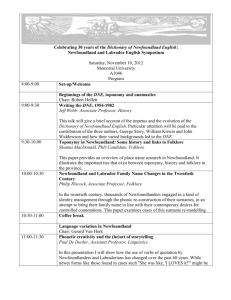

Spring 2008 - Department of Business, Tourism, Culture and Rural

advertisement