Capacity Planning Determinants of Effective

advertisement

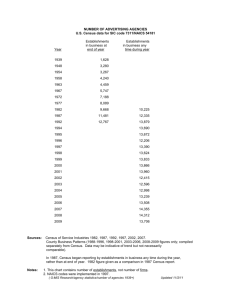

Capacity Planning Definition of Capacity “ Capacity is the limiting capability of a productive unit to produce within a stated time period , normally expressed in terms of output units per unit of time. time. ” Capacity needs include • Equipment • Space • Employee skills Determinants of Effective Capacity Facilities Product and service factors Process factors Human factors Policy factors Supply chain factors External factors 1 Strategic Capacity Planning Goal To achieve a match between the long-term supply capabilities of an organization and the predicted level of long-run demand • Overcapacity Overcapacity operating costs that are too high • Undercapacity Undercapacity strained resources and possible loss of customers Capacity Planning Questions Key Questions: What kind of capacity is needed? How much capacity is needed to match demand? When is it needed? Related Questions: How much will it cost? What are the potential benefits and risks? Are there sustainability issues? Should capacity be changed all at once, or through several smaller changes Can the supply chain handle the necessary changes? 2 Capacity Decisions Are Strategic Capacity decisions impact the ability of the organization to meet future demands affect operating costs are a major determinant of initial cost often involve longlong-term commitment of resources can affect competitiveness affect the ease of management are more important and complex due to globalization need to be planned for in advance due to their consumption of financial and other resources Capacity Design capacity maximum output rate or service capacity an operation, process, or facility is designed for Effective capacity Design capacity minus allowances such as personal time, maintenance, and scrap Actual output rate of output actually achieved-cannot achieved--cannot exceed effective capacity. 3 Measuring System Effectiveness Actual output The rate of output actually achieved It cannot exceed effective capacity Efficiency Efficiency actual output effective capacity Utilization Utilization actual output design capacity Measured as percentages Example– Efficiency and Utilization Design Capacity = 50 trucks per day Effective Capacity = 40 trucks per day Actual Output = 36 trucks per day Efficiency actual output 36 90% effective capacity 40 Utilization actual output 36 72% design capacity 50 4 Measures of capacity for different types of organizations Type of Organizations Capacity Measure Auto plant Number of autos Steel Plant Tons of steel Beer Plant Cases of beer Nuclear power plant Megawatts of electricity Airline Available seat miles (ASMs) Hospital Available bedbed-days Movie theater Available seatseat-performance Restaurant Available seatseat-turns Jobbing machine shop Available laborlabor-hours School of Business Administration Available semester or quarter sections * When output units are more diverse , it is common to use a measure of the availability of the limiting resource as the capacity measure. Determinants of Effective Capacity Facilities Product and service factors Process factors Human factors Policy factors Supply chain factors External factors 5 Capacity Strategies Leading Build capacity in anticipation of future demand increases Following Build capacity when demand exceeds current capacity Tracking Similar to the following strategy, but adds capacity in relatively small increments to keep pace with increasing demand Strategy Formulation Strategies are typically based on assumptions and predictions about: Long-term demand patterns Technological change Competitor behavior 6 Capacity Cushion Capacity Cushion Extra capacity used to offset demand uncertainty Capacity cushion = 100% - Utilization Capacity cushion strategy • Organizations that have greater demand uncertainty typically have greater capacity cushion • Organizations that have standard products and services generally have greater capacity cushion Steps in Capacity Planning 1. Estimate future capacity requirements 2. Evaluate existing capacity and facilities; identify gaps 3. Identify alternatives for meeting requirements 4. Conduct financial analyses 5. Assess key qualitative issues 6. Select the best alternative for the long term 7. Implement alternative chosen 8. Monitor results 7 Calculating Processing Requirements Calculating processing requirements requires reasonably accurate demand forecasts, standard processing times, and available work time pD k NR i i 1 i T where N R number of required machines p i standard processing time for product i D i demand for product i during the planning horizon T processing time available during the planning horizon Service Capacity Planning Service capacity planning can present a number of challenges related to: The need to be near customers • Convenience The inability to store services • Cannot store services for consumption later The degree of demand volatility • Volume and timing of demand • Time required to service individual customers 8 Demand Management Strategies Strategies used to offset capacity limitations and that are intended to achieve a closer match between supply and demand Pricing Promotions Discounts Other tactics to shift demand from peak periods into slow periods In-House or Outsource? Once capacity requirements are determined, the organization must decide whether to produce a good or service itself or outsource Factors to consider: Available capacity Expertise Quality considerations The nature of demand Cost Risks 9 Developing Capacity Alternatives Things that can be done to enhance capacity management Design flexibility Take stage of life cycle into account Take a “bigbig-picture” picture” approach to capacity changes Prepare to deal with capacity “chunks” chunks” Attempt to smooth capacity requirements Identify the optimal operating level Choose a strategy if expansion is involved Predicting Future Capacity Requirements Industry Capacity and Competitive Dynamics Mature Products with Stable Demand OR New Products and Risky Situations 10 Predicted Requirements , Current Capacities, and Projected capacity differences Capacity, Units per Year Predicted capacity requirements Machine shop capacity Capacity (gap) or slack Assembly capacity Capacity (gap) or slack Receiving, shipping, and factory warehouse capacity Capacity (gap) or slack Current, 1987 1989 1992 1997 10,000 12,000 15,000 20,000 11,000 - - - 1,000 (1,000) (4,000) (9,000) 10,000 - - - - (2,000) 15,000 - - - 5,000 3,000 - (5,000) (5,000) (10,000) Expected, Optimistic, and Pessimistic Predictions of Requirements Capacity, Units per Year Expected capacity requirements Optimistic requirements Pessimistic requirements Current, 1987 1989 1992 1997 10,000 12,000 15,000 20,000 10,000 14, 14,500 25,000 62,000 10,000 11,000 12,800 16,000 11 The Optimistic Prediction Capacity, Units per Year Predicted capacity requirements Machine shop capacity Capacity (gap) or slack Assembly capacity Capacity (gap) or slack Receiving, shipping, and factory warehouse capacity Capacity (gap) or slack Current, 1987 1989 1992 1997 10,000 14,500 25,000 62,000 11,000 - - - 1,000 (3,500) 10,000 - - (4,500) 15,000 - 5,000 500 (14,000) (51,000) - - (15,000) (52,000) - - (10,000) (47,000) The Pessimistic Prediction Capacity, Units per Year Predicted capacity requirements Machine shop capacity Capacity (gap) or slack Assembly capacity Capacity (gap) or slack Receiving, shipping, and factory warehouse capacity Capacity (gap) or slack Current, 1987 1989 1992 1997 10,000 11,000 12,800 16,000 11,000 - - - 1,000 - (1,800) (5,000) 10,000 - - - - (1,000) (2,800) (6,000) 15,000 - - - 5,000 4,000 2,200 (1,000) 12 Generation of Alternative Capacity Plans Large or small Capacity Increments Noted: Whether smaller or larger increments of capacity will be more economical depends on the balance of incremental capital and the operating costs of a particular organization and on whether or not economies of scale exist. Alternative sources of Capacity Noted: The cost effects of using alternative sources of capacity are the tradetrade-off of some of the costs carrying slack capacity against the costs of overtime and multiple shifts, productivity losses resulting from pushing capacity beyond normal limits, and the extra costs of subcontracting units of output. 22000 2000 unit every 2 years 20000 18000 16000 14000 12000 1987 (current) capacity 10000 1987 1989 1991 1993 1995 1997 1999 13 22000 4000 unit every 4 years 20000 18000 16000 14000 12000 1987 (current) capacity 10000 1987 1989 1991 1993 1995 1997 1999 22000 20000 18000 Planned use of alternative sources of capacity 16000 14000 12000 1987 (current) capacity 10000 1987 1989 1991 1993 1995 1997 1999 14 15 Economies of Scale Cost per unit A B C Monthly production, units Economic Evaluation of Capacity Plans Mature Products with Stable Demand Growth Example 1.Capacity added January 1, 1987, and January 1, 1989, in increments increments of 2000 units. 2.Capacity of 4000 units added January 1, 1987. 3.Capacity added July 1, 1987, and July 1, 1989, in increments of of 2000 units, depending on overtime and multiple shifts to meet requirements requirements during the first six months of 1987 and 1989. 4.Capacity of 4000 units added January 1, 1988, depending on overtime overtime and multiple shifts to meet requirements during 1987. 16 Original Invesment Requirements and Operating Cost Plant Size, Units per Year Original invesment Operating Costs per unit Operating Costs per Unit When Using Alternative Sources of Capacity 2000 4000 $1,000,000 1,8000,000 $ 10 9 $ 11 10 i = annual interest rate in decimals = 0.15 17 18 19 The present value for the four alternative are 1. $ 1,812,070 2. $ 1,850,463 3. $1,697,665 4. $1,617,398 20 New Products and Risky Situations An Example Suppose that we are planning future capacity for a product that is in the rapid development phase. Present annual capacity is 20,000 units. units. New competition is becoming very aggressive ,but the enterprise expects expects retain its market share. The sales department feels that market shares should should be increased with aggressive promotion. Estimates of the total market vary, with with some feeling that growth might be explosive in the next four to five years. On On the other hand, there is the additional uncertainty concerning continuing technological technological innovation that could stunt the growth of the current line. Thus, expected, optimistic, and pessimistic market prediction are made and assigned probabilities probabilities that each might occur. The predictions are converted to capacity requirements per per year as follows: 1987, 1988 1989 1990 1991 Current Optimistic (p (p = 0.25) 17,000 24,000 34,000 48,000 66,000 Expected (p (p = 0.50) 17,000 20,000 34,000 29,000 35,000 Pessimistic (p (p = 0.25) 17,000 19,000 21,000 23,000 25,000 Strategies. Three alternative strategies are developed,each designed with the three market assumptions in mind.The variable cost of production are the same as for the present capacity because no new process technology is involved. The three alternative are. 1. Install new capacity in 1989,1990 and 1991 in increments of 15,000 units. Install new capacity in 1989, 1990, and 1991 in increments of 5,000 units Make no capacity additions. 2. 3. 21 22 23 24