technical data

advertisement

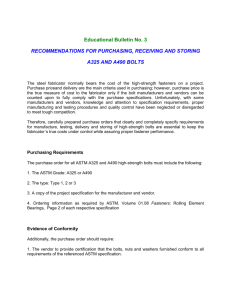

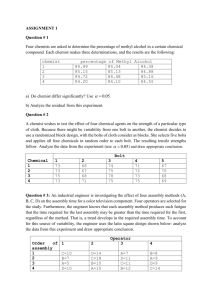

TECHNICAL DATA CONTENTS • STEEL FLANGE BOLT CHART • MECHANICAL JOINTS T-HEAD BOLT CHART • FLANGE THICKNESS CHARTS PAGES 1 & 2 • GASKET DIMENSIONS • WRENCH SIZE CHARTS • DECIMAL CONVERSION CHART • INSUSTRY STANDARDS • HEX BOLTS AND NUTS • HEAVY HEX BOLTS AND NUTS • WASHERS PAGES 1 & 2 • WATER WORKS T-HEAD BOLTS • OVAL NECK TRACK BOLTS • A325 BOLTS • COATINGS • PROPER FLANGE BOLTING PAGES 1 & 2 A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TRIPAC MARKETING, INC. STEEL FLANGE BOLT CHART CLASS 150 LB Chart may be used for: C110 DIP/DIP E4 x E4 E4 x (valve) in some cases PIPE QTY OF DIAMETER BOLTS 1" 4 1 1/4" 4 1 1/2" 4 2" 4 2 1/2" 4 3" 4 4" 8 5" 8 6" 8 8" 8 10" 12 12" 12 14" 12 16" 16 18" 16 20" 20 22" 20 24" 20 30" 28 36" 32 42" 36 48" 44 54" 44 60" 52 72" 60 84" 64 96" 68 108" 72 BOLT SIZE 1/2 - 13 x 1 3/4" 1/2 - 13 x 2" 1/2 - 13 x 2" 5/8 - 11 x 2 1/4" 5/8 - 11 x 2 1/2" 5/8 - 11 x 2 1/2" 5/8 - 11 x 3" 3/4 - 10 x 3" 3/4 - 10 x 3 1/4 " 3/4 - 10 x 3 1/2 " 7/8 - 9 x 3 3/4" 7/8 - 9 x 4" 1 - 8 x 4 1/4" 1 - 8 x 4 1/2" 1 1/8 - 7 x 4 3/4" 1 1/8 - 7 x 5" 1 1/4 - 7 x 5 1/2" 1 1/4 - 7 x 5 1/2" 1 1/4 - 7 x 6 1/4" 1 1/2 - 6 x 7" 1 1/2 - 6 x 7 1/2 " 1 1/2 - 6 x 7 3/4" 1 3/4 - 5 x 8 1/2" 1 3/4 - 5 x 8 3/4" 1 3/4 - 5 x 9 1/2" 2 - 4.5 x 10 1/2 " 2 1/4 - 4.5 x 11 1/2" 2 1/2 - 4 x 14" CLASS 300 LB PIPE QTY OF DIAMETER BOLTS 1" 4 1 1/4" 4 1 1/2" 4 2" 8 2 1/2" 8 3" 8 3 1/2" 8 4" 8 5" 8 6" 12 8" 12 10" 16 12" 16 14" 20 16" 20 18" 24 20" 24 24" 24 30" 28 36" 32 42" 36 48" 40 Table 6 FxF BOLT SIZE 5/8 - 11 x 2 1/2" 5/8 -11 x 2 1/2" 5/8-11 x 2 3/4" 5/8 - 11 x 2 3/4" 3/4 - 10 x 3 1/4 " 3/4 - 10 x 3 1/2 " 3/4 - 10 x 3 1/2 " 3/4 - 10 x 3 3/4" 3/4 - 10 x 4" 3/4 - 10 x 4" 7/8 - 9 x 4 1/2 " 1 - 8 x 5 1/4" 1 1/8 - 7 x 5 1/2" 1 1/8 - 7 x 6" 1 1/4 - 7 x 6 1/4" 1 1/4 - 7 x 6 1/2" 1 1/4 - 7 x 6 3/4" 1 1/2 - 6 x 7 3/4" 1 3/4 - 5 x 8 1/2" 2 - 4.5 x 9 1/2" 2 - 4.5 x 10 1/4" 2 - 4.5 x 10 3/4" T-HEAD BOLTING CHART AWWA C110 MECHANICAL JOINTS NOM PIPE SIZE NO. BOLTS DIAMETER & LENGTH 2” 2 5/8 X 3 3” 4 5/8 X 3 4” 4 3/4 X 3 1/2 6” 6 3/4 X 3 1/2 8” 6 3/4 X 4 10” 8 3/4 X 4 12” 8 3/4 X 4 14” 10 3/4 X 4 1/2 16” 12 3/4 X 4 1/2 18” 12 3/4 X 4 1/2 20” 14 3/4 X 4 1/2 24” 16 3/4 X 5 30” 20 1X6 36” 24 1X6 42” 28 1 1/4 X 6 48” 32 1 1/4 x 6 TRIPAC FASTENERS IS A MEMBER OF THE AWWA AND HAS THE TECHNICAL EXPERTISE TO ASSIST YOU IN SELECTING THE PROPER MATERIALS FOR YOU NEEDS. CALL OR FAX FOR QUOTES, ADITIONAL INFORMATION, SPECIAL ORDERS OR FOR TECHNICAL ASSISTANCE. A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TRIPAC MARKETING, INC. FLANGE THICKNESS CHARTS Steel Pipe Flanges For Waterworks Service 125/150 * Information extracted from AWWA C207-94 NOM PIPE SIZE BOLT SIZE 1 1 1/2 2 2 1/2 3 4 5 6 8 10 12 14 16 18 20 24 30 36 42 48 54 60 66 72 84 90 96 102 108 120 144 1/2 1/2 5/8 5/8 5/8 5/8 3/4 3/4 3/4 7/8 7/8 1 1 1 1/8 1 1/8 1 1/4 1 1/4 1 1/2 1 1/2 1 1/2 1 3/4 1 3/4 1 3/4 1 3/4 2 2 1/4 2 1/4 2 1/2 2 1/2 2 3/4 3 1/4 * Table 4 may be used for valve thickness calculation in some cases TABLE 2 CLASS E ANSI SLIP ON FLANGE CLASS B CLASS B CLASS D — — — — — 1.125 1.188 1.313 1.500 1.563 1.750 1.875 2.000 2.125 2.375 2.625 2.875 3.125 3.125 3.500 3.750 3.875 4.250 4.375 4.750 5.125 5.125 5.500 5.500 5.875 6.750 0.563 0.688 0.750 0.875 0.938 0.938 0.938 1.000 1.125 1.188 1.250 1.375 1.438 1.562 1.688 1.875 2.125 2.375 2.375 — — — — — — — — — — — — — — — — — 0.625 0.625 0.688 0.688 0.688 0.688 0.688 0.688 0.688 0.688 0.750 0.875 1.000 1.125 1.250 1.375 1.500 1.625 1.750 2.000 2.250 2.250 2.500 2.500 2.750 3.250 — — — — — 0.500 0.562 0.562 0.562 0.688 0.688 0.750 0.750 0.750 0.750 1.000 1.000 1.125 1.250 1.375 1.375 1.500 1.500 1.500 1.750 2.000 2.000 — — — — — — — — — 0.500 0.562 0.562 0.562 0.688 0.688 0.750 0.750 0.750 0.750 1.000 1.000 1.125 1.250 1.375 1.375 1.500 1.500 1.500 1.750 2.000 2.000 — — — — TABLE 2 TABLE 4 TABLE 5 NO. BOLTS CLASS D CLASS E 4 4 4 4 4 8 8 8 8 12 12 12 16 16 20 20 28 32 36 44 44 52 52 60 64 68 68 72 72 76 84 — — — — — 0.625 0.625 0.688 0.688 0.688 0.812 0.938 1.000 1.062 1.125 1.250 1.375 1.625 1.750 1.875 2.125 2.250 2.500 2.625 2.875 3.000 3.250 3.250 3.375 3.500 4.125 — — — — — 0.938 0.938 1.000 1.125 1.188 1.250 1.375 1.438 1.562 1.688 1.875 2.125 2.375 2.375 2.750 3.000 3.125 3.375 3.500 3.875 4.250 4.250 — — — — A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TABLE 3 TRIPAC MARKETING, INC. FLANGE THICKNESS CHARTS Steel Pipe Flanges For Waterworks Service 125/150 NOM AWWA C110 AWWA C153 BLIND FLANGES NO . PIPE BOLT SIZE DUCTILE AND GRAY DUCTILE IRON BOLTS CLASS B CLASS D CLASS E SIZE IRON FITTINGS COMPACT FITTINGS 3 5/8 4 — — — 0.75 ± .12 in. 0.60 ± .12 in. 4 5/8 8 0.625 0.625 1.125 0.94 ± .12 in. 0.63 ± .12 in. 6 3/4 8 0.688 0.692 1.313 1.00 ± .12 in. 0.63 ± .12 in. 8 3/4 8 0.688 0.805 1.500 1.12 ± .12 in. 0.70 ± .12 in. 10 7/8 12 0.688 0.947 1.563 1.19 ± .12 in. 0.75 ± .12 in. 12 7/8 12 0.752 1.110 1.750 1.25 ± .12 in. 0.81 ± .12 in. 14 1 12 0.835 1.127 1.875 1.38 ± .19 in. 0.87 ± .19 in. 16 1 16 0.941 1.258 2.000 1.44 ± .19 in. 0.90 ± .19 in. 18 1 1/8 16 1.013 1.326 2.125 1.56 ± .19 in. 0.93 ± .19 in. 20 1 1/8 20 1.108 1.442 2.375 1.69 ± .19 in. 0.96 ± .19 in. 24 1 1/4 20 1.275 1.657 2.625 1.88 ± .19 in. 1.00 ± .19 in. 30 1 1/4 28 1.530 2.003 2.875 2.12 ± .25 in. 2.12 ± .25 in. 36 1 1/2 32 1.834 2.369 3.344 2.38 ± .25 in. 2.38 ± .25 in. 42 1 1/2 36 2.084 2.725 3.789 2.62 ± .25 in. 2.62 ± .25 in. 48 1 1/2 44 2.341 3.067 4.246 2.75 ± .25 in. 2.75 ± .25 in. 54 1 3/4 44 2.634 3.431 4.776 — — 60 1 3/4 52 2.892 3.774 5.236 — — 66 1 3/4 52 3.139 4.132 5.674 — — 72 1 3/4 60 3.399 4.476 6.137 — — 250/300 NOM PIPE SIZE 1 1 1/2 2 2 1/2 3 4 5 6 8 10 12 14 16 18 20 24 30 36 42 48 BOLT SIZE NO. BOLTS 5/8 3/4 5/8 3/4 3/4 3/4 3/4 3/4 7/8 1 1 1/8 1 1/8 1 1/4 1 1/4 1 1/4 1 1/2 1 3/4 2 2 2 4 4 8 8 8 8 8 12 12 16 16 20 20 24 24 24 28 32 36 40 TABLE 6 CLASS F — — — — — 1.130 1.210 1.310 1.310 1.500 1.630 1.940 2.140 2.250 2.330 2.690 3.150 3.460 3.810 4.500 ANSI SLIP ON FLANGES 0.688 0.813 0.875 1.000 1.125 1.250 1.375 1.438 1.625 1.875 2.000 2.125 2.250 2.375 2.500 2.750 — — — — A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF BLIND FLANGES CLASS F — — — — — 1.125 — 1.316 1.316 1.534 1.730 1.938 2.139 2.294 2.401 2.799 3.419 4.017 4.450 4.991 TRIPAC MARKETING, INC. ANSI GASKET DIMENSIONS ANSI GASKET SIZE CL 125/150 Flange Size RING ID RING OD FULL FACE ID FULL FACE OD 2” 2 3/8 4 1/8 2 3/8 6 2 1/2” 2 7/8 4 7/8 2 7/8 7 3” 3 1/2 5 3/8 3 1/2 7 1/2 4” 4 /2 6 7/8 4 1/2 9 5” 5 9/16 7 3/4 5 9/16 10 6” 6 5/8 8 3/4 6 5/8 11 8” 8 5/8 11 8 5/8 13 1/2 10” 10 3/4 13 3/8 10 3/4 16 12” 12 3/4 16 1/8 12 3/4 19 14” 14 17 3/4 14 21 16” 16 20 1/4 16 23 1/2 18” 18 21 5/8 18 25 20” 20 23 7/8 20 27 1/2 24” 24 28 1/4 24 32 30” 30 34 3/4 30 38 3/4 36” 36 41 1/4 36 46 42” 42 48 42 53 48” 48 54 1/2 48 59 1/2 A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TRIPAC MARKETING, INC. WRENCH SIZE CHARTS This chart may be used for This chart may be used for HEX Bolts & Nuts A307 Gr. A, Gr. 5, HEAVY Hex Bolts & Nuts A307 Gr. B, ASTM F593/F594 Type 304 & 316 BOLT AND NUT DIAMETER WRENCH SIZE 1/4 5/16 7/16 1/2 0.4375 0.5000 3/8 7/16 9/16 5/8 0.5625 0.6250 1/2 9/16 3/4 13/16 5/8 A325, A193 B7, B8 (304), B8M (316) Stainless BOLT AND NUT DIAMETER WRENCH SIZE 1/2 7/8 0.8750 5/8 1 1/16 1.0625 3/4 1 1/4 1.2500 0.7500 0.8125 7/8 1 7/16 1.4375 15/16 0.9375 1 1 5/8 1.6250 3/4 7/8 1 1/8 1 5/16 1.1250 1.3125 1 1/8 1 13/16 1.8125 1 1 1/2 1.500 1 1/4 2 2.0000 1 1/8 1 11/16 1.6875 1 1/4 1 7/8 1.8750 1 3/8 2 3/16 2.1875 1 3/8 2 1/16 2.0625 1 1/2 2 3/8 2.3750 1 1/2 2 1/4 2.2500 1 5/8 2 9/16 2.5625 1 5/8 2 7/16 2.4375 1 3/4 2 5/8 2.6250 1 3/4 2 3/4 2.7500 1 7/8 2 13/16 2.8125 1 7/8 2 15/16 2.9375 2 3 3.000 2 1/4 3 3/8 3.3750 2 3 1/8 3.1250 2 1/2 3 3/4 3.7500 2 1/4 3 1/2 3.5000 2 3/4 1 1/8 4.1250 3 4 1/2 4.5000 2 1/2 3 7/8 3.8750 3 1/4 4 7/8 4.8750 2 3/4 4 1/4 4.2500 3 1/2 5 1/4 5.2500 3 3/4 5 5/8 5.6250 3 4 5/8 4.6250 4 6 6.0000 3 1/4 5 5.0000 A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TRIPAC MARKETING, INC. DECIMAL CONVERSION CHART FRACTIONS DECIMALS FRACTIONS DECIMALS FRACTIONS DECIMALS 1/64 .015625 23/64 .359375 45/64 .703125 1/32 .03125 3/8 .3750 23/32 .71875 3/64 .046875 25/64 .390625 47/64 .734375 1/16 .0625 13/32 .40625 3/4 .7500 5/64 .078125 27/64 .421875 49/64 .765625 3/32 .09375 7/16 .4375 25/32 .78125 7/64 .109375 29/64 .453125 51/64 .796875 1/8 .1250 15/32 .46875 13/16 .8125 9/64 .140625 31/64 .484375 53/64 .828125 5/32 .15625 1/2 .5000 27/32 .84375 11/64 .171875 33/64 .515625 55/64 .859375 3/16 .1875 17/32 .53125 7/8 .8750 13/64 .203125 35/64 .546875 57/64 .890625 7/32 .21875 9/16 .5625 29/32 .90625 15/64 .234375 37/64 .578125 59/64 .921875 1/4 .2500 19/32 .59375 15.32 .9375 17/64 .265625 39/64 .609375 61/64 .953125 9/32 .28125 5/8 .6250 31/32 .96875 19/64 .296875 41/64 .640625 63/64 .984375 5/16 .3125 21/32 .65625 1 1.000 21/64 .328125 43/64 .671875 11/32 .34375 11/16 .6875 A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TRIPAC MARKETING, INC. INDUSTRY STANDARDS MECHANICAL PROPERTIES When strength requirements are moderate, low-carbon steel is used. High-strength fasteners are made from medium-high carbon or alloy steels and are heat treated to develop desired properties. ASTM & SAE HEAD MARKINGS FOR BOLTS ASTM—A307 GR A A307 B ASTM—A307 • Low or Medium Carbon Steel GR B Most fasteners are covered by specifications that define required mechanical properties such as tensile strength, yield strength, proof load and hardness. • Tensile Strength: The maximum tensile stress in pounds per sq in. which a material is capable of sustaining, as developed by a tension test. • Yield Strength: The stress at which a material exhibits a specified deviation from the proportionality of stress to strain. The deviation is expressed in terms of strain, and in the offset method, usually a strain of 0.2% is specified. • Proof Load: The point to which a material may be stressed without evidence of permanent deformation. • Hardness: The resistance of a material to plastic deformation. Usually measured in steels by the Brinell, Rockwell, or Vickers indentation-hardness test methods. ASTM—J429 GR 5 ASTM—A193 • Chrom-Moly Steel GR B7 Quenched & Tempered A325 ASTM—A325 • Medium Carbon Steel Type 1 Quenched & Tempered Heat treatment covers various techniques that may be used to develop certain end-product characteristics. Customary procedures for fasteners include: • Annealing: A thermal cycle involving heating to and holding at a suitable temperature and then cooling at a suitable rate, for such purposes as reducing hardness, improving mechinability, facilitating cold working, producing a desired microstructure, or obtaining desired mechanical or other properties. • Case Hardening: A term descriptive of one or more processes of hardening steel in which the outer portion, or case, is made substantially harder than the inner portion, or core. • Quenching and Tempering: Quenching is a thermal process used to increase the hardness and strength of steel. Tempering improves ductility and toughness but reduces the quenched hardness. • Medium Carbon Steel Quenched & Tempered B7 HEAT PROPERTIES • Stress Relieving: A thermal cycle involving heating to a suitable temperature, usually 1000/1200°F, holding long enough to reduce residual stresses from either cold deformation or thermal treatment, and then cooling slowly enough to minimize the development of new residual stresses. • Low or Medium Carbon Steel A307 A 18-8 18 Chromium 8 Nickel • “300” Series Stainless Steel Same Material as T-304 T-304 or F 593 C or D ASTM—T 304 • “300” Series Stainless Steel or ASTM F 593 • Either Marking May Appear T-316 or F 593 G or H ASTM—T 316 or ASTM F 593 • “300” Series Stainless Steel • Either Marking May Appear B8 ASTM—A193 • Solution Treated 304 - 304L Gr B8 Stainless Steel B8M ASTM—A193 • Solution Treated 316 - 316L GR B8M Stainless Steel A D I V I S I O N OF T RIPAC M A R K E T I N G , IN C . 475 K LUG C IRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 HEX BOLTS & NUTS Hex Bolts UNC 2A ANSI/ASME B18.2.1 • UNC 2B ANSI/ASME B18.2.2 This chart may be used for A307 Grade A, SAE J429, and ASTM F593 Type 304 & 316 Stainless NOMINAL SIZE OR BASIC BOLT DIA E F G H R LT (REF) BODY DIA WIDTH ACROSS FLATS WIDTH ACROSS CORNERS HEIGHT RADIUS OF FILLET THREAD LENGTH MAX BASIC MAX MIN MAX MIN BASIC MAX MIN MAX MIN FOR BOLT LENGTH < 6 IN. FOR BOLT LENGTH > 6 IN. 1/4 5/16 3/8 7/16 .2500 0.3125 0.3750 0.4375 0.260 0.324 0.388 0.452 7/16 1/2 9/16 5/8 0.438 0.425 0.500 0.484 0.562 0.544 0.625 0.603 0.505 0.577 0.650 0.722 0.484 0.522 0.620 0.687 11/64 0.188 0.150 7/32 0.235 0.195 1/4 0.268 0.226 19/64 0.316 0.272 0.03 0.03 0.03 0.03 0.01 0.01 0.01 0.01 0.750 0.875 1.000 1.125 1.000 1.125 1.250 1.375 1/2 5/8 3/4 7/8 0.5000 0.6250 0.7500 0.8750 0.515 0.642 0.768 0.895 3/4 15/16 1 1/8 1 0.750 0.725 0.938 0.906 1.125 1.088 1.312 1.269 0.866 1.083 1.299 1.516 0.826 1.033 1.240 1.447 11/32 0.364 0.302 27/64 0.444 0.378 1/2 0.524 .0455 37/64 0.604 0.531 0.03 0.06 0.06 0.06 0.01 0.02 0.02 0.02 1.250 1.500 1.750 2.000 1.500 1.750 2.000 2.250 1.0000 1.1250 1.2500 1.3750 1.500 1.022 1.149 1.277 1.404 1.531 1 1/2 1.500 1.450 1.732 1.653 1 1.688 1.631 1.949 1.859 1 7/8 1.875 1.812 2.165 2.066 2 2.062 1.994 2.382 2.273 2 1/4 2.250 2.175 2.598 2.480 43/64 0.700 0.591 3/4 0.780 0.658 27/32 0.876 0.749 29/32 0.940 0.810 1 1.036 0.902 0.09 0.09 0.09 0.09 0.09 0.03 0.03 0.03 0.03 0.03 2.250 2.500 2.750 3.000 3.250 2.500 2.750 3.000 3.250 3.500 1 1 1 1 1 1/8 1/4 3/8 1/2 Below 6” : 2x Dia. + 1/4 = T.L. Above 6” : 2x Dia. + 1/2 = T.L. Hex Nuts and Hex Jam Nuts ASTM A563/F594 NOMINAL SIZE OR BASIC BOLT DIA F G H H1 WIDTH ACROSS FLATS WIDTH ACROSS CORNERS THICKNESS HEX NUTS THICKNESS HEX JAM NUTS BASIC 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1 1/8 1 1/4 .2500 0.3125 0.3750 0.4375 0.5000 0.5625 0.6250 0.7500 0.8750 1.0000 1.1250 1.2500 MAX MIN 7/16 0.438 0.428 1/2 0.500 0.489 9/16 0.562 0.551 11/16 0.688 0.675 3/4 0.750 0.736 7/8 0.875 0.861 15/16 0.938 0.922 1 1/8 1.125 1.088 1 5/16 1.312 1.269 1 1/2 1.500 1.450 1 1.688 1.631 1 7/8 1.875 1.812 MAX MIN 0.505 0.577 0.650 0.794 0.866 1.010 1.083 1.299 1.516 1.732 1.949 2.165 0.488 0.557 0.628 0.768 0.840 0.982 1.051 1.240 1.447 1.653 1.859 2.066 HEX NUTS WITH SPECIFIED PROOF LOADS LESS THAN 150,000 PSI AND ALL HEX JAM NUTS HEX NUTS WITH SPECIFIED PROOF LOADS EQUAL TO 150,000 PSI AND GREATER MIN MAX MAX 0.150 0.180 0.210 0.240 0.302 0.301 0.363 0.398 0.458 0.519 0.579 0.687 0.015 0.016 0.017 0.018 0.019 0.020 0.021 0.023 0.025 0.027 0.030 0.033 0.010 0.011 0.012 0.013 0.014 0.015 0.016 0.018 0.020 0.022 0.025 0.028 1.20 1.13 25/3 0.815 0.747 1.31 1.24 27/3 0.880 0.808 0.036 0.039 0.031 0.034 BASIC MAX MIN BASIC MAX 7/32 17/64 21/64 3/8 7/16 31/64 35/64 41/64 3/4 55/64 31/32 1 1 3/8 1.3750 2 1/16 2.062 1.994 2.382 2.273 1 1 1/2 1.5000 2 1/4 2.250 2.175 2.598 2.480 1 RUNOUT OF BEARING SURFACE-FIR 0.22 0.27 0.33 0.38 0.44 0.49 0.55 0.66 0.77 0.88 0.99 1.09 0.21 0.25 0.32 0.36 0.42 0.47 0.53 0.61 0.72 0.83 0.93 1.03 5/32 3/16 7/32 1/4 5/16 5/16 3/8 27/6 31/6 35/6 39/6 23/3 0.164 0.195 0.227 0.260 0.323 0.324 0.387 0.446 0.510 0.575 0.639 0.751 A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TRIPAC MARKETING, INC. HEAVY HEX BOLTS & NUTS Heavy Hex Bolts UNC 2A ANSI/ASME B18.2.1 • UNC 2B ANSI/ASME B18.2.2 This chart may be used for A307 Grade B, A193 B7, B8 (304), and B8M (316) Stainless NOMINAL SIZE OR BASIC BOLT DIA 1/2 5/8 3/4 7/8 1 1 1/8 1 1/4 1 3/8 1 1/2 1 3/4 2 2 1/4 2 1/2 2 3/4 3 0.5000 0.6250 0.7500 0.8750 1.0000 1.1250 1.2500 1.3750 1.5000 1.7500 2.0000 2.2500 2.5000 2.7500 3.0000 E BODY DIA M AX 0.515 0.642 0.768 0.895 1.022 1.149 1.277 1.404 1.531 1.785 2.039 2.305 2.559 2.827 3.081 F W IDTH ACROSS FLATS BASIC M AX M IN 7/8 1 1/16 1 1/4 1 7/16 1 5/8 1 2 2 3/16 2 3/8 2 3/4 3 1/8 3 1/2 3 7/8 4 1/4 4 5/8 G W IDTH ACROSS CORNERS M AX M IN 0.875 0.850 1.062 1.031 1.250 1.212 1.438 1.394 1.625 1.575 1.812 1.756 2.000 1.938 2.188 2.119 2.375 2.300 2.750 2.662 3.125 3.025 3.500 3.388 3.875 3.750 4.250 4.112 4.625 4.475 1.010 1.227 1.443 1.660 1.876 2.093 2.309 2.526 2.742 3.175 3.608 4.041 4.474 4.907 5.340 0.969 1.175 1.383 1.589 1.796 2.002 2.209 2.416 2.622 3.035 3.449 3.862 4.275 4.688 5.102 H HEIGHT BASIC M AX R RADIUS OF FILLET M AX M IN M IN 11/32 0.364 0.302 27/64 0.444 0.378 1/2 0.524 0.455 37/64 0.604 0.531 43/64 0.700 0.591 3/4 0.780 0.658 27/32 0.876 0.749 29/32 0.940 0.810 1 1.036 0.902 1 5/32 1.196 1.054 1 1.388 1.175 1 1/2 1.548 1.327 1 1.708 1.479 1 1.869 1.632 2 2.060 1.815 0.03 0.06 0.06 0.06 0.09 0.09 0.09 0.09 0.09 0.12 0.12 0.19 0.19 0.19 0.19 0.01 0.02 0.02 0.02 0.03 0.03 0.03 0.03 0.03 0.04 0.04 0.06 0.06 0.06 0.06 LT (R EF) THREAD LENGTH FOR BOLT FOR BOLT LENGTH < 6 IN . LENGTH > 6 IN . 1.250 1.500 1.750 2.000 2.250 2.500 2.750 3.000 3.250 3.750 4.250 4.750 5.250 5.750 6.250 1.500 1.750 2.000 2.250 2.500 2.750 3.000 3.250 3.500 4.000 4.500 5.000 5.500 6.000 6.500 Below 6” : 2x Dia. + 1/4 = T.L. Above 6” : 2x Dia. + 1/2 = T.L. Heavy Hex Nuts and Hex Jam Nuts ASTM A563 & A194 2H NOMINAL SIZE OR BASIC BOLT DIA F G H H1 W IDTH ACROSS FLATS W IDTH ACROSS CORNERS THICKNESS HEAVY HEX NUTS RUNOUT OF BEARING SURFACE-FIR HEX NUTS WITH HEX NUTS WITH SPECIFIED PROOF THICKNESS SPECIFIED PROOF LOADS LOADS EQUAL TO HEAVY HEX JAM NUTS LESS THAN 150,000 PSI 150,000 PSI AND AND ALL HEX JAM NUTS GREATER 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1 1/8 1 1/4 1 3/8 1 1/2 1 5/8 1 3/4 1 7/8 2 2 1/4 2 1/2 2 3/4 3 3 1/4 .2500 0.3125 0.3750 0.4375 0.5000 0.5625 0.6250 0.7500 0.8750 1.0000 1.1250 1.2500 1.3750 1.5000 1.6250 1.7500 1.8750 2.0000 2.2500 2.5000 2.7500 3.0000 3.2500 BASIC 1/2 9/16 11/16 3/4 7/8 15/16 1 1 1/4 1 1 5/8 1 2 2 2 3/8 2 2 3/4 2 3 1/8 3 1/2 3 7/8 4 1/4 4 5/8 5 M AX M IN 0.500 0.488 0.562 0.546 0.688 0.669 0.750 0.728 0.875 0.850 0.938 0.909 1.062 1.031 1.250 1.212 1.438 1.394 1.625 1.575 1.812 1.756 2.000 1.938 2.188 2.119 2.375 2.300 2.562 2.481 2.750 2.662 2.938 2.844 3.125 3.025 3.500 3.388 3.875 3.750 4.250 4.112 4.625 4.475 5.000 4.838 M AX 0.577 0.650 0.794 0.866 1.010 1.083 1.227 1.443 1.660 1.876 2.093 2.309 2.526 2.742 2.959 3.175 3.392 3.608 40.41 4.474 4.907 5.340 5.774 M IN 0.556 0.622 0.763 0.830 0.9691 1.037 1.175 1.382 1.589 1.796 2.002 2.209 2.416 2.622 2.828 3.035 3.242 3.449 3.862 4.275 4.688 5.102 5.515 BASIC 15/64 19/64 23/64 27/64 31/64 35/64 39/64 47/64 55/64 63/64 1 1 1 1 1 1 1 1 2 2 2 2 3 M AX 0.25 0.31 0.37 0.44 0.50 0.56 0.63 0.75 0.88 1.01 1.13 1.25 1.37 1.50 1.63 1.75 1.88 2.01 2.25 2.50 2.75 3.01 3.25 M IN 0.21 0.28 0.34 0.40 0.46 0.52 0.58 0.71 0.83 0.95 1.07 1.18 1.31 1.43 1.55 1.67 1.80 1.92 2.15 2.40 2.64 2.89 3.12 BASIC 11/64 13/64 15/64 17/64 19/64 21/64 23/64 27/64 31/64 35/64 39/64 23/32 25/32 27/32 29/32 31/31 1 1 1 1 1 1 1 M AX 0.188 0.220 0.252 0.285 0.317 0.349 0.381 0.446 0.510 0.575 0.639 0.751 0.815 0.880 0.944 1.009 1.073 1.138 1.251 1.505 1.634 1.763 1.876 M IN 0.156 0.186 0.216 0.247 0.277 0.307 0.337 0.398 0.458 0.519 0.579 0.687 0.747 0.808 0.868 0.929 0.989 1.050 1.155 1.401 1.522 1.643 1.748 M AX 0.017 0.020 0.021 0.022 0.029 0.031 0.033 0.035 0.029 0.031 0.033 0.035 0.038 0.041 0.044 0.048 0.074 0.081 0.080 0.094 0.074 0.081 0.087 M AX 0.011 0.012 0.014 0.015 0.022 0.024 0.027 0.030 0.022 0.024 0.027 0.030 0.033 0.036 0.038 0.041 0.064 0.070 0.075 0.081 0.064 0.070 0.075 WASHERS USS Steel Flat Washers Commonly used with carbon steel bolting and all thread studs, such as A307 Grade A or B. NOMINAL SIZE ACTUAL ID 3/16 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1 1/8 1 1/4 1 3/8 1 1/2 1 5/8 1 3/4 1 7/8” 2 2 1/4 2 1/2 2 3/4 3 1/4 5/16 3/8 7/16 1/2 9/16 5/8 11/16 13/16 15/16 1 1/16 1 1/4 1 3/8 1 1/2 1 5/8 1 3/4 1 7/8 2 2 1/8 2 3/8 2 5/8 2 7/8 3 1/8 ACTUAL OD 9/16 3/4 7/8 1 1 1/4 1 3/8 1 1/2 1 3/4 2 2 1/4 2 1/2 2 3/4 3 3 1/4 3 1/2 3 3/4 4 4 1/4 4 1/2 4 3/4 5 5 1/4 5 1/2 THICKNESS GAUGE 18 (3/64) 16 (1/16) 14 (5/64) 14 (5/64) 14 (5/64) 12 (7/64) 12 (7/64) 10 (9/64) 9 (5/32) 8 (11/64) 8 (11/64) 8 (11/64) 8 (11/64) 7 (3/16) 7 (3/16) 7 (3/16) 7 (3/16) 7 (3/16) 7 (3/16) 5 (7/32) 4 (15/64) 3 (1/4) 2 (17/64) SAE Steel Flat Washers SAE washers have smaller inside and outside diameters and are commonly used with carbon steel bolts and studs. ACTUAL ID ACTUAL OD THICKNESS GAUGE 6 (1/8) 8 (5/32) 5/32 3/16 3/8 7/16 18 (3/64) 18 (3/64) 10 7/32 1/2 18 (3/64) 12 1/4 9/16 18 (3/64) 1/4 9/32 5/8 16 (1/16) 5/16 11/32 11/16 16 (1/16) 3/8 13/32 13/16 16 (1/16) 7/16 15/32 59/64 16 (1/16) 1/2 17/32 1 1/16 13 (3/32) NOMINAL SIZE 9/16 19/32 1 3/16 13 (3/32) 5/8 21/32 1 5/16 13 (3/32) 3/4 13/16 1 1/2 10 (9/64) 7/8 15/16 1 3/4 10 (9/64) 1 1 1/16 2 10 (9/64) 1 1/8 1 3/16 2 1/4 10 (9/64) 1 1/4 1 5/16 2 1/2 9 (5/32) 1 3/8 1 7/16 2 3/4 9 (5/32) 1 1/2 1 9/16 3 9 (5/32) Fender Washers Fender washers have a larger outside diameter than other steel washers. NOMINAL SIZE Washers are intended for general use with bolt, nut, and stud applications to provide increased bearing surface, spacing and to prevent galling. Unless otherwise specified, the washers are furnished with dimensions conforming to ANSI B.18.22.1. * ASTM Designation: F844-90, page 265, 1.2-1.3 * Available in plain, zinc plated, HDG, Tripac 2000 Blue Coating System THICKNESS GAUGE 1/8 3/16 1 1 .062/.080 .062/.080 3/16 1 1/8 .062/.080 3/16 1 1/4 .062/.080 1/4 1 .062/.080 1/4 1 1/4 .062/.080 1/4 1 1/2 .062/.080 5/16 1 1/4 .062/.080 5/16 1 1/2 .062/.080 3/8 1 1/4 .062/.080 3/8 1 1/2 .062/.080 3/8 2 .096/.116 1/2 1 1/2 .062/.080 1/2 2 .062/.080 1/2 2 .096/.116 A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 ACTUAL OD OF TRIPAC MARKETING, INC. WASHERS Stainless Steel Washers With Large and Small I.D./O.D. Commonly used with stainless steel bolts and studs such as ASTM F593, A193, B8 & B8M. ASTM F436 (A325) Washers Commonly used with alloy steel, high strength bolting and studs, such as ASTM A193B7, SAE J429 & Grade 8, A325 & A490. NOMINAL SIZE ACTUAL ID ACTUAL OD THICKNESS GAUGE A B T NOMINAL SIZE ACTUAL ID ACTUAL OD THICKNESS GAUGE A B T 1/4 5/16 9/32 11/32 5/8 11/16 .051/.08 .051/.08 1/4 5/16 .281 .343 5/8 3/4 .050 .050 3/8 13/32 13/16 .051/.08 3/8 .406 7/8 .050 7/16 15/32 59/64 .051/.08 3/8 .406 1 .050 1/2 17.32 1 1/16 .097/.17 7/16 .500 1 1/8 .062 5/8 11/16 1 5/16 .122/.17 1/2 .531 1 1/4 .062 3/4 13/16 1 .122/.17 5/8 .687 1 5/16 .078 7/8 15/16 1 3/4 .136/.17 5/8 .687 1 1/2 .078 1 1 1/8 2 .136/.17 3/4 .812 1 1/2 .109 1 1/8 1 1/4 2 1/4 .136/.17 3/4 .812 1 3/4 .109 1 1/4 1 3/8 2 1/2 .136/.17 3/4 .812 1 7/8 .109 1 3/8 1 1/2 2 3/4 .136/.17 7/8 .937 1 3/4 .109 1 1/2 1 5/8 3 .136/.17 7/8 .937 1 7/8 .109 1 3/4 1 7/8 3 3/8 .178/.28 1 1.062 2 .125 2 2 1/8 3 3/4 .178/.28 1 1.062 2 1/4 .125 2 1/4 2 3/8 4 .24/.34 1 1.062 2 1/2 .125 2 1/2 2 5/8 4 1/2 .24/.34 1 1/8 1.187 2 1/4 .125 2 3/4 2 7/8 5 .24/.34 1 1/8 1.187 2 1/2 .125 3 3 1/8 5 1/2 .24/.34 1 1/4 1.312 2 1/4 .125 3 1/4 3 3/8 6 .24/.34 1 1/4 1.312 2 3/4 .125 1 1/2 1.562 2 3/4 .140 1 1/2 1.562 3 1/4 .140 1 3/4 1.812 3 1/2 .140 2 2.125 3 3/4 .187 2 2.125 4 .187 Washers are intended for general use with bolt, nut, and stud applications to provide increased bearing surface, spacing and to prevent galling. Unless otherwise specified, the washers are furnished with dimensions conforming to ANSI B.18.22.1. B T A A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TRIPAC MARKETING, INC. WATER WORKS T-HEAD BOLTS ANSI/AWWA C111/A21.11.95 ANSI/ASME B1.1 CLASS 2A, B1.2 CLASS 2B DIMENSIONAL INFORMATION A UN THREADED SHANK + 0.030 - 0.074 B 5/8 - 11 x 3 1.50 0.625 3.0 2.00 0.625 0.312 0.625 ± 0.04 1.062 ± 0.00 - 0.04 5/8 - 11 x 5 1.75 0.625 5.0 2.00 0.625 0.312 0.625 ± 0.04 1.062 ± 0.00 - 0.04 3/4 - 10 x 3 1/2 1.75 0.750 3.5 2.50 0.750 0.375 0.750 ± 0.06 1.250 ± 0.00 - 0.06 3/4 - 10 x 4 1.75 0.750 4.0 3.00 0.750 0.375 0.750 ± 0.06 1.250 ± 0.00 - 0.06 3/4 - 10 x 4 1/2 1.75 0.750 4.5 3.00 0.750 0.375 0.750 ± 0.06 1.250 ± 0.00 - 0.06 3/4 - 10 x 5 1.75 0.750 5.0 3.00 0.750 0.375 0.750 ± 0.06 1.250 ± 0.00 - 0.06 3/4 - 10 x 5 1/2 1.75 0.750 5.5 3.00 0.750 0.375 0.750 ± 0.06 1.250 ± 0.00 - 0.06 3/4 - 10 x 6 1.75 0.750 6.0 3.00 0.750 0.375 0.750 ± 0.06 1.250 ± 0.00 - 0.06 3/4 - 10 x 6 1/2 1.75 0.750 6.5 3.50 0.750 0.375 0.750 ± 0.06 1.250 ± 0.00 - 0.06 3/4 - 10 x 7 1.75 0.750 7.0 4.00 0.750 0.375 0.750 ± 0.06 1.250 ± 0.00 - 0.06 3/4 - x 9 1.75 0.750 9.0 5.00 0.750 0.375 0.750 ± 0.06 1.250 ± 0.00 - 0.06 1-8x5 2.25 1.000 5.0 3.00 1.000 0.500 0.100 ± 0.08 1.625 ± 0.00 - 0.08 1-8x6 2.25 1.000 6.0 3.00 1.000 0.500 0.100 ± 0.08 1.625 ± 0.00 - 0.08 1 1/4 - 7 x 6 2.50 1.250 6.0 3.50 1.250 0.625 0.125 ± 0.08 2.000 ± 0.00 - 0.08 1 1/4 - 7 x 6 1/2 2.50 1.250 6.5 3.50 1.250 0.625 0.125 ± 0.08 2.000 ± 0.00 - 0.08 SIZE ± 0.05 Available in: • T-316 Stainless + 0.25 - 0.06 THREAD LENGTH + .015 - 0.03 C D E NUT THICKNESS NUT WIDTH ACROSS FLATS G H F • ASTM A242 Weathering Steel (Atmospheric corrosion resistant steel) Tripac 2000 Blue can be applied upon request A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TRIPAC MARKETING, INC. OVAL NECK TRACK BOLTS ANSI/ASME B18.10 DIMENSIONAL INFORMATION NOMINAL HEAD DIAMETER OVER THREAD NECK L I H R1 R2 O R P 1/2 - 13 x 2 3/4 7/8 5/16 11/16 9/32 5/8 19/32 5/16 1 1/8 5/8 - 11 x 3 1/4 1 5/64 25/64 59/64 23/64 13/16 25/32 3/8 1 1/4 5/8 - 11 x 4 1/2 1 5/64 25/64 59/64 23/64 13/16 25/32 3/8 1 1/4 5/8 - 11 x 6 1 5/64 25/64 59/64 23/64 13/16 25/32 3/8 1 1/4 5/8 - 11 x 8 1 5/64 25/64 59/64 23/64 13/16 25/32 3/8 5/8 - 11 x 9 1/2 1 5/64 25/64 59/64 23/64 13/16 25/32 5/8 - 11 x 10 1 5/64 25/64 59/64 23/64 13/16 25/32 5/8 - 11 x 10 1/2 1 5/64 25/64 59/64 23/64 13/16 25/32 5/8 - 11 x 15 1 5/64 25/64 59/64 23/64 13/16 25/32 3/4 - 10 x 5 1 9/32 15/32 1 5/32 7/16 1 1/16 1 1/32 7/8 - 9 x 5 1 31/64 35/64 1 25/64 33/64 1 7/32 1 3/16 1 - 8 x 3 1/2 1 11/16 5/8 1 5/8 19/32 1 3/8 1 11/32 9/16 2 1/4 1 - 8 x 5 1/2 1 11/16 5/8 1 5/8 19/32 1 3/8 1 11/32 9/16 2 1/4 1 - 8 x 6 1/2 1 11/16 5/8 1 5/8 19/32 1 3/8 1 11/32 9/16 2 1/4 1 1/8 - 7 x 4 1 57/64 1 1/2 V THREAD LENGTH MIN A 45/64 1 55/64 43/64 1 17/32 R3 LENGTH UNDER HEAD 1 1/4 Under 7 3/8 in. by 1 1/4 Same steps of 3/8 1 1/4 as 1/2 1/4 in. body body 3/8 1 1/4 diam. diam. From 7 to 10 in. 1 1/4 of 3/8 of bolt bolt by steps of 1/2 1 3/4 7/16 in. 1/2 2 5/8 2 1/2 * Information obtained from the Industrial Fasteners Institute, “Fastener Standards, Sixth Edition” Page C-58 A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TRIPAC MARKETING, INC. A325 BOLTS Heavy Hex Structural Bolts UNC 2A ANSI/ASME B18.2.1 I This chart is used for A325 high strength structural bolting to be used with A194 2H Nuts F G H LT I WIDTH ACROSS FLATS WIDTH ACROSS CORNERS HEIGHT THREAD LENGTH NUT THICKNESS INCH MAX MIN MAX MIN MAX MIN BASIC MAX MIN 1/2 - 13 0.875 0.850 1.010 0.969 0.323 0.302 1.00 0.504 0.464 5/8 - 11 1.062 1.031 1.227 1.175 0.403 0.378 1.25 0.631 0.587 3/4 - 10 1.250 1.212 1.443 1.383 0.483 0.455 1.38 0.758 0.710 7/8 - 9 1.438 1.394 1.660 1.589 0.563 0.531 1.50 0.885 0.833 1-8 1.625 1.575 1.876 1.796 0.627 0.591 1.75 1.012 0.956 1 1/8 - 7 1.812 1.756 2.093 2.002 0.718 0.658 2.00 0.139 1.079 1 1/4 - 7 2.000 1.938 2.309 2.209 0.813 0.749 2.00 1.251 1.187 1 3/8 - 6 2.188 2.119 2.526 2.416 0.878 0.810 2.25 1.378 1.310 1 1/2 - 6 2.375 2.300 2.742 2.622 0.974 0.902 2.25 1.505 1.433 A DIVISION OF NOMINAL SIZE AND THREADS PER 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 TRIPAC MARKETING, INC. COATINGS Zinc Plating Process HOT ALKALINE CLEANER WATER RINSE HYDROCHLORIC ACID WATER RINSE WATER RINSE ZINC PLATE Electroplated ASTM specifications B633 electroplating is an electrochemical process used to deposit a metallic coating on the base material of an object by immersing it in an electrically charged solution so that a suitable low voltage flows through it, causing the metallic coating to be attracted to the object being plated. • WATER RINSE • BLACK CHROMATE • CLEAR CHROMATE YELLOW CHROMATE WATER RINSE • • Inexpensive Sacrificial protection against corrosion Commonly used on nuts, bolts, washers, anchor bolts, fittings, pipe hangers, pipe supports, etc. Commercial zinc plate .0002 thickness Zinc Plating process provided by Sonic Plating Co., Inc., Santa Fe Springs, CA HOT WATER HOT AIR DRY Galvanizing Process SURFACE PREPARATION GALVANIZING FINISHING − Abrasive blasting − Immersion into molten − Alkaline cleaning zinc from 1 to 5 min. − Finish process in clean zinc bath − Acid Cleaning − Removal of excess zinc − Quenching − Inspection Hot Dip Galvanized Galvanizing is the practice of coating clean, oxide-free iron or steel with a thin layer of zinc to protect the surface against corrosion. ASTM A153 specification applies to coated fabricated products such as nuts, bolts, washers and anchor bolts. ASTM A123 specification applies to coated fabricated products such as fittings, pipe hangers, channel & pipe supports. • Shields the base metal from the atmosphere because zinc gives cathodic or sacrificial protection • Hot Dip Galvanized process provided by Atlas Galvanizing, LLC, Los Angeles, CA A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TRIPAC MARKETING, INC. PROPER FLANGE BOLTING Flanges In theory, if it were possible to have two perfectly mated flanges with total effective contact at all points, a gasket would not be required to effect a seal. Obviously since this is not possible, a gasket is required and its function is to seal two imperfect surfaces. There are limits on the degree of flange surface imperfections that can be sealed successfully with a gasket. Large nicks, dents and gouges must be avoided, since a gasket cannot seal against them properly. Also, a gasket cannot seal improperly aligned flanges. Another problem is waviness in the flanges and warped or bowed flanges. This can be caused by heat during the manufacturing or welding process, internal stress and excessive bolt loads during installation. See figure 1. To obtain a satisfactory seal, it is necessary that basic procedures are followed during installation. These procedures are of fundamental importance for a successful operation no matter what style of gasket or type of bolting materials are used. While these flange installation procedures may seem elementary, they are extremely important and should be carefully followed. Flange Installation Procedures 1. Inspect the flanges. Check for tool marks, dents, scratches or corrosion. Look for pitting and any other defects which would make sealing impossible. Repairs must be made before bolting. 2. Inspect the gasket. Verify to be sure the gasket is of the proper material and style. Look for defects or damage. 3. Inspect and clean bolts, nuts and washers. Verify to be sure they are of the specified material. 4. Lubricate the bolt threads and the nut contact surfaces. This cannot be overstressed. The use of an anti-seize compound should be considered to facilitate subsequent disassembly. The better the lubricant, the more consistent the actual achieved bolt stress at installation will be. 5. Center the gasket on the flange. This is extremely vital when raised faced flanges are used. 6. Tighten the bolts approximately 30% to the final torque following the sequence shown in Figure 2 (shown on next page). If the correct tightening sequence is not followed, the flanges can be misaligned, making it impossible to have uniform seating of the gasket. Numbering the bolts may be helpful in following the bolt sequence. 7. Repeat step 6, elevating the torque to 50 to 60 percent of the final torque. 8. Continue tightening in the recommended sequence until the final torque value is reached. Each bolt normally has to be tightened more than once. A - Bowing of flange due to too high bolt load 9. All gaskets relax after seating. Retightening is recommended 24 hours after installation to compensate for the relaxation. On highpressure or high-temperature applications, it is recommended that the flanges be retorqued to the required stress after 24 hours at operating pressure and temperatures to compensate for any relaxation. A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TRIPAC MARKETING, INC. PROPER FLANGE BOLTING Gaskets Bolting Gaskets are used to create a static seal between two flanges and to maintain that seal under operating conditions. Proper gasket selection is critical and must be considered during the design and engineering process of any system. A bolt is a spring. It is an elastic member which has been stretched to develop a load by elongating its length. It must not be overelongated (over-strained), or the elastic limit of the steel will be exceeded. The bolt then deforms and with continued loading (stressing) will quickly fail. Once the type of material and style of gasket is determined, proper installation is critical to achieve “seating” of the gasket. A seal is effected by compressing the gasket material and causing it to flow into the imperfections on the flanges so that intimate contact is made preventing leaking of the joint. The most common method of effecting a seal on a flange joint is through compression force applied by bolting. Torque Torque is a twisting force. When applied to a bolt it is generally expressed in foot pounds. The formula for torque is T = R x S where: To avoid such problems with bolt tightening, the use of a torque wrench is recommended. The designer of the flange system normally specifies the torque required to achieve a proper seal. The inch-per-inch relationship demonstrates that the longer the bolt, the more it must be strained to yield a desired load; thus, the more follow-up or comeback there will be in actual inches. This is highly desirable, since most gasketing materials tend to remold, to relax, to take a permanent set. This is called the creep-relaxation phenomenon. The more follow-up of spring provided by the bolt, the better the retention of stress on the gasket to maintain a leakproof joint. In the same respect, a smaller diameter bolt must be Properly fastened studs and bolts achieve strained more to develop the same load. With their holding power from the tension (or the smaller diameter bolt, there is a serious torque) that is derived from the mating of the danger that it may be over-strained and external and internal threads subject to the stressed beyond the elastic limit, and finally elastic limit of the material. broken. The smaller bolt, within its elastic limit, could give the same additional follow-up What torque to apply is a generally as the larger diameter bolt of greater asked question, but the answer Figure 2 length. depends on the variables of R = radius or length of lever S = pounds pull on scale material, threads, and lubrication, if any. As previously stated the designer of the flange system normally specifies the required torque. Bolting Patterns Regardless of the number of bolts, this circular bolt pattern with modification, will provide the correct tightening sequence. Circular Multi-Bolt Installation Pattern A DIVISION 475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 OF TRIPAC MARKETING, INC.