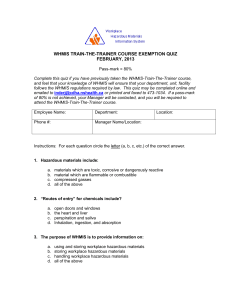

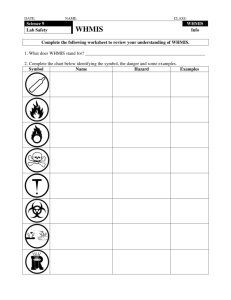

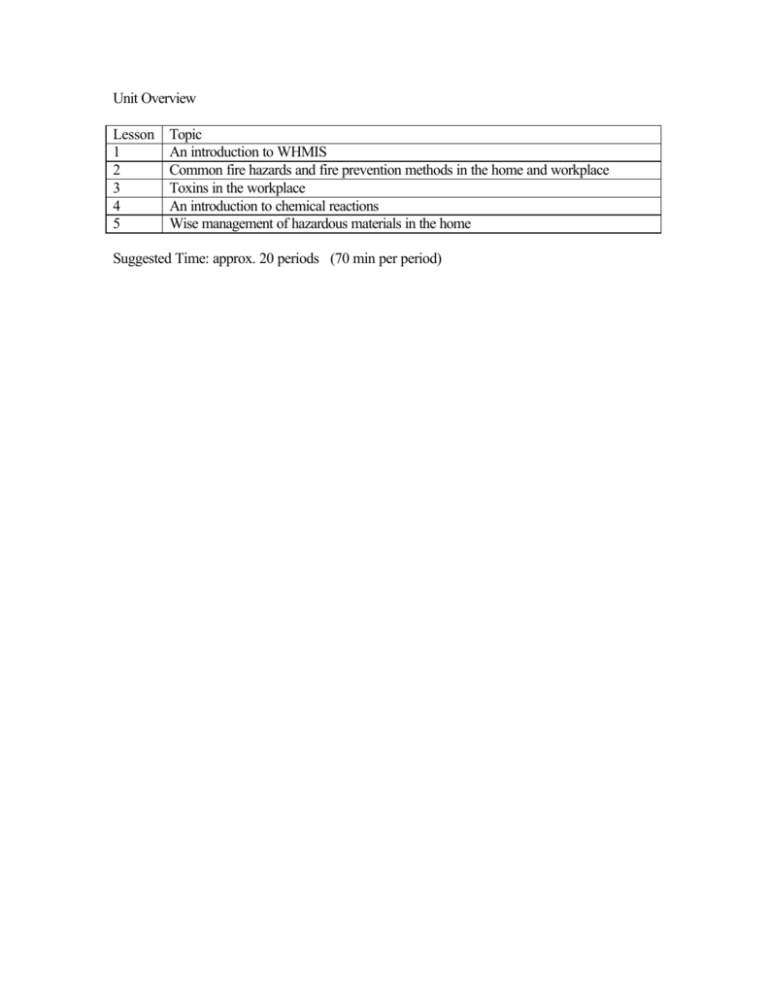

Unit Overview Lesson Topic 1 An introduction to WHMIS 2

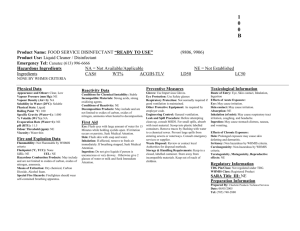

advertisement