STUDY OF TAPERED INTERNAL DIAMETER TUBING STRING

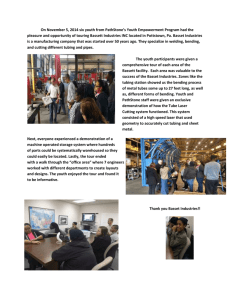

advertisement