NCAR NSF07

advertisement

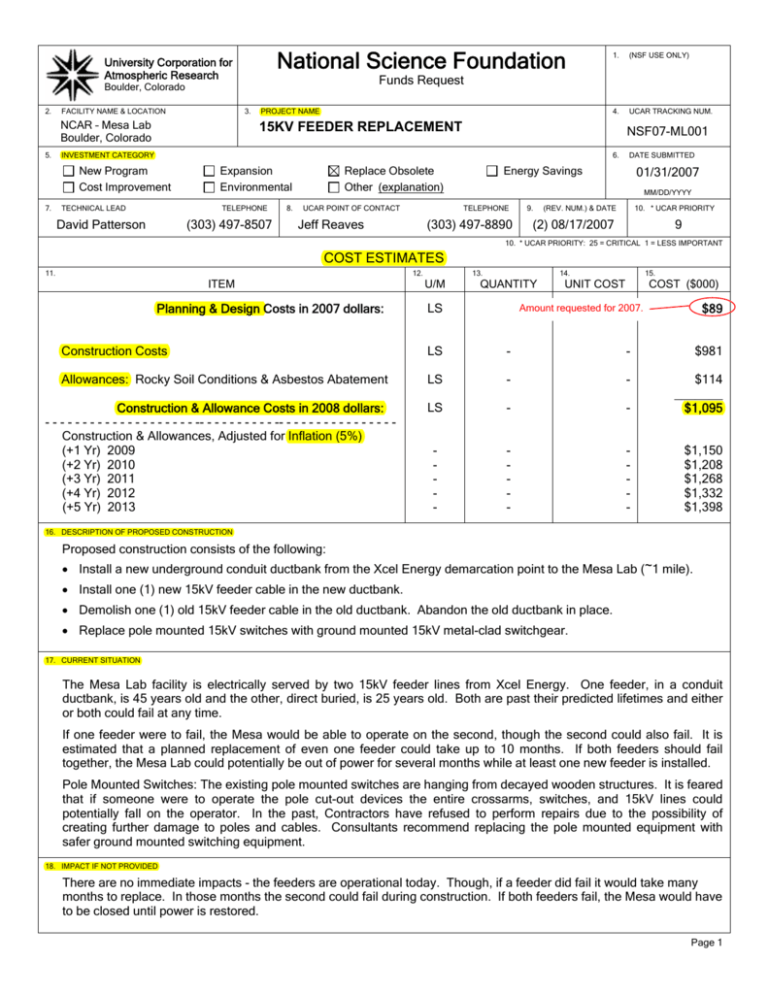

National Science Foundation University Corporation for Atmospheric Research FACILITY NAME & LOCATION 3. NCAR – Mesa Lab Boulder, Colorado 5. PROJECT NAME 4. UCAR TRACKING NUM. 15KV FEEDER REPLACEMENT NSF07-ML001 INVESTMENT CATEGORY 6. New Program Cost Improvement 7. (NSF USE ONLY) Funds Request Boulder, Colorado 2. 1. TECHNICAL LEAD Expansion Environmental TELEPHONE David Patterson (303) 497-8507 8. Replace Obsolete Other (explanation) UCAR POINT OF CONTACT 01/31/2007 MM/DD/YYYY TELEPHONE Jeff Reaves DATE SUBMITTED Energy Savings (303) 497-8890 9. (REV. NUM.) & DATE 10. * UCAR PRIORITY (2) 08/17/2007 9 10. * UCAR PRIORITY: 25 = CRITICAL 1 = LESS IMPORTANT COST ESTIMATES 11. ITEM 12. U/M 13. QUANTITY 14. 15. UNIT COST COST ($000) $89 Amount requested for 2007. - LS - Construction Costs LS - - $981 Allowances: Rocky Soil Conditions & Asbestos Abatement LS - - LS - - $114 _______ $1,095 - - - $1,150 $1,208 $1,268 $1,332 $1,398 Planning & Design Costs in 2007 dollars: Construction & Allowance Costs in 2008 dollars: - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - -- - - - - - - - - - - - - - - Construction & Allowances, Adjusted for Inflation (5%) (+1 Yr) 2009 (+2 Yr) 2010 (+3 Yr) 2011 (+4 Yr) 2012 (+5 Yr) 2013 16. DESCRIPTION OF PROPOSED CONSTRUCTION Proposed construction consists of the following: • Install a new underground conduit ductbank from the Xcel Energy demarcation point to the Mesa Lab (~1 mile). • Install one (1) new 15kV feeder cable in the new ductbank. • Demolish one (1) old 15kV feeder cable in the old ductbank. Abandon the old ductbank in place. • Replace pole mounted 15kV switches with ground mounted 15kV metal-clad switchgear. 17. CURRENT SITUATION The Mesa Lab facility is electrically served by two 15kV feeder lines from Xcel Energy. One feeder, in a conduit ductbank, is 45 years old and the other, direct buried, is 25 years old. Both are past their predicted lifetimes and either or both could fail at any time. If one feeder were to fail, the Mesa would be able to operate on the second, though the second could also fail. It is estimated that a planned replacement of even one feeder could take up to 10 months. If both feeders should fail together, the Mesa Lab could potentially be out of power for several months while at least one new feeder is installed. Pole Mounted Switches: The existing pole mounted switches are hanging from decayed wooden structures. It is feared that if someone were to operate the pole cut-out devices the entire crossarms, switches, and 15kV lines could potentially fall on the operator. In the past, Contractors have refused to perform repairs due to the possibility of creating further damage to poles and cables. Consultants recommend replacing the pole mounted equipment with safer ground mounted switching equipment. 18. IMPACT IF NOT PROVIDED There are no immediate impacts - the feeders are operational today. Though, if a feeder did fail it would take many months to replace. In those months the second could fail during construction. If both feeders fail, the Mesa would have to be closed until power is restored. Page 1 National Science Foundation University Corporation for Atmospheric Research FACILITY NAME & LOCATION NCAR – Mesa Lab Boulder, Colorado (NSF USE ONLY) 4. UCAR TRACKING NUM. Funds Request Boulder, Colorado 2. 1. 3. PROJECT NAME 15KV FEEDER REPLACEMENT NSF07-ML001 19. ALTERNATIVE SOLUTIONS CONSIDERED Install new direct buried 15kV feeders rather than install a new ductbank. Reason for rejecting: Rocky soil and shifting soil conditions could damage direct bury cables and direct bury cables have a shorter life expectanncy than cables in conduit. In the long-term, a new ductbank/conduit system will make future feeder replacements cheaper than direct burying cables each time a new one is needed. We also considered trying to "rout out" and re-line the old ductbank conduits. Reason for rejecting: It is not a common technology for electrical conduits to be re-lined plus the existing Orangeburg type conduits contain asbestos. Grinding or routing out asbestos containing conduits would be cost prohibitive. 20. DELIVERABLES AT END OF PROJECT 1. One new underground ductbank with 4 conduits; 1 for the new 15kV feeder, 2 for 15kV spares, and 1 for fiber optic cable in order to monitor both the pump house and new ground mounted switchgear. 2. One set of ground mounted 15kV outdoor switchgear at the Xcel demarcation point to be connected to one existing Xcel Energy 15kV line. Another spare switch will be installed for a future connection to the 2nd Xcel Energy 15kV line. 3. One new 15kV copper feeder conductor from the Xcel demarcation point (new ground mounted switchgear) to the Mesa Lab main switchgear; completely installed, terminated and tested. 4. Removal of 1 pole and pole switches. The 2nd pole will remain in place until the 2nd (direct buried) 15kV feeder is replaced. 21. ADDITIONAL The 2nd 15kV (direct buried) feeder will not be replaced on this project. Either a planned replacement will occur when funds become available or it will be allowed to fail and then replaced. Either option is acceptable once the new feeder is installed. During this project, the intent is not to disturb the 2nd feeder in any way, so as not to initiate premature failure. Page 2 1. PROJECT DETAILS PROJECT NAME 2. REPLACE OBSOLETE 15KV POWER FEEDS UCAR TRACKING NUM. NSF07-ML001 BACKGROUND Electrical power to the Mesa Lab is delivered from Xcel Energy via two 13,200 volt electrical lines (also referred to as 15kV lines). The two electrical feeds begin at the same substation which Xcel calls their “NCAR Substation”. It is located east southeast of the Mesa Lab at the bottom of the hill near the residential areas. A combination of underground and overhead lines, owned by Xcel Energy, bring power through the residential areas to the east and around to an area north of Mesa Lab, at the bottom of a deep ravine, we refer to as the “Pump House” area. At this location is where Xcel Energy’s responsibility for power feeder care ends and NCAR’s begins. As a side note, the Xcel Energy feeders serve NCAR, the NOAA Campus to the north, the NIST campus to the north, and a large section of residential areas to the east. Much of the lines through residential areas are above ground with large trees very near the lines. Several residents do not allow trimming of their trees thus several outages each year can be attributed to wind and snow loads forcing trees against the main power lines feeding the Mesa Lab. At the Xcel Energy demarcation point, NCAR owns two poles and their associated switching equipment. Figure 1 illustrates typically how each appears in relation to the Xcel demarcation point, though the older original pole is not shown in this photo. Figure 1 - Xcel/ NCAR Poles The original older pole, equipment and cables were installed in 1965 when the building was built (~42 years old). The original work included a concrete ductbank from near the pole up to the Mesa through a series of manholes. Later, when the supercomputing computer room was built, around 1985, the second direct-buried feeder was installed to the right of the existing ductbank (~22 years old). The spare conduits in the old ductbank were unusable. The existing switching poles are rotted and there is concern that “pulling” on the pole mounted cut-outs may cause the entire cross-arm structure to fall. Contractors have been requested to repair the pole equipment but all have advised against it, citing that any work on the equipment could permanently damage the feeder cables and equipment, thus leaving the Mesa with a useless feeder. Both 15kV feeder cables to the Mesa Lab are well past their predicted lives. There is concern that one, or both, electrical feeders could fail anytime in the near future. Work to replace them will likely take several months. PROPOSED SOLUTION The proposed solutions put forth by UCAR Engineering are conceptual and primarily based on experience and what is known today. The final design solution could be different in concept, cost and schedule. 1. Install a new ductbank “over” the old ductbank. It will save cost by installing new ductbanks and cables in the same area as the originals. Any digging outside this pre-dug zone will likely result in problems digging through granite rock. (See Figure 2 – 15kV Route) The old ductbank cannot be used. The ductbank sleeves are Orangeburg conduits and have swelled shut. Orangeburg conduits are asbestos containing material so trying to drill through or rout out the old conduits would be expensive and hazardous. The old ductbank may be deep enough to place a new one directly on top thereby using the existing manholes. The old ductbank would be sealed and abandoned. This scenario can be performed with both feeders “hot”. During construction the oldest feeder, also the one being built upon, would be turned-off for safety. The building would continue to operate on the other feeder. Each evening the feeder would be re-energized to provide redundant feeds to the building. The entire new feeder can be installed with only a brief outage for final terminations on each end. Page 3 1. PROJECT DETAILS PROJECT NAME 2. REPLACE OBSOLETE 15KV POWER FEEDS UCAR TRACKING NUM. NSF07-ML001 If it is not possible to build over the existing duct bank, then significant work would be required to install the feeders directly adjacent to the old ductbank, again trying to avoid excavating new granite filled ground. The new ductbank would contain extra conduits; one for the 2nd feeder replacement which would occur once the direct bury cable fails. A second spare would be installed for a future wire pull and if one of the other two were damaged and unusable. An additional small conduit would also be installed for fiber optic cable to the new switchgear and pump house for monitoring system connections. Figure 2 - 15kV Route 2. The poles and associated equipment at the Xcel demarcation point would be converted from pole mounted equipment to ground mounted switching equipment, for safety and ease of use. The new ground mounted gear configuration would be for two 15kV feeds from Xcel Energy out to two feeds to the Mesa Lab. Additionally, there would be a feed/switch to the pump house. The pump house should be able to get its power from either main feeder. A manual switch would allow the end-user to select either 15kV feeder. In the past, we have lost the one 15kV feeder feeding the pump house for long periods of time. There was concern that a) the water tank would run dry and thus the Mesa Lab would not have fire suppression, and b) the pump house would freeze and break the supply lines to the water tank, again leaving the Mesa without water. Without water the Mesa Lab would have to be closed. 3. While work is being done on the old manholes (used for the new ductbank) it is proposed we add gravity drains to each manhole. Currently, manholes fill with ever present ground water. Water has a tendency to degrade power lines. In the past, sump pumps were placed in the manholes and would keep them dry. Since then the sump pumps have failed and the manholes are continuously filled. While the manholes are being excavated, a simple core drill and drain pipe could be installed to allow any water accumulation to be drained downhill (to the east side of the access road). A better, simpler solution. 4. Possible Risks: The existing 15kV ductbank lies next to the access road. Just to the right of this 15kV ductbank is a fiber optic and communications ductbank. Just to the right of that is the direct buried 15kV power line. Damage could occur to one or all of these systems during construction. PREDECESSORS/ SUCCESSORS The ductbank work should occur before any repaving of the Mesa Lab access road. Installing the new 15kV ductbank is likely to damage the existing road edge. Another fund request to the NSF is, “Replace the Pump House Switchgear”. The pump house connects to the 15kV feeder pole that is to be replaced on this package. This means the old wire from the 15kV service point to the pump house would have to be replaced. While the pump house is down, the main transformer and pump house gear could easily be replaced. The new transformer and gear would be safer than the old equipment. At a minimum, this project and the replace obsolete pump house gear project should be “designed” together so the final systems can work as an integrated unit. Page 4 1. PROJECT DETAILS PROJECT NAME REPLACE OBSOLETE 15KV POWER FEEDS 2. UCAR TRACKING NUM. NSF07-ML001 COST ESTIMATE DETAIL - (see attached) Estimate Assumptions: • It is assumed an Electrical Contractor will self perform all work and no sub-contractors will be used. • The UCAR Staff will be required to review designs and to project manage the installation. Markups are included for their support. • The old Orangeburg conduits are asbestos containing materials. An allowance is shown in case the old ductbank has to be disturbed and the old conduits removed. • An allowance is shown for rocky soil conditions in case excavation must be done “away from” the existing ductbank routes. The surrounding soils are full of solid granite and boulders. • Planning and Design costs include money for a) potholing the depth of the existing ductbank, and b) survey work. Potholing is required to see if a new ductbank can be constructed directly over the old ductbank and still meet code requirements for minimum depth of coverage over the new ductbank. PROJECT SCHEDULE - (see attached) Schedule Assumptions & Details: • The existing feeders are operational at the time of construction; not an emergency. • Engineering drawings and estimates are completed one year prior to construction. • The Contractor will procure the long-lead switchgear and materials after winning the project bid. • The 15kV Power Feed project and the Replace Pump House Gear and Transformer project are interrelated and design should be coordinated. Therefore, the pump house design will occur the same time as design for this work. • Construction of the pump house electrical can either occur the same time as this project or separately. The schedule shown includes the pump house construction. A separate, stand-alone schedule is shown for the pump house should it be constructed separately. • Underground work is scheduled to occur in spring or summer. • A milestone is shown for “underground work complete” and “the paving of the access road can begin”, at this milestone date or later. Page 5 Job Title: Replace Obsolete 15kV Power Feeds PPS Project No.: NSF07-ML001 Estimate Summary - Contractor Install Description Qty Electrical Demolition Unit Pad Mounted Switches Feeder Ductbank and Cables Subtotal Subcontractor Material Markup ubcontractor Labor Overhead and Profit Subcontractor Equipment Markup Price w/ Subcontractor Markups 10% 56% 10% General Contractor Markup on Sub Bond Permit Price w/ Contractor Markups 0% 2.5% 0.0% Conceptual Design/ Study 08/17/07 Material $ $10,189 Labor $ $80,547 Equip $ $6,944 Total $ $97,680 % of Subtotal $160,378 $16,869 $152,855 $95,884 $323,422 $193,300 $2,464 $47,984 $57,391 $179,711 $296,722 $574,113 $5,739 $63,130 $32,342 $108,248 $5,739 $355,764 $301,548 $32,342 $108,248 $5,739 $720,442 $0 $0 $8,894 $7,539 $0 $0 $364,658 $309,087 $0 $1,578 $0 $64,708 $0 $18,011 $0 $738,453 $0 $18,011 $0 $12,725 $751,178 $12,725 $32,342 $108,248 UCAR Overhead (on 1st $25K per year) 50.9% Contractor w/ UCAR OH A/E design fees Markups to Roll Markup Amt For Into Base Items Each Base Item New Totals NSF Sheet 17% $61,300 $158,980 $159 31% 52% 100% $112,780 $186,213 $360,294 $292,491 $482,935 $934,406 $292 $483 $934 $88,614 $89 $25,000 $84,000 $25 $84 12% $88,614 UCAR Overhead (on 1st $25K per year) 50.9% AE Fees w/ UCAR OH $12,725 $101,339 $12,725 $0 $0 $0 $0 $852,517 $0 $0 $0 $0 $170,503 $170,503 Traffic services Doc Furniture relocation fees NETS plates/services Maintenance Support Price w/ UCAR Costs Budget Contingency 0 ls ea 0 ea ls $0 $0 $1,200 $1,500 $0 $0 20% Allowance for Asbestos Mitigation Allowance for Rocky Soil Conditions $25,000 $84,000 Estimated Construction Project Cost $1,132,021 Inflation Rate Original 2007 Values + Inflation 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 Page 1 Totals for $360,294 $1,132,021 $1,132 Sum of Markups Check Total NSF Total 5.0% Design Construct Allowance Total Replace (1) 15kV Feeder and Pole Mounted Switches $89 +1 yr +2 yr +3 yr +4 yr +5 yr +6 yr +7 yr +8 yr +9 yr +10 yr $934 $981 $1,030 $1,082 $1,136 $1,193 $1,252 $1,315 $1,381 $1,450 $1,522 $109 $114 $120 $126 $132 $139 $146 $153 $161 $169 $178 8/17/2007 $1,132 $1,095 $1,150 $1,208 $1,268 $1,332 $1,398 $1,468 $1,542 $1,619 $1,700 Values highlighted in green and bold outline are used on NSF Request form NSF07-ML001 COSTEST - 15kV Feeder Replacement.xls ID 1 Task Name 15kV Feeder Replacement Duration 472 days Start Fri 9/28/07 0 days Fri 9/28/07 6 wks Fri 9/28/07 2 Design Funds Received from NSF 3 A/E Bids/ Award 4 A/E Design 5 Construction Funds Received from NSF 6 Construction Bids/ Award 7 Procure long-lead materials 8 Underground ductbank 2 mons Tue 3/31/09 9 Access road paving can begin 0 days Mon 5/25/09 10 Ground mounted 15kV primary switches 1 mon Tue 5/12/09 11 15kV cable install & test 3 wks Tue 6/9/09 12 Energize 0 days Mon 6/29/09 13 O&M Manuals/ Closeout 3 wks Tue 6/30/09 105 days Tue 2/3/09 3 mons Tue 2/3/09 4 wks Tue 6/2/09 2 mons Fri 11/9/07 0 days Tue 9/30/08 2.5 mons Tue 9/30/08 5 mons Tue 1/6/09 May 5/6 September January May 6/24 8/12 9/30 11/18 1/6 2/24 4/13 6/1 7/20 September January 9/7 10/26 12/14 2/1 9/28 9/30 5/25 6/29 14 15 Pump House Gear & Xfmr 16 Procure long-lead materials 17 Replace pump house gear & xfmr Title: Replace Obsolete 15kV Power Feeders Project: NSF07-ML001 Date: Fri 8/17/07 May Se 3/22 5/10 6/28 8/16 Task Milestone External Tasks Split Summary External Milestone Progress Project Summary Deadline Page 1