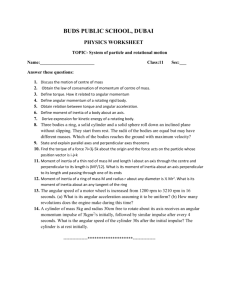

Chapter 3 Mechanical Systems

advertisement

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

Chapter 3

Mechanical Systems

Dr. A.Aziz. Bazoune

3.1 INTRODUCTION

Mathematical Modeling and response analysis of mechanical systems are the subjects

of this chapter.

3.2 MECHANICAL ELEMENTS

Any mechanical system consists of mechanical elements. There are three types of

basic elements in mechanical systems:

¾

¾

¾

Inertia elements

Spring elements

Dampers elements

Inertia Elements. Mass and moment of inertia. Inertia may be

defined as the change in force (torque) required to make a unit change in

acceleration (angular acceleration). That is,

inertia (mass) =

change in force

N

change in acceleration

m/s

inertia (moment of inertia) =

2

or

kg

change in torque

N-m

change in ang. accel.

rad/s

2

or

kg

Spring Elements.

A linear spring is a mechanical element that can

be deformed by external force or torque such that the deformation is directly

proportional to the force or torque applied to the element.

Translational Springs

For translational motion, (Fig 3-1(a)), the force that arises in the spring is

proportional to x and is given by

F = kx

(3-1)

where x is the elongation of the spring and k is a proportionality constant called

the spring constant and has units of [force/displacement]=[N/m] in SI units.

1/34

ME 413 Systems Dynamics & Control

At point

at point

Chapter Three: Mechanical Systems

P , the spring force F

P.

X

P

acts opposite to the direction of the force

f

f

x2

P

Q

f

X+x1 −x2

(a) One end of the spring is deflected; (b) both ends of the spring are

deflected. ( X is the natural length of the spring)

Figure 3-1(b) shows the case where both ends

deflected due to the forces

is

applied

X + x1

X+x

Figure 3-1

F

f

P

and

Q

of the spring are

applied at each end. The net elongation of the spring

x1 − x2 . The force acting in the spring is then

F = k ( x1 − x2 )

Notice that the displacement

X + x1

and

x2

of the ends of the spring are measured

relative to the same reference frame.

Practical Examples.

Pictures of various types of real-world springs are found below.

2/34

(3-2)

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

Torsional Springs

Consider the torsional spring shown in Figure 3-2 (a), where one end is fixed

and a torque τ is applied to the other end. The angular displacement of the free

end is

θ . The torque T

in the torsional spring is

T = kT θ

where

θ

(3-3)

is the angular displacement and

kT

is the spring constant for

torsional spring and has units of [Torque/angular displacement]=[N-m/rad] in SI

units.

θ

θ1

θ2

τ

τ

τ

Figure 3-2

(a) A torque τ is applied at one end of torsional spring, and the other

end is fixed; (b) a torque τ is applied at one end, and a torque τ , in

the opposite direction, is applied at the other end.

At the free end, this torque acts in the torsional spring in the direction opposite to

that of the applied torque τ .

For the torsional spring shown in Figure 3-2(b), torques equal in magnitude

but opposite in direction, are applied to the ends of the spring. In this case, the

torque

T

acting in the torsional spring is

T = kT (θ1 − θ 2 )

(3-4)

At each end, the spring acts in the direction opposite to that of the applied torque at

that end.

For linear springs, the spring constant

spring constant k =

1442443

for translational spring

for torsional spring

may be defined as follows

change in force

N

change in displacement of spring

m

spring constant kT =

1442443

k

change in torque

N-m

change in angular displacement of spring

rad

Spring constants indicate stiffness; a large value of

hard spring, a small value of

k

or

kT

k

or

kT

corresponds to a

to a soft spring. The reciprocal of the spring

3/34

ME 413 Systems Dynamics & Control

constant

k

Chapter Three: Mechanical Systems

is called compliance or mechanical capacitance

C.

Thus

C =1 k.

Compliance or mechanical capacitance indicates the softness of the spring.

Practical Examples.

Pictures of various types of real-world springs are found below.

http://www.esm.psu.edu/courses/emch13d/design/animation/animation.htm

Practical spring versus ideal spring. Figure 3-3 shows

displacement characteristic curves for linear and nonlinear springs.

•

•

All practical springs have inertia

and damping.

the

force

F

An ideal spring has neither mass

nor damping (internal friction)

and will obey the linear force

displacement law.

o

Figure 3-3 Force-displacement

characteristic curves for linear and

nonlinear springs.

x

Damper Elements. A damper is a mechanical element that dissipates

energy in the form of heat instead of storing it. Figure 3-4(a) shows a schematic

diagram of a translational damper, or a dashpot that consists of a piston and an-oilfilled cylinder. Any relative motion between the piston rod and the cylinder is resisted

4/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

by oil because oil must flow around the piston (or through orifices provided in the

piston) from one side to the other.

x1

x2

x& 1

x& 2

f

θ&2

f

Figure 3-4

θ&1

τ

τ

(a) Translational damper; (b) torsional (or rotational) damper.

Translational Damper

In Fig 3-4(a), the forces applied at the ends of translation damper are on the

same line and are of equal magnitude, but opposite in direction. The velocities of the

ends of the damper are

same frame of reference.

x&1

and

x& 2 . Velocities x&1

F

In the damper, the damping force

velocity differences

x&1 − x& 2

and

x& 2

are taken relative to the

that arises in it is proportional to the

of the ends, or

F = b ( x&1 − x& 2 ) = bx&

where

x& = x&1 − x& 2

and the proportionality constant

to the velocity difference

x&

b

(3-5)

relating the damping force

F

is called the viscous friction coefficient or viscous

friction constant. The dimension of

b

is [force/Velocity] = [N-s/m] in SI units.

Torsional Damper

For the torsional damper shown in Figure 3-4(b), the torques τ applied to

the ends of the damper are of equal magnitude, but opposite in direction. The

θ&2

and they are taken

relative to the same frame of reference. The damping torque

the

angular velocities of the ends of the damper are

θ&1

and

T that arises in

&

&

damper is proportional to the angular velocity differences θ1 − θ 2 of the ends, or

(

)

T = bT θ&1 − θ&2 = bTθ&

where, analogous to the translation case,

constant

bT

relating the damping torque

5/34

T

θ& = θ&1 − θ&2

(3-6)

and the proportionality

to the angular velocity difference

θ&

is

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

called the viscous friction coefficient or viscous friction constant. The

dimension of

b

is [torque/angular velocity] = [N-m-s/rad] in SI units.

A damper is an element that provides resistance in mechanical motion, and,

as such, its effect on the dynamic behavior of a mechanical system is similar to that

of an electrical resistor on the dynamic behavior of an electrical system.

Consequently, a damper is often referred to as a mechanical resistance element

and the viscous friction coefficient as the mechanical resistance.

Practical Examples.

Pictures of various examples of real-world dampers are found below.

Practical damper versus ideal

damper

•

•

All practical dampers produce inertia

and spring effects.

An ideal damper is massless and

springless, dissipates all energy, and

obeys the linear force-velocity law (or

linear torque-angular velocity law).

Nonlinear friction.

Friction that obeys a linear law is called linear

friction, whereas friction that does not is

described as nonlinear. Examples of nonlinear

friction include static friction, sliding friction,

and square-law friction. Square law-friction

occurs when a solid body moves in a fluid

medium. Figure 3-5 shows a characteristic

curve for square-law friction.

6/34

Figure 3-5

Characteristic curve

for square-law friction.

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

3.3 MATHEMATICAL

MODELING

MECHANICAL SYSTEMS

OF

SIMPLE

A mathematical model of any mechanical system can be developed by applying

Newton’s laws to the system.

Rigid body.

When any real body is accelerated , internal elastic

deflections are always present. If these internal deflections are negligibly small

relative to the gross motion of the entire body, the body is called rigid body. Thus,

a rigid body does not deform.

Newton’s laws.

Newton’s first law: (Conservation of Momentum)

The total momentum of a mechanical system is constant in the absence of

external forces. Momentum is the product of mass m and velocity v , or m v , for

translational or linear motion. For rotational motion, momentum is the product of

moment of inertia

J

and angular velocity

ω,

or

Jω ,

and is called angular

momentum.

Newton’s second law:

Translational motion: If a force is acting on rigid body

through the center of mass in a given direction, the acceleration of the rigid body in

the same direction is directly proportional to the force acting on it and is inversely

proportional to the mass of the body. That is,

acceleration =

or

force

mass

( mass ) ( acceleration ) = force

Suppose that forces are acting on a body of mass m . If

∑F

is the sum of all

forces acting on a mass m through the center of mass in a given direction, then

∑F = m a

(3-7)

where a is the resulting absolute acceleration in that direction. The line of action of

the force acting on a body must pass through the center of mass of the body.

Otherwise, rotational motion will also be involved.

Rotational motion. For a rigid body in pure rotation

about a fixed axis, Newton’s second law states that

7/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

( moment of inertia ) ( angular acceleration ) = torque

or

∑T = J α

where

∑T

is the sum of all torques acting about a given axis,

inertia of a body about that axis, and

α

(3-8)

J

is the moment of

is the angular acceleration of the body.

Newton’s third law. It is concerned with action and reaction

and states that every action is always opposed by an equal reaction.

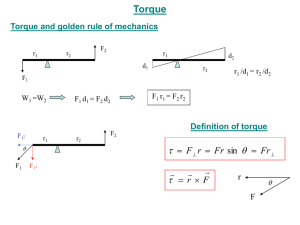

Torque or moment of force.

Torque, or moment of force, is

defined as any cause that tends to produce a change in the rotational motion of a

body in which it acts. Torque is the product of a force and the perpendicular distance

from a point of rotation to the line of action of the force.

⎡⎣Torque ⎤⎦ = [ force × distance ] = [ N-m ] in SI units

Moments of inertia. The moment of inertia J of a rigid body about an

axis is defined by

J = ∫ r 2 dm

(3-9)

Where dm is an element of mass, r is the distance from axis to dm , and integration

is performed over the body. In considering moments of inertia, we assume that the

rotating body is perfectly rigid. Physically, the moment of inertia of a body is a

measure of the resistance of the body to angular acceleration.

Figure 3-6

Moment of inertia

Parallel axis theorem.

Sometimes it is necessary to calculate the

moment of inertia of a homogeneous rigid body about an axis other than its

geometrical axis.

8/34

ME 413 Systems Dynamics & Control

Figure 3-7

Chapter Three: Mechanical Systems

Homogeneous cylinder rolling on a flat surface

As an example to that, consider the system shown in Figure 3-7, where a cylinder of

mass m and a radius R rolls on a flat surface. The moment of inertia of the cylinder

is about axis CC’ is

Jc =

1

mR2

2

The moment of inertia J x of the cylinder about axis xx’ is

Jx = Jc + m R 2 =

1

3

mR2 + mR2 = mR2

2

2

Forced response and natural response. The

behavior

determined by a forcing function is called a forced response, and that due initial

conditions is called natural response. The period between initiation of a response and

the ending is referred to as the transient period. After the response has become

negligibly small, conditions are said to have reached a steady state.

Figure 3-8

Transient and steady state response

Parallel and Series Springs Elements.

In many

applications, multiple spring elements are used, and in such cases we must obtain

the equivalent spring constant of the combined elements.

9/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

Parallel Springs.

3-9, the equivalent spring constant

keq

For the springs in parallel, Figure

is obtained from the relation

x

k1

x

k eq

F

k2

Figure 3-9

F

Parallel spring elements

F = k1 x + k2 x = ( k1 + k2 ) x = keq x

where

keq = k1 + k2

This formula can be extended to

n

n

keq = ∑ ki

i =1

( for parallel springs )

(3-9)

springs connected side-by-side as follows:

( for parallel springs )

(3-10)

Series Springs. For the springs in series, Figure 3-10, the force in

each spring is the same. Thus

y

k1

x

k2

k eq

F

F

Figure 3-10 Series spring elements

F = k1 y ,

F = k2 ( x − y )

Eliminating from these two equations yields

⎛

F⎞

F = k2 ⎜ x − ⎟

k1 ⎠

⎝

or

F = k2 x −

k2

F ⇒

k1

k2 x = F +

10/34

⎛k +k ⎞

k2

F = ⎜ 1 2 ⎟F

k1

⎝ k1 ⎠

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

or

⎛

⎞

⎜ 1 ⎟

⎛ k1 + k2 ⎞

⎛ k2 k1 ⎞

x=⎜

⎟F ⇔ F = ⎜

⎟x = ⎜ 1 1 ⎟x

⎜ + ⎟

⎝ k2 k1 ⎠

⎝ k1 + k2 ⎠

⎜k k ⎟

1

2 ⎠

⎝14

24

3

keq

where

1

1 1

= +

keq k1 k2

which can be extended to the case of

n

1

1

=∑

keq i =1 ki

( for series springs )

n

(3-11)

springs connected end-to-end as follows

( for series springs )

(3-12)

Free Vibration without damping.

Consider the mass spring system shown in Figure 3-11. The equation of motion can

be given by1

m &&

x+k x=0

or

&&

x+

k

x = 0 ⇒ &&

x + ωn2 x = 0

m

K

where

ωn =

k

m

is the natural frequency of the system and is expressed in

rad/s.

Taking LT of both sides of the above equation where

x ( 0 ) = xo

and

x& ( 0 ) = x&o

gives

s 2 X ( s ) − sx ( 0 ) − x& ( 0 ) + ωn2 X ( s ) = 0

1444

424444

3

M

x (t )

Figure 3-11 Mass

Spring System

L [ x&&]

rearrange to get

1

The weight

W = mg

of the mass

m

is equal to the static deflection of the spring. Therefore, they

will cancel each other, (See Appendix A).

11/34

ME 413 Systems Dynamics & Control

X (s) =

Chapter Three: Mechanical Systems

sxo + x&o

, ⇒ Remember poles are s = ± jωn

1

424

3

s 2 + ωn2

complex conjugates

X ( s) =

x (t )

and the response

ωn

s

+ xo 2

2

ωn s + ωn

s + ωn2

x&o

2

is given by

x (t ) =

It is clear that the response

x&o

ωn

sin (ωnt ) + xo cos (ωnt )

x (t )

consists of a sine and cosine terms and depends

on the values of the initial conditions

xo

and

x&o . Periodic motion such that described

by the above equation is called simple harmonic motion.

x (t )

slope = x&o

Im

s − plane

ωn

xo

Re

t

−ωn

Period = T =

2π

ωn

Figure 3-12 Free response of a simple harmonic motion and pole location on the s-plane

if

x& ( 0 ) = x&o = 0,

x ( t ) = xo cos (ωnt )

The period T is the time required for a periodic motion to repeat itself. In the

present case,

Period T =

The frequency

f

2π

ωn

seconds

of a periodic motion is the number of cycles per second (cps), and

the standard unit of frequency is the Hertz (Hz); that is 1 Hz is 1 cps. In the present

case,

12/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

Frequency f =

The undamped natural frequency

1 ω

=

Hz

T 2π

ωn

is the frequency in the free vibration of a

system having no damping. If the natural frequency is measured in Hz or in cps, it is

denoted by

fn .

If it is measured in rad/sec, it is denoted by

ωn .

In the present

system,

ωn = 2π f n =

Rotational System.

k

rad/sec

m

Rotor mounted in bearings is shown in figure 3-

13 below. The moment of inertia of the rotor about the axis of rotation is

J . Friction

in the bearings is viscous friction and that no external torque is applied to the rotor.

ω

b

J

J

ω

bω

1442443

T (t )

Figure 3-13 Rotor mounted in bearings and its FBD.

Apply Newton’s second law for a system in rotation

∑ M = Jθ&& = J ω&

J ω& + bω = 0 ⇒ ω& + ( b / J ) ω = 0

or

ω& +

Define the time constant

1

ω =0

( J / b)

τ = ( J / b ) , the previous equation can be written in the

form

1

ω& + ω = 0, ω ( 0 ) = ωo

τ

which represents the equation of motion as well as the mathematical model of the

system shown. It represents a first order system. To find the response

LT of both sides of the previous equation.

13/34

ω ( t ) , take

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

⎡

⎤

⎡

⎤

⎢ sΩ ( s ) − ω ( 0 ) ⎥ + 1 ⎢ Ω ( s ) ⎥ = 0

4244

3 ⎥ τ ⎢ {⎥

⎢ 14

L[ω& ]

⎣ L[ω ] ⎦

⎣⎢

⎦⎥

where

1⎞

⎛

⎜ s + ⎟ Ω ( s ) = ωo

⎝ τ⎠

the denominator s + (1 τ )

equation

s + (1 τ ) = 0

Ω(s) =

⇒

ωo

s + (1 τ )

is known as the characteristic polynomial and the

is called the characteristic equation. Taking inverse LT of the

above equation will give the expression of

ω (t )

ω ( t ) = ωo e −(b / J ) t = ωo e −(1/ τ )t = ωo e −α t

It is clear that the angular velocity decreases exponentially as shown in the figure

below. Since

lim e

t →∞

−( t / τ )

= 0;

then for such decaying system, it is convenient to

depict the response in terms of a time constant.

Free response of a rotor bearing system

1.5

α=0

ω

o

α=0.2

ω (t)

α=0.5

α=0.7

α=1

0.5

α=2

α=5

α =10

0

0

5

10

time (t)

Figure 3-14 Graph of

ωo e −α t

14/34

15

for ranges of

α.

20

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

A time constant is that value of time that makes the exponent equal to -1. For this

system, time constant τ = J / b . When t = τ , the exponent factor is

e

−( t / τ )

=e

−(τ / τ )

= e −1 = 0.368 = 36.8 %

This means that when time

constant = τ ,

the

time

response

is

reduced

to

36.8 %

of its final value.

We also have

τ = J / b = time constant

ω (τ ) = 0.37 ωo

ω ( 4τ ) = 0.02 ωo

Figure 3-15 Curve of angular velocity

versus time

ω

t for the rotor shown in Figure 3-13.

Spring-Mass-Damper System.

Consider the simple mechanical system

shown involving viscous damping. Obtain the mathematical model of the system

shown.

Fb = b x&

k

b

m

Fk = k x

m

+x

x (t )

14444244443

Free Body Diagram (FBD)

Figure 3-16 Mass -Spring –Damper System and the FBD.

i)

ii)

The FBD is shown in the figure 3-16.

Apply Newton’s second law of motion to a system in translation:

∑F

= m x&&

⇒

Rearranging

15/34

− bx& − kx = mx&&

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

m x&& + bx& + k x = 0

The above equation represents the mathematical model as well as the free vibration

for a second order model. If m = 0.1 kg, b = 0.4 N/m-s, and k = 4 N/m , the

above differential equation becomes

0.1 &&

x + 0.4 x& + 4 x = 0 ⇒

To obtain the free response x

&&

x + 4 x& + 40 x = 0

( t ) , assume x ( 0 ) = xo

x& ( 0 ) = 0.

and

Take Laplace

transform of both sides of the given equation

⎡ s 2 X ( s ) − s x ( 0 ) − x& ( 0 ) ⎦⎤ + 4 ⎡⎣ sX ( s ) − x ( 0 ) ⎤⎦ + 40 ⎡⎣ X ( s ) ⎤⎦ = 0

⎣14444

1442443

1

424

3

244443

L ⎣⎡ x& ( t ) ⎦⎤

L ⎡⎣ &&

x( t ) ⎤⎦

Substitute in the transformed equation

obtain

or solving for

L ⎣⎡ x( t ) ⎦⎤

x ( 0 ) = xo

and

x& ( 0 ) = 0,

and rearrange, we

⎡⎣ s 2 + 4 s + 40 ⎤⎦ X ( s ) = [ sxo + 4 xo ]

X (s)

yields

X (s) =

( sxo + 4 xo )

s + 4 s + 40

2

=

( s + 4)

s + 4 s + 40

14243

2

xo

Characteristic polynomial

which can be written as

G (s) =

X (s)

( s + 4)

= 2

xo

s + 4 s + 40

14243

Characteristic polynomial

where

G (s)

is referred to as the transfer function that gives the relationship

between the input

xo

xo

and the output

X (s) . G (s)

can be shown graphically as:

(s + 4 )

s14

+44244

s+3

40

2

X(s)

Characteristic polynomial

144424443

Transfer function

Figure 3-17 Transfer function between input and output.

iii)

It is clear that the characteristic equation of the system is

has complex conjugates roots.

16/34

s 2 + 4 s + 40 = 0

and

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

2

s 2 + 4s + 40 = s1

+24

4 s +34 + 36 = ( s + 2 ) + 62 = 0

4

2

( s + 2 )2

The roots of the above equation are therefore complex conjugate poles given by

s1 = −2 + j 6 and s2 = −2 − j 6

iv)

The expression of

X (s) =

=

v)

( s + 4)

s + 4 s + 40

2

xo =

can be written now as:

2

( s + 2 + 2) x = ( s + 2) x +

x

o

o

2

2

2

2

2

2 o

+

+

+

+

+

+

s

2

6

s

2

6

s

2

6

(

)

(

)

(

)

( s + 2) x + 1

6

xo

2

2 o

3 ( s + 2 )2 + 62

( s + 2) + 6

Solving for

Or

X (s)

x ( t ) = L−1 ⎡⎣ X ( s ) ⎤⎦

yields

2

x (t ) =

1

⎛

⎞

x ( t ) = xo ⎜ e −2t cos 6t + e −2t sin 6t ⎟

3

⎝

⎠

10 −2t

xoe ( sin 6t + 71.56o )

3

x ( t)

e −2t

s1 = −2 + j 6

1

x (t ) = xo ⎜⎛e−2t cos 6t + e−2t sin 6t ⎞⎟

3

⎝

⎠

−2

2π

ωd

s − plane

j6

t

Td =

Im

Re

− j6

s2 = −2 − j 6

Figure 3-18 Free Vibration of the mass-spring-damper system described by

&&

x + 4 x& + 40 x = 0 with initial conditions x ( 0 ) = xo

2

(See Appendix B).

17/34

and

x& ( 0 ) = 0, .

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

Pole-Zero Map

10

Imaginary Axis

5

0

-5

-10

-4

-3.5

-3

-2.5

-2

-1.5

-1

-0.5

0

Real Axis

Free vibration of mass-spring-damper system

1.5

x(t)

xo

0.5

0

-0.5

0

0.5

1

1.5

2

2.5

t (sec)

3

3.5

4

4.5

5

Figure 3-18 Free Vibration of the mass-spring-damper system described by

&&

x + 4 x& + 40 x = 0 with initial conditions x ( 0 ) = xo

and

x& ( 0 ) = 0, .

3.4 WORK ENERGY, AND POWER

Work.

The work done in a mathematical system is the product of a

force and a distance (or a torque and the angular displacement) through which the

force is exerted with both force and distance measured in the same direction.

d

d

F

θ

F

W = F d cos θ

W =F d

Figure 3-19 Work done by a force

The units of work in SI units are :

[ work ] = [ force × distance ] = [ N-m ] = [ Joule ] = [ J ]

The work done by a spring is given by:

18/34

.

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

x

1

W = ∫ k x dx = k x 2

{

2

0 F

k

F

F

l

l+x

Figure 3-19 Work done by a spring.

Energy.

Energy can be defined as ability to do work. Energy can be

found in many different forms and can be converted from one form to another. For

instance, an electric motor converts electrical energy into mechanical energy, a

battery converts chemical energy into electrical energy, and so forth.

According to the law of conservation of energy, energy can be neither created

nor destroyed. This means that the increase in the total energy within a system is

equal to the net energy input to the system. So if there is no energy input, there is

no change in the total energy of the system.

Potential Energy.

The Energy that a body possesses because of its

position is called potential energy.

• In mechanical systems, only mass and spring can store potential

energy.

• The change in the potential energy stored in a system equals the work

required to change the system’s configuration.

• Potential energy is always measured with reference to some chosen

level and is relative to that level.

m

h

x

mg

F

Figure 3-20 Potential energy

Refer to Figure 3-20, the potential energy,

x

U of a mass m

U = ∫ mg dx = mgh

0

19/34

is given by:

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

For a translational spring, the potential energy U (sometimes called strain energy

which is potential energy that is due to elastic deformations) is:

x

x

0

0

U = ∫ F dx = ∫ k x dx =

If the initial and final values of

Change in potential energy

x

are

1 2

kx

2

x1 and x2 , respectively, then

x2

x2

x1

x1

ΔU = ∫ F dx = ∫ k x dx =

1 2 1 2

k x2 − k x1

2

2

Similarly, for a torsional spring

Change in potential energy ΔU

θ2

θ2

θ1

θ1

= ∫ T dθ = ∫ kT θ dx =

1

1

kT θ 22 − kT θ12

2

2

Only inertia elements can store kinetic energy in

Kinetic Energy.

mechanical systems.

⎧1

2

mv

⎪⎪

T = Kinetic energy= ⎨ 2

⎪ 1 Jθ& 2

⎪⎩ 2

(Translation)

(Rotation)

The change in kinetic energy of the mass is equal to the work done on it by

an applied force as the mass accelerates or decelerates. Thus, the change in kinetic

energy

T

of a mass

m

moving in a straight line is

Change in kinetic energy

x2

t2

x1

t1

dx

dt

dt

ΔT = ΔW = ∫ F dx = ∫ F

t2

t2

v2

t1

t1

v1

= ∫ F v dt = ∫ mv& v dt = ∫ m v dv

1

1

= mv22 − mv12

2

2

The change in kinetic energy of a moment of inertia in pure rotation at

angular velocity

θ&

is

Change in kinetic energy

20/34

ΔT =

1 &2 1 &2

Jθ 2 − Jθ1

2

2

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

Dissipated Energy.

Consider the damper shown in Figure 3-21 in

x1

which one end is fixed and the other end is moved from

energy

ΔW

to

x2 . The dissipated

in the damper is equal to the net work done on it:

x2

x2

t2

t

2

dx

ΔW = ∫ F dx = ∫ b x& dx = b ∫ x&

dt = b ∫ x& 2 dt

{

dt

x1

x1 F

t1

t1

x2

x1

x

b

Figure 3-20 Damper.

Power.

Power is the time rate of doing work. That is,

Power = P =

dW

dt

where dW denotes work done during time interval dt .

In SI units, the work done is measured in Newton-meters and the time in seconds.

The unit of power is :

N-m ⎤ ⎡ Joule ⎤

=

= [ Watt ] = W .

⎣ s ⎥⎦ ⎢⎣ s ⎥⎦

[ Power ] = ⎡⎢

Passsive Elements. Non-energy producing element. They can only

store energy, not generate it such as springs and masses.

Active Elements.

Energy producing elements such as external

forces and torques.

Energy Method for Deriving Equations of Motion. Equations

of motion are derive from the fact that the total energy of a system remains the

same if no energy enters or leaves the system.

Conservative Systems.

Systems that do not involve friction

(damping) are called conservative systems.

21/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

Δ (T + U )

1424

3

=

Δ

W

{

Net work done on the

system by external forces

Change in the total energy

If no external energy enters the system ( ΔW

forces) then

= 0 , no work done by external

Δ (T + U ) = 0

or

(T + U ) = constant

Conservation of energy only

for conservative systems

(No friction or damping)

An Energy Method for Determining Natural Frequencies.

The natural frequency of a conservative system can be obtained from a

consideration of the kinetic energy and the potential energy of the system. Let us

assume that we choose the datum line so that the potential energy at the equilibrium

state is zero. Then in such a conservative system, the maximum kinetic energy

equals the maximum potential energy , or

Tmax = U max

Solved Problems.

Example 3-5 Page 80 (Textbook)

Consider the system shown in the Figure shown. The displacement

measured from the equilibrium position.

The Kinetic energy is:

The potential energy is:

x

is

k

1

T = m x& 2

2

1

U = k x2

2

The total energy of the system is

m

1

1

T + U = m x& 2 + k x 2

2

2

The change in the total energy is

d

d 1

1

(T + U ) = ⎛⎜ m x& 2 + k x 2 ⎞⎟ = 0

dt

dt ⎝ 2

2

⎠

1

1

&&& + × 2 × k xx& = 0

= × 2 × m xx

2

2

= x& ( m x&& + k x ) = 0

Since

x& is not zero then we should have

m x&& + k x = 0

22/34

x

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

or

&&

x+

k

x = 0 ⇒ &&

x + ωn2 x = 0

m

where

ωn =

k

m

is the natural frequency of the system and is expressed in rad/s. Another way of finding the

natural frequency of the system is to assume a displacement of the form

x = A sin ωnt

Where

A is the amplitude of vibration. Consequently,

1

1

2

T = m x& 2 = m A2ω 2 ( cos ωn t )

2

2

1

1

2

U = k x 2 = k A2 ( sin ωn t )

2

2

Hence the maximum values of

T

and

U

are given by

1

Tmax = m A2ωn2 ,

2

Since

U max =

Tmax = U max , we have

From which

1

1

m A2ωn2 = k A2

2

2

ωn =

k

m

23/34

1

k A2

2

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

Problem 24/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

Problem 25/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

26/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

27/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

28/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

29/34

ME 413 Systems Dynamics & Control

TABLE 1.

Chapter Three: Mechanical Systems

Summary of elements involved in linear

mechanical systems

Rotation

Translation

Element

x

F4

Inertia

F2

F1

m

F3

T

∑F = m a

∑T = J α

x1

x2

F

F

k

θ1

F = k ( x1 − x2 ) = kx

F

b

F

b

T

T

θ&1

F = b( x&1 − x& 2 ) = bx&

θ2

T = k (θ1 − θ 2 ) = kθ

x& 2

x& 1

Damper

T

T

k

Spring

θ

J

θ&2

T = b(θ&1 − θ&2 ) = bθ&

PROCEDURE

The motion of mechanical elements can be described in various dimensions as

translational, rotational, or combination of both. The equations governing the motion

of mechanical systems are often formulated from Newton’s law of motion.

1. Construct a model for the system containing interconnecting elements.

2. Draw the free-body diagram.

3. Write equations of motion of all forces acting on the free body diagram. For

translational motion, the equation of motion is Equation (1), and for rotational

motion, Equation (2) is used.

30/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

APPENDIX A:

Static Equilibrium

k

Lo

k

k

δ st

m

m

x

kδ st

k( x +δst )

m

m

mg

mg

At static equilibrium, we have:

mg = K δ st

Let the mass be displaced a distance x downward from its equilibrium, the spring

force becomes

f = − K ( x + δ st ) . Apply Newton’s second law for the mass-spring

system, one can write:

∑ F = mx&&

or

− K ( x + δ st ) + mg = mx&&

or

− Kx − K δ st + mg = mx&&

14243

= 0 ( Static Equilibrium )

Therefore

mx&& + Kx = 0

31/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

The above equation represents the mathematical model for the mass-spring

system. It is a second order ordinary differential equation with constant

coefficients. It is clear that the weight mg cancels with the static deflection − K δ st of

the system. Therefore, it does not appear in the equation of motion.

32/34

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

APPENDIX B:

The expression of

sin (ωt ) , that is

a cos (ωt ) + b sin (ωt )

can be written in terms of

cos (ωt )

or

⎛

⎞

a

b

(

)

(

)

ω

ω

a cos ( ωt ) + b sin ( ωt ) = a 2 + b2 ⎜ 2

cos

t

sin

t

+

⎟

2

a 2 + b2

⎝ a +b

⎠

Define

ψ

such that

a

⎫

a + b ⎪⎪

⎬⇒

b

⎪

2

2

a + b ⎪⎭

cos ψ =

2

sin ψ =

2

b

ψ = tan −1 ⎜⎛ ⎟⎞

⎝a ⎠

Therefore

a 2 + b 2 (cos ψ cos ( ωt ) + sin ψ sin ( ωt ) )

a cos ( ωt ) + b sin ( ωt ) =

Using the identity

cos ( ωt − ψ ) = cos ( ωt ) cos ψ + sin ( ωt ) sin ψ

Therfore,

a cos ( ωt ) + b sin ( ωt ) =

a 2 + b 2 (cos ωt − ψ )

a cos ( ωt ) + b sin ( ωt ) =

a 2 + b 2 (sin ωt + ϕ )

or

Where

sin ϕ =

cos ϕ =

a

⎫

a + b ⎪⎪

⎬

b

⎪

a 2 + b 2 ⎭⎪

2

2

⇒

33/34

a

ϕ = tan −1 ⎛⎜ ⎞⎟

⎝b ⎠

ME 413 Systems Dynamics & Control

Chapter Three: Mechanical Systems

Useful Sites Torsion

http://www.esm.psu.edu/courses/emch13d/design/animation/animation.htm

Mass Spring System

http://www.colorado.edu/physics/phet/simulations/massspringlab/MassSpringLab2.swf

http://physics.bu.edu/~duffy/java/Spring2.html

http://www.ngsir.netfirms.com/englishhtm/SpringSHM.htm

http://www.myphysicslab.com/spring1.html

http://www.walter-fendt.de/ph11e/springpendulum.htm

http://webphysics.davidson.edu/physlet_resources/gustavus_physlets/VerticalSpring.html

http://www.sciences.univ-nantes.fr/physique/perso/gtulloue/equadiff/equadiff.html

Response of First and second Order Systems

http://www.sciences.univ-nantes.fr/physique/perso/gtulloue/equadiff/equadiff.html

34/34