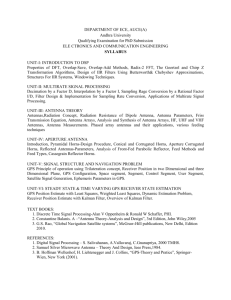

universiti teknologi malaysia

advertisement