Electric Resistance Melting: A Low Cost, Efficient

advertisement

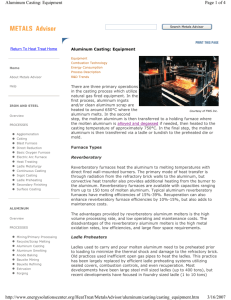

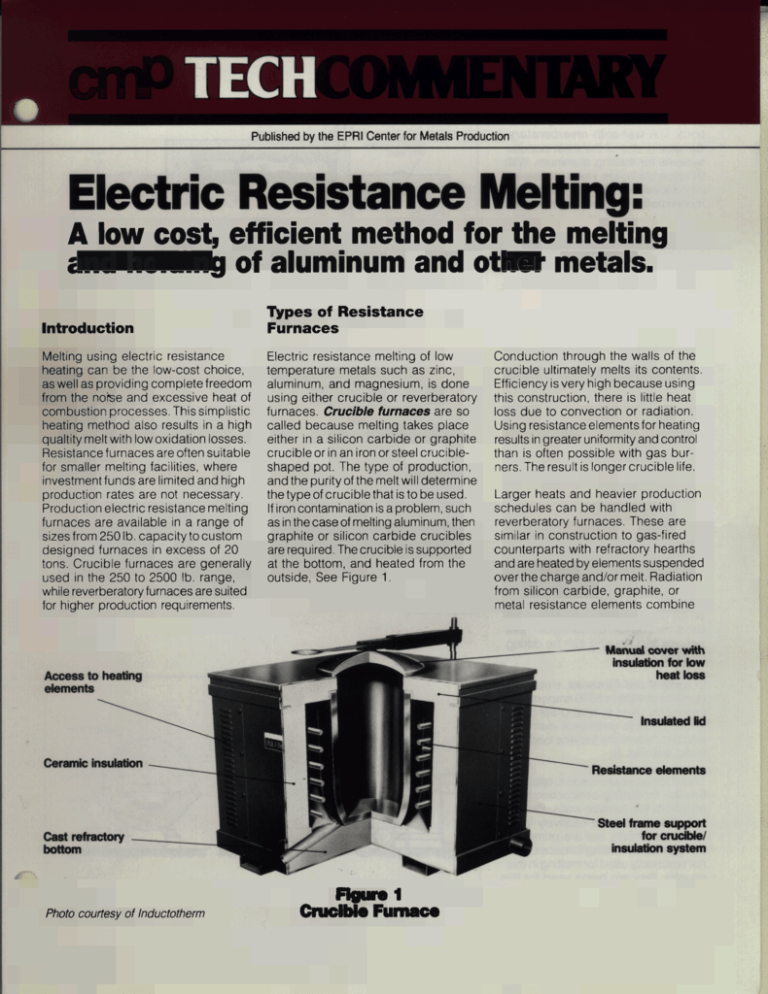

Published by the EPRl Center for Metals Production A low cost, efficient method for the melting metals. # Z K T X i ! of aluminum and c "" Introduction Types of Resistance Furnaces Conduction through the walls of the Melting using electric resistance Electric resistance melting of low crucible ultimately melts its contents. heating can be the low-cost choice, temperature metals such as zinc, Efficiency is very high because using as well asproviding complete freedom aluminum, and magnesium, is done from the noise and excessive heat of using either crucible or reverberatory this construction, there is little heat loss due to convection or radiation. combustion processes. This simplistic furnaces. Crucible furnaces are so Using resistance elements for heating heating method also results in a high called because melting takes place results in greater uniformity and control qualtity melt with low oxidation losses. either in a silicon carbide or graphite than is often possible with gas burResistancefurnaces are often suitable crucible or in aniron or steel crucibleners. The result islonger crucible life. shaped pot. The type of production, for smaller melting facilities, where and the purity of the melt will determine investment funds are limited and high the type of crucible that is to be used. Larger heats and heavier production production rates are not necessary. If iron contamination is a problem, such schedules can be handled with Production electric resistance melting as inthe case of melting aluminum, then reverberatory furnaces. These are furnaces are available in a range of similar in construction to gas-fired graphite or silicon carbide crucibles sizes from250 Ib.capacity to custom counterparts with refractory hearths are required.The crucible is supported designed furnaces in excess of 20 and are heated by elements suspended tons. Crucible furnaces are generally at the bottom, and heated from the over thecharge and/or melt. Radiation outside, See Figure 1. used in the 250 to 2500 Ib. range, from silicon carbide, graphite, or while reverberatory furnaces are suited metal resistance elements combine for higher production requirements. Photo courtesy of lnductotherm -1 ~ F u m a c e .: e . . Moveable Resistance Heatini Door Elements , :,!i The rincipaladvantageofthis is the extremely low energy for holding. For example, to Ib. of aluminum at 1380°F ontv 4 to 5 kW comDared to l~&UkWfbconventionalfurnaces. When highcapacityfurnacesare used, m&mg can be during off-peak psriods and pouring canbe during I' ctow I L m&m ~ ~~~. ,A fn M ,electric curt"S of4OOO to 5OOO amperes are wmmcady used to heat graphite or bilicism-crrclJide mistance elements w h i mdiat~tothe furnace load and walls, see Fi.5. These furnaces are made to oscillate, thereby facilitating conduction totfm melt from the furnace walls. Radiant require relatively Icw mwm@ne@costs, but are primarily bei#gussdasRolding furnaces.While not reportedly used for melting in this country,theyarebeingusedforthis I Europe. purpose in CIIYI, Radiant rod timace. Klsl:fwmaxs , ' &t Rad Radiant Rod EcoL....~ Electric R Furnaces 1 i f . .I j Comparisons in thistable are for heating aluminum alloys f m ambient temperature to furnace will vary depending temperatures prior to pouring; metal losses and energy required>for melting on the meltinQtemperatuepnd &by group. Losses shown for naturalgas arefor luminous fiameb u m .R-rtedly, reapt& developed radiant tub gas- fired units reduce metal loss. t y ~ e,,? lccs a comparisonof \ I - I , I I .,;# YI using aluminum as an ?he energy values listed in llllbe are presented for comconverting from Btu's per a. to €heequivalentinelectrical e f m g y , kwh per Ib., or vice vew Efficiency values arenow being reported as high as 75% for electric resistance furnaces. a. GAS Cost: Fuel LUMINOUS ,:*'by -:' t FLAMETYPE 1.5cuFHbAL X loooE'u/C~Ft X $4.59/10 6 8 t u X 1OOO'bAh X 4000Vyr = $ 27,54 MetalLoss: 1OOO'bAYhr X 40OO'Vyr X $l/lb X 4% * = $160,00 Total Cost: $187,54 i InstaHation costs of electric resistanceELECTRICPowerCost(On-Peak): and fo$sil-fuel-fired furnaces are wmpmable. It is not practical to hypdbsize a specific example as tlmwmmm many possibilitiesto take ' ,WBECOUnt. In general, fossil-fuel- 0.23kWh%x 10001bAhr x $0.0667/kWhr x 40OOhVyr I = $ 61,361 Metal Loss: 10001bAfir x 4000hr/vr x $l/lb x (1% max) = $ 40,001 TotalCost: S101,36r Difference: S 86,174 I '~costsmtajnthemost &dbg~whichWuenw final ~ s i o n sAn . OPbMtingGaet . .: higher quality staridards maybe the final persuader in selecting electric resistance melting, as these furnaces have a decided edge in producing molten metal free of unwanted gases, oxides, and other impurities. The absence of fluing creates a situation where the melt can be isolated from convection heat losses and where the usualnoise levelassociated with fossilfurHiredfumaces is virtually eliminated. R.@mr, since electric furnaces do not require fluing, enviromental 6. Furnace downtime is reduced, : minimized. cutting down on labor costs. 7 m Daily furnace cleaqhg can be s and relatively low substantially minirnized.bcause where initial capital ladles and tundishes. of lower maintenance, thereby dominant factor, the , on labor costs. cutting down might be the logical 8. Long term problems of pollution naces offer a high both inside and outside the plant of flexibility changing in from are dramatically reduced, paving l m “Fossil Fuels or Electric - Ho m e alby to another, as crucibles can the way for better relations with Should You Melt” by Scott F be quickly removed and replaced to environmental authorities. Kennedy-Courtesy of Frank accommodate jobbing demands. +. Schaefer, Inc. Larger castings or higher production 9. Increased worker comfort can requirements may dictate the need for lead to greater employee satis- 2 “Electric Process Heating” by . faction with fewr comphints. Maurice Orfeuil. a reverberatory furnace utilizing the 1 0 . Melts can be produced at any advantages of continuous melting. deaar ierj loprd M,i.e., it.@not necessary to fill the furr#csto a minimum level as isc required by other electric meltingmethods. - (slc43). TIroat amy are*memJ. casrhg,rdilhpprsd~,and ” ’) . a :; + ” EPRt lyel? Jeff- ” \ I . This Techcommentary prepared was by Robert L. Kirchner, Special Consultant to JoaphE.ooQkrQl ,, CMP. Technical and editorial review were provided by Robert J. Schmitt, Manager of Technical Projects and John Kollar, Manager of Communications. r ~1988~farMe?alsprodudion okrdor c.nkrkr” Mellon Institute 4400 Fifth Avenue Pittsburgh,PA 1521 3-2683 412-268-3243 CMP- <: . . , . . .