The new 'poles and empolia' for the columns of the ancient Greek

advertisement

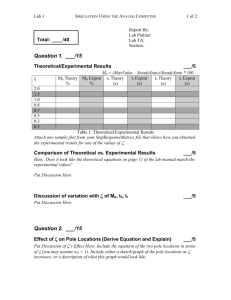

Built Heritage 2013 Monitoring Conservation Management The new ‘poles and empolia’ for the columns of the ancient Greek temple of Apollo Epikourios Konstantinos Papadopoulos1; Elizabeth Vintzileou2 1 Technical Team of the Committee for the Preservation of Apollo Epikourios, Bassai, Greece; 2 National Technical University of Athens, Faculty of Civil Engineering, Athens, Greece 1. Introduction During the archaic and classical period in Greece, the ancient builders were placing a cylindrical wooden pin, called pole, of small height, at every interface of the columns of monumental structures. These cylindrical elements were being used by the ancient builders, for centering the column drums accurately one upon another, during construction. The poles, maid usually of hard wood, were inserted not directly to the stone-drums, but into pairs of plugs of prismatic shape, the ‘empolia’, maid of softer wood. The empolia were wedged into holes (mortises) cut in the contact surfaces of the drums (Fig.1). When two adjusted drums were placed, the ancient masons rotated the top drum with respect to the bottom drum (only for few degrees), in order to treat the interface and achieve the best possible contact. As the poles and empolia were remained in place after the erection of the columns, they were composing a low-strength (supplementary to the friction ties at the stone interfaces) system of the drums. In the present paper the study of the new titanium poles and empolia carried out for purposes of the ongoing restoration of the ancientGreek temple of Apollo Epikourios, is presented. As in this monument no pole or empolio has been preserved, the preliminary objective of the study was to estimate the shape and dimensions of the ancient wooden elements. Subsequently, the new titanium elements were designed to have similar shape and shear strength to the estimated respective characteristics of the ancient poles Fig.1 - Left: Schematic illustration of two adjacent drums and of their wooden connection, with the two empolia and one pole; Right: Photographs of wooden poles and empolia from Athenian 759 Acropolis monuments Built Heritage 2013 Monitoring Conservation Management and empolia. The final stage of the study included numerical investigation of the influence of the titanium poles to the seismic behaviour of a temple column, using the computer code ABAQUS, and records of three earthquakes, occurred in Greece, with very different characteristics. The results showed that the installation of the new pole at the drums (top or every) interface leads to limitation of the maximum and residual deformations of the column, without altering significantly the main characteristics of its rocking response. 2. Brief description of the restoration project The temple dedicated by the ancient Greeks to Apollo Epikourios (the Helper) is located in a mountainous part of Peloponnesus (South-West Greece) called Bassai, at an elevation of 1130 m. The temple was built in the late 5th century B.C., mainly of local limestone. It has 6 x 15 Doric columns at its perimeter, and it measures 16.14*39.84 m, at foundation level. The monument presents many severe structural damages (foundation deformations, stone-blocks fractures, significant tilts of the columns etc.), which have diminished significantly its stability and endanger its safety, in case of future earthquakes. In 1987 the temple was covered with a temporary enclosed canopy, for protection from damage from the environment. In January 2001, restoration works began, focused on the north part of the building, which are still ongoing. The restoration consists in: removing architraves and columns in full height; dismantling the stone blocks of the three steps and the foundation top course; repairing and strengthening the foundation; joining the fragments of the multi-fractured stone blocks and supplementing them with new stone pieces (patches); resetting the blocks of the dismantled courses, and reconnecting them using new clamps and dowels made of titanium; re-instating the columns in vertical positions; removing the columns capitals which need patches, and supplementing them; repositioning the dismantled capitals using new poles and empolia of titanium; supplementing the epistyles and repositioning them, using new titanium clamps to reconnect them. Having completed these tasks in the north side of the monument [Papadopoulos, 2009], the work is currently ongoing in the northern-most parts of its two long sides. The restoration is being carried out under the overall supervision of the Ministry of Culture and under the direction of the Committee for the Conservation of the Temple of Apollo Epikourios, composed by Dr. Dimitrios Bairactaris, as President, and other prominent scientists of the Ministry. The project is funded by the European Union and the Greek State. 3. Estimations for the ancient poles and empolia In the temple of Apollo Epikourios no pole or empolio has been preserved. Their initial presence in the building is certified by the fact that in all cases where a column was partially or totally dismantled, a pair of cuttings suitable for empolia was uncovered at every drums interface. However, there are numerous classical monuments, mostly maid of marble, in which wooden poles and empolia have been preserved. The diameter of the documented ancient poles varies from 2.7 cm to over 5.0 cm, and their length from 6.7 cm to 12.0 cm. The height of the documented empolia prisms varies from 4.7 up to 7.8, 760 Built Heritage 2013 Monitoring Conservation Management and the side of their usually square upper surface from 6.3 cm to 13.5 cm. In the Bassai monument the cuttings uncovered at the upper drums interfaces in five columns of the north size, are close to 7.0 cm (up to 7.5 cm) deep and their sections are approximately rectangular with minimum and maximum sides of 9.0 to 11.2 cm and 9.8 to 12.2 cm. Obviously, the decomposed corresponding empolia had the same external dimensions. These are very close to the dimensions of the empolia from the contemporary Athenian temples Erechtheion and Parthenon. Based on this observation, it can be assumed that the poles in the perimeter columns of Apollo Epikourios temple were of similar size to the poles of the Erechtheion (diameter: 4.2 cm, length: 12 cm) and the Parthenon (diameter: 5 cm, length: around 10,5 cm), as were the empolia of these temples. Thus, the probable dimensions of the Apollo temple poles are 4.0 – 5.0 cm (diameter) and 10.0 – 12.0 cm (length). For the estimation of the ancient poles ability to resist sliding of the drums, shear strength experiments on ten wooden cylinders resembling ancient poles were carried out at the Parthenon worksite in 1999. The experiments were carried out in such a way to imitate the laboratory double shear test. It must be noticed that the specimen constructed identical to the ancient poles (with its cylindrical axe parallel to the grain and passing through the center of the growth rings) presented the highest strength (18.38 MPa), and that the shape of its surfaces of fracture was almost identical to the shape of the fracture surfaces of a pole uncovered in a column at the Parthenon Pronaos. This experimental result leads to the estimation that the ancient wooden poles with 4.0 – 5.0 cm diameter were able to resist shear forces in the vicinity of 23–36 kN. 4. The design of the new poles and empolia Aiming to provide the structure with supplementary resistance to dynamic loads, the ancient builders of Apollo Epikourios temple used iron clamps or dowels to connect most of the stone blocks in the superstructure. The main exception to this rule was at the interfaces of the columns drums were they placed wooden poles and empolia. For restitution of the lost metal connectors and for replacement of the preserved ones, new clamps and dowels made of titanium are being used during the ongoing restoration of the monument. The new connectors have been designed to have similar shape to the ancient elements, and to present lesser resistance than the bearing capacity of the blocks in the regions of the connections [Papadopoulos, 2009]. The same design approach was followed for the titanium poles and empolia for the monument columns (Fig.2). More specifically, the new poles are constructed from a titanium bar of 28 mm diameter, and with 95 mm length. Their central part has reduced cross section of 12 mm diameter, whereas a mild reduction in the diameter at the two end parts leads to diameter of 24 mm at their end sides. The formation of neck in the middle part of the poles favors plastic deformation in that area. Moreover, their minimum (neck) diameter secures that they will fracture when loaded with shear force within the estimated levels of shear resistance of the temple ancient poles (23 – 36 kN). Each pole is inserted into cavities at the titanium empolia pair of 30 mm diameter. The cavity lip diameter is bigger (35 mm), in order to facilitate the in761 Built Heritage 2013 Monitoring Conservation Management Fig.2 - Sketches presenting the shape and typical dimensions of the new titanium poles and empolia (dimensions in mm), designed for the columns of Apollo Epikourios temple sertion of the pole. The empolia outer dimensions are slightly smaller than the dimensions of the respective cuttings at the adjacent column drums, for reasons related to the anchoring of the empolia, which is achieved using white cement mortar. Shallow channels at the lateral and bottom surfaces of the empolia, provide additional interlocking with the mortar, stabilizing further their position. The small difference between the maximum diameter of the pole and the minimum diameter of the empolia cavities, serve two purposes. It allows minor adjustments of the position of the upper drum, in respect to the bottom drum, in the effort to achieve the best aesthetically (final) result during the repositioning of the upper drum. Moreover, it creates of a small margin of space in which sliding and/or rocking of the drums can occur during the response of the column to dynamic events, without resistance from the pole. Thus, relative displacements of the drums can take place (within an accepted level of magnitude) along with the consequent desirable dissipation of kinetic energy in many interfaces. The truncated cone shape of the end parts of the pole increases further, but not too much, the magnitude of the unopposed rocking of the adjacent drums, and it is a feature included in the design after a proposal of Dr. Costas Zambas, civil engineer, member of the supervisory Committee. 5. Verification of numerical model used for the estimation of the new pole shear resistance The numerical part of the study for the new poles and empolia of the monument was conducted using the commercially available finite element program ABAQUS/Explicit (version 6.9). In order to investigate the efficiency of this software in predicting the shear resistance of the new titanium pole, three shear experiments were simulated (two out of which were identical) for comparison of the numerical predictions with the corresponding experimental results. The experiments are part of five double shear tests performed on titanium tubular specimens at the Laboratory of Strength of Materials of N.T.UA. in March and April of 2000. The tubular specimens were constructed from bars made of the titanium type used in the recent and ongoing restoration projects of ancient monuments in Greece. This material is the commercially pure titanium Grade 2 in accordance with ASTM B265 (for sheets and plates) and B348 (for bars and billets). All five specimens were constructed with external diameter equal 762 Built Heritage 2013 Monitoring Conservation Management to 24.5 mm (Fig.3 left). In the selected for simulation experiments, the internal diameter of the specimens was 22.0 mm (in experiment III and IV) and 20.5 mm (in experiment V). The twin experiments (III and IV) resulted shear force at failure 26.75 kN and 24.75 kN, respectively, whereas the experiment with the thicker tubular specimen (V) 43.25 kN. The simulations of the experiments were carried out in three dimensions, following almost exactly the dimensions of each specimen (Fig.3 right). The material of the specimens was simulated using an elastic-plastic model, which uses the Mises yield surface to define isotropic yielding. The material parameters used in the model are: 105000 MPa modulus of Elasticity, 0.32 Poisson’s ratio, 350 MPa yield strength, and 450 MPa tensile strength. The values for the yield and tensile strength were selected on the bases of the results of experiments carried out in May of 2010 for purposes of the present study. The material of the machine parts was simulated with an elastic model, using the mechanical properties of steal (Ε = 210000 MPa, ν = 0.32). The behaviour in the tangential direction of the interfaces was simulated using a classical friction model with coefficient of friction 0.25. This model was used in conjunction with a model for the interaction normal to the surfaces, which allows when two surfaces are in contact, any pressure to be transmitted between them and, when the surfaces separated, it reduces the contact pressure to zero. The numerical results were very satisfactory. The software was able to produce results very similar to the experimental data both for the ultimate external load and for the shape of failure of the specimens (Fig.3). More specifically, the numerical predictions for the shear force at failure was 25.50 kN regarding the specimens III and IV (when the experimental results were 26.75 kN and 24.75 kN, respectively), and 39.50 kN regarding the specimen V (when the test resulted 43.25 kN). 6. The shear resistance of the new pole For the estimation of the new titanium pole’s resistance to shear load (as a result of sliding of the adjacent drums), a numerical model was created which Fig.3 - Left: The five tubular titanium specimens after tested in double shear; Right: The numerical model of the double shear test (top), and the deformed models of the specimens III/IV and V763 at the instance before failure (bottom) Built Heritage 2013 Monitoring Conservation Management Fig.4 - Left: The pole/empolia numerical model (the pole is visible at right side); Right: Three characteristic shapes of the deformed model (with the movable empolio hidden): a) the pole starts to resist the sliding of the upper (movable) empolio, b) the external load reaches the maximum value, and c) pole fracture is almost complete included a pole and the corresponding pair of empolia. The model followed almost exactly the geometry of the new poles and empolia as presented in Figure 2 (see Fig.4). In the model the upper empolio, upon which the external load was applied perpendicular to one of its lateral surface, was free only to translate along the direction of the load, whereas the other empolio was fixed. The pole was free to move in any direction, inside the cavities of the emplolia. For the simulation of the material of the pole, the same inelastic model and material parameters were used as for the titanium tubular specimens, which were described in the latter paragraph. However, in this simulation the material inelastic model was used in conjunction with a shear failure model that allows for the removal of elements from the mesh (Fig.4 right, c)). The material of the empolia was modeled as elastic. Another similarity to the modeling of the double shear tests was the simulation of the behaviour at the interfaces. The main results of the numerical analysis are the following: i) the pole started to resist the sliding movement when the top empolio (upon which the external load was applied) was displaced by 7 mm, and the pole was fractured when the empolio was displaced by 12 mm (Fig.4 right, a) and b)); these displacement values are less or in the neighbourhood of the displacements of drums observed in the temple columns as the result of earthquakes (which are 10 to 20 mm). ii) Pole failure was initiated when the external applied force reached 28 kN (Fig.4 right, b)), which is within the estimated range of the shear resistance of the temple ancient poles (23 – 36 kN). Thus, the numerical predictions support the main objectives of the design for the new poles and empolia. It is interesting to notice that the same simulation was conducted two more times, with the parameter for the coefficient of friction equal to zero and 0.75. The results were almost identical in every case. This implies that the transfer of forces is dominated by the interlocking of the pole with the empolia, and that the effect of the friction ties is marginal. 7. Numerical investigation of the effect of the new poles in the seismic behaviour of a temple column In order to estimate the effect of the new titanium poles in the rocking response of the temple columns, numerical simulations were conducted, using the F.E. software ABAQUS/Explicit (version 6.9). The efficiency of the code 764 Built Heritage 2013 Monitoring Conservation Management in predicting the seismic response of ancient columns has been verified in a previous comprehensive effort conducted by a team of researchers at the National Technical University of Athens [Dasiou et. al., 2009]. More specifically, a 3-dimentional model of the 3rd from the east column of the north side of the Bassai temple (column KB3) was created. The column, which is 5.97 m high, has six drums and capital, and its base diameter is equal to 1.16 m, was simulated free-standing, in vertical position, and with its base block. Three models of the column were created. In the first the column had no poles. In the second model a titanium pole was included at the upper drum – capital interface of the column (as it was the plan for the next step of the temple restoration). The third model had a pole at every column interface (so, in total, it had six poles). Aiming to reduce the computational cost, no empolia were included in the models, and the poles were inserted into holes on the surfaces of the column drums. The discretization took place using 8-nodes hexahedra elements. The material of the poles was simulated using the inelastic model and material parameters described in paragraph 5 and 6. The limestone of the column and its base was modeled as elastic on the bases of the (known from experiments) properties of the temple building material. In the tangential direction of the interfaces a classical friction model was used, with friction coefficient of 0.75, based also on experimental invistigation for the temple material. For the interactive behaviour of the model members normal to their interfaces the ‘hard’ contact model was used, which is described in paragraph 5. The models, loaded by their own weight, were seismically excited using three records with different characteristics, suitable scaled to reach the highest magnitude levels of anticipated earthquakes in the area of the monument. The seismic records are the following: (a) The Griva earthquake, December 21st 1990 (Magnitude MS = 5.9). The accelerogram used in the study was recorded in Edessa, and it shows an almost sinusoidal motion with a period of about 0.6 sec, and has PGA = 0.10g, PGV = 10.9 cm/sec and PGD = 1.1 cm. (b) The Aigion earthquake, June 15th 1995 (Magnitude MS = 6.2). Its accelerogram is dominated by a 0.5 sec period pulse of approximately 0.5g amplitude (PGV = 48.1 cm/sec and PGD = 6.7 cm). (c) The Athens earthquake, September 7th 1999 (Magnitude MS = 5.9). The accelerogram used in the study was recorded on the one-story RC building of K.E.D.E. The record presents PGA = 0.30g, PGV = 16.1 cm/sec and PGD = 2.1 cm, and a period of about 0.20 sec. The scaling factors of the records were 4.0, 1.0 and 3.0, respectively, leading to peak velocity excitation for the column base of 43.6, 48.1 and 48.3 cm/sec. In Figure 5 the main results of the rocking response of the column models are presented. It is obvious that the presence of pole at the upper drums interface led to small limitation of the maximum and residual deformations of the column model, whereas the existence of pole at every drums interface had similar effect, but with significant limitation at the column residual deformations. Moreover, the rocking response of the column is more or less similar in every case. The delay in the damping of the column oscillations in the models with the pole/es in respect to the behaviour of the model without any pole (more obvious in the analyses with the Aigion seismic record), is attributed to the re765 Built Heritage 2013 Monitoring Conservation Management Fig.5 - The main numerical results, concerning the rocking response of the three column models in their longitudinal direction duction of the dissipation of energy at the drums interfaces, which is due to the presence of the poles and the consequent diminishing of the drums impacts and slips; in other words this result is the side-effect of the limitation on the residual deformations which the poles impose at the column models. 8. Concluding remarks As a result of this study, during 2012, new poles and empolia made of titanium were installed at the upper interfaces in five columns at the north side of Apollo Epikourios temple. As the design of the new titanium connectors is based on characteristics of ancient elements of typical shape and dimensions, it is believed that the new connectors can be used, with only minor adjustments, for restitution of the missing, or replacement of the preserved, poles and empolia and in other restoration projects of ancient monuments. Acknowledgments The authors gratefully acknowledge the contribution of the engineers, technicians and masons who participated in the preparation and materialization of the experiments presented in this paper. The first author is grateful to the President and Members of the Committee for the Preservation of Apollo Epikourios temple, and in particular to Dr. Costas Zambas, for their valuable suggestions and warm encouragement. References Dasiou M.E., Psycharis I.N., Vayas I., 2009, Verification of numerical models used for the analysis of ancient temples, in Protection of Historical Buildings, 1269-1274. Papadopoulos K., 2009, The restoration of the north façade of the temple of Apollo Epikourios, in Protection of Historical Buildings, 971-976. 766