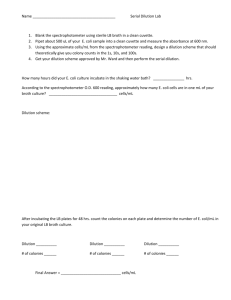

Complete PDF Version - College of Tropical Agriculture and Human

advertisement