IE 7315: Production Systems

advertisement

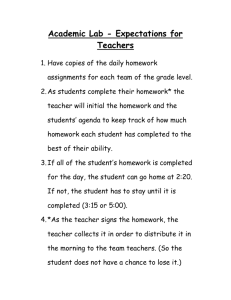

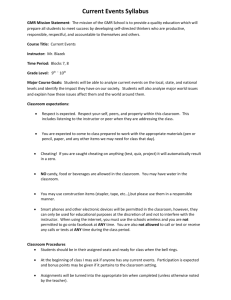

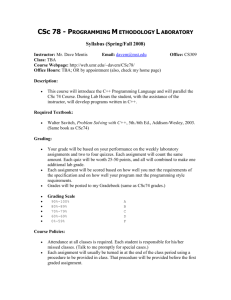

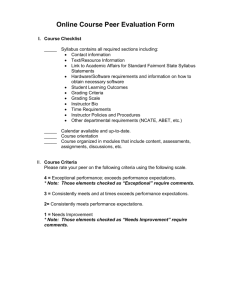

WAYNE STATE UNIVERSITY IE 7315: Production Systems INDUSTRIAL & SYSTEMS ENGINEERING DEPARTMENT IE 7315: Production Systems (4 Credits) Course Syllabus – Winter 2014 Instructor: Dr. Ratna Babu Chinnam, Associate Professor Class Room: Office: Office Hours: Telephone: Fax: E-mail: Course Websites: 5:30PM- 7:20PM, Tuesdays and Thursdays; MEB 1005 (4815 Fourth Street) Room 2161, Manufacturing Engineering Building (4815 Fourth Street) Tuesdays & Thursdays: 3:30-4:30PM or by appointment 313-577-4846 313-578-5902 ratna.chinnam@wayne.edu http://blackboard.wayne.edu http://www.factory-physics.com Teaching Assistant: Ying Tang (ytang@wayne.edu) Office Hours: TBA on Blackboard Official Course Description: Fundamental theories and concepts in the design and operation of production systems for manufacturing and service organizations. Topics may include: Inventory Management, Production Planning (MRP, JIT, ERP), Factory Physics, Production Control, Introduction to Supply Chain Management. Prereq: IE 6210, IE 6560 Prerequisites: Recommended -- Applied Engineering Statistics (IE6210) & Deterministic Optimization (IE 6560) Course Objectives: Keeping pace and improving a corporation's performance in areas of cost, quality, speed, and customer service is vital in today's increasingly competitive marketplace. Imitating the practices of rivals or relying on buzzwords and slogans is not enough to generate a sustainable advantage. Manufacturing firms must be able to identify leverage points with the greatest impact on the bottom line to achieve world-class performance. This course presents a framework and a science for diagnosing, improving, and designing effective production systems. After completing the course, students should be able to: ►Explain the effect of variability on production systems ►Choose an appropriate production or inventory model for a given situation - Derive the Economic Order Quantity (EOQ) and Newsboy models - Apply (Q,r) inventory models - Use linear programming and dynamic programming to model inventory systems ►Explain the concepts involved in Material Requirements Planning (MRP) and Just-in-Time (JIT) production systems ►Employ several different forecasting tools to raw data, including exponential smoothing and regression analysis ►Understand heuristics available for solving operation scheduling and sequencing problems ►Apply basic queuing models to production systems for the purposes of design, diagnostics, and improvement Students will also be exposed to best business practices and trends in such areas as lean manufacturing, flexible manufacturing, agile manufacturing, and supply chain management. Books*: Required: Factory Physics, 3/E by Wallace J. Hopp and Mark L. Spearman. Waveland Pr Inc (August 31, 2011). ISBN10: 1577667395. ISBN-13: 978-1577667391 Other Books of Interest: Nahmias S., Production and Operations Analysis, 4th Edition, Irwin/McGraw-Hill, MA: Boston, 2001 (ISBN: 0072312653). Quick Reads: Goldratt E. M. and Cox J., The Goal: A Process of Ongoing Improvement, 2nd Edition, North River Press Publishing Corporation, 1992 (ISBN: 0884270610). Goldratt E. M., It’s Not Luck, North River Press Publishing Corporation, 1994 (ISBN: 0884271153). Womack J. P., Jones D. T., and Roos D., The Machine That Changed the World: The Story of Lean Production, HarperCollins, 1991 (ISBN: 0060974176). * Additional material will be distributed through the course website as needed to complement the material from the textbook. Prepared by Dr. Ratna Babu Chinnam for “IE 7315: Production Systems” at Wayne State University Page 1 of 4 IE 7315: Production Systems Commercial Websites: http://www.factoryphysics.com – Factory Physics Inc. http://www.productionplanning.com – Production Planning Portal http://www.productionplanning.com/software.asp - Production Planning Software http://www.activplant.com - Commercial Throughput Analyzer Software Grading: Grading will be "tentatively" based upon a maximum attainable point total of 535 points. Term Exams Final Exam Homework Quiz – Manufacturing in America MRP DSS Project Review Paper (Team Based) @ 100 x 2 @ 100 @ 15 x 6 @ 10 @ 40 @ 45 200 pts 100 pts 90 pts 10 pts 40 pts 45 pts __________ Total 485 pts Individual exams, home work, project, topic presentation, and term paper might be curved at the discretion of the instructor. The actual number of home works assigned might vary depending on class composition and prerequisite knowledge. Make-up examinations will not be offered unless excused by instructor due to the most extenuating circumstances such as personal illness, and documentation may be required. Homework Policy: Homework assignments will be posted on course website and announced in class. Homework will be due at the beginning of the class period. Homework submitted late by one class will be evaluated at 50% credit and late by two (or more) classes will not receive any credit. Homework should be submitted on clean sheets and will be evaluated based on completeness. Depending on the size of the class and length of the homework, individual homework grades could be based on randomly sampled problems. When feasible, solutions for homework problems will be posted on the course website. Students are strongly encouraged to use Excel templates from Book Website to verify calculations and results. In case the student is unable to attend class for submitting the homework, e-mail the work to the Teaching Assistant. Collaboration during the conceptualization and formulation process of homework assignments is allowed. However, all homework assignments must be completed and written up individually. Violation of this policy will certainly lead to a failing grade for the homework and action that is more stringent might be taken. Review Paper: Each team of 3 students (formed by instructor if requested) is required to identify a topic for the "review" paper and submit a one page abstract for approval by e-mail to the instructor by March 16th (as well as through Blackboard course website Digital Drop Box). It is advised that the students review the following journals for selecting a topic: Journal of Operations Management International Journal of Operations and Production Management International Journal of Production Research Production and Inventory Management Journal European Journal of Operations Research Interfaces It is expected that the group will review "recently" published literature on the topic of interest (using technical literature search databases such as Axiom and ScienceDirect available through the Science and Engineering Library homepage at http://www.lib.wayne.edu) and report their findings in the form of methods employed, trends, recent applications, success stories, failure stories, and challenges ahead. Absolutely no plagiarism will be tolerated. Students caught plagiarizing in writing the term paper will be given a failing grade for the course.*** The following website contains good information on citing sources, plagiarism, and copyrights: http://www.lib.wayne.edu/services/instruction_tutorials/searchpath/mod6/contents.html The paper will be evaluated based on technical content (40%), quality of documented references (20%), and quality of technical writing (40%). The term paper has to be typed and submitted by e-mail for evaluation to the instructor by April 19th (as well as through Blackboard Digital Drop Box). Detailed guidelines for authoring & formatting the paper are available on the course website. Individuals that fail to make good contribution will receive no credit. Participation will be evaluated by peer group members. Groups that utilize the services of The Writing Center at 2310 Adamany Undergraduate Library (Tel: 7-2544 for appointment) before April 10th will receive 5 bonus points. The Writing Center normally does not give appointments during the last few weeks of the semester. To avoid potential problems with your assignments, reports, and projects, it is imperative that you familiarize yourself with report writing standards, appropriate use and citation of material, and the definition of plagiarism. Plagiarism will be prosecuted fully, including failing the course/program and remanding the case to student judicial processes. "I didn't know" will not be an acceptable excuse if your report is found to be plagiaristic. Be aware that the team-based nature of the course extends any penalty to the whole group. *** Prepared by Dr. Ratna Babu Chinnam for “IE 7315: Production Systems” at Wayne State University Page 2 of 4 IE 7315: Production Systems MRP DSS The project will involve demonstration of your capacity to effectively carryout manufacturing resource planning Simulation Project: activities through an Excel based simulation model of a fictitious manufacturing company. In this assignment, you play the role of a production planner for “Greek Manufacturing Company”, and develop a decision support system to help you in that role. More detailed information is available on the course website along with the Excel template. The project report (2 to 3 pages of executive summary on overall results and experiences) has to be typed and electronically submitted (through Blackboard course website Digital Drop Box) for evaluation by April 12th. It is also expected that completed Excel templates will be submitted (these will be used to check for originality in effort). Students caught cheating in completing the project will be given a failing grade for the course. Special Needs: If you feel that you may need an accommodation based on the impact of a disability, please feel free to contact me privately to discuss your specific needs. Additionally, the Office of Educational Accessibility Services (EAS) coordinates reasonable accommodations for students with documented disabilities. The office is located in the Student Center Building, Room 583, Phone: 313-577-1851 (Voice)/577-3365(TTY). Attendance Policy: Without special permission, students attending any given class are required to join the class within the first five minutes to minimize any class disruptions. Cheating/Conduct Policy: It is the responsibility of each student to adhere to the principles of academic integrity. Academic integrity means that a student is honest with him/herself, fellow students, instructors, and the University in matters concerning his or her educational endeavors. Thus, a student should not falsely claim the work of another as his/her own, or misrepresent him/herself so that the measures of his/her academic performance do not reflect his/her own work or personal knowledge. In this regard, cheating will not be tolerated. Cheating includes (but is not limited to) any communication (written or oral) during examinations and sharing of work, such as using the same models or computer programs or copying work. All assignments and projects must be an individual effort unless specifically noted. All written assignments and oral presentations are expected to conform to accepted standards for citation (referencing). STUDENTS WHO CHEAT ON ANY ASSIGNMENT OR DURING ANY EXAMINATION WILL BE ASSIGNED A FAILING GRADE FOR THE COURSE. Therefore, avoid all appearance of improper behavior! Students who witness cheating should report the incident to the instructor as soon as possible. Students are also welcome to discuss any concerns related to cheating with the department Chair. The following site offers some good information: http://www.otl.wayne.edu/wsu_integrity.php Withdrawal Policy: All withdrawals should be done via Pipeline. Select "Withdraw from a Class" on Pipeline menu to withdraw. Here are some important dates for Winter 2014: Deferred Grades Policy: Last Day to Drop with Tuition Cancellation Friday, January 17 Last Day to Withdraw Sunday, March 23 A grade of 'I' can only be assigned if all of the following criteria are met: 1. the student IS NOT currently failing the class and, 2. there is NOT a substantial quantity of work yet to be completed, 3. there is no extra work required of the instructor beyond the normal duties of grading the paper/exam, 4. there is no need for the student to attend the class in subsequent terms. The final decision to assign an incomplete grade rests with the instructor. An 'I' grade MUST be made up within one year of assignment of the grade. Prepared by Dr. Ratna Babu Chinnam for “IE 7315: Production Systems” at Wayne State University Page 3 of 4 IE 7315: Production Systems Tentative Course Outline: Dates Topic Introduction to the course, structure of classes. Motivational Exercise: Goldratt’s Capacity Allocation Problem PART I: The Lessons of History Topic: Inventory Management Special Reading Assignments: Jan.9 – Jan.23 Lee, H.L. and Billington, C. “Managing Supply Chain Inventory -- Pitfalls and (5 Classes) Opportunities,” Sloan Management Review, Spring 1992. Chapter 17: Supply Chain Management – pg. 582-586 EOQ Models – One Class Dynamic Lot Sizing (Wagner-Whitin Model) – One Class Statistical Inventory Models (News Vendor Model and Base Stock Model) – One Class Jan. 7 Statistical Inventory Models (Single- and Multi-Product (Q,r) Models) – Two Classes Jan. 28, Jan, 30 (1.5 Classes) Jan. 30, Feb. 4 (1.5 Classes) Feb. 6 Feb. 11, Feb. 13 (2 Classes) Feb. 18, Feb. 20 (2 Classes) Feb. 25, Feb. 27 (2 Classes) Mar. 4, Mar. 6 (2 Classes) Mar. 10-15 Mar. 18, Mar. 20 (2 Classes) Mar. 25 Mar. 27 Apr. 1, Apr. 3 (1.5 Classes) Apr. 3, Apr. 8 (1.5 Classes) Apr. 10, Apr. 15 (1.5 Classes) Apr. 15, Apr. 17 (1.5 Classes) Apr. 22 Apr. 24 Book Reading Book Reading Assignment Assignment 2nd Edition 3rd Edition Ch. 0 and 1 Ch. 0 and 1 (Quiz on Jan 14th) (Quiz on Jan 14th) Ch. 2: 48-56 Ch. 2: 56-64 Ch. 2: 64-75 Ch. 2: 75-89 Ch. 17: 601-621 Ch. 2: 49-57 Ch. 2: 58-65 Ch. 2: 66-78 Ch. 2: 78-92 Ch. 17: 623-643 Topic: MRP, MRP II, and ERP Special Reading Assignments: Miller, J.G. and Sprague, L.G. “Behind the Growth in Materials Requirements Planning,” Ch. 3: 109-145 Ch. 3: 114-149 Harvard Business Review, Sep-Oct 1975. “A Note on Manufacturing Resources Planning (MRPII),” Harvard Business Review, Jun 1987 (9-687-097). Topic: JIT Special Reading Assignments: “Just-in-Time Production Controlled by Kanban,” Harvard Business Review, Jan 1984 (9684-047). Ch. 4 & 5: 151-182 Ch. 4 & 5: 155-191 Walleigh, R.C. “What's Your Excuse for Not Using JIT?,” Harvard Business Review, MarApr 1986. Topic: What Went Wrong? 1st Exam (5:30PM-7:20PM): Room to be identified if not MEB 1005 PART II: Factory Physics (Production Modeling/Diagnostics) Topic: Basic Factory Dynamics Ch. 6: All of it Ch. 6: All of it Special Reading Assignments: Ch. 7: 213-243 Ch. 7: 227-258 “Process Fundamentals,” Harvard Business Review, Apr 1999 (9-696-023). Topic: Variability Basics Special Reading Assignments: Duggan, K.J. “Facilities Design for Lean Manufacturing,” IIE Solutions, Dec 1998. Ch. 8: 248-283 Ch. 8: 264-302 Upton, D.M. “What Really Makes Factories Flexible?,” Harvard Business Review, Jul-Aug 1995. Topic: The Corruptive Influence of Variability Special Reading Assignments: Ch. 9: 287-333 Ch. 9: 306-351 Suarez, F.F. et al. “An Empirical Study of Flexibility in Manufacturing,” Sloan Management Review, Fall 1995. Topic: Push and Pull Production Systems Special Reading Assignments: Ch. 10: 339-363 Ch. 10: 356-381 Bonvik, A.M. et al. “A Comparison of Production-Line Control Mechanisms,” International Journal of Production Research, Vol. 35, pp. 789-804, 1997. Spring Break PART III: Principles in Practice Topic: A Pull Planning Framework CONWIP based Hierarchical Planning Framework – One Class Ch. 13: 408-445 Ch. 13: 434-473 Demand Forecasting – One Class 2nd Exam (5:30PM-7:20PM): Room to be identified if not MEB 1005 MRP DSS Assignment Progress Review & Discussion Topic: Shop Floor Control Ch. 14: 453-483 Ch. 14: 481-512 Topic: Production Scheduling Ch. 15: 488-531 Ch. 15: 516-549 Topic: Aggregate and Workforce Planning Ch. 16: 535-569 Ch. 16: 553-590 Topic: Capacity Management Ch. 18: 626-642 Ch. 18: 648-665 Study Day–NO CLASS Final Exam (5:30–7:20PM) Prepared by Dr. Ratna Babu Chinnam for “IE 7315: Production Systems” at Wayne State University Page 4 of 4