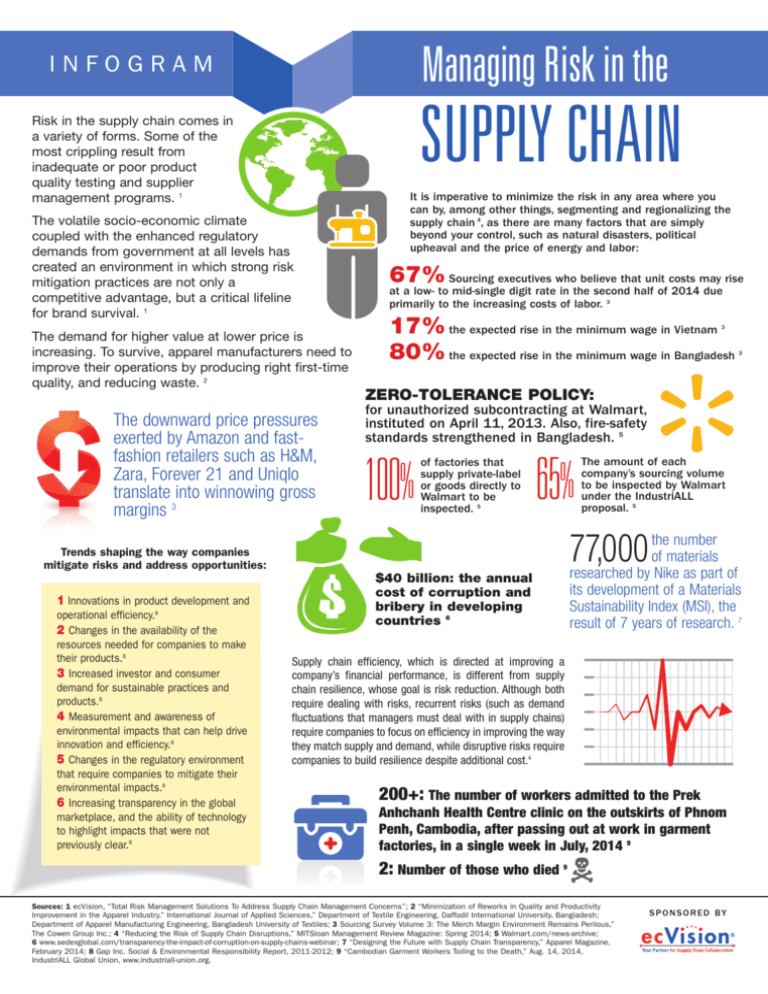

Managing Risk in the Supply Chain

advertisement

Managing Risk in the INFOGRAM SUPPLY CHAIN Risk in the supply chain comes in a variety of forms. Some of the most crippling result from inadequate or poor product quality testing and supplier management programs. 1 The volatile socio-economic climate coupled with the enhanced regulatory demands from government at all levels has created an environment in which strong risk mitigation practices are not only a competitive advantage, but a critical lifeline for brand survival. 1 It is imperative to minimize the risk in any area where you can by, among other things, segmenting and regionalizing the supply chain 4, as there are many factors that are simply beyond your control, such as natural disasters, political upheaval and the price of energy and labor: 67% Sourcing executives who believe that unit costs may rise at a low- to mid-single digit rate in the second half of 2014 due primarily to the increasing costs of labor. 3 17% the expected rise in the minimum wage in Vietnam 80% the expected rise in the minimum wage in Bangladesh 3 The demand for higher value at lower price is increasing. To survive, apparel manufacturers need to improve their operations by producing right first-time quality, and reducing waste. 2 The downward price pressures exerted by Amazon and fastfashion retailers such as H&M, Zara, Forever 21 and Uniqlo translate into winnowing gross margins 3 ZERO-TOLERANCE POLICY: for unauthorized subcontracting at Walmart, instituted on April 11, 2013. Also, fire-safety standards strengthened in Bangladesh. 5 100% of factories that supply private-label or goods directly to Walmart to be inspected. 5 65% The amount of each company’s sourcing volume to be inspected by Walmart under the IndustriALL proposal. 5 the number of materials researched by Nike as part of its development of a Materials Sustainability Index (MSI), the result of 7 years of research. 7 77,000 Trends shaping the way companies mitigate risks and address opportunities: 1 Innovations in product development and operational efficiency.8 2 Changes in the availability of the resources needed for companies to make their products.8 3 Increased investor and consumer demand for sustainable practices and products.8 4 Measurement and awareness of environmental impacts that can help drive innovation and efficiency.8 5 Changes in the regulatory environment that require companies to mitigate their environmental impacts.8 6 Increasing transparency in the global marketplace, and the ability of technology to highlight impacts that were not previously clear.8 3 $40 billion: the annual cost of corruption and bribery in developing countries 6 Supply chain efficiency, which is directed at improving a company’s financial performance, is different from supply chain resilience, whose goal is risk reduction. Although both require dealing with risks, recurrent risks (such as demand fluctuations that managers must deal with in supply chains) require companies to focus on efficiency in improving the way they match supply and demand, while disruptive risks require companies to build resilience despite additional cost.4 200+: The number of workers admitted to the Prek Anhchanh Health Centre clinic on the outskirts of Phnom Penh, Cambodia, after passing out at work in garment factories, in a single week in July, 2014 9 2: Number of those who died 9 Sources: 1 ecVision, “Total Risk Management Solutions To Address Supply Chain Management Concerns”; 2 “Minimization of Reworks in Quality and Productivity Improvement in the Apparel Industry,” International Journal of Applied Sciences,” Department of Textile Engineering, Daffodil International University, Bangladesh; Department of Apparel Manufacturing Engineering, Bangladesh University of Textiles; 3 Sourcing Survey Volume 3: The Merch Margin Environment Remains Perilous,” The Cowen Group Inc.; 4 “Reducing the Risk of Supply Chain Disruptions,” MITSloan Management Review Magazine: Spring 2014; 5 Walmart.com/news-archive; 6 www.sedexglobal.com/transparency-the-impact-of-corruption-on-supply-chains-webinar; 7 “Designing the Future with Supply Chain Transparency,” Apparel Magazine, February 2014; 8 Gap Inc. Social & Environmental Responsibility Report, 2011-2012; 9 “Cambodian Garment Workers Toiling to the Death,” Aug. 14, 2014, IndustriALL Global Union, www.industriall-union.org. SPONSORED BY