Assignment #1: Case Study on Sport Obermeyer

advertisement

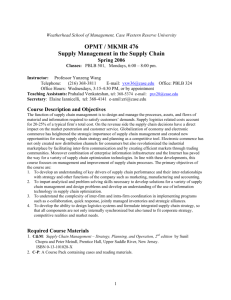

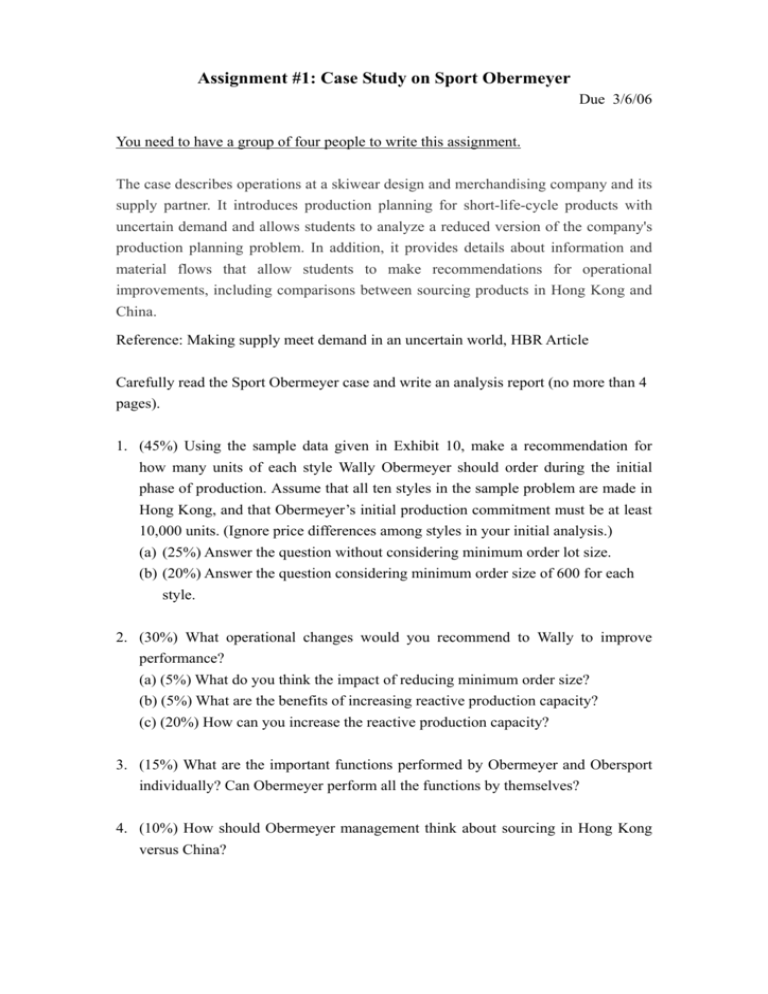

Assignment #1: Case Study on Sport Obermeyer Due 3/6/06 You need to have a group of four people to write this assignment. The case describes operations at a skiwear design and merchandising company and its supply partner. It introduces production planning for short-life-cycle products with uncertain demand and allows students to analyze a reduced version of the company's production planning problem. In addition, it provides details about information and material flows that allow students to make recommendations for operational improvements, including comparisons between sourcing products in Hong Kong and China. Reference: Making supply meet demand in an uncertain world, HBR Article Carefully read the Sport Obermeyer case and write an analysis report (no more than 4 pages). 1. (45%) Using the sample data given in Exhibit 10, make a recommendation for how many units of each style Wally Obermeyer should order during the initial phase of production. Assume that all ten styles in the sample problem are made in Hong Kong, and that Obermeyer’s initial production commitment must be at least 10,000 units. (Ignore price differences among styles in your initial analysis.) (a) (25%) Answer the question without considering minimum order lot size. (b) (20%) Answer the question considering minimum order size of 600 for each style. 2. (30%) What operational changes would you recommend to Wally to improve performance? (a) (5%) What do you think the impact of reducing minimum order size? (b) (5%) What are the benefits of increasing reactive production capacity? (c) (20%) How can you increase the reactive production capacity? 3. (15%) What are the important functions performed by Obermeyer and Obersport individually? Can Obermeyer perform all the functions by themselves? 4. (10%) How should Obermeyer management think about sourcing in Hong Kong versus China? Case Supplement 1. This is an ambitious case and covers three general topics: a) production planning for short-life-cycle fashion products; b) operational changes that reduce costs of mismatched supply and demand; c) coordination issues in a global supply chain. 2. It is strongly recommended to read the reference HBR article, “Making supply meet demand in an uncertain world,” very carefully because of its rich relevance with the case. In order to help you understand better the key issues of the case and the connection between the article and case, I am giving you more specific hints. 3. The production planning problem that Obermeyer faces is a mathematically complex stochastic optimization problem. You don’t need to formally structure and solve the problem, but you should be able to devise a heuristic rule for solving the planning problem. The “risk-based producing sequencing” as described in the article provides you some guidelines in devising your heuristic rule. Here are some hints: (i) Obermeyer should follow a strategy that minimizes the expected cost of stockouts and markdowns. (ii) Obermeyer should fill nonreactive capacity (the initial phase of production) with those styles with low risks based on information from predicted sales and fill reactive capacity with those styles with high risks based on information from actual sales. (iii) When there is no constraint of minimum order size, try to produce styles with higher expected demand and lower demand uncertainty in the initial phase of production. Style Initial production 1 2 3 4 5 6 7 8 9 10 Total Roughly 10000 (iv) When there is a constraint of minimum order size of 600, try to produce styles with higher “safety factor” in the initial phase of production. Definitions of safety factor are as follows: Type 1 parka (µi > 1200 ), safety factor = (µi – 1200)/σi Type 2 parka (µi < 600 ), safety factor = (600–µi )/σi Type 3 parka (600< µi < 1200 ), safety factor = 0 Notice that Type 1 products are safe to produce in the initial production stage since we are not likely to be overly constrained by the minimum order size. However, Type 3 products are the riskiest products to make in the initial production period. Why? If commit to producing some amount during the initial production period, we will likely not be able to adjust the total production of this style after receiving early demand information in Las Vegas. Style µi σi Seduced Assault Electra Anita Daphne Entice Gail Isis Teri Stephanie 4017 2525 2150 3296 2383 1358 1017 1042 1100 1113 1113 680 807 2094 1394 496 388 646 762 1048 Total 20001 Safety factor 2.53 1.95 1.18 1.00 0.85 0.32 0.00 0.00 0.00 0.00 Initial production Roughly 10000 4. The operational changes question has been updated as: (a) What do you think the impact of reducing minimum order size? (b) What are the benefits of increasing reactive production capacity? (c) How can you increase the reactive production capacity? 5. The coordination question has been updated as: What are the important functions performed by Obermeyer and Obersport individually? Can Obermeyer perform all the functions by themselves? How should Obermeyer management think about sourcing in Hong Kong versus China?