An Improved Technique for Tensile Testing of Sheet Metals

advertisement

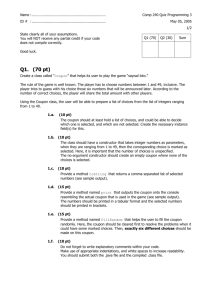

Proceedings of the XIth International Congress and Exposition June 2-5, 2008 Orlando, Florida USA ©2008 Society for Experimental Mechanics Inc. An Improved Technique for Tensile Testing of Sheet Metals Wei Tong, Yue Xuan, and Hang Yao Department of Mechanical Engineering Southern Methodist University Dallas, Texas 75275-0337 USA Introduction Whole-field strain mapping measurements based on digital image correlation techniques have been increasingly applied in recent years to investigate deformation and failure behaviors of sheet metals [1-5]. The experiments have been done essentially with measurements by a single camera at a one fixed viewing angle when the thin sheet metal test coupons are used and their surfaces remain planar with respect to the imaging plane. In order to provide a more accurate data about the diffuse and localized necking process in a sheet metal and the deformation and failure of a welded joint, the deformation measurement on both flat surfaces as well one or both side edges of a test coupon are often needed. Any possible out-of-plane motion between the sheet metal surface and the camera imaging plane during the test is also needed to be monitored for reliable determination of elastic modulus and the plastic strain ratio at small strains. To measure the surface deformation of a test sample over a wider viewing angle or a test sample undergoing some relative 3D motion with respect to the camera, multiple (two or more) cameras or a single camera with multiple rotated positions usually have to be used, which incur considerable additional cost in hardware and often require lengthy and tedious multiple-camera calibration steps in practical applications. A Strain Measurement Technique using a Single-Camera with Two 45-Degree Mirrors A simple experimental configuration for measuring three surfaces (i.e., at a viewing angle of 270º) of a sheet metal test coupon simultaneously has recently been developed in our lab, as shown in Fig.1(a) and Fig.1(b). Such an experimental configuration uses only a single camera along with two 45-degree mirrors and is most suitable for situations when the surfaces of a flat sheet metal test coupon are undergoing mostly translations with only small rotations respect to the imaging plane. Because the large length-to-width ratio of a typical sheet metal tensile test coupon, a single digital image (with a typical aspect ratio of 4:3) can record the three surfaces without much loss of the spatial resolution. If the deformation measurement over the side surface (the middle one in Fig.1b) is desired, a lens with small aperture setting should be used so all three surfaces are within the depth of focus of the imaging system. Errors due to any relative motion between the sheet metal coupon and the camera along either the y-axis or z-axis can be effectively corrected. Z (ND) Y (TD ) Y (TD) Test C oupon X (RD) X (RD) Front SurFace Z (ND) Z (ND) Flat Mirrors Test Coupon Side SurFace X (RD) Camera Back Su rface X (RD ) Y (TD) Y (TD) Lens Figure 1(a). Schematic of imaging three surfaces of a rectangular tensile sheet metal coupon using a single camera. The orientation of the test coupon is defined by a 3D XYZ coordinate system (RD, TD, and ND). Figure 1(b). The three surfaces of the rectangular test coupon captured in a single image. The 2D coordinate system for each surface of the test coupon is noted as well. Laboratory Implementation and Sample Results Fig. 2(a) shows an actual experimental set-up of the proposed measurement technique for a compact tension test coupon using an Instron universal material testing machine 5582. Fig. 2(b) provides a close-up view of the test coupon and mirror arrangement along the camera viewing direction. The gage section of the test coupon is 25mm long, 5mm wide, and 2mm thick. A sample digital image with three surfaces of the test coupon recorded by a firewire digital camera (1280-by-960 pixels, 8-bit grayscale) and a 55mm telecentric lens is shown in Fig. 3(a). The right and left edges of the image correspond respectively to the lower and upper grip ends of the Instron testing machine. As an example, the plastic strain ratio data of a dual-phase steel sheet coupon along the rolling direction are shown in Fig. 3(b), which are measured from both upper and lower surfaces of the test coupon. The out-of-plane motion at small strains has the opposite effects and thus its total effect can be canceled out by averaging them. The resulting plastic strain ratio is shown to be nearly constant within the experimental error. Upper Grip Lights Lower Grip Camera Lights Figure 2(a). An actual experimental set-up of the proposed technique for tension testing using an Instron universal material testing machine 5582. Upper (Right/Front) Surface Lower (Left/Back) Surface Mirrors Middle (Side/Edge) Surface Mounted Test Coupon Figure 2(b). Close-up view of the mounted test coupon and the mirror placement. 2 Upper (Right/Front) Surface 1 .6 Plastic Strain Ratio (R) Middle (Side/Edge) Surface Lower (Left/Back) Surface 1 .8 1 .4 1 .2 1 0 .8 0 .6 0 .4 0 .2 0 Figure 3(a). A sample digital image recorded with three surfaces of a sheet metal tensile test coupon. 0 .1 0 .2 0 .3 T ru e P la s t ic S tra in Figure 3(b). The plastic strain ratios measured by using upper and lower surfaces of a dual-phase steel test coupon. Conclusions A simple technique has been developed to measure the deformation of three surfaces of a sheet metal test coupon simultaneously using only a single digital camera. Such a technique has also a particular advantage of avoiding synchronization of the timings among two or multiple high-speed digital cameras. References 1. Tong, W., H. Tao, X. Jiang, N. Zhang, M. Marya, L.G. Hector, and X.Q. Gayden, Metall. Mater. Trans. A, vol.36, 2651-2669, 2005. 2. Tong, W., Exp. Tech., vol.28, 63-67, 2004. 3. Tong, W., Strain, vol. 41, 167-175, 2005. 4. Tong, W., H. Tao, N. Zhang, and L.G. Hector, Scripta Mater., vol.53, 87-92, 2005. 5. Tong, W., Exp. Mech., vol. 44, 502-511, 2004.