Sustainable and reliable robotics for part handling in manufacturing

advertisement

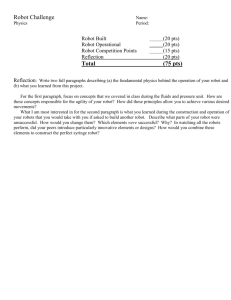

alborg Universitet, Denmark – – – – role: R&D, technology transfer mission instruction, planning and control industrial manipulation visual perception for quality control lberts-Ludwig Universität, Germany – role: R&D, technology transfer – life-long navigation – precise local navigation and fast docking WWW.STAMINA-ROBOT.EU LR, Germany Sustainable and reliable robotics for part handling in manufacturing automation – role: R&D, technology transfer – 3D modelling and object/obstacle recognition – manipulation: picking and placing of load carriers and parts TAPAS Proposal – 3 November 2009 27 OVERVIEW WHY? Motivation of the Proposal! • WHAT? Objectives of the Proposal! • HOW? Activities! • WHO? Partners! • Conclusions • WHY? Motivation of the Proposal • STAMINA : building the Factory of the Future with the help of new robotics technologies! • Find profitable solutions to increase the competitiveness of EU! • Increase the flexibility of production facilities to face:! • Ever increasing customisation of products! • Production volumes variations! • Address ageing workforce issues and occupational diseases! • Allow the deployment of workers to tasks of greater interest and value added for the customer Synchronization of referenced parts Transfer parts to the production line Kitting operations Transfer parts to the production The challenge •Unload heavy parts from a bulk-storage or palette ! •Feed the isolated part in the proper position and orientation! •7 seconds / part The benefits •Ergonomics : 4000 parts / shift (up to 20 tons)! •Cost-effective : 75% of the price of installations on feeders! •Deployment : 215 applications with bulkstored parts identified Synchronization of referenced parts The challenge •Reorder parts according to production request! •Fragile parts (7kg) can only be grasped by specific zones! •9 different parts in different storage conditions! •3 min to prepare 20 parts The benefits •Ergonomics : 12 tons / shift! •Quality (conformity, traceability)! •Deployment : every plant Kitting operations Definition : Process in which individually separate but related items are grouped, packaged, and supplied together to the production line The challenge •Gather a selection of parts and place it on a carrier! •Diversity of parts (shape, flexibility, colour)! •Different storage conditions in a wide area! The benefits •60 sec to prepare a full kit •Flexibility to production changes! •Quality (traceability)! •Deployment : 99% of vehicle parts are delivered in kits (goal) TECHNOLOGICAL CHALLENGES Bin picking, de-palletising, kitting and part feeding! • Object recognition and Grasping capabilities! • Safe navigation among humans! • Cooperation with fleet of mobile robots and/or manual forklifts! • Control through the ERP System! • Easy programmable by humans! • Compliance with safety regulations • TECHNOLOGICAL CHALLENGES ! • Sustainability: ! • easy adaptability to new tasks and missions! • able to automatically compensate for limited variability ! • programmable even by shop-floor workers! • Complies with safety requirements as far as possible WHAT? Objectives of the Proposal Solve the above three use-cases with a mobile robot such that the robot has the following set if skills ! 1.able to navigate safely! 2.able to bin-pick within the given use-cases! 3.able to place parts + inspect part! 4.able to communicate with other robots! 5.do all this in a safe way The Solutions are Reliable and Sustainable ! 1.works in all three use-cases! 2.only minor re-programming efforts! 3.with parameters provided by human / MES system Advanced Human Robot Interface ! 1.normal shop-floor workers! 2.MES system of the company can interface with the robot! 3.safety requirements are assured by the HRI The System Complies as much as Possible with the Safety Requirements ! 1.Proactive work on safety measures by choosing right HW, sensors! 2.Provide input to revision of industrial requirements for use of mobile, cooperative robots! 3.Risk analysis across all test-sprints HOW? 1. AVAILABLE ROBOT TYPES Robm@rket, based on Artemis AGV, BA-Systémes! • ROBY, BA-Systémes! • Little Helper Robot, AAU --> Skill concept, HRI • 2. LEAN DEVELOPMENT R&D 3 3 Validation Implementation Testing at End-user Site 2 0 2 4 1 3 2 4 1 2 4 1 1 5 Knowledge Transfer M10 M21 M31 M41 M42 Regular test-sprints will assure constant ! • focus, ! • fast identification of safety issues and fast accommodation of user feedback! • Tests under realistic conditions! • direct technical feedback • Review, Feedback University/Lab Integration&Developmet UBO - Bin Picking! • • ALU-FR - Navigation! • INESC - Fleet-control! UEDIN - Planning! • •AAU - Skills, HRI, part-feeding, • • • inspection! ! Provide code that ! is state-of-art! runs under lab conditions! works on the use-case objects • BAS - Integration! ! Provide ! • prepare code to run under use-case conditions! • prepare the hardware for usecase conditions.! • documentation, quality control! safety ! • testing • Review, Feedback Shop Floor • PSA - Experiments! ! Provide ! use-case scenario! • • optimize code under use-case conditions! • optimize hardware for usecase conditions.! • documentation, quality control! safety ! • testing! • user-testing • Review, Feedback WP1: Integration, testing, Use case-definition, validation and evaluation! ! T1.1 T1.2 T1.3 T1.4 Direct implementation only for the M10 experiments WP2: Robot Control ! T2.1 Feedback from the experiments T2.2 T2.3 T2.4 T2.5 Skill Concept, & Architecture WP3: Skills for differentiated robot fleets T3.1 T3.2 T3.3 T3.4 WP4: Mission tasks and vertical enterprise integration T4.1 T4.2 T3.3 T4.4 • • • Implementation input: ! Code works in lab space! on parts! embedded in skills WP1 INTEGRATION, TESTING, USE CASE-DEFINITION, VALIDATION AND EVALUATION definition of the targeted use-cases ! • hardware requirements! • define user requirements and performance and usability criteria ! • allow incremental integration of hardware and software designed in WP2-4 ! • conduct iterative test cycles for evaluation and feedback to R&D partners! • assure safety proactively where possible, and derive new solutions where necessary, together with WP2-4! • carry out a safety risk assessment with associated risk reduction measures • WP2: ROBOT CONTROL Provides the “low-level” capabilities of the STAMINA-Robot! • Localization and Mapping! • Robot Navigation! • Picking! • Single Part Feeding and Inspection! • Inter-robot coordination and communication! • Safety criteria are provided by WP1 and are considered within each sub-task.! ! Success-criteria: Provided code runs under lab-simulated use-cases settings while taking into account the requirements provided by WP1.! -ICT-2013-10 7/2012 v1 STREP proposal STAMINA WP3: SKILLS FOR DIFFERENTIATED ROBOT FLEETS h skill is defined by a Precondition check, by a Prediction, and by an Evaluation (see Figure 7). The cution contains the robot control (motion primitives) On the robot: check is meant to assert the m WP2. The precondition essful execution a robot control (WP2). E.g. forof robot • defines “skillofAPI” to supports integration ing, the object from must WP2! be reachable. If the precondition controls k evaluates to true, the skill may be executed. After • the set checks of necessary skills required e.g., to ution,identify the evaluation if all was successful, complete common e object is in thethe gripper of the missions! robot. Precondition WP 2 code k and evaluation evaluate vector,robot whichcontrols is • actually integrate thestate different from posedWP2 of task state world-state into theinformation, skill structure! rmation and robot state information. Sensory devices • implement task-planner that controls skills! used to compute the state vector. Figure 7 depicts a skill [Bøgh et al.2012]. It • define HRI based on touch pad and possibly othercontains the Preconditions that assert correct example, imagining the kitting use-case 2.3: the robot execution given the present task state, the modalities is to fill the kit with different parts that need to be Evaluation evaluates if the skill execution was hed from different pallets. For picking a part, the robot successful, the function block for the physical Execution, and the Prediction is given by the o be close enough before the pick-skill can be expected outcome. The gray parts are necessary uted. If the robot is not close enough the navigation for planning. has to be executed to bring the robot closer to the Which skill to execute is ideally up to the decision of WP4: MISSION PLANNER AND VERTICAL ENTERPRISE INTEGRATION Mission Planner Skills Robot Task Planner Enterprise Not on the robot: • specify API between MES system and mission-planning subsystem! • integration mechanisms with MES systems! • provide the software level integration to support communication between MES and mission planner! • define and implement the mission planning subsystem MES WP5: KNOWLEDGE TRANSFER, DISSEMINATION AND EXPLOITATION • Academic Partner: • public dissemination! • conferences, workshops! • fairs! • journal publications! ! • Industrial Partners: • exhibitions, fairs (Automatica, Hannover industrual fair, etc)! • shop-floor of PSA show-case to partners (e.g. EADS) and suppliers (manufacturing and product parts)! ! use of the stamina robot at the PSA plants! • BAS: building and selling advanced AGVs • WHO? Partners and Roles Aalborg University, Denmark (Coordinator) coordinator, project administration, research! •part-feeding and inspection! •robot skills concept PSA Peugeot Citröen, France: system integrator, end-user! •application development! •testing and validation! •use-case definition, definition of benchmarks, ! •safety BA Systémes, France: technology provider, system integrator ! •robot and application development, safety; ! •testing and validation! •safety – mission instruction, planning and control – industrial manipulation – visual perception for quality control University of Freiburg,Universität, Germany Germany • Alberts-Ludwig •mapping!– role: R&D, technology transfer •localization! – life-long navigation in dynamic environments •robust navigation – precise local navigation and fast docking University Bonn, Germany • DLR,ofGermany •Bin-picking – role: R&D, technology transfer – 3D modelling and object/obstacle recognition INESC-Porto, Portugal – manipulation: picking and placing of load coordination and cooperative mapping, ! carriers and parts •multi robot •ERP integration, Network interfaces TAPAS Proposal – 3 November 2009 University of Edinburgh, UK •task planning, execution monitoring of robot task plans, ! •fleet-level/mission planning 27 CONCLUSIONS • Key objective • build a robot system that is equipped with capabilities to handle a set of logistic tasks while assuring that the system is sustainable:! • it is NOT overspecialised! • it is easily adaptable to new scenarios ! ! • 3 use-cases are used to achieve that: • kitting • bin-picking • de-palletizing