Fact Sheet

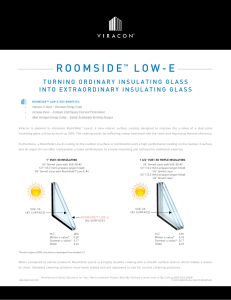

advertisement

Definition: • • • • “U” describes thermal conductivity, that is, the heat flow through the glazing and is expressed in terms of BTUs per hour per square foot per degree Fahrenheit temperature difference. Many people are familiar with the term R-value when discussing thermal insulation. R-value is the thermal resistance and U-value is the thermal conductance. The R-value is simply the inverse of the U-value. R=1/U or U=1/R. For example: R of 0.9 = U of 1.1 U of 0.3 = R of 3.3 The lower the U-value the better The higher the R-value the better General: • • • • • • The U-value is calculated for the entire window, including the frame material and the glass. The U-value is also calculated incorporating the style of window, fixed or operable. The test procedure includes a minor air flow on the test specimen, therefore an operable window, with the same glass type as a fixed window, will have inferior U-value rating. The U-value can be either physically tested or simulated with a computer program. o Physical tests – AAMA 1503 or NFRC 100 o Computer Simulations – NFRC 100 using computer programs written by Lawrence Berkeley National Laboratory The thermal resistance of steel is 5 times greater than that of aluminum. The thermal performance of steel windows has been a controversial subject for many years, in that steel has always been thought of as a poor thermal performer. While the specific material may not be as good as thermal break aluminum, wood or vinyl, the strength of steel affords narrow sightlines thus reducing the ratio of glass to framing. The more glass there is in a window, the better the U-value. Due to its life span, steel windows with ventilators often out perform, other types of construction over the long term because steel does not deform and change shape like other materials, causing U-value loss. The strength of steel is critical. Factors for Improved Thermal Performance in Steel Windows • • • • Insulated glass is better than monolithic glass or laminated glass Low-E coatings Gas filled units Heat Mirror between panes Low-E Coatings • • • • A Low-E coating is a thin metallic layer on a glass surface designed to reflect long wavelength infrared heat energy, but not the visible energy, that’s why it is nearly invisible. Low-E coated glass reflects or redirects radiant heat generated from a warm object back towards the source of warmth up to five times better than uncoated glass. The lower the emittance of a glass surface, the higher the infrared reflectance. The emittance of clear glass is normally 0.84. • • The emittance of Low-E coatings is in the range of 0.35 to 0.05. Low-E coatings reduce the U-value of an insulated unit by approximately 25 to 40%. Gas Filled Units • • • • • • Traditionally, the space between the layers of glass is filled with air. Air is a good insulator as long as it is still. Gaps greater than 1/2” tend to increase natural convection; therefore, the wider the gap does not translate to better U-value performance. To further decrease the heat transfer between two layers of glass, there must be gases that have a lower thermal conductivity than air: Argon and Krypton. Argon is inexpensive, nontoxic, non-reactive, clear and odorless gas that performs best with a 1/2” wide gap. Krypton has better thermal performance than argon but is more expensive to produce. Gas filled units improve the thermal performance over an air filled unit by approximately 6 to 20%. Heat Mirror between Panes • • • • Adding a layer between the glass panes to create a triple pane unit to improve the thermals performance. Heat Mirror is a clear, colorless, coated film that is permanently suspended between two panes of glass. This suspended film divides the space into two smaller compartments, which in turn provide additional insulation and thermal performance. Traditionally, the space between the layers of glass is filled with air. Heat Mirror provides better thermal performance than Low-E. Heat Mirror is a patented process from Southwall Technologies. Test Results Window Series Window Type Size U-Value Glass Type Jamestown175™ Fixed .525 47.24 x 59.06 .345 .268 Casement (sgl) .630 23.62 x 59.05 .498 .437 1” insulating glass / 1/4” panes / 1/2” air filled space (001) 1” insulating glass / 1/4” panes / Low-E #2 surface / 1/2” argon 90% filled space (003) 1” insulating glass / 1/4” panes / heat mirror TC88 / 1/2” krypton 90% filled space (021) 1” insulating glass / 1/4” panes / 1/2” air filled space (001) 1” insulating glass / 1/4” panes / Low-E #2 surface / 1/2” argon 90% filled space (003) 1” insulating glass / 1/4” panes / heat mirror TC88 / 1/2” krypton 90% filled space (021) University™ Fixed 47.24 x 59.06 .519 .331 .254 3/4” insulating glass / 1/8” panes / 1/2” air filled space (042) 3/4” insulating glass / 1/8” panes / Low-E #2 surface / 1/2” argon 90% filled space (025) 3/4” insulating glass / 1/8” panes / heat mirror TC88 / 1/2” krypton 90% filled space (033) Casement (sgl) .611 23.62 x 59.05 .463 .403 3/4” insulating glass / 1/8” panes / 1/2” air filled space (042) 3/4” insulating glass / 1/8” panes / Low-E #2 surface / 1/2” argon 90% filled space (025) 3/4” insulating glass / 1/8” panes / heat mirror TC88 / 1/2” krypton 90% filled space (033) Landmark175™ Fixed 47.24 x 59.06 .525 .345 .268 1” insulating glass / 1/4” panes / 1/2” air filled space (001) 1” insulating glass / 1/4” panes / Low-E #2 surface / 1/2” argon 90% filled space (003) 1” insulating glass / 1/4” panes / heat mirror TC88 / 1/2” krypton 90% filled space (021) Casement (sgl) .613 23.62 x 59.05 .471 .456 1” insulating glass / 1/4” panes / 1/2” air filled space (001) 1” insulating glass / 1/4” panes / Low-E #2 surface / 1/2” argon 90% filled space (003) 1” insulating glass / 1/4” panes / heat mirror TC88 / 1/2” krypton 90% filled space (021) 7000 Series™ Wall System .42 1” insulating glass / 1/4” panes / Low-E #2 surface / 1/2” argon 90% filled space™ The above thermal simulations we conducted using WINDOW 5 and THERM 5 computer programs by Lawrence Berkeley National Laboratory