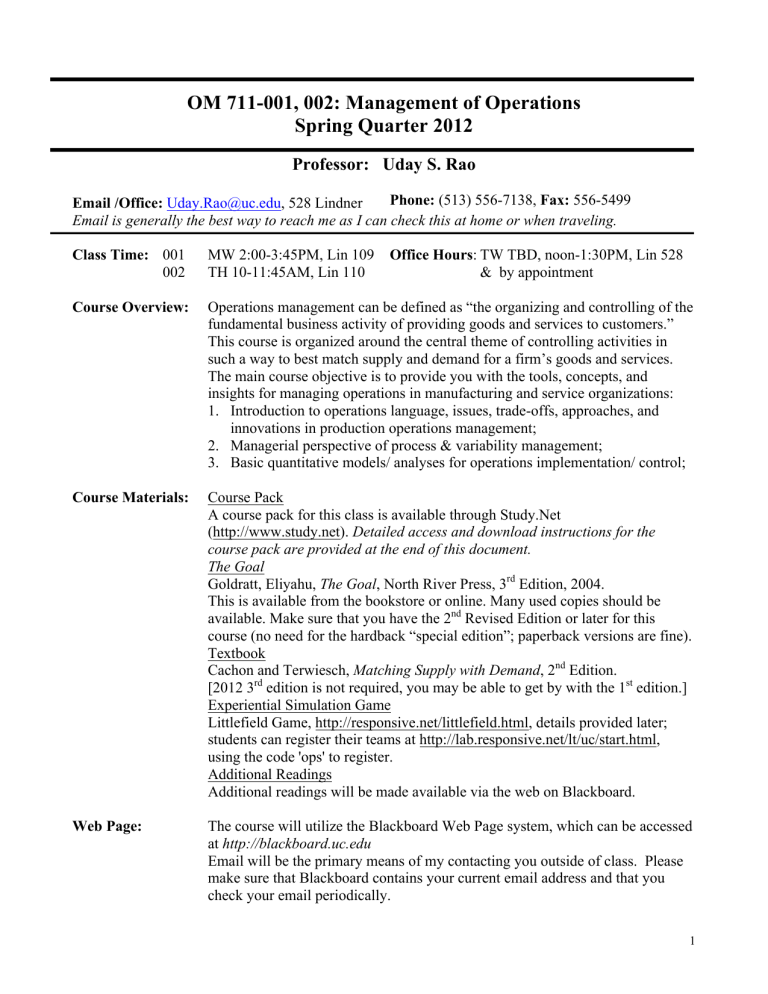

OM 711-001, 002: Management of Operations Spring Quarter 2012

OM 711-001, 002: Management of Operations

Spring Quarter 2012

Professor: Uday S. Rao

Email /Office: Uday.Rao@uc.edu

, 528 Lindner Phone: (513) 556-7138, Fax: 556-5499

Email is generally the best way to reach me as I can check this at home or when traveling.

Class Time: 001 MW 2:00-3:45PM, Lin 109

002 TH 10-11:45AM, Lin 110

Office Hours : TW TBD, noon-1:30PM, Lin 528

& by appointment

Course Overview: Operations management can be defined as “the organizing and controlling of the fundamental business activity of providing goods and services to customers.”

This course is organized around the central theme of controlling activities in such a way to best match supply and demand for a firm’s goods and services.

The main course objective is to provide you with the tools, concepts, and insights for managing operations in manufacturing and service organizations:

1.

Introduction to operations language, issues, trade-offs, approaches, and innovations in production operations management;

2.

Managerial perspective of process & variability management;

3.

Basic quantitative models/ analyses for operations implementation/ control;

Course Materials: Course Pack

A course pack for this class is available through Study.Net

(http://www.study.net). Detailed access and download instructions for the course pack are provided at the end of this document.

The Goal

Goldratt, Eliyahu, The Goal , North River Press, 3 rd Edition, 2004.

This is available from the bookstore or online. Many used copies should be available. Make sure that you have the 2 nd Revised Edition or later for this course (no need for the hardback “special edition”; paperback versions are fine).

Textbook

Cachon and Terwiesch, Matching Supply with Demand , 2 nd Edition.

[2012 3 rd edition is not required, you may be able to get by with the 1 st edition.]

Experiential Simulation Game

Littlefield Game, http://responsive.net/littlefield.html, details provided later; students can register their teams at http://lab.responsive.net/lt/uc/start.html, using the code 'ops' to register.

Additional Readings

Additional readings will be made available via the web on Blackboard.

Web Page: The course will utilize the Blackboard Web Page system, which can be accessed at http://blackboard.uc.edu

Email will be the primary means of my contacting you outside of class. Please make sure that Blackboard contains your current email address and that you check your email periodically.

1

Blackboard will also be used as a repository for materials used in class and for posting homework assignments . Please check the Blackboard web site regularly.

Course Method: This class will be a mix of lectures, case discussions, and hands-on (or experiential) exercises. Case studies/ readings will be heavily emphasized and active discussion is expected.

You are expected to come to class fully prepared and willing to participate in class discussions. Prepared means that you have read the assignments, familiarized yourself with the presented theory from the previous class, given thought to the problems presented in the readings, considered how these problems could be addressed using applications of the theory presented in this class, and completed any assigned write-ups or problems. Your willingness and ability to contribute to class discussion and ask meaningful questions will be included in your class participation grade.

Cases

Case write-ups in this course generally include the opportunity, and expectation, for quantitative analysis and a problem solving methodology. Your case writeups should be carefully thought out and your recommendations/ conclusions should be supported by analysis. Additionally, you will be graded on the clarity of your writing and overall presentation. Cases may be completed in groups of no more than 4 students. I will post questions to guide your analysis on

Blackboard. You should be able to complete your write-ups in four pages or less (minimum 11 point font, 1.5 line spacing, 1 inch margins), but you can also include a technical appendix that contains calculations, additional figures, etc.

Note: Several of the cases in this class are somewhat challenging and you should set aside sufficient time to fully analyze these cases.

Practice Problems

In addition to case write-ups, I will occasionally assign quantitative practice problems. The problems will not be graded , but you are STRONGLY

ENCOURAGED to work on these problems, as they will help you prepare for cases and the exams. You can work on these practice problems in groups, I will post solutions and sometimes go over solutions in class. You will do much better in this class if you complete the practice problems! Failure to complete practice problems is a good method for ensuring poor course performance.

Exams

There will be two in-class exams: Exam I in week 5 and Exam II in week 10.

Goal Bonus Study Questions

Study questions designed to help your reading and comprehension of the book

The Goal are posted on Blackboard. There are two sets of these questions. You can turn in written answers to the bolded questions for extra credit. Each set of questions is worth up-to 5 bonus points, which will be added to your Exam II raw score. Note that even if you do not turn in written answers to these questions, you are still required to read The Goal and be prepared to discuss the

2

reading in class. The Study Questions will help you prepare for our discussions whether or not you provide written answers.

Grading Policy: Case Write-Ups

Littlefield Game

Exam I

30%

10% 5-20%*

20% 15-25%*

Exam II

Class Participation

25% 10-35%*

15%

*Students may pick their own grading % for Littlefield, Exam I, and Exam II within the specified ranges for a total of 55% of grade , e.g. Littlefield 20%, Exam I 15%, implying Exam II 20%.

Class

Participation: Class participation includes being present, fully prepared and participating in class discussions. In particular, I expect active discussions during our case analysis classes, but I will also occasionally ask questions and expect feedback throughout this course. A portion of class participation will be based on group evaluation (for team-based work).

Academic

Dishonesty: Cases of academic dishonesty are taken very seriously and may result in a failing grade as well as being reported to the college. For a discussion of what constitutes academic dishonesty at the University of Cincinnati please see http://www.uc.edu/ucinfo/conduct.html

. Be especially aware that plagiarism and the use of past case write-ups constitute academic dishonesty.

Special Needs Policy:

If you have any special needs related to your participation in this course, including identified visual impairment, hearing impairment, physical impairment, communication disorder, and/or specific learning disability that may influence your performance in this course, you should meet with the instructor to arrange for reasonable provisions to ensure an equitable opportunity to meet all the requirements of this course. At the discretion of the instructor, some accommodations may require prior approval by Disability Services.

Computer Usage: The use of computer programs, specifically Microsoft Excel and internet access, will be required for this course. You are encouraged to make sure that you have access to these, either through the university or your own computer, and to familiarize yourself with the basics of Excel. Use of computers in class should be restricted to class work.

Cell Phones: Out of respect for your fellow classmates, I ask that you please turn off (or put on vibrate) all cell phones while you are in class.

Other Interesting Readings on OM Topics:

The Machine that Changed the Wo rld, James Womack, et al., 1991.

It’s Not Luck , Eliyahu Goldratt, 1994. Clockspeed , Charles H. Fine, 1998.

The Toyota Way , Jeffrey K. Liker, 2004. The World is Flat , Thomas Friedman, 2005.

The Resilient Enterprise , Yossi Sheffi, 2005. The Wal-Mart Effect , Charles Fishman, 2006.

The Economic Naturalist , Robert H. Frank, 2007.

3

Nudge , Richard H. Thaler and Cass R. Sunstein, 2009.

Tentative Course Schedule:

Class Date

001 (002)

1.a 3/26 (3/27)

1.b 3/28 (3/29)

2.a

Topic

OM Intro

Process Analysis

4/2 (4/3) HBS: National Cranberry Case

Labor Costs

Text Reading

2 nd Edition

Chapters 1, 2

Chapter 3

Chapter 4

2.b

3.a

4/4 (4/5)

4/9 (4/10)

3.b 4/11 (4/12)

Batch Sizes

Variability and Waiting Times

More Variability

Chapter 6

Chapters 7

Chapter 7

4.a 4/16 (4/17)

4.b 4/18 (4/19)

Throughput Losses

HBS: Manzana Case

Chapter 8

5.a 4/23 (4/24)

5.b 4/25 (4/26)

6.a 4/30 (5/1)

6.b

7.a

7.b

5/2 (5/3)

5/7 (5/8)

5/9 (5/10)

May 11?

8.a 5/14 (5/15)

Case

Study/Readings

HBS: National

Cranberry Case

Due

Case Write-Up

Review

1 st Goal Discussion

HBS: Manzana

Case

Case Write-Up

Goal Bonus Study

Questions (1-20)

Exam I

Newsvendor Model

Revenue Management

Return Exams

Risk Pooling

Chapter 11

Chapter 15

Chapter 14 WSJ : GM-Cadillac

Capacity-Constrained

Production

Sport Obermeyer

Case

Case Write-Up

Begin Littlefield Online Game Play (data available May 7)*

8.b 5/16 (5/17)

May 18

9.a 5/21 (5/22)

9.b 5/23 (5/24)

10.a 5/28

Quality

Lean Operations

Chapter 9

Chapter 10

Fast Company :

Toyota

HBR : Fixing

Healthcare …

End Littlefield Game Play -- report due May 23 (24)

2 nd Goal Discussion

Course Review

Goal Bonus Study

Questions (20-40)

Post-Littlefield Debrief,

Exam Review

Littlefield Report

No class, Memorial Day

10.a (5/29)

10.b 5/30 (5/31)

Guest Speaker, TBD

Exam II

This schedule has very little slack so we will need to work regularly to stay on track. Final exam must be on the last day of class or before, instructor is not available over exam week.

*Instructor has chosen to run the experiential learning simulation Littlefield game from among the set of Littlefield, HBS Project Management, Benihana Restaurant Operations, Goldratt OPT game. We will discuss this experiential learning game briefly in the first class of OM711, as there is a fee involved. At the end of this exercise, please provide the instructor feedback on its value.

4

Accessing Your Course Pack Materials at Study.Net

If you have any questions regarding the use of Study.Net, please contact study.net at: e-mail …………………………………………….. customerservice@study.net telephone (Toll-Free) …………………………….. (888) 462-0660 telephone (outside USA) ……………………….… (954) 462-0660

To access your course materials, please follow the steps below:

1.

Go to: http://www.study.net. a) If this is your first time using Study.Net, register as a student to obtain a login and password.

There is a link for student registration on the Study.Net home page. After registration, select your school and course to get started. b) If you have already registered as a Study.Net user, login and click on My Courses . After the page refreshes, click on the link to purchase or access new course material, then select your school and course, 22 OM 711: Management of Operations – Rao (Spring 2012).

2.

To purchase course materials, complete the billing and shipping information and print a receipt for your personal records after your transaction has been processed.

3.

To order a printed version of your online course materials, select this option during the order process.

Make sure that your shipping address is correct. All printed TEXTPAK orders are processed within 48 hours and shipped by USPS Priority Mail for delivery 2-3 days later.

4.

Many of the materials distributed by Study.Net are stored in a PDF file format and protected with a

“digital rights management” application that utilizes Adobe’s eBook Reader.

• To view any protected PDF files you must use version 6.0.1 or higher of Adobe Acrobat

Reader . For best results, we highly recommend using to Version 7.0 if this is possible. Adobe’s eBook Reader must also be activated on your computer to view pdf eBook files. With Adobe

Acrobat Version 7.0, this process is automatic. With older versions of Acrobat, activation instructions will appear automatically on your computer screen, after logging in.

6.

After selecting a material to view, the material will be downloaded to a new browser window that will appear on your computer screen. If you are unable to view a file or activate your eBook Reader because of firewalls or corporate proxy limitations, please contact Study.Net Customer Service, customerservice@study.net.

Accessing the Littlefield Simulation Game

In order to reduce costs (20% saving), the instructor has elected to send payment by check to Responsive Learning

(we will be invoiced based on the number of students, each student will need to pay15$, details available soon).

Students can register their teams at http://lab.responsive.net/lt/uc/start.html, using the code 'ops' to register. [You will need to enter a team name and a password consisting of numbers and lower case letters, no spaces and no punctuations. You will need to enter the names of all members of your team.]

Once the simulator has started, students can access their teams from http://lab.responsive.net/lt/uc/entry.html.

5

Stanford University Graduate School of Business

March 26, 2012

1

Lead Time Management at Littlefield Technologies

Background

In early January, Littlefield opened a new factory to produce DSS receivers. Expert advisors predict demand for this new product will grow at a constant rate over the next four months before stabilizing.

Daily customer demand has a random component, but expected daily demand should follow the predicted trend. Management knows the factory will no longer be required on Day 268 when demand ceases abruptly. Any remaining machinery or inventory on hand after Day 268 will become useless and thus have no residual value.

Management’s main concern is purchasing capacity to serve the predicted demand pattern within contracted lead times. They would like to increase revenue while also minimizing costs. They trust a more responsive factory will increase revenue and they understand a well-balanced inventory policy should help to minimize costs.

Operations Policies at Littlefield

It is now late February, and LT has started to notice lead times are on the rise as demand grows.

Delays, resulting from insufficient capacity or poor inventory management, could undermine LT's contractual lead times and ultimately affect their reputation. Daily data from their first 50-day’s operations is available. It represents the period from early January to late February.

Management has just employed a high-powered operations team (that’s you!) to optimize factory performance. There is only one metric for success: total cash in hand on Day 268. They trust you will be able to whip this factory into shape before it obsolesces. For the next 168 simulated days you will buy or sell machines, determine scheduling priorities, and adjust the inventory policy to maximize their final cash position.

Littlefield’s factory is currently equipped with one stuffing machine, one tester, and one tuning machine. Examination of their production process shows some variability in the time required to fulfill an order. Management has not done any analysis of step-by-step process times but they do record daily average utilization rates at each station. Average Utilization is the fraction of each of each day that machines are processing jobs averaged over the number of machines provided at a station.

1 Based on a document written by Sunil Kumar and Samuel C. Wood, Stanford University Graduate School of Business.

Copyright 2009. No part of this document may be reproduced without permission from Responsive Learning

Technologies, Inc. info@responsive.net

6

Additional machines can be purchased anytime during the assignment. Board stuffing machines cost

$90,000 each, testing machines cost $80,000 each, and tuners cost $100,000 each. Selling machines, while the factory is still operational, will net a salvage value of $10,000—provided at least one machine remains at each station.

You may change the way testing is scheduled at Station 2. Littlefield’s operators have been following a first-in-first-out (fifo) policy, but they will give priority status to either the shorter initial tests (pri2) or the longer final tests (pri4). They just need to know which step is more important.

New customer orders arrive randomly throughout each day. Each order is for 60 new DSS receivers.

Upon arrival, an order is matched with 60 kits to become a job. If an order arrives and there are no kits on hand, that order must wait in a queue of customer orders requiring raw materials inventory. The factory can accommodate no more than 100 jobs in process and/or waiting. Arriving orders in excess of this limit will be turned away.

Littlefield uses an automated Reorder Point and Order Quantity mechanism to replenish inventory.

Fresh kits are purchased from a single supplier at a cost of $10 per kit and a fixed order cost of $1000 per shipment. The supplier is very reliable, delivering the exact order quantity precisely four days after receiving payment. Orders for new inventory are placed only when the following three mutually dependant criteria are all met:

• the inventory of kits is less than or equal to the materials Reorder Point,

• there are no outstanding orders for kits in transit,

• there is sufficient cash on-hand to purchase the specified order quantity.

Inventory reorder points and reorder quantities may be changed by clicking the Edit Data button found on your Materials Buffer pop-up window; you should edit only one parameter at a time. There is no physical holding cost associated with inventory—other than the opportunity cost of the purchase price.

Research has shown Littlefield’s customers will pay premium prices for shorter lead times.

Management has prepared three pricing contracts for you to choose from:

1.

quoted lead time = 7 days; maximum lead time = 14 days; price = $750

2.

quoted lead time = 24 hours; maximum lead time = 72 hours; price = $1000

3.

quoted lead time = 12 hours; maximum lead time = 24 hours; price = $1250

During the first 50 days, management has only accepted jobs under Contract 1. They doubt you will ever be able to deliver 100% on time for the most lucrative contract, but believe it might be worth pursuing.

Contracts are assigned to each order upon arrival. The assigned contract for that order may not be subsequently changed. Contracts can be assigned to future orders by clicking the Edit Data button on your Customer Order pop-up window and selecting from the resulting menu.

7

Littlefield’s lead time pricing contracts have quoted lead times and maximum lead times. Orders filled within the quoted lead time earn full revenue. Orders filled after the quoted lead time incur penalties.

Specifically, pro-rated revenue decreases—at a constant rate—from the quoted price to zero once the stated maximum lead time is surpassed. All orders taking longer than the maximum time are delivered free of charge. For example, consider a contract paying $1,000 per order with a quoted lead time of 24 hours and a maximum lead time 72 hours delivered to the customer 30 hours after the order was placed. That order’s rebate penalty would be…

30 − 24 ℎ 𝑟𝑠 .

72 − 24 ℎ 𝑟𝑠 .

× $1 , 000 𝑝𝑒𝑟 𝑜𝑟𝑑𝑒𝑟 = $125 𝑟𝑒𝑏𝑎𝑡𝑒

...and that order would earn $1 , 000 − $125 = $875

Production began with $100,000 in operating cash and raw materials inventories of 9600 kits. Revenue earned from filled orders increases your cash balance while capital investments and inventory purchases reduce your cash balance. Capacity purchases are never allowed when the resulting cash balance would prevent your next planned inventory order. Cash held earns interest at an annual rate of

10%. There are no taxes, payrolls, nor fixed overhead costs to consider.

Management has obtained a line of credit that will become available on Day 124. Interest compounds daily at an effective annual rate of 20%. A onetime 5% financing fee is deducted from each loan. You can borrow or repay loans by clicking CASH, in the menu bar below the factory schematic, followed by the change debt button.

Littlefield’s factory simulation will run at the rate of one simulated day per real hour for the next seven real days. On simulated Day 218, you will relinquish control of Littlefield’s factory and the simulator will run its final 50 simulated days at an accelerated rate. Management expects that you will leave all factory parameters set to values that maximize their final cash position on simulated Day 268. You may review the final status of your factory and download historic data after the simulation ends, but your factory will no longer be active.

Deliverables

Your team will write a three-page executive summary of the actions taken during your tenure. This report will explain your reasoning for the decisions made and provide a retrospective assessment of their effectiveness. You must show analysis to justify your conclusions and make recommendations that could improve factory performance given similar circumstances.

8