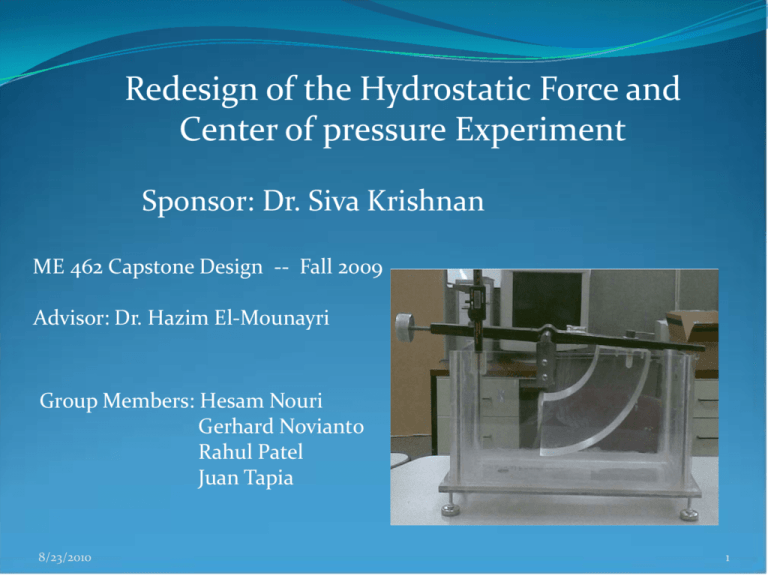

Redesign of the Hydrostatic Force and Center of pressure Experiment

advertisement

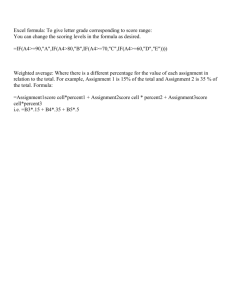

Redesign of the Hydrostatic Force and Center of pressure Experiment Sponsor: Dr. Siva Krishnan ME 462 Capstone Design -- Fall 2009 Advisor: Dr. Hazim El-Mounayri Group Members: Hesam Nouri Gerhard Novianto Rahul Patel Juan Tapia 8/23/2010 1 Experiment Lab’s objective Measuring Hydrostatic Force Calculate Center of Pressure 8/23/2010 2 Customer Requirements Increased ergonomics in terms of operation Improved repeatability Minimum experimental error and operational time Possible safety issues are to be addressed as well. Instructional Video Manual 8/23/2010 3 Vision, Critical Success Factors, and Strategy Vision: Run the experiment and calculate the results. Identify the most effective parameters. Find optimum solution for those parameters. Build a virtual prototype and analysis using Ansys. Manufacture the parts and assemble it. Rerun the experiments to validate it. Budget < $500 Critical Success Factors: Communication Team Management Planning Clear Goal Strategy: Keep in touch with the Customer Weekly Group Meetings 8/23/2010 4 Engineering Deliverable Items Quantity 8/23/2010 Description of Deliverable Exit Criteria 1 Redesigned units of this experiment Delivered 1 Instructional Video Manual Delivered 5 Technical Approach Customer’s Key Technical Requirements Decrease the percent error Key Technical Issues Hard to balance the tank Takes 2 hour performance the lab Safety issue in emptying the tank Key Features and Benefits Efficient way to measure height Hanger Extension for balancing 8/23/2010 6 Engineering Schedule 9/7/2009 9/17/2009 9/27/2009 10/7/2009 10/17/2009 10/27/2009 11/6/2009 11/16/2009 11/26/2009 Obtain Customers' Requirement Create Development Plant Generate Specifications Function Decomposition Function - Concept Mapping Generate Design Concept Draft Evaluate Design Concept Draft Engineering Drawing Analysis of Engineering Drawing Re Evaluation of concept draft Finalize Bill of Material Manufacture Process Assembly Process Product Evaluation (Test) 8/23/2010 7 House of Quality 8/23/2010 8 Function Decomposition 8/23/2010 9 Function Concept Mapping 8/23/2010 10 Overall Concept 1 8/23/2010 11 Overall Concept 2 8/23/2010 12 Decision Matrix Importance Dr.Krishnan Lab TA Students Concept 2 26 28 5 +1 +1 10 23 26 +1 +1 Attractive looks 2 1 20 S +1 Ease to Maintenance 21 20 0 S 6 4 30 +1 5 5 19 S S 5 19 0 S S 25 0 0 S S Experimental result's accuracy Minimum operational time Ergonomics/ Easy to operate Able to use simultaneously Durable equipment Cost Total + Total – Overall 3 Current DATUM Customer Requirements Concept 1 S -1 - 3 1 - 1 2 - 2 42 - 32 55 - 48 61 - 21 Weighted (Dr Krishnan) Weighted (Lab TA) Weighted (Students) 8/23/2010 13 Final Concept 8/23/2010 14 Final Design in Pro-Engineering 8/23/2010 15 Generated Mesh 8/23/2010 16 Safety Margin 8/23/2010 17 Maximum Shear Stress 8/23/2010 18 Bill of Material 8/23/2010 19 Results Summary Operational time of 30-45 minutes for new redesign with minimum effort 8/23/2010 20 Lessons Learned Positive Items: Awareness of the dynamics of working in a team. Experience of exchanging ideas and inspiring others to work together. Demonstrating professional behaviors such as taking responsibility, showing up on time and meeting deadlines. Learning from and helping one’s peers. Future Improvement: Water speed controller can be installed on the elbow(bottom part) Different kind of glue for more attractive looks Better awareness of the responsibilities and duties pertaining to industry roles. 8/23/2010 21 Questions 8/23/2010 22