Syllabus - Engineering Online

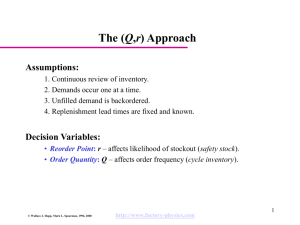

advertisement

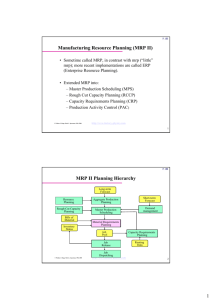

! ISE 589-003! SPECIAL TOPICS IN INDUSTRIAL AND SYSTEMS ENGINEERING! DESIGN AND CONTROL OF PRODUCTION AND SERVICE SYSTEMS! FALL 2014! Instructor: Dr. Reha Uzsoy Tel: 513-1681 Office: DAN300! e-mail: ruzsoy@ncsu.edu Office Hours by appointment! ! Teaching Assistant: TBA Office hours TBA.! ! Text (required): Hopp, W. J., Spearman, M. L., Factory Physics (3rd Edition), McGrawHill (2008).! ! Objectives of Course: In order to achieve the flexible, cost-effective manufacturing systems required to survive in today's volatile, global markets, a thorough understanding of the basic dynamics of factories is essential. This course focuses on understanding the behavior of manufacturing plants and service systems through a thorough, generalizable and fundamental understanding of the factors affecting their behavior. We do this by discussing the basic techniques of production and inventory control in use in industry today, and then focusing on material flow through the plant to examine a number of alternative approaches.! ! Prerequisites:! ! This course will assume knowledge of probability and statistics at the level of ST370 and 371, as well as related engineering mathematics.! ! Planned Course Content:! 1. Introduction! ! Motivation and approach! Part 1: Basic Material Control Approaches! 2. Inventory Control! ! Hopp and Spearman Chapter 2! 3. Material Requirements Planning and Master Production Scheduling! ! Hopp and Spearman Chapter 3; class notes; Vollmann et al. book! Part 2: Capacity Meets Variability - The Behavior of Capacitated Resources! 4. Basic Factory Dynamics! ! Hopp and Spearman Chapter 7! 5. Effects of Variability! ! Hopp and Spearman Chapters 8, 9! Part 3: Lean Manufacturing! 6. Just-in-Time Manufacturing! ! Hopp and Spearman Chapter 4; Sugimori et al. paper; Liker, Monden book! 7. Single and Mixed Model Assembly Systems! ! Class notes; Thomopoulos paper! ! ! The instructor reserves the right to modify this content as the semester progresses and needs emerge.! ! Course Grading: The course will be graded based on two midterms (15% each), a comprehensive final (35%), homework (10%) and case studies (25%). The homework is designed to reinforce and supplement the material covered in lectures, and as such forms an integral part of the course. The purpose of the case studies is to expose you to open-ended, ill-structured real-world applications of the concepts and methods learned in class. There will be three case studies throughout the semester, on which you will work in groups of three. Each case study will require a formal, technical report that will be graded on organization and presentation as well as technical content.! ! Course administration: All materials, assignments and grades will be distributed via Moodle, which will also be used for announcements to the class. Moodle will also be used to submit assignments. It is the student’s responsibility to become familiar with Moodle and to access it in a timely manner; see particularly the regrade policy below. ! ! Computer Usage: You will be expected to use computer tools, particularly Microsoft Excel, throughout the semester in the homework and the case studies. The course will have a Moodle site, which will be used for announcements, grades etc.,and most other communication with students.! ! Captured Lectures: This on campus course will be captured and distributed via the Internet and/or electronic media as part of the Engineering Online (EOL) program for the distance students. These video recordings may contain an image of you entering the classroom, asking a questions or being a part of the studio class. Please notify both the instructor and Dr. Linda Krute, Director of EOL (ldkrute@ncsu.edu) in writing if you DO NOT want your image to be included in the lecture presentation. If we do not hear from you after the first week of the class, we will assume that you are in agreement with this procedure.! Homework: Homework will be assigned roughly each week. Students can collaborate on homework, but must submit the names of those with whom they worked. Note, however, that collaboration provides many opportunities for learning, but learning does not take place when one student does the work and another copies it. Homework will be submitted via Moodle. Late homework will not be accepted since solutions will be posted as soon as submission closes.! ! Projects: Two and perhaps three projects will be assigned. Students will work on these in groups of at most three. The engineering analysis performed must be submitted in the form of a formal technical report, which will be graded for organization, presentation and English in addition to technical content. Examples of project reports will be made available to students at the time of assignment. Students will need to purchase the case studies as a course package from the University Bookstore.! ! Academic Integrity: It is understood and expected that all work turned in under your name is your own work or, if a group assignment, the work of you and your group members, and that you have neither given nor received unauthorized aid. The University policy on academic integrity can be found in the Code of Student Conduct (see Appendix L of the Handbook for Advising and Teaching: www.fis.ncsu.edu/ ncsulegal/41.03-codeof.htm).! ! Incomplete Grades: If requested by a student, the grade of Incomplete may be given for work not completed because of a serious, documented interruption in the student’s work not caused by their own negligence.! ! Absences and Scheduling Make-up Work: No makeup examinations or homework assignments will be scheduled. In the event that a student has an excused absence (see http://www.ncsu.edu/provost/academic_regulations/ attend/reg.htm for NC State’s policy on excused absences), the grade for the missed work will be assigned to the final examination.! ! Students with Disabilities: Reasonable accommodations will be made for students with verifiable disabilities. In order to take advantage of available accommodations, students must register with Disability Services for Students at 1900 Student Health Center, Campus Box 7509, 515-7653 (http://www.ncsu.edu/dss/). For more information on NC State’s policy on working with students with disabilities, please see http:// www.ncsu.edu/ provost/hat/current/appendix/appen_k.html. Students requiring accommodations must notify the instructor within the first two weeks of classes.! ! References:! A. Background Material:! Francis, R.L., McGinnis, L.F., White, J.A., Facility Layout and Location: An Analytical Approach, Prentice-Hall, 1992 Chapter 2.! ! Sule, D.R., Manufacturing Facilities Location, Planning and Design, PWS-Kent Publishers, 1988 ! ! Bedworth, D.D., and Bailey, J.E., Integrated Production Control Systems Management Analysis, Design, John Wiley&Sons, 1987. ! ! B. Supplementary Books:! Goldratt, E.M., Cox, J., The Goal: A Process of Ongoing Improvement North River Press, 1986.! ! Liker, J., The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer, McGraw-Hill, New York, 2004.! ! Monden, Y., Toyota Production System, Industrial Engineering and Management Press, 1983.! ! Vollmann, T. E., Berry, W. L., Whybark, D. C., Jacobs, F. R., Manufacturing Planning and Control for Supply Chain Management, McGraw-Hill, 2004.! ! C. Papers! Sugimori, Y, Kusunoki, K., Cho, F., Uchikawa, S., “Toyota Production System: Materialization of Just-in-Time and Respect for Human System”, International Journal of Production Research 15, 553-564 (1977).! ! Thomopoulos, N.T., “Line Balancing-Sequencing for Mixed-Model Assembly”, Management Science 14, B-59-B-75 (1967).