Overview

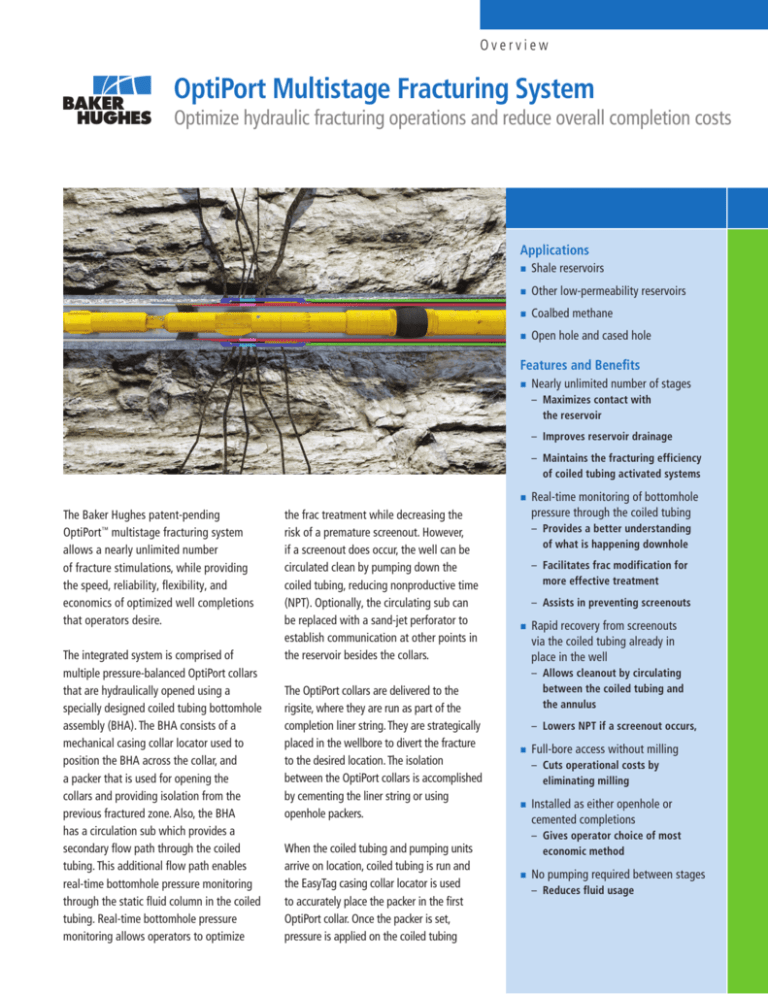

OptiPort Multistage Fracturing System

Optimize hydraulic fracturing operations and reduce overall completion costs

Applications

Shale reservoirs

Other low-permeability reservoirs

Coalbed methane

Open hole and cased hole

Features and Benefits

Nearly unlimited number of stages

–– Maximizes contact with

the reservoir

–– Improves reservoir drainage

–– Maintains the fracturing efficiency

of coiled tubing activated systems

The Baker Hughes patent-pending

OptiPort™ multistage fracturing system

allows a nearly unlimited number

of fracture stimulations, while providing

the speed, reliability, flexibility, and

economics of optimized well completions

that operators desire.

The integrated system is comprised of

multiple pressure-balanced OptiPort collars

that are hydraulically opened using a

specially designed coiled tubing bottomhole

assembly (BHA). The BHA consists of a

mechanical casing collar locator used to

position the BHA across the collar, and

a packer that is used for opening the

collars and providing isolation from the

previous fractured zone. Also, the BHA

has a circulation sub which provides a

secondary flow path through the coiled

tubing. This additional flow path enables

real-time bottomhole pressure monitoring

through the static fluid column in the coiled

tubing. Real-time bottomhole pressure

monitoring allows operators to optimize

the frac treatment while decreasing the

risk of a premature screenout. However,

if a screenout does occur, the well can be

circulated clean by pumping down the

coiled tubing, reducing nonproductive time

(NPT). Optionally, the circulating sub can

be replaced with a sand-jet perforator to

establish communication at other points in

the reservoir besides the collars.

The OptiPort collars are delivered to the

rigsite, where they are run as part of the

completion liner string. They are strategically

placed in the wellbore to divert the fracture

to the desired location. The isolation

between the OptiPort collars is accomplished

by cementing the liner string or using

openhole packers.

When the coiled tubing and pumping units

arrive on location, coiled tubing is run and

the EasyTag casing collar locator is used

to accurately place the packer in the first

OptiPort collar. Once the packer is set,

pressure is applied on the coiled tubing

Real-time monitoring of bottomhole

pressure through the coiled tubing

–– Provides a better understanding

of what is happening downhole

–– Facilitates frac modification for

more effective treatment

–– Assists in preventing screenouts

Rapid recovery from screenouts

via the coiled tubing already in

place in the well

–– Allows cleanout by circulating

between the coiled tubing and

the annulus

–– Lowers NPT if a screenout occurs,

Full-bore access without milling

–– Cuts operational costs by

eliminating milling

Installed as either openhole or

cemented completions

–– Gives operator choice of most

economic method

No pumping required between stages

–– Reduces fluid usage

annulus, opening the ports and allowing the fracture treatment to

be pumped. The packer is then released and moved on to the next

collar where the process continues until all zones are treated. This

process does not require pumping between stages, minimizing the

total volume of fluid required.

The system does not have any inner diameter restrictions, so

the production conduit has full-bore access without the need

for post-stimulation milling, which further improves the speed

of the operation.

Contact your Baker Hughes representative today or visit

www.bakerhughes.com/optiport to find out how our OptiPort

multistage fracturing system can help you optimize hydraulic

fracturing operations and reduce overall completion costs.

www.bakerhughes.com

Disclaimer of Liability: This information is provided for general information purposes only and is believed to be accurate as of the date hereof; however, Baker Hughes Incorporated and its affiliates do

not make any warranties or representations of any kind regarding the information and disclaim all express and implied warranties or representations to the fullest extent permissible by law, including

those of merchantability, fitness for a particular purpose or use, title, non-infringement, accuracy, correctness or completeness of the information provided herein. All information is furnished “as is”

and without any license to distribute. The user agrees to assume all liabilities related to the use of or reliance on such information. BAKER HUGHES INCORPORATED AND ITS AFFILIATES SHALL NOT BE

LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, PUNITIVE, EXEMPLARY OR CONSEQUENTIAL DAMAGES FROM ANY CAUSE WHATSOEVER INCLUDING BUT NOT LIMITED TO ITS NEGLIGENCE.

© 2011 Baker Hughes Incorporated. All rights reserved. 32197