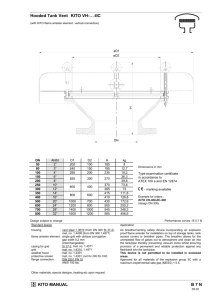

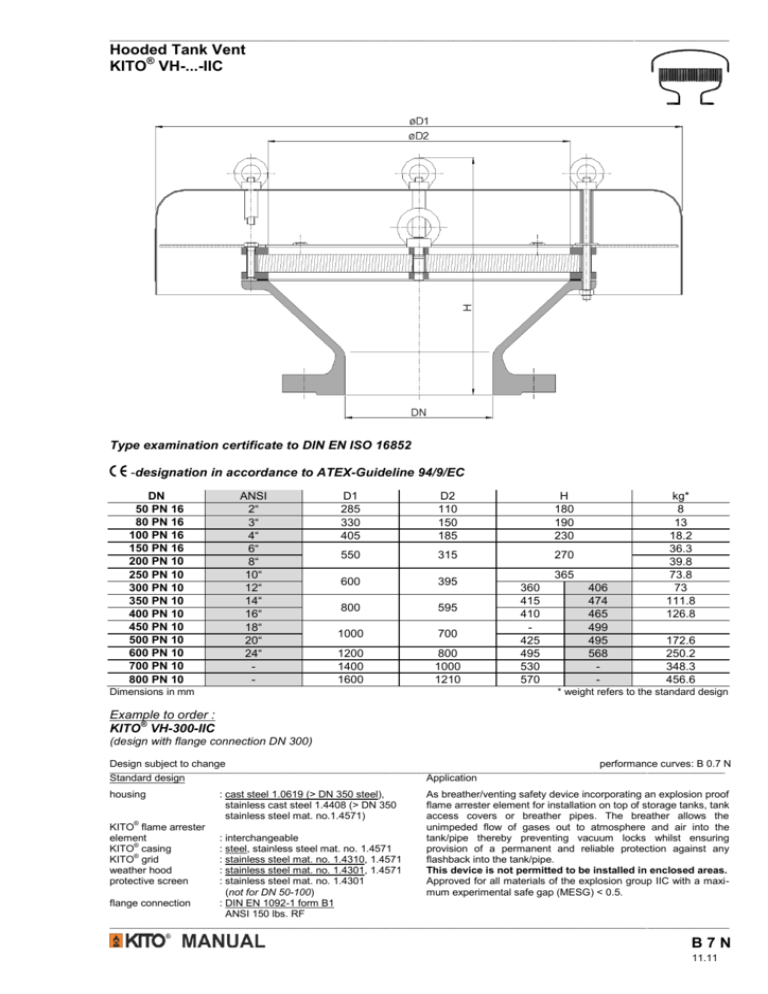

B 7 N Hooded Tank Vent KITO VH-...-IIC

advertisement

__________________________________________________________________________________________________________________________ ______________________ Hooded Tank Vent KITO® VH-...-IIC Type examination certificate to DIN EN ISO 16852 -designation in accordance to ATEX-Guideline 94/9/EC DN 50 PN 16 80 PN 16 100 PN 16 150 PN 16 200 PN 10 250 PN 10 300 PN 10 350 PN 10 400 PN 10 450 PN 10 500 PN 10 600 PN 10 700 PN 10 800 PN 10 ANSI 2“ 3“ 4“ 6“ 8“ 10“ 12“ 14“ 16“ 18“ 20“ 24“ - D1 285 330 405 D2 110 150 185 H 180 190 230 550 315 270 600 395 800 595 1000 700 1200 1400 1600 800 1000 1210 Dimensions in mm 365 360 415 410 425 495 530 570 406 474 465 499 495 568 - kg* 8 13 18.2 36.3 39.8 73.8 73 111.8 126.8 172.6 250.2 348.3 456.6 * weight refers to the standard design Example to order : ® KITO VH-300-IIC (design with flange connection DN 300) Design subject to change performance curves: B 0.7 N _____________________________________________________________________________________________________________________________ __________________ Standard design housing KITO® flame arrester element KITO® casing KITO® grid weather hood protective screen flange connection Application : cast steel 1.0619 (> DN 350 steel), stainless cast steel 1.4408 (> DN 350 stainless steel mat. no.1.4571) : interchangeable : steel, stainless steel mat. no. 1.4571 : stainless steel mat. no. 1.4310, 1.4571 : stainless steel mat. no. 1.4301, 1.4571 : stainless steel mat. no. 1.4301 (not for DN 50-100) : DIN EN 1092-1 form B1 ANSI 150 lbs. RF As breather/venting safety device incorporating an explosion proof flame arrester element for installation on top of storage tanks, tank access covers or breather pipes. The breather allows the unimpeded flow of gases out to atmosphere and air into the tank/pipe thereby preventing vacuum locks whilst ensuring provision of a permanent and reliable protection against any flashback into the tank/pipe. This device is not permitted to be installed in enclosed areas. Approved for all materials of the explosion group IIC with a maximum experimental safe gap (MESG) < 0.5. _____________________________________________________________________________________________________________________________ ___________________ B7N 11.11 _____________________________________________________________________________________________________________________________ ___________________ Hooded Tank Vent KITO® VH-...-IIC B7N _____________________________________________________________________________________________________________________________ ___________________ Flow capacity V based on air of a density ρ = 1.29 kg/m³ at T = 273 K and atmospheric pressure p = 1.013 mbar. For other gases the flow can be approximately calculated by . . V Vb b 1.29 . or . Vb V 1.29 b 1000 DN 800 DN 700 500 DN 600 DN 500 DN 400 DN 350 DN 300 DN 250 DN 200 DN 150 100 /min) 50 . gas flow V (Nm 3 DN 100 DN 80 10 DN 50 5 1 0,5 0,1 1 2 3 4 5 8 10 pressure drop 20 30 40 50 80 100 p (mbar) Design subject to change ________________________________________________________________________________________________________________________________________________ B 0.7 N 11.11