construction Services NC State University March 2011 The built environment has a profound impact on our natural environment, economy, health, and productivity. In the United States alone, buildings account for: • 72% of electricity consumption, • 39% of energy use, • 38% of all carbon dioxide (CO2) emissions, • 40% of raw materials use, • 30% of waste output (136 million tons annually), and • 14% of potable water consumption. More statistics on the built environment in the U.S. and the growing size of USGBC membership and LEED are available in the Green Building Facts document. PREFACE: In 2000, when NC State University began its $468 million dollar 2000 Higher Education Bond Program in earnest, two projects were identified to utilize the Triangle J Council of Government’s High Performance Guidelines version 2.0. Those projects were the Jordan Hall Addition, and the Leazar Hall Renovation. At the time, the Triangle J’s building program was aimed at public facilities, and was intended to be a “roadmap “ for the design and construction of efficient, cost-effective, durable, and environmentally sound buildings in the Triangle. Since public buildings are a financial investment by taxpayers, as well as buildings that are highly visible and symbolic in their communities, it was hoped public projects would encourage the private sector to invest in Sustainable Design Principles. Various rating systems have been developed to certify green building and construction, including a the U.S. Green Building Council’s (USGBC) Leadership in Energy and Environmental Design (LEED) Green Building Rating System. LEED certification is a third-party validation of a building’s performance in order to improve efficiency with which buildings and developments use resources while reducing impacts on human health and the environment. In 2007, NC State’s Chancellor made a commitment that all “major” projects, those over 20,000 gross square feet, would attain LEED Silver certification. TIMELINE 1998 : Governor Hunt issued Executive Order 156 which “directed state agencies to develop and incorporate policies and practices to preserve natural resources, conserve energy, eliminate waste and emissions, and lessen overall environmental impact” 1999: NCSU approved the “Commitment to Environmental Sustainability – Guiding Principles” policy 1999 : Chancellor Mary Anne Fox appointed a campus “Sustainability Officer” 2000 : The University “Environmental Sustainability Task Force” was created 2002: NCSU advocacy groups of students, staff, and faculty was formed called the NC State Sustainability Coalition 2002 : First NCSU “Earth Day” celebration 2003: A Campus Environmental Sustainability Taskforce (CEST) created as a tool to implement the goals of Task Force 2004: An in-house sustainability assessment was undertaken to identify focus areas 2006: The first NCSU Environmental Assessment was released 2007: Signed the ACUPCC 2007: NCSU Chancellor commits that all new “major” projects to be LEED Silver -Certified 2008: First Director of Sustainability Office hired, now consists of full time staff of three, with several interns 2008: 15 staff achieve LEED AP 2009: Inaugural Greenhouse Gas Inventory (carbon footprint) 2009: Restructure CEST as an Administrative Advisory Committee (now reports to Board of Trustees) 2010: First Climate Action Plan 2010: First Strategic Energy Management Plan (87% GHG emission from energy) 2010: 1st LEED project completed 2011: Draft Sustainability Strategic Plan completed January(note: comprehensive plan looking across the focus areas of academics and research, buildings, communications, energy and water, land use, materials and purchasing, transportation, and waste reduction and recycling). CAP and Energy Management Plan are supplemental documents. Mission/vision next slide… 2011: 8 additional LEED projects in progress JORDAN HALL ADDITION This building was funded by the 2000 Higher Education Bond Program Building Statistics: • • • 54,800 gross square feet, 46,000 net square feet $16.324 million dollar project Construction Completed 2006 Program Includes: • View of southeast elevation from Faucette Drive • • • • • View of Environmental Education Lab The College of Natural Resources is the building occupant, specifically the Department of Forestry and Environmental Resources Three (52) seat classrooms One (100) seat classroom Teaching and research labs for CNR and MEAS Offices for teaching faculty and extension faculty Utilized Triangle J Council of Gov’t “High Performance Guidelines” Ver.2.0 JORDAN HALL ADDITION Design Team: • • • • BBH Design, PLLC - Architect Stewart Engineering- Structural RMF Engineering, Inc- PME Lab Planning- GPR Planners Collaborative, Inc. Construction Team: South elevation of Jordan Hall before Addition • • • • View looking south AFTER Jordan Hall Addition was constructed. DH Griffin Construction Company Trigon for special inspections F&R and Kimley Horne for geotechnical services AEI, Affiliated Engineers, Inc Commissioning Agent Sustainable Building Features Site Selection The NC State Physical Master Plan which guides all planning and development for the University showed the future addition to the Jordan Hall building located on the parking lot located at the corner of Western Boulevard and Morrill Drive. The good news: By designating an existing impervious surface for a building site, the requirement to provide for often expensive storm water solutions was not present for this project (since it was not a “greenfield “, pervious site). Jordan Hall Addition The bad news: Early in the design process, the use of the parking lot was questioned by the design team as replacement parking would have to be found somewhere else on campus to make up for these lost spaces, or the project would have to pay $11,000 per space to Transportation, which would be cost prohibitive for the project. Over180 parking spaces were either permanently or temporarily displaced by this project, so a resolution to the parking problem had to be found. Master Plan location for Addition Aerial Photograph with Final Building Configuration/Layout PARKING OPTIONS 18 7 14 8 9 17 16 1 5 2 3 4 15 13 10 11 19 20 12 Parking Location Options Considered 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 3 SPACES 2 SPACES 3 SPACES 4 SPACES 3 SPACES 18 SPACES 10 SPACES 8 SPACES 5 SPACES 77 SPACES 23 SPACES 11 SPACES 30 SPACES 50 SPACES 100 SPACES 54 SPACES 22 SPACES 12 SPACES 150 SPACES 100 SPACES H PARKING OPTIONS F G B E REYNOLDS DECK C D A Parking Solution to Achieve 186 Spaces A B C D E F G H 27 SPACES 40 SPACES 4 SPACES 19 SPACES 54 SPACES 8 SPACES 22 SPACES 12 SPACES What makes this project “green”? Initially, this project was to be delivered by the CM at Risk process, and a construction manager was hired who to work with the Owner and Design team throughout the design process. We had a difficult time reconciling the cost of work with them at DD’s, so we opted to bid single-prime. FEATURES: • Cast–in- place concrete structure - concrete and steel rebar have a high % of recycled material • Low albedo membrane flat roof to reduce heat island effect • Solar orientation and vertical glazing used to maximize day-lighting / views from 75% of spaces • Lab and Office functions were separated physically and mechanically to improve control and reduce air flows • Low VOC materials, including paint, carpet, ceiling tiles, adhesives and sealants • Low- flow plumbing for 30% reduction • Operable windows alls for a high degree of occupant control of comfort • Shower facilities and bike racks were provided for those using bicycles as alternative transportation • Recycling stations were integrated into the design • Occupancy sensors utilized in public spaces • Sun shading devices to minimize solar gain • Chain of custody required for materials, etc, wood used was FSC certified • Construction waste management – divert 75% of waste stream • Monthly progress reports from contractor • “Green” material submittal requirements • Water efficient landscaping – no irrigation system • Thermal comfort controllability • Water Efficient Landscaping (drought tolerant) • Storm water quantity and quality control on site • Full building commissioning – AEI in this case • Rapidly renewable materials, including bamboo sports flooring • Recycled Content materials, including denim jean insulation • Construction IAQ plan before and during occupancy Jordan Hall - HPG Points 9% 1% 36% 17% 1.0 Management 2.0 Site 3.0 Water 4.0. Energy & Atmosphere 5.0 Materials & Resources 6.0 Indoor Environmental Quality 12% 7.0 Innovation & Design Process 18% 8% Sustainable Building Features High Performance Guidelines A section of the Jordan Hall Addition Project Specifications Manual was entitled “High Performance Guidelines” (Section 01352), which required the contractor to adhere to and comply with certain standards and practices in order to meet the sustainability goals of the project. These guidelines were based on the Triangle Region Public Facilities High Performance Guidelines, Version 2.0, published January 2001. The goal of this project was BRONZE equivalent certification, which meant achieving 340427points. This project achieved 385 points. Rendering of Aerial View of Northeast These guidelines were included in the specifications to guarantee the contractor who won the low bid on the project would be a partner in the building process. By having a specification section with requirements that defined high performance definitions, materials submittal requirements, reporting requirements, documentation requirements, etc, the goals of sustainability as defined were more apt to be met. View from Southeast Elevation Sustainable Building Features Cast-In Place Concrete Frame Structure Utilized Early in the project it was determined that using a cast-in place concrete frame structure for the high rise building’s superstructure would be more economical than a steel frame structure. A by product of this decision was that cast-in place concrete is a building material that is extremely “green” and can be made from a high % of recycled material. Also, the reinforcing bars are made of steel which can also be made from nearly 100% recycled materials. Sustainable Building Features Construction Waste Management The contractor was required to submit for approval a construction waste management plan which listed how each material was to be handled on site. The contractor was required to separate the demolition and construction waste streams so recycling could occur more easily. The goal was to recycle 75% by weight or volume of grading, land clearing and site preparation materials. The goal for other construction waste was 50% by weight or volume. Waste from Jordan II was sent to Reclamation Services, which used to accept waste for recycling and they even sorted it on-site. Sustainable Building Features Indoor Air Quality Testing and Monitoring As part of the construction of the building, an independent agent was used to determine the baseline IAO test for maximum indoor pollutant concentrations, and to do a preoccupancy test to assure the EPA’s IAQ program criteria were met. Also, the sequencing of finish material installation, and the changing of filters in the duct work were all prescribed as part of the project. Low Albedo Roof Material Jordan Hall Addition incorporates a low albedo roof membrane. The LEED requirement for non-vegetated roofs states: Use ENERGY STAR Roof-compliant, high-reflectance and high-emissivity roofing (initial reflectance of at least 0.65 and three-year-aged reflectance of at least 0.5 when tested in accordance with ASTM E903 and emissivity of at least 0.9 when tested in accordance with ASTM E408) for a minimum of 75% of the roof surface. LEED version 2.2, released in October 2005, is the first national specification to use a relatively new measure of reporting a cool roof's properties. LEED 2.2 sustainable site credit 7.2 states that to receive one point, building owners should use a roof with a Solar Reflective Index (SRI) of 78 over at least 75% of the roof surface for roofs with slopes less than 2:12. The new twist is SRI, a unit developed by scientists at Lawrence Berkeley National Laboratory. SRI incorporates reflectivity and emissivity properties into one, easy to read, standardized measure so that roof buyers won't have to scratch their heads and try to figure our if a high reflectivity and low emissivity is better or worse than a medium reflectivity and high emissivity. Sustainable Building Features Operable Windows Rarely used on lab buildings due to outside air requirements, operable windows were utilized in this project to improve occupant control, and provide for improved indoor air quality/quantity in the office zone. Integrated Sun-Shading Devices on South Elevation Partially successful – low eastern sun in winter is not addressed by geometry of shading devices. Interior light shelves were also designed as a way to direct more sunlight deeper in to spaces, but were not integrated into the final project due to cost constraints. Day lighting and Views Large windows were used to maximize the infiltration of daylight deep into the spaces on both the south and north elevations. Studies have shown that occupants are more productive in spaces that have day lighting and views. Sustainable Building Features ENERGY Reduction? Energy Savings Lab buildings are one of the most difficult building types to reduce energy consumption in because they are notorious for being energy “hogs” due to the constant cycling of air through the fume hood/HVAC systems. Although this building, like most others on campus, has full DDC controls to allow for remote control capability of the HVAC system, methods for heat recovery such as desiccant wheels, ice storage, and other options were discussed, but in the end were not incorporated due to funding shortages. Building Commissioning The LEED for New Construction requires as a prerequisite that all buildings striving for certification have basic building system Commissioning as part of the project. The Jordan Hall Addition had full building commissioning . Systems to be commissioned are: Heating, ventilating, and Air conditioning, chilled water system, hot water heating system, steam system, automatic temperature control, and the emergency power supply system. A third party consultant determined the functional protocols for all these systems. Once a baseline was established, final commissioning occurred prior to building occupancy, with the goal of monitoring and correcting any system deviations. One year after completion, prior to the one-year warranty ending, all systems were checked for efficiencies, defects, and potential warranty repairs. Sustainable Building Features Building Space Zoning By separating the office/conference functions from the lab functions, the HVAC system can be zoned to allow different air requirements to be addressed, achieving some energy savings, and improved comfort control. Shower Facilities for Commuters Shower facilities are rare on campus. LEED stresses the importance of providing shower and changing facilities to facilitate commuters choosing alternative ways of getting to work. Sustainable Building Features Integrated Recycling Areas Not successful due to lack of “buy in” by current campus recycling/waste management as an acceptable approach to “managing “ recycling items. Occupancy Sensors to Reduce Lighting Power Demand Routinely used on campus in “public” spaces that don’t have anyone directly responsible for turning out the lights. Lighting accounts for a high % of total building energy usage. Sustainable Building Features Recycled Content/Regional Material Usage This project required the contractor to provide a list of all products to be used on the project with associated costs as a % of the project costs . This documentation assure that the projects meet the goals for chain of custody, rapidly renewable materials, regionally manufactured materials, materials with a high recycled or reclaimed content, wood used meets FSC guidelines . Also a consideration is that products are manufactured within 500 miles to minimize the need for shipping materials great distances. Another consideration is that the materials contain no CFCs or HCFCs, and that materials have low or no VOC offgassing per South Coast Air Quality Management District rule 1168. Sustainable Building Features Bike Racks for Commuters A common feature of campus. Placement of bicycle storage is usually located by entrances, under cover if possible, and near “hearths” or common gathering areas. Proximity to Campus and TTA Bus Routes Projects that can utilize alternative modes of transportation can often take advantage of that to achieve sustainable points. Low-Water Landscaping Xeriscape or landscaping that requires no or little watering was the goal of the project. The landscape materials chosen for Jordan Hall Addition kept that goal in mind. Jordan Hall Addition Potential Shortcomings… ITEMS DISCUSSED BUT NOT INCLUDED IN THE PROJECT: 1. Since first costs and utility costs are funded by different sources, often the long-term view is not taken. 2. 3. 4. 5. 6. 7. 8. Heat recovery on HVAC system was not integrated – a desiccant wheel and glycol loops were considered as possible methods to recover heat on this project but were not incorporated due to initial cost. Larger exterior sun shading devices were designed, but they were “Value engineered” to smaller depths. Interior light shelves were “value engineered” out of the project which would have improved daylight transfer further into the building. Interior blinds were “value engineered” out of the project which would have aided in light control and comfort. Interior connections to the existing building were “value engineered” out of the project, with exterior bridges becoming the final solution. Variable volume Phoenix valves at fume hoods were replaced with less expensive constant volume valves. Stainless steel ductwork continuous to roof fans were “value engineered” out and replaced with partial SS and galvanized ductwork. To improve storm water quality as it leaves the site, under parking pervious pavement areas were investigated, but not incorporated into the project due to lack of buy in by campus maintenance and lack of enthusiasm by the campus storm water community. The good news is NC State’s first LEED Silver certified project is now complete. Certification is expected March 2011. Eastern 4H Conference and Recreation Center The Site Raleigh Location This project is located in Tyrrell County, which is 2 ½ hours east of Raleigh, off of Highway 64. The Eastern 4H Environmental Education Center is a retreat/conferencing and camp facility managed by the NC State University 4H Extension program, as part of the University’s mission (see below). Wetlands NC State University MISSION STATEMENT: The mission of North Carolina State University is to serve its students and the people of North Carolina as a doctoral/research-extensive, land-grant university. Through the active integration of teaching, research, extension, and engagement, North Carolina State University creates an innovative learning environment that stresses mastery of fundamentals, intellectual discipline, creativity, problem solving, and responsibility. Enhancing its historic strengths in agriculture, science, and engineering with a commitment to excellence in a comprehensive range of academic disciplines, North Carolina State University provides leadership for intellectual, cultural, social, economic, and technological development within the state, the nation, and the world. Map showing location of the Eastern 4H Environmental Education Center eastern4Hcenter.org Eastern 4H Environmental Education Center Conference and Recreation Hall This building was funded by a 2006 State Appropriation for Improvements to 4H Camps/ Centers statewide. Building Statistics: • • • 20,800 gross square feet $3.6 million dollar project Construction Complete 2010 Program Includes: • View from South at night • • • • • • • • View of the Entry at night Occupants are 4H campers, those attending conferences or retreats at the Camp, and the local community Three (45) seat classrooms High School-size gymnasium Catering kitchen Dining seating for 300 people One office Lobby, restrooms Future exterior rock wall Utilized USGBC’s LEED for New Construction Guidelines 2.2 Eastern 4H Environmental Education Center – New Conference and Recreation Building Design Team: • • • • MHA Works (Greenville office) - Architect FDH Engineering - Structural Springs Stoops McCullen Engineering - PME Rivers & Associates – Civil/Landscape Contractor: • • • Centurion Construction Company ECS of the Carolinas, LLP for Special Inspections AEI , Affiliated Engineers, Inc Commissioning Agent CONTEXT: It was important to stay consistent with the architectural context of the existing buildings at the 4H Center. The New Conference and Recreation Hall The gazebo by the waterfront The original conference and dining building Entrance to the administrative office building The boat house New Building The Site Bulls Bay Site Selection The NC State Master Plan doesn’t address areas located remote to the Raleigh campus, so we relied on a previously completed master plan of the entire Eastern 4H Environmental Education Center site to locate this new building. It was programmed as both a place to provide shelter from the rain when kids are either playing field activities, using the pool, or using the shooting ranges, as well as serving the larger community for various functions. It is one of the largest buildings in the county of roughly 7,000 people. Wetlands What makes this project “green”? Initially, this project was just under 20,000gsf, the definition of a “major” project, and off campus, so it wasn’t necessarily subject to NCSU’s commitment to purse LEED silver certification. However, due to a strong commitment from the NC State 4H Extension Program, early on the process, it was decided to go ahead and pursue LEED silver certification . Also, because this camp one of five “4H Environmental Education Centers” across the state, it was deemed an important goal of the project to use the opportunity to build a “green” project as an education tool for the 4H campers in North Carolina. FEATURES: • Geothermal well system to optimize energy – there are nearly 250 wells for this project, located adjacent to the geothermal well field that serves the rest of the camp • Precast concrete tilt-up structure uses local materials • Low albedo membrane flat roof (on gym) to reduce heat island effect • Solar orientation and vertical glazing used to maximize day-lighting / views from 75% of spaces • Low VOC materials, including paint, carpet, ceiling tiles, adhesives and sealants • Low flow and bivalve plumbing for 30% reduction • Construction waste management – divert 75% of waste stream • Bimonthly LEED documentation progress reports from contractor • LEED material submittal requirements • Water efficient landscaping • Thermal comfort controllability • Occupancy sensors •University’s “No Smoking” policy •Walk-off mats at entrances to minimize particulates • Water Efficient Landscaping (drought tolerant) • Storm water quantity and quality control on site • Full building commissioning – AEI in this case • Rapidly renewable materials, including bamboo sports flooring • Recycled Content materials, including denim jean insulation • Construction IAQ plan before and during occupancy • A bike rack is provided, as well as changing facilities Sustainable Building Features Site Features The programming intent for this building was two-fold. It was designed to provide shelter from inclement weather for children attending summer camp when they were playing on the fields , using the pool, or using the shooting ranges nearby. The large gymnasium space will serve well as a multiple use space, as well other use of the building was to provide classroom , catering kitchen and large meeting space for the community at large to be able to utilize. The rendering shows how the rain garden was meant to be a “site feature” for the nearby entry and outdoor dining area. Onsite water treatment structures includes a wet detention pond, and a planted rain garden. Drought resistant plants were used since no irrigation was provided. Rendering depicts how the rain gardens and wet detention ponds were used to control storm water on site. The SITE DESIGN provides the following LEED Credits: •SS CREDIT 6.1: Storm water quality control •SS CREDIT 6.2: Storm water quantity control •MR CREDIT 7: Certified Wood (FSC) Sustainable Building Features Tilt-up Concrete Construction The concrete floor slabs are first poured, then the wall formwork is put in place using a form release agent to assure the walls release from the formwork and slab. Then any thin break, windows, form patterns, etc are added. Tilt-up concrete structural panels were selected as the structure because they are site formed using ready mix concrete and allow for tall structures like gymnasiums to be constructed quickly and efficiently. The concrete is typically 3000psi with a 4 inch slump. Panels are 8 inches thick, and are lifted into place after 7 days of curing. They panels are attached by welding attachment points, and grout is injected. The tilt-up concrete structure was also a good choice because of local materials , recycled materials, and it provides for a highly-insulated wall system. Here you can see the in-bedded brick veneer at the entry and base, and striations in the panel formwork to give a convincing wood siding appearance to the exterior. Sustainable Building Features LEED Credits The Tilt-Up Concrete panel construction provides the following LEED Credits: •LEED Credit M 4 - Recycled Content Recycled materials such as fly ash, slag cement, silica fume, and recycled aggregates can be incorporated into concrete, thereby diverting materials from the landfill and reducing the use of virgin materials. The southeast elevation, which shows how the lower tilt-up walls drop down the scale of the higher gymnasium tilt-up walls. •LEED Credit M 5.1 Local Materials Wall panels are constructed with locally available labor and materials. •LEED Credit EA 1 Energy Performance Energy savings are achieved in buildings by combining the thermal mass of concrete with the optimal amount of insulation in tilt-up walls. Concrete acts as an air barrier, reducing air infiltration, and saving more energy. The camp director, Lee Scripture, mentioned that the 3-phase power to the entire 4-H campus went out over Christmas because of the severe winter weather, and this building maintained a Thetemperature north elevationwith is fullno of HVAC. windows, both for 62 degree views and day lighting, which makes the space very pleasant. Sustainable Building Features Green Materials = LEED Credits Two unusual materials were utilized in this project: Ultra Touch Cotton Denim insulation by CARAGREEN and Bamboo Sports Flooring by PLYBOO. The PLYBOO flooring provides the following LEED Credits: •IEQ CREDIT 4.3: Low-Emitting Materials – Flooring •MR CREDIT 6: Rapidly Renewable Materials •MR CREDIT 7: Certified Wood (FSC) The CARAGREEN denim insulation provides the following LEED Credits: EQ Credit 4.4 : Low Emitting Materials MR Credit 4 : Recycled Content ( 85%) MR Credit 6 : Rapidly Renewable Materials (85%) Eastern 4H Environmental Education Center Conference and Recreation Building Site Points LEED POINT DISTRIBUTION: Water Efficiency Points 7% 20% Energy and Atmosphere Points 25% 7% Materials & Resources Points 19% 22% Indoor Environmental Quality Points Innovation & Design Process Points Sustainable Building Features Photographs from the Ribbon Cutting Ceremony, January 6, 2011 Sustainable Building Features Photographs from the Ribbon Cutting Ceremony, January 6, 2011 Sustainable Building Features Other Photos Eastern 4H Building Potential Shortcomings… ITEMS DISCUSSED, BUT NOT INCLUDED IN THE PROJECT: 1. 2. 3. 4. 5. Heat recovery on HVAC system was not integrated – a desiccant wheel and a glycol loop were considered as possible methods to recover heat on this project but were not incorporated due to initial cost. To improve storm water quality as it leaves the site, under parking pervious pavement areas was discussed, but not incorporated into the project, which is a shame because the sandy soil here is ideal for such as system. N o grey water recovery or water reuse schemes were utilized on the project due to limited funds. Cisterns could be added later for local irrigation. The underground ground source heat pump wells, though efficient for many reasons, do not count toward LEED energy credits due to the electric heat pumps…although they exceed the ASHRAE 90.1 standards and achieved 7 points out of 10 for EA Credit 1 for Optimize Energy Performance. The asphalt drive and parking lot had to be VE’d out of the project after bidding in order to award the project, and were left as gravel…that work is now being done with the help of DOT and University funds. The two projects I’ve described today are very different building types, different sized projects, in different locations, and will serve very different building occupants, yet they have in common the goal of utilizing sustainable building design principles. Also, both buildings are designed to fulfill specific goals of the mission of NC State University. They share a campus-type setting, and they both had departments involved that had a passion for pursuing a project with sustainable building principles, with the goal of using the building as an environmental educational tool for the building occupants, for years to come. Questions?