English Dress and Irish Dress

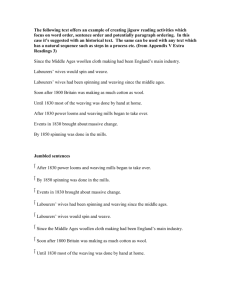

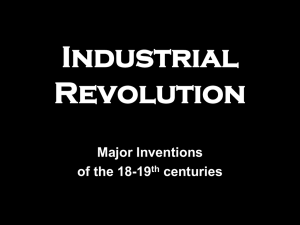

advertisement

The Woollen Trade in Kilkenny – Machinery for Spinning and Weaving Machinery Tuck mills The use of water power to operate textile machinery started with fulling mills or tuck mills. In these the cloth was pounded by wooden hammers powered by a mill wheel. The civil survey lists a tuck mill in Kilkenny in 1654. The 18th century saw the textile industry changed completely by a series of inventions. The Flying Shuttle In 1733 John Kay invented the flying shuttle. Up to his time the shuttle had to be thrown by hand from one side of the loom to the other. He arranged the shuttle so that pulling a lever could do the same job, and this speeded up the work of weaving. The Spinning Jenny James Hargreaves arranged several spindles in a row, with the spindles facing upwards, so that one spinner could do the work of several spinning wheels. He took out a patent for his new machine in 1770 but had been using it in his factory for several years beforehand. The Spinning Mule Samuel Crompton combined the spinning jenny with the Water Frame, invented by Richard Arkwright, and produced his first Spinning Mule in 1778. This applied water power to spinning, and meant that yarn for cloth making could be produced quite fast and in large quantities. The yarn could be produced cheaply. The Power Loom By 1785 the only part of the production of cloth that couldn’t be done by machine was the weaving. That ended in that year when the Reverend Edmund Cartwright patented the power loom. It was improved over the years and by the 1820s was in common use. Tighe’s Statistical Survey of the County Kilkenny Kilkenny had a considerable blanket manufacture at the end of the 18th century. This involved Spinning, Weaving, Milling and Dressing. Writing at the beginning of the 19th century William Tighe wrote: “Spinning Jennies have lately been introduced, which curtail the manual labour at least two thirds; those worked by water are found most effectual; one of them is near Black-Mill Bridge; each water jenny employs eleven hands and does the work of thirty-six; two only have been introduced in town within these two years.” He gives details of the industry in Kilkenny: There were fifty looms with two journeyman weavers employed at each loom, making a total of one hundred 1 The Woollen Trade in Kilkenny – Machinery for Spinning and Weaving journeyman weavers. There were in addition thirty master weavers and six hundred men and women employed in other parts of the manufacture of woollen blankets. The spinning of each piece of cloth cost £1..2s..9p and the journeyman weaver was paid twenty shillings, or one pound. Over the next few years, spinning was mechanized. Fulling had been done in tuck mills for a long time, and in the 19th century, spinning was mechanised as well. In 1841 the weavers were complaining of unemployment. They said that from 1800 to 1829 the trade had been protected by a duty on English cloth, but that since then English cloth was coming in and replacing the Irish manufactured cloth. They didn’t mention the invention of the power loom in England in the 1830’s but already English cloth was much cheaper than the old hand-woven cloth. The weaving was done on hand looms until 1846. In the beginning of that year power looms worked by water power were introduced in Ormonde Mills. It was a very anxious time in Ireland. The potato crop had failed the previous year and famine threatened the whole country. Hundreds of weavers lost their jobs, and the new looms were worked by women, who were employed in weaving for the first time, and were paid much less than the men. Ormonde Woollen Mills survived until 1868, closed for some years and re-opened in 1880. In this old photograph you can see the mills and the weir which diverted the water into the mill race. Kilkenny Castle is in the distance. The building was destroyed by fire in 1969. The ruins may be seen on the Canal Walk about a quarter of a mile below John’s Bridge. 1. What work was done in a tuck mill? 2. Who invented the flying shuttle and what did it do? 3. What was a spinning jenny? 4. What power source did the first power looms use? 5. What did William Tighe say about the number of men needed to work the spinning jennies, compared with the older way of spinning thread? 6. What was the main product made in Kilkenny’s woollen mills around the year 1,800? 7. How was employment affected by the change to power looms in Ormonde Mills? 8. When did Ormonde Mills finally close? 9. Where was Ormonde Mills located? 2