Chapter 12 Body electrical system

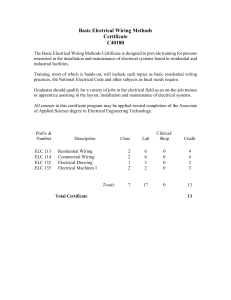

advertisement