Consumer Durables Industry In India

advertisement

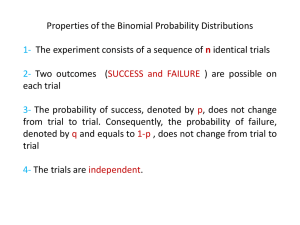

A BRIEF REPORT ON CONSUMER DURABLES INDUSTRY IN INDIA July, 2015 For more information, contact: sateesh.kulkarni@asa.in A brief report on Consumer Durable Industry in India 1. OVERVIEW OF CONSUMER DURABLES MARKET 1.1 Overview Share in the consumer durables market in India (FY15) India is expected to become the fifth largest consumer durables market in the world by 2025. The consumer electronics market is expected to increase to USD 400 billion by 2020. The production is expected to reach USD 104 billion by 2016.The sector is expected to double at 14.7 per cent compound annual growth rate (CAGR) to USD 12.5 billion in FY15 from USD 6.3 billion in FY10. Rural, 35% Urban, 65% Urban markets account for the major share (65 per cent) of total revenues in the consumer durables sector in the country. Demand in urban markets is expected to increase for non-essential products such as LED TVs, laptops, split ACs and, beauty and wellness products. In rural markets, durables like refrigerators as well as consumer electronic goods are likely to witness growing demand in the coming years as the government plans to invest significantly in rural electrification. The Government of India has increased liberalisation which has favoured foreign direct investments (FDI). Also, policies such as National Electronics Mission and digitisation of television and setting up of Electronic Hardware Technology Parks (EHTPs) is expected to boost the growth of this sector. Size of Consumer Durable Market in India (Figures in USD billion) 14 12 10 8 6 4 2 0 12.5 3.8 4.2 4.7 5.2 FY06 FY07 FY08 FY09 6.3 FY10 7.3 7.3 FY11 FY12 2015E * Latest data as available The consumer durables market is anticipated to expand at a CAGR of 14.8 per cent to USD 12.5 billion in FY15. Also, the demand from rural and semi-urban areas is projected to expand at a CAGR of 25 per cent to USD 6.4 billion in FY15, with rural and semi-urban markets likely contributing majorly to consumer durables sales. Private & Confidential Page 2 of 9 A brief report on Consumer Durable Industry in India 1.2 Key Categories The Indian Consumer Durables segment can be segmented into three groups: White Goods Categories Brown Good Consumer Electronics White goods · Air conditioners · Refrigerators · Washing Machines · Sewing Machines · Watches and clocks · Cleaning equipment · Other domestic appliances Brown goods · Microwave Ovens · Cooking Range · Chimneys · Mixers · Grinders · Electronic fans · Irons Consumer electronics · TVs · Audio and video systems · Electronic accessories · PCs · Mobile phones · Digital cameras · DVDs · Camcorders Brown goods 1.3 This is a highly penetrated market Electric fans are an essential utility for more than six months of the year in most parts of the country Market Share by Segments (Electronics) 1400 1305 1200 1000 735 800 618 600 435 400 200 0 262 223231 257 37 47 68 2009 Private & Confidential 514 87 74 77 2013 Washing Machine 101 81 86 2014 Refrigerator 122 87 96 140 108 93 2015E 2016E 2020E Air Conditioner Televisions Page 3 of 9 A brief report on Consumer Durable Industry in India 2. MAJOR PLAYERS 1.4 Samsung India Samsung India commenced its operations in India in December 1995, today enjoys a sales turnover of over USD 1 billion in just a decade of operations in the country. Samsung design centres are located in London, Los Angeles, San Francisco, Tokyo, Shanghai and Romen. Samsung India has its headquartered in New Delhi and has a network of 19 Branch Offices located all over the country. The Samsung manufacturing complex housing manufacturing facilities for Colour Televisions, Colour Monitors, Refrigerators and Washing Machines is located at Noida, near Delhi. Samsung ‘Made in India’ products like Colour Televisions, Colour Monitors and Refrigerators are being exported to Middle East, CIS and SAARC countries from its Noida manufacturing complex. Samsung India currently employs over 1600 employees, with around 18% of its employees working in Research & Development. 1.5 Whirlpool India Whirlpool was established in 1911 as first commercial manufacturer of motorized washers to the current market position of being world's number one manufacturer and marketer of major home appliances. The parent company is headquartered at Benton Harbor, Michigan, USA with a global presence in over 170 countries and manufacturing operation in 13 countries with 11 major brand names such as Whirlpool, KitchenAid, Roper, Estate, Bauknecht, Laden and Ignis. Today, Whirlpool is the most recognized brand in home appliances in India and holds a market share of over 25 per cent. The company owns three state-of-the-art manufacturing facilities at Faridabad, Pondicherry and Pune. 1.6 LG India LG Electronics was established on October 1, 1958 (As a private Company) and in 1959, LGE started manufacturing radios, operating 77 subsidiaries around the world with over 72,000 employees worldwide it is one of the major giants in the consumer durable domain worldwide. The company has as many as 27 R & D centers and 5 design centers. Its global leading products include residential air conditioners, DVD players, CDMA handsets, home theatre systems and optical storage systems. 1.7 Godrej India Godrej India was established in 1897. The company was incorporated with limited liability on March 3, 1932, under the Indian Companies Act, 1913. The Company is one of the largest privately-held diversified industrial corporations in India. The Company has a network of 38 Company-owned Retail Stores, more than 2,200 wholesale dealers, and more than 18,000 retail outlets. The company has Representative Offices in Sharjah (UAE), Nairobi (Kenya), Colombo (Sri Lanka), Riyadh (Saudi Arabia) and Guangzhou (China-PRC). Private & Confidential Page 4 of 9 A brief report on Consumer Durable Industry in India 1.8 Sony India Sony Corporation, Japan, established its India operations in November 1994. In India, Sony has its distribution network comprising of over 7000 channel partners, 215 Sony World and Sony Exclusive outlets and 21 direct branch locations. The company also has presence across the country with 21 company owned and 172 authorized service centres. 1.9 Hitachi India Hitachi India Ltd (HIL) was established in June 1998 and engaged in marketing and sells a wide range of products ranging from Power and Industrial Systems, Industrial Components & Equipment, Air Conditioning & Refrigeration Equipment to International Procurement of software, materials and components. Some of HIL’s product range includes Semiconductors and Display Components. It also supports the sale of Plasma TVs, LCD TVs, LCD Projectors, Smart Boards and DVD Camcorders. Private & Confidential Page 5 of 9 A brief report on Consumer Durable Industry in India 2. GOVERNMENT INITIATIVES 2.1 Government Initiatives The Indian Government is majorly concerned about the development of rural markets and hence, keeps introducing policies and initiatives to encourage their growth. In a bid to make economic development inclusive, the Indian Government has initiated many schemes and programs that aim at improving the standard of living in India villages or rural areas. For instance, the Government launched a time-bound business plan for action called Bharat Nirman for enhancing the infrastructure in hinterlands. Under this program, action is proposed in the areas of Water Supply, Housing, Telecommunication and Information Technology, Roads, Electrification and Irrigation. The other initiatives are: National Policy on Electronics (NPE) 2012 was launched with an objective to transform India into a global hub for Electronic System Design and Manufacturing (ESDM) and to expand the manufacturing base of electronic products in India. Key goals for 2020 are to attract investment of USD 100 billion, enhance exports to USD 80 billion, achieve a turnover of USD 400 billion and create employment of around 28 million As per Foreign Trade Policy (2015-2020), the Focus Product Scheme, Market Linked Focus Product Scheme and Focus Market Scheme are now under a single MEIS scheme. Export of notified goods (includes Ac parts and compressors, refrigerating equipment compressors, fully automatic washing machines and color TV) and Asia-Oceania block) will be payable as percentage of realized FOB value (in free foreign exchange). Moreover, there will be a provision for higher level of rewards under MEIS scheme for export items with high domestic content and value addition. According to the Modifies Special Incentives Package Scheme (MSIPS) the government will reimburse certain taxes and duties for 10 years, amounting to 20% (SEZs) to 25% (non-SEZs) of capital investment. However, white goods are not covered in this scheme and are in the draft MSIPS document. Zero duty EPCG scheme allows import of capital goods for pre-production, production and post-production (including CKD/SKD thereof as well as computer software systems) at zero Customs duty. As per the Foreign Trade Policy 2015-20 the specific export obligation under EPCG scheme where capital goods are procured from indigenous manufacturers has been reduced to 75% from 90% in order to promote domestic capital goods manufacturing industry. An Electronics development fund of USD 2 billion has been created to promote innovation, intellectual property creation, product commercialization etc. Private & Confidential Page 6 of 9 A brief report on Consumer Durable Industry in India 3. CHALLENGES, OPPORTUNITIES & FUTURE PROSPECTS 3.1 Challenges and Opportunities The consumer durables sector in India is one that will be passing through some very interesting times. On the one hand there is substantial scope for expansion as the favourable demographics of India are a positive for the sector. On the other hand there are many factors which pose as a challenge to this industry, some of these challenges are: Tax and duty structure: India’s taxation system is unusually complex, especially where indirect taxes are concerned. While income tax, excise and customs duty are set by the Central Government, states and municipalities also levy their own taxes. Limited scale and quality: Most of the suppliers of raw material and components in India do not have the scale to cater to the substantial demand in the industry, making them less cost competitive as compared to imports. Moreover, the quality of inputs is not as competitive to Chinese or other SE Asian counterparts. This has led various global majors to scale down operations in the country. Increasing competition: Indian manufacturers face strong competition from Chinese and other SE Asian counterparts which have a huge supply base and installed capacities. Moreover, China government provides numerous subsidies for manufacturing unit development which the Indian government is unable to match. Capital intensive nature of business: Cost of production in India is higher as compared to China and other SE Asian countries due to high finance costs. Moreover, given the frequently changing energy efficient norms manufacturers will need to invest substantial amounts for products with high rating. The cost of capital at 12%–14% is much higher than the global average of 5%–7%. Infrastructure Deficiency: India’s spend on infrastructure was only 7.2% of its GDP in 2012. The basic infrastructure for any industry comprises good roads, power, water, telecommunications, finance, raw materials, components, and logistics. In India, these facilities are not up to the mark even in established industrial estates. Domestic markets are growing at a brisk pace with continued dependence on imports. About 30-35% electronic components required for local equipment manufacturing are available from domestic sources. For semiconductors, there is almost 100% dependence on imports. Private & Confidential Page 7 of 9 A brief report on Consumer Durable Industry in India 3.2 Inverted Duties due to dual use of Inputs such as Plastics, Copper, Aluminum, etc continue to plague hardware manufacturers. Specific items are covered under Customs Notification 25/99, although the procedure for claiming this benefit is extremely convoluted and time taking. Domestic Taxes and Levies impose Fiscal Disabilities with very high indirect taxes Cascading impact of CST on components detrimental for finished products manufacturing High cost of Finance, Power and Logistics/ Regulatory and Procedural problems add to disabilities estimated at 7-8%. This discourages capital intensive, high value add investments in manufacture of components / parts which require high and long term investments necessitating a supportive fiscal and infrastructural environment. SWOT Analysis 3.2.1 Strengths Presence of established distribution networks in both urban and rural areas Presence of well-known brands In recent years, organized sector has increased its share in the market vis a vis the unorganized sector. 3.2.2 Weaknesses Demand is seasonal and is high during festive season Demand is dependent on good monsoons Poor government spending on infrastructure Low purchasing power of consumers 3.2.3 Opportunities In India, the penetration level of white goods is lower as compared to other developing countries. Unexploited rural market Rapid urbanization Increase in income levels, i.e. increase in purchasing power of consumers Easy availability of finance 3.2.4 Threats Higher import duties on raw materials imposed Cheap imports from Singapore, China and other Asian countries 3.3 Future Prospects India is emerging as the third largest internet market and its e-commerce business is likely to touch Rs 40 billion (USD 742.76 million) in 2015 against Rs 12 billion (USD 222.83 million) at present. Also, with mobiles becoming a major medium for advertising and content delivery, every three out of four users in the country are expected to access the net through a mobile phone by 2015. During 2012-22, cumulatively around USD 500 billion of ad spend is expected to happen on mobile phones, according to industry estimates. Private & Confidential Page 8 of 9 A brief report on Consumer Durable Industry in India Moreover, companies in the last decade have positioned tea and coffee as recreational products, which have majorly attracted younger population. Growing at a compounded annual growth rate (CAGR) of 20 per cent, it is expected to touch Rs 330 billion (USD 6.13 billion) by 2015 from the current level of Rs 195 billion (USD 3.62 billion) (in 2011). Domestic coffee outlets, which have a lot of appeal for the new generation, are set to double over 2012-15, majorly driven by the foray of global players such Starbucks and Dunkin’ Donuts in India. Private & Confidential Page 9 of 9