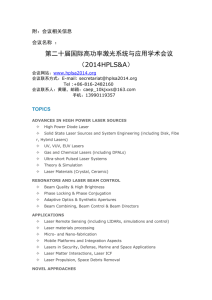

Safety Information

advertisement

Safety Information Atomic & Fundamental Molecular Physics Group Every member of the group has to be familiar with the rules and regulations for safety in the laboratories (including the theoreticians!). On joining the group everyone has to read and understand the safety procedures listed in this document. You also MUST follow these instructions while working in the laboratories. A signed and dated copy of p.2 must be given to Eleanor Campbell before you begin to work in the laboratories. Contents: General Information Laser Safety Working with Gases Working with High Voltage Working with Chemicals Laser Case Studies General Information: Responsibility: The Dean (prefekten) has the ultimate responsibility for safety at the School of Physics. This responsibility has been delegated to the Professors of each group. For the Atomic and Fundamental Molecular Physics Group this is Eleanor Campbell. The minimum safety regulations for working in our group are stated in this document. Every member of the group (students and personell) is personally responsible for being aware of the risks involved in their work and following these regulations. The Arbetsmiljöombudet (Heinrich Riedl) is elected by the union and has the power of terminating activities if he thinks this is necessary to maintain safety. Good Safety Means Having Things in Good Order This means, among other things, keeping a reasonably tidy laboratory and ensuring that the corridors are kept clear in case of emergencies (e.g. fire). No flammable material should be stored - even for a short time - in the corridors (this includes empty boxes). In Case of Emergency No matter how careful we all are accidents can still happen. All accidents should be reported immediately to the arbetsmiljöombudet (Heinrich Riedl) and the professor (Eleanor Campbell). They will let you know of further procedures that need to be followed. Please be aware of what to do if the Emergency Services have to be contacted (fire, ambulance etc.). This information should be available in every laboratory. Receipt. I have obtained a copy of the "Safety Information" document of the Atomic and Fundamental Molecular Physics Group. I have read this document carefully and fully understood the instructions given in it. Name: …………………………………… Signature:………………………………... Date:……………………… P. Hagberg, February 1999 Laser Safety Regulations In the Atomic Physics group we use a number of different lasers for various applications. They may differ a lot in size, wavelength, power, etc, but they have one thing in common: The light they generate is a serious hazard and the dangers associated with this must be taken very seriously. Even a very short exposure to a fraction of a reflected laser beam may cause permanent loss of vision. So far, our laboratory has been spared from serious accidents but this is not to be regarded as a warranty. To maintain this record each person working with lasers must be aware of the dangers and adhere to the safety rules. Attached you will find some case histories which describe what happens when the eye is exposed to relatively weak laser beams. Background If a laser beam strikes your eye, the eye lens will focus the light to a small spot on your retina.The collimated laser light is focused down to a 10 µm spot that will quickly burn a hole in the tissue and damage the nerves. Bleeding and haemorrhage can give severe complications that might lead to permanent loss of vision. Nothing can be done to repair retinal damage! The eye lens transmits and focuses light in the ocular focus range 350 - 1400 nm. Intense light outside this range can still damage the surface of the eye but light inside the ocular focus range will be focused 105 times on the retina. Especially dangerous is light inside the ocular focus range but outside the visible range (400 - 750 nm) since it is invisible but still will be focused in the eye. Viewed head-on, the light is focused onto the fovea, which is responsible for the most accurate vision. When exposed from the side, parts of the retina responsible for the peripheral vision are struck. If the beam strikes the blind spot, where the optic nerve enters the eye, loss of vision is complete. Since the eye will focus the laser beam so tightly, exposure to a weak reflection is enough to cause permanent damage. The time you need to close your eye (blink) when exposed to a bright light is approx. 0,15 s. The maximum permissible exposure during this time for a cw He-Ne laser is 1 mW. The burn-threshold (permanent damage) exposure for the retina is only about 30 mW. Lasers are classified from safety class I (eye safe) to IV (hazardous to both eye and skin). In our lab, all lasers are class IV except the lowpower HeNe lasers that are class IIIb. The Law All work with lasers is governed by the regulations laid down by the National Institution of Radiation Protection and in the legislation governing working environment. These regulations must be applied at the Atomic & Fundamental Molecular Physics Group. This legislation states that the employer (the School of Physics) shall appoint one person who is responsible for laser safety and well acquainted with the regulations and use of the lasers. If you have questions or comments about the laser safety in your lab, you should first talk to your supervisor or the professor. If you are unhappy with the outcome of these discussions you should address the huvudskyddsombud (head safety officer. Heinrich Riedl) at the department. A copy of the regulations for laser safety can be found at the huvudskyddsombud. Dangers In a well designed optical system, no hazardous laser beams should be present. Hence the risk of accidental exposure is greatest during set-up and alignment of the system. The major dangers are: • Horizontal stray beams at table height. • Beams travelling out of the plane of the table. • Reflections off optical components in the set-up. • Reflections off watches, rings, etc, during set-up. • Uncontrolled, "wandering" beams during alignment. The rules below are designed to minimise the risk of accidental exposure and ensure the safety of people working in the lab. Rules for all persons working with lasers in our laboratories 1) Warning lights. The warning lights must always be turned on before the lasers are started. The lights should be flashing (position 1, "blinkljus"). 2) Personal equipment. Watches must be taken off before alignment work. Also other effects that may cause reflections, such as rings, jewellery, belt buckles, etc, must be removed or covered so that no deflections can occur. 3) Laser start. Always start the laser with the exit aperture blocked by a power meter or a beam blocker that withstands high power. 4) Safety goggles. Always use safety goggles when the exit aperture of the laser is uncovered. Safety goggles are available for UV-light, 514 nm (argon ion laser) IR and Nd:Yag wavelengths. For the dye lasers, see below under the section on lasers. 5) Set-up. During set-up, never let the laser beam free. Always block the beam path with the beam-blocking screens (beam stops) that are available in the lab. Always use lowest possible power level during set-up. When introducing a new optical component in the optical path, follow this procedure: • • • • • Block the beam. Introduce the new component and align it roughly so you know approximately were the beam will travel. Put a beam stop immediately after the component. Remove the first blocker. The beam should now be blocked by the second beam stop. During alignment, keep the beam blocked by the stop. When the beam is positioned correctly for the next component, repeat the procedure. Do not use the black cardboard as a beam blocker, it will easily burn and cause a fire hazard as well as an unblocked beam. 6) Alignment. Keep your optical path in the table plane and as low as possible. If you need to change the height of the system, always lift the beam vertically at 90° to the table. For vertical beams, be very careful to terminate the beam path as soon as possible. Always observe your optical system at 90° to the beam plane, never lean down and look in the plane. 7) Stray beams. After introducing a new optical component, always be sure to track down stray beams and block them off with beam stops. Typical stray beams emerge from lenses and windows (4% retro-reflection) or polarisers. When your set-up is complete, turn the lights off and turn away from the system. Look for any possible stray beams on the walls by lifting your goggles. Be sure to keep your back to the system and never turn around without wearing the goggles. Note: This is only a final check, you should foresee and block off all stray beams before you perform this. You will also find a lot of diffusely scattered light in the room. This light is normally not hazardous. 8) Chambers and cells. Before looking into a chamber or cell, all laser beams travelling into it must be blocked. 9) Skin hazards. Never block the beam with your hand, always use a beam stop. A 1 W laser beam will give a nice, circular burn after a few seconds of exposure. High power pulsed UV-sources may also be harmful to the skin. 10) Leaving room. When leaving the room, make sure that all doors are locked and the warning light on. Note: Do not forget to shut off the warning lights when the lasers are off and do not leave doors open with the warning light on. Such behaviour, although not hazardous in itself, will deteriorate the safety conscience. 11) Visitors. Visitors must be accompanied. Visitors should wear safety goggles if possible and they should be informed about laser hazards (loss of vision) and the rules of the lab (no bending, sitting down, leaning over optical table, etc.) Be careful with short people or children with the optical system at eye level. Our laser systems In the group there is a number of different laser systems. We have both pulsed and continuous (cw) lasers that range from deep UV to IR. The laser systems are listed below together with the special safety regulations that apply to them. UV-lasers These lasers emit invisible UV light. Extra care must be taken in the set-up when using these lasers since reflections and stray beams will be invisible. Excimer lasers There are two types of excimer lasers in the group: Argon-Fluoride/Krypton-Fluoride (ArF/KrF) lasers and Xenon-Chloride (XeCl) lasers. They are ns-pulsed lasers that emit UV light at 193 nm (ArF, deep UV), 248 nm (KrF) and 308 nm (XeCl). These lasers are all very powerful and since the emitted light is invisible to the eye, extra care must be taken to block off stray beams. When working with the excimer lasers, UV goggles must always be used. Also, UV-light can have a cancerogenic effect when the skin is exposed, this holds especially for the 248 nm emission of the KrF laser. Be very careful when working with KrF lasers and use protective clothing (eg gloves) if necessary. The gases that supply the laser are very reactive, follow the security regulations for gases. Also, high voltages are present in the laser assembly, consult the safety instructions for high voltages. Nitrogen laser This laser emits 337 nm UV light in ns pulses. The N2 laser light is on the threshold of being focused by the eye lens and therefore extra care must be taken to use protective UV goggles and block off stray beams. Visible lasers These lasers emit visible light that is focused by the eye lens. They will cause retinal damage if exposed to the unprotected eye! Argon-Ion laser The argon ion lasers are high power cw lasers that are usually run at 514.5 nm and at 0.1 - 10 W output power. For the Ar-lasers there is a set of alignment goggles that will allow you to see the beam with the goggles on. The goggles will absorb up to 100 mW of laser power before they break. Therefore, the same caution must be taken when working with these as when working with an unprotected eye! Never use the goggles as a filter since you might burn them. There will then be a spot on the goggles with null protection. Broken goggles must be thrown away! The Ar-lasers contain high voltage parts and special care must be taken when working with the cover off, see the section about high voltage safety. Dye lasers The dye lasers are pumped by the 308 nm XeCl lasers and emit pulsed light in the range 400800 nm. Since they can be tuned over such a wide range of wavelengths there is no set of protective glasses that can cover the whole spectra. Therefore, extra care must be taken when working with these lasers! Beam blocking is crucial and for a more permanent optical set-up (valid for weeks) make a permanent shielding box to minimise hazards. The dyes used in these lasers may be toxic and/or hazardous to the skin. Consult the safety regulations for toxic substances. Helium-Neon lasers Our HeNe lasers (633nm, 612nm, and 543nm) are low power and fairly safe to work with. Avoid eye exposure to direct reflections. There are no goggles for these lasers. Titanium-Sapphire laser The Ti-Saph laser is pumped by an Ar-Ion laser and produces tuneable cw light in the near IR regime (700 nm - 840 nm). The output ranges from 0 to 300 mW. The spot produced by the Ti-Saph looks very weak since the eye is not very sensitive at these wavelengths so care must be taken when using this laser. At present there are no protective goggles for this laser, therefore the same care must be taken as for dye lasers! When run at IR wavelengths, use IR goggles. Infrared lasers These lasers emit IR-light that is invisible to the eye but will be focused by the eye lens. They are therefore perhaps the most dangerous lasers to work with and must be handled very cautiously! Stray beams must be blocked and can be found with an IR-viewer. High power diode laser This is a diode laser emitting 200mW of cw 820 nm light. The light is invisible to the eye but will be focused onto the retina. Use protective IR goggles. Stray beams must be blocked and can be found with an IR viewer. IR light is absorbed by the skin and may cause burn injuries. Nd:YAG laser The Nd:YAG laser emits pulsed IR light at 1064 nm. The pulses are very powerful and extreme care must be taken when working with this laser. Often the laser light is frequency doubled or tripled and then there can be laser light present at 1064, 532 and 354 nm. Therefore, special Nd:YAG protective goggles that block all these wavelengths must be used! Frank Rohmund, 29/1/99 A short gas handling safety manual Many of the gases used in research laboratories are poisonous and/or corrosive and therefore represent a danger for health and life of people working in the lab (not only those handling the gas!). For that reason it is very important to be cautious while using such gases and to follow some basic safety rules. Before using any gas one must read the chemical data sheet of the gas which provides informations on its toxicity, corrosiveness, odor, reactiveness etc. Some information can also be found in the catalogues of the gas suppliers. On the basis of these data, a safe way to use the gas in the laboratory should be worked out. Some gases are more dangerous than others, but in principle all gases should be handled with the same (large) amount of care. Many of the nasty gases have a strong characteristic odor that makes them detectable with the human nose in small not neccessarily dangerous doses (examples: NH3, HCl, F2). However, it is the goal of careful gas handling not to make use of that detector. Some very toxic gases are colorless and free of odor (example: CO). If such gases are used, a proper gas warning system must be used in the laboratory and the gas storage room. Gases are delivered in metal tanks, either as highly pressurized gases or liquids in equilibrium with their vapor. A regulator connected to such a tank is used to select an appropriate pressure under which the gas is injected into the gas handling system. The latter normaly consists of tubing, valves, mass flow controllers, etc. The materials out of which the regulator and the gas handling system are manufactured must be compatible with the gases they are exposed to. This is particulary important for the use of corrosive gases like the halogens for excimer lasers. All tubing and gas handling equipment has certain limits to the pressure which can be applied to it. To prevent blowing of the system this pressure must not be exceeded. Before using a gas handling system with dangerous gas is should be leak-checked with a nonharmful gas like Argon. A newly installed gas handling system has to be checked by someone outwith the group. The gas tanks must be stored in designated gas storage rooms. There are special gas storage rooms for flammable gases. Gas tanks must be chained to a wall. When not in use, the main valve of a gas tank must be covered with a protecting lid. If the gas goes through a vacuum pump make sure that the gas will not corrode the pump. If necessary neutralizing elements need to be introduced into the gas flow system in front of the pump (filters, cold traps, bubblers, etc.). The pump must be connected to the main exhaust system of the building. Working with a regulator: It is not only important for the safety of the people in the lab but also for the purity of the gas that the regulator is connected to the gas tank in the correct manner. In the following the steps for that procedure are given: 1. 2. 3. 4. 5. make sure that the gas tank is chained to a wall remove protecting lid from the gas tank (if present) remove the plug from the exit port (if present) clean the inside of the exit port with alcohol in the case of a nontoxic and noncorrosive gas: a) connect the regulator loosely to the tank, use an appropiate gasket b) open the main valve of the tank for a short moment while tightening the nut of the regulator. Most of the air in the volume between the gas tank and the regulator will be blown out by this method c) leak-check the connection between gas tank and regulator in case of a toxic and/or corrosive gas: a) connect the regulator tightly to the gas tank, use an appropriate gasket b) connect the exit port of the regulator to a vaccuum pump (in most cases using the gas handling system of the future application of the gas, must be free of leaks!) c) pump out the gas handling system d) open the regulator to pump out the volume between gas tank and regulator e) close regulator f) open main valve of the gas tank for a short moment to pressurize the volume between gas tank and regulator, leak-check the connection of regulator to gas tank g) open the regulator valve carefully (gas handling system still under vacuum) to pump out the volume between gas tank and regulator h) repeat the procedure starting from f) two to three times 6. keep the volume between gas tank and regulator pressurized as long as the gas tank is connected to the gas handling system 7. keep the main valve of the gas tank closed when no gas is actually used before dismounting the regulator make sure that the complete gas handling system is free of hazardous gases up to the gas tank exit port J. Sandström, February 1999 HIGH VOLTAGE SAFETY AND MAINTAINING SAFETY!!! How does electrical current affect your body? 0.5 mA 10 mA >50 mA Threshold value for feeling the current You are not able to let go from an object you are holding. (muscular spasm) Risk for heart fibrillation which can be fatal. Rules for good safety: • All people working with electrical equipment should receive information according to the high current regulations (starkströmsföreskrifterna) every other year. (ELSÄK-FS 1994 : 7 avd C § C125 b). This can be obtained from Heinrich Riedel. • When working with high voltage, at least two people should be present in such a way that • • • • • • • they can see and hear each other. Construction parts and test objects should be regarded as if they were connected to a voltage until the opposite has been confirmed. Recouplings on a central coupling board must be performed by qualified personnel. Always disconnect power supplies and discharge capacitors before attempting to carry out any work on electrical equipment. Metal items should be kept away from electrical circuits that are not isolated. Avoid huge metal constructions. Metal constructions should always be grounded. Ensure that HV/current connections to vacuum apparatus are protected to avoid anyone from accidentally coming into contact with them. THINGS TO DO IF A BAD ACCIDENT OCCURS WITH HIGH VOLTAGE!!!! 1. Disconnect the electrical current. 2. Start heart and lung massage if competent to do so. If not find someone who can (e.g. Heinrich Riedl) 3. Call 112 and wait for reply. Clearly state your name, the address of the building (Fysikgränd 3) and the whereabouts of the lab in the building. Send someone to meet the ambulance at the entrance. 4. Accidents should be informed immediately to the arbetsmiljöombudet (Heinrich Riedl), the professor (Eleanor Campbell), the dean and the security engineer (phone: 7722635). 5. Do not touch anything in the lab until an investigation has been carried out. Working with Hazardous Chemicals and Biological Material Before working with any chemicals (this includes e.g. solvents and laser dyes) make sure that you have read the relevant data sheet and are aware of how to handle the material in a safe way. Your immediate supervisor should be able to supply you with this information or tell you where it can be found. Special care has to be taken with biological materials (used in the optical tweezers group). Some of this material is toxic and/or carcinogenic. Information on the materials being investigated or stored in the group is available in the small "biology lab" (room F5310). Laser Case Studies CASE HISTORY NO. 1 This is an accident victim's viewpoint of his experience. The necessity for safety precautions with high-power lasers was forcibly brought home to me last January when I was partially blinded by a reflection from a relatively weak neodymiumyag laser beam. Retinal damage resulted from a 6-millijoule, 10-nanosecond pulse of invisible 1064-nanometer radiation. I was not wearing protective goggles at the time, although they were available in the laboratory. As any experienced laser researcher knows, goggles not only cause tunnel vision and become fogged, they become very uncomfortable after several hours in the laboratory. When the beam struck my eye I heard a distinct popping sound, caused by a laser-induced explosion at the back of my eyeball. My vision was obscured almost immediately by streams of blood floating in the vitreous humor, and by what appeared to be particulate matter suspended in the vitreous humor. It was like viewing the world through a round fishbowl full of glycerol into which a quart of blood and a handful of black pepper have been partially mixed. There was local pain within a few minutes of the accident, but it did not become excruciating. The most immediate response after such an accident is horror, As a Vietnam War Veteran, I have seen terrible scenes of human carnage, but none affected me more than viewing the world through my bloodfilled eyeball. In the aftermath of the accident I went into shock, as is typical in personal injury accidents. As it turns out, my injury was severe but not nearly as bad as it might have been. I was not looking directly at the prism from which the beam had reflected, so the retinal damage is not in the fovea. The beam struck my retina between the fovea and the optic nerve, missing the optic nerve by about three millimeters. Had the focused beam struck the fovea, I should have sustained a blind spot in the center of my field of visions. Had it struck the optic nerve, I probably would have lost sight of that eye. The beam did strike so close to the optic nerve, however, that it severed nerve-fiber bundles radiating from the optic nerve. This has resulted in a crescent-shaped blind spot many times the size of the lesion. The effect of the large blind area is much like having a finger placed over one's filed of vision Also, I still have numerous floating objects in the field of view of my damaged eye, although the blood streamers have disappeared. These `floaters' are more a daily hindrance than the blind areas, because the brain tries to integrate out the blind area when the undamaged eye is open. There is also recurrent pain in the eye, especially when have been reading too long or when I get tired. The moral of all this is to be careful and wear protective goggles when using high power lasers. The temporary discomfort is far less than the permanent discomfort of eye damage. The type of reflected beam which injured me also is diffraction gratings, and by all beamsplitters or polarizers used in optical chains. CASE HISTORY NO. 2 Another viewpoint from a victim describing the circumstances an accident follows: As I read my November issue of Laser Focus I took note of the eye injury report, curious about the particulars of this novel accident. Even though I have been working with lasers for five yearn the presence of many of the same hazards pointed to in this article, I didn't think while reading it, "This could happen to me!" But it did. On January 22, 1982, I spent several hours aligning a low-power, frequency-doubled Nd:YAG beam through a laser set-up. In order to see the 532 nm pump beam propagation I was not wearing goggles. I had also removed a beam block intended to absorb a Brewster's angle reflection, to observe end pumping of an amplifier cell. The green power was incred to determine the extent of dye lasing without replacing the beam block. I did not put on goggles. While placing a power meter at the dye laser output I leaned over the uncovered amplifier and caught a reflection in my right eye. Because I was in continuous motion looking at the meter and not the beam, I doubt that more than one 10 to 15 nsec pulse of ~20 microjoules was focused onto the fovea. While I do remember seeing a green flash there was no pain. I was not immediately aware of any significant eye damage. It wasn't until I shut the lasers off and returned to my desk to record the day's activity that I realized I had a blind spot comparable to a camera flash, but only in my right eye. It was almost 5:00 on a Friday, and I didn't report the accident because I couldn't believe that any serious damage was done. By Saturday afternoon I knew I had a problem. Monday the 25th I notified our safety division and started my visits to an ophthalmologist. The initial examination supported the probability of permanent damage although haemorrhaging in the affected area obstructed detail. By the end of the first week, peripheral vision around the spot was improving (due to decreased swelling), and the actual contact point was observed to be on the right side of the macula (that corresponds to a blind spot slightly off center left). I was encouraged and felt fortunate considering the negative potential of this careless mistake. But by week two peripheral vision had declined. Distortion (curving) of resolution around the spot became more noticeable due to additional blood pooling around the retina. If this haemorrhaging were to persist, laser cauterization would be necessary. But for now "treatment" consists of waiting, observing, and photographing. Although recovery has not been straightforward, and my vision may get worse before it gets better, I still feel lucky in that one eye totally escaped injury. So while reading was difficult at first, my daily life has remained largely unaffected because the brain and stereo vision compensate the anomaly. But more important than the actual event is the idea that this incident could have been avoided. Don't let it happen to you or a co-worker. Take time to assess safety conditions, and do it again in six months or a year; additional hazards arise in an ever-changing research environment. Safety deserves thoughtful consideration, now, before YOUR accident. If even one other injury can be prevented by publication of this accidental account, then more positive than negative outcome may result from the mistake. CASE HISTORY NO. 3 A 31-year old man with many year's experience with lasers was struck in the left eye with an argon laser beam, causing an immediate paracentral visual blur. Circumstances of injury were as follows: Without wearing his safety glasses, the patient was inspecting a clear glass laser beam splitter for dust particles as part of a normal production line procedure. During this examination, laser power was accidentally turned on by another person, causing the beam to strike the patient's eye. The laser was continuous wave argon with wavelengths of 488.0 and 514.5 nm; Power incident at the cornea was 70 mW and beam diameter was 1.4 mm. The exposure duration depended on the blink reflex of the patient, estimated as being 0.125 seconds.