Sypply Chain Management

Sypply Chain Management

Dr Mariusz Maciejczak

Basic reading

Essentials of Supply Chain Management

Second Edition

By Michale Hugos

Published by John Wiley& Sons, Inc.,

Hoboken, New Jersey, 2006

Chapter 6

Supply Chain Coordination

Is supply chain so simple?

Supplier Manufacturer Distributor Retailer Customer

Supplier Manufacturer Distributor Retailer Customer

Supplier Manufacturer Distributor

Upstream Downstream

Retailer Customer

Supply Chain of a Typical Original Equipment Manufacturer

Bullwhip Effect

§ Demand propagates from the lower levels of the supply chain

(consumer end) to the upper levels (supplier end).

§ Unfortunately, variability does the same and is amplified by each echelon of the chain. Terms for this include

§ Information distortion

§ Bullwhip Effect

§ Modest movement at the whip handle (representing consumer demand fluctuations) leads to wild swings at the whip’s tip

(demand experienced by the supplier). Bullwhip cracks are loud because of the Doppler effect (e.g. as seen visibly in a boat’s wake) which generates a small sonic boom as the whip tip breaks the sound barrier at about 800 mph. The supply chain bullwhip crack can be heard through bankruptcy filings as vulnerable suppliers and manufacturers experience deadly cash flow variability.

The Bullwhip Effect

Because customer demand is rarely perfectly stable, businesses must forecast demand to properly position inventory and other resources. Forecasts are based on statistics, and they are rarely perfectly accurate.

Because forecast errors are a given, companies often carry an inventory buffer called " safety stock ". Moving up the supply chain from end-consumer to raw materials supplier, each supply chain participant has greater observed variation in demand and thus greater need for safety stock. In periods of rising demand, down-stream participants increase orders. In periods of falling demand, orders fall or stop to reduce inventory.

The effect is that variations are amplified as one moves upstream in the supply chain (further from the customer). This sequence of events is well simulated by the Beer Distribution Game which was developed by the MIT Sloan School of Management in the 1960s.

Bullwhip Effect

The magnification of variability in orders in the supplychain

Retailer’s Orders Wholesaler’s Orders Manufacturer’s Orders

A lot of retailers each with little variability in

Time Time

…can lead to greater variability for a fewer number of

Time

…can lead to even greater variability for a single manufacturer.

The Bullwhip Effect in action

The Bullwhip Effect

Causes of the Bullwhip Effect

Solutions ?

• Write your suggestions

Principles of Supply Chain Management: A Balanced Approach by Wisner, Leong, and Tan.

Integration Model Cont.

Identify Critical Supply Chain Trading Partners

– Enable sale & delivery of end products to final customers

– Identifying primary trading partners allows the firm to concentrate on managing these links

Review & Establish Supply Chain Strategies regarding:

– Parts purchased & suppliers

– Shop layout & manufacturing processes

– Design of the products manufactured

– Mode of transportation

– Warranty & return services

– Employee training methods

Integration Model Cont.

Align SC Strategies with Key SC Process Objectives

Integration Model Cont.

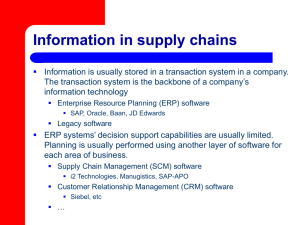

Develop Internal Performance Measures for Key Processes

– Performance should be continuously measured w/metrics for each process.

– ERP systems support internal performance measures

– Firm is able to track progress for each of the key processes.

Assess & Improve Internal Integration of Key SC Processes. Internal integration requires:

– Empowered teams & cooperation across all functions

– Management support & resources

– ERP system

– an understanding of the internal supply chain

Integration Model Cont.

Develop SC Performance Measures for Key Processes

– Monitor the links with trading partners in the key SCM processes.

– Trading partners should monitor a number of costoriented measures averaged across the member firms for each of the key supply chain processes.

Assess & Improve External Process Integration & Performance

– Build, maintain & strengthen relationships

– Share information concerning:

• Sales, forecast information, new products, expansion plans, new processes, & new marketing campaigns process integration will enable firms to collaborate & share this information.

Along the Supply Chain Cont.

Lack of Supply Chain Visibility

– In a 2002 survey, 67% of manufacturers had not yet successfully synchronized their supply chain operations with those of their trading partners

– And 67% said they used different supply chain management applications than their partners

Anonymous, “Survey Finds Manufacturers’ Supply Chains Come Up Short,” Logistics

Management 41, no. 9 (2002): 19-20.

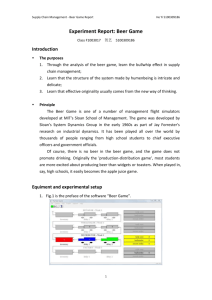

The Beer Game

Orders

Delay Delay

Factory

Delay Delay

Distributor

Retailer

Delay Delay

Wholesaler

Delay Delay

Material

Bullwhip effect in the beer game

Near Beer Game Simulation

http://forio.com/nearbeer.htm

Root Beer Game - Supply Chain Management Simulation http://forio.com/simulation/harvard-root-beer-game-demo/