NRM Examination Guide.doc - American Society for Microbiology

Examination Guide

National Registry of Microbiologists

The National Registry of Microbiologists

© 2007 American Society for Microbiology

Rev. 8/16/07

2

T ABLE OF C ONTENTS

General Information

........................................................................................................................................................................... 4

What is the NRM? ................................................................................................................................................................... 4

What is Certification? ............................................................................................................................................................... 4

What Areas does the NRM Test? ............................................................................................................................................ 4

When and Where are the Examinations Given? ...................................................................................................................... 4

About the Examination

..................................................................................................................................................................... 5

Examination Format ................................................................................................................................................................. 5

Scoring ..................................................................................................................................................................................... 5

Examination Content

Consumer Products and Quality Assurance Microbiology –RM(NRM)

Task List ................................................................................................................................................................................... 6

Sample Questions .................................................................................................................................................................... 8

Resources .............................................................................................................................................................................. 13

Consumer and Industrial Microbiology –SM(NRM)

Task List ................................................................................................................................................................................. 15

Sample Questions .................................................................................................................................................................. 17

Resources .............................................................................................................................................................................. 21

Biological Safety Microbiology –SM(NRM)

Task List ................................................................................................................................................................................. 23

Sample Questions .................................................................................................................................................................. 25

Resources .............................................................................................................................................................................. 29

Eligibility

.......................................................................................................................................................................................... 31

How to Apply

................................................................................................................................................................................... 35

Application Form .................................................................................................................................................................... 35

Official Transcripts .................................................................................................................................................................. 35

International Transcripts ......................................................................................................................................................... 35

Conditional Registrants .......................................................................................................................................................... 36

Reference Forms .................................................................................................................................................................... 36

Application Fees ..................................................................................................................................................................... 36

Obtaining Proctor ................................................................................................................................................................... 37

The Test Day

.................................................................................................................................................................................... 38

Examination Results

........................................................................................................................................................................ 38

Reexaminations

............................................................................................................................................................................... 38

3

GENERAL INFORMATION

WHAT IS THE NATIONAL REGISTRY OF MICROBIOLOGISTS

?

The National Registry of Microbiologists (NRM) was founded in 1958 and has certified microbiologists in all 50 states, the District of Columbia, and

Puerto Rico and on six continents.

The goals of the NRM are to:

minimize risk to the public by identifying qualified microbiologists.

encourage mastery of microbiological knowledge and skills that contribute to improving the human condition.

foster professional pride and a sense of accomplishment in qualified microbiologists.

The NRM encourages its Registrants to keep up to date with the concepts, skills, and issues of import to their field through recertification.

Recertification demonstrates a continued commitment to maintaining a standard of excellence in the field.

WHAT IS CERTIFICATION

?

Certification is the process by which a non-governmental agency or association grants recognition of competence to an individual who has met certain predetermined qualification as specified by the agency or association.

The NRM certifies professional microbiologists at the baccalaureate (Registered Microbiologist, [RM]NRM); master's, doctoral, and baccalaureate

(Specialist Microbiologist, [SM]NRM); and prebaccalaureate/baccalaureate (Conditional Registrant) levels.

WHAT AREAS DOES THE

NRM

TEST

?

The NRM tests in industrial and biological safety microbiology. It offers four different certification examinations, three in industrial microbiology and one in biological safety microbiology.

The three industrial examinations are

Consumer Products and Quality Assurance Specializing in Pharmaceutical/Medical Device/Cosmetics . It tests for factual knowledge, concepts, and laboratory skills needed in a consumer product microbiology testing laboratory.

Consumer Products and Quality Assurance Microbiology Specializing in Food and Dairy . It tests for factual knowledge, concepts, and laboratory skills needed in a consumer product microbiology testing laboratory.

Consumer and Industrial Microbiology Specializing in Pharmaceutical/Medical Device/Cosmetics. It tests for ability to supervise the effective operation of biological procedures in a consumer product microbiology testing laboratory.

The one biological safety microbiology examination tests pertinent knowledge and the ability to develop, implement, and manage a comprehensive biological safety program.

WHEN AND WHERE ARE THE EXAMINATIONS GIVEN

?

The examinations for certification in industrial microbiology are administered each year on the first Friday in October at locations worldwide. The examinations for certification in biological safety microbiology are administered each year in mid-October at the annual meeting of the

American Biological Safety Association and at locations worldwide.

4

ABOUT THE EXAMINATION

Examination Format

The examination consists of 150 multiple-choice questions.

It is a paper and pencil test.

Each question has only one correct answer.

Questions have a stem and up to five possible responses.

Questions are updated and re-evaluated annually.

Questions are classified by domain and then by task.

The examination will have at least one question from each task. A task list for each specialty examination is included in the examination guide.

The number of questions from each domain is listed next to the domain’s description on the task list for each examination.

Scoring

The NRM uses a criterion-referencing system for determining examination scores. This method sets a standard of performance in absolute, not relative, terms. As a result, you are not graded on a curve and do not compete against other examinees. If you perform at or above the established criterion standard, you pass the examination and are certified.

The number of correct answers determines your score. One point is given for each correct answer. There is no penalty for guessing; therefore, it is in your best interest to answer all questions. Answer sheets are scored electronically.

5

Consumer Products and

Quality Assurance (CP/QA)

Task List

Specialty examinations consist of 100 general questions and 50 specialty questions.

General Tasks

LABORATORY INSTRUMENTS AND EQUIPMENT (21 questions)

1. Validate, use, and monitor a steam autoclave.

2. Use a pH or conductivity meter.

3. Use various types of microscopes (e.g., light field, dark field, phase contrast, fluorescence).

4. Use filtration equipment for sterilization of solutions.

5. Use analytical equipment (pH meters, spectrophotometers, etc.)

6. Use fermentors and/or continuous culture apparatuses.

7. Use laminar flow hood and biosafety cabinets.

8. Use incubation equipment and appropriate controls.

LABORATORY PREPARATIONS (12 questions)

9. Use general stains (e.g., Gram, nigrosin, spore, Ziehl-Neelsen,

Kinyoun, flourescent).

10. Prepare and perform appropriate quality control checks on media from commercial dehydrated materials and supplements.

11. Use general, selective, or differential media for bacteria.

12. Use general, selective, or differential media for fungi.

13. Prepare solutions of known molarity, molality, and normality.

14. Prepare and use buffers.

LABORATORY PROCEDURES (43 questions)

15. Isolate and identify Bacillus or other gram-positive, aerobic bacilli.

6

16. Isolate and identify Pseudomonas and other oxidative, gramnegative bacilli.

17. Isolate and identify Enterobacteriaceae .

18. Isolate and identify Staphylococcus .

19. Isolate and identify Streptococcus .

20. Perform precipitation, agglutination, immunoassay, and immunofluorescence tests.

21. Perform broth or agar susceptibility tests of antimicrobials.

22. Detect and measure the growth of microorganisms (e.g., by substrate utilization, turbidity, impedance, and rapid methodologies).

23. Determine inactivation rates of microorganisms by chemical and physical means.

24. Use viable plate count procedures.

25. Use most-probable-number technique.

26. Perform tests for water suitability in production systems.

27. Perform phenol coefficient tests or similar tests on disinfectants.

28. Use and maintain cell cultures.

29. Apply appropriate statistical and analytical techniques to test results.

30. Perform standard biochemical tests for organism identification.

31. Use specialized techniques for identification of bacteria and yeasts (e.g., fatty acids, electrophoresis, DNA probes, enzymelinked immunosorbent assay [ELISA], commercial kits).

32. Understand the advantages and limitations of various sterilization procedures.

LABORATORY OPERATIONS (24 questions)

33. Use appropriate safety techniques for the isolation and transfer of biological materials (e.g., loops, pipets, dilutor tips).

34. Handle, store, transport, and dispose of etiologic agents or biologics in compliance with laboratory and government regulations.

35. Handle, store, and dispose of hazardous chemicals and radiologic agents in compliance with laboratory and government regulations.

36. Document and maintain laboratory records and procedures.

37. Monitor the environment during process operations.

38. Maintain stock cultures.

39. Perform studies to determine sources of contamination.

40. Operate within environmentally controlled rooms, including clean rooms.

41. Evaluate clean-in-place and sterilize-in-place systems (e.g., validation procedures, monitoring procedures, troubleshooting).

CP/QA Pharmaceutical/Medical Device/Cosmetic

Specialty Tasks

SAMPLE COLLECTION AND HANDLING (13 questions)

42. Prepare samples for microbiological analysis (e.g., sample size, blending, and dilutions).

43. Collect and evaluate industrial samples for quality assurance and quality control testing.

44. Select appropriate methods for transport, handling, and storage of samples.

LABORATORY PROCEDURES (27 questions)

45. Isolate and identify yeasts of importance in industry.

46. Perform and validate tests for sterility.

47. Perform bacteriostatic or fungistatic tests.

48. Perform tests for particulate matter.

49. Perform and validate tests for pyrogens.

50. Perform and validate bioburden tests.

51. Perform tests for the effectiveness of preservatives.

52. Perform mutagen and cytotoxicity assays.

53. Perform process equipment and/or product validation studies.

STERILIZATION AND DEPYROGENATION

VALIDATION (10 questions)

54. Ethylene oxide sterilization.

55. Radiation sterilization.

56. Chemical sterilization.

57. Sterilization by filtration.

58. Depyrogenation.

CP/QA Food and Dairy Specialty Tasks

SAMPLE COLLECTION AND HANDLING (12 questions)

59. Prepare samples for microbiological analysis (e.g., sample size, blending, dilutions, and incubation conditions).

60. Collect and evaluate samples for environmental and quality control/quality assurance testing.

61. Select appropriate methods for transport, handling, and storage of samples.

LABORATORY PROCEDURES (38 questions)

62. Isolate and identify Listeria.

63. Isolate and identify Enterobacteriaceae (e.g., Salmonella,

Proteus, Citrobacter , pathogenic Escherichia coli ).

64. Isolate and identify Vibrio and Campylobacter.

65. Isolate and identify Clostridium species.

66. Isolate and identify microorganisms in food and dairy products.

67. Isolate, identify, and handle cultures of importance in food and dairy production (e.g., commercial starters).

68. Perform tests for spoilage and sterility in canned foods.

69. Perform shelf life studies.

70. Perform microbiological growth factor assays.

71. Perform tests for and identify extraneous materials in foods.

72. Use irradiation, biocontrol agents, preservatives, and other processing methods to control pathogens and spoilage bacteria in foods.

73. Perform aseptic process and/or product validation studies.

74. Perform direct microscopic counts.

7

8

CP/QA

S AMPLE Q UESTIONS

The sample questions included in this examination guide are actual questions from previous examinations. They have been removed from the question pool. Do not judge the content as indicative of content in current questions, but use these sample questions as templates for the format and design of questions and answers.

General CP/QA questions (for both Pharmaceutical/

Medical Device/Cosmetic and Food and Dairy examinations)

1. Phase-contrast microscopy enables the human eye to observe structures not visible by bright field-microscopy by modifying the light: a. path by 90°. b. contrast. c. intensity. d. wavelength. e. amplitude.

Corresponds to task #3.

2. To achieve Kohler illumination, the height adjustment of the condenser should be: a. at its upper stop. b. at its lower stop. c. halfway between its upper and lower stops. d. lowered slightly from its upper stop.

Corresponds to task #3.

3. What is the greatest drawback in the use of UV-visible spectrophotometry in quantitative analysis? a. Inadequate linearity b. Inadequate sensitivity c. Inadequate specificity d. Excessive noise levels e. Problems in choosing appropriate blanks

Corresponds to task #5.

4. Before a laminar flow hood is used, it should be running a minimum of: a. 2 hours. b. 24 hours. c. 15 to 30 minutes. d. 5 to 10 minutes. e. 1 week.

Corresponds to task #7.

5. Which quality control procedure is necessary to perform with every batch of media? a. Shelf life determination b. Endotoxin content c. Buffering capacity d. Bacteriostatic/fungistatic tests e. Sterility check

Corresponds to task #10.

6. Pyrogallic acid with sodium hydroxide would be added for which of the following functions? a. Provide for anaerobic conditions b. Provide essential nutrients to the organisms c. Alter the pH of the medium d. Chelate metallic elements in the medium e. Bacteriocidal action

Corresponds to task #13.

7. When isolating motile, oxidative, nonfermenting gram-negative rods, which of the following should one look for in order to separate them from Pseudomonas species? a. An oxidative reaction on O/F glucose b. Polar pili c. The fermentation of dextrose d. Peritrichous versus polar flagella e. A negative indophenol oxidase reaction

Corresponds to task #16.

8. A gram-negative organism was isolated with the following characteristics: oxidase-positive, motilitypositive, growth at 42°C and production of pyocyanin. The organism isolated is: a. Escherichia coli. b. Pseudomonas cepacia.

c. Pseudomonas aeruginosa.

d. Staphylococcus aureus.

e. Pseudomonas stutzeri.

Corresponds to task # 16.

9. For the formation of immunoprecipitates, the almost universal optimal agar gel (Ouctherlony) concentration is: a. 0.03 to 0.15%. b. 0.15 to 0.3%. c. 0.3 to 1.5%. d. 1.5 to 3.0%. e. 3.0 to 5.0%.

Corresponds to task #20.

10. Precipitation tests for the detection of antigens are often carried out using: a. the agar diffusion method. b. high-performance liquid chromatography (HPLC). c. the complement fixation method. d. passive agglutination. e. polyacrylamide gel electrophoresis (PAGE).

Corresponds to task #20.

11. Fluorescence detected in immunofluorescent technique is photons emitted from the: a. antigen. b. antibody. c. antiglobulin antibody. d. antigen-antibody complex. e. fluorescent dye.

Corresponds to task #20.

12. A microscope outfitted with excitation, suppression, and heat filters is necessary to detect: a. peritrichous flagella. b. immunofluorescence. c. capsules. d. beta-hemolysis. e. fat soluble granules.

Corresponds to task #20.

13. Cross-reactivity in serologic reactions may lead to false-positive reactions and can be expected when: a. antigens are not in optimal proportions to the antibodies. b. there is no electrolyte in the system. c. several antigens are closely related. d. complement has not been inactivated. e. the dilutent is hypotonic.

Corresponds to task #20.

9

14. The scientific literature contains a number of references showing that antibiotic potency tests carried out with saturated paper disks are equivalent to the United States Pharmacopeia (USP) cylinder plate method. A laboratory wanting to change from cylinders to paper disks should: a. proceed to do so without further ado. b. provide definite proof of equivalence of the two tests for each antibiotic from the literature. c. provide proof of equivalence for each family of antibiotics for each medium used. d. provide some proof of equivalence for each test organism. e. provide some proof of equivalence for each antibiotic.

Corresponds to task #21.

15. The agar diffusion test is the most convenient for antimicrobic susceptibility testing. However, antimicrobial dilution tests may be required if: a. simple qualitative information is needed. b. isolates are capable of growing at a uniform rapid rate. c. the drug has no diffusion problems. d. a fairly large number of drugs need to be screened at the same time. e. quantitative information is needed.

Corresponds to task #21.

16. The time at a given temperature required to destroy 90% of the organisms is called the: a. thermal death time. b. thermal death point. c. D value. d. F value. e. Z value.

Corresponds to task #23.

17. A 24-hour culture of Bacillus subtilis contains 2.4 × 10 6 CFU/ml.

Sequential dilutions of 1:10, 1:5, 1:100, and 1:3 were made from the original samples. The final titer is: a. 4.8 × 10 3 CFU/ml. b. 1.6 × 10 3 CFU/ml. c. 8.0 × 10 2 CFU/ml. d. 4.8 × 10 2 CFU/ml. e. 1.6 × 10 2 CFU/ml.

Corresponds to task #24.

18. The process of disinfection refers to: a. the destruction of disease-producing organisms. b. sterilization. c. the removal of all bacteria. d. the killing of all vegetative bacteria. e. the destruction of all bacterial spores.

Corresponds to task #27.

19. What standard is used for comparing the effectiveness of certain disinfectants? a. Iodine index b. Phenol coefficient c. Alcohol index d. Hexachlorophene coefficient e. Creosol index

Corresponds to task #27.

20. In order to identify a gram-negative, aerobic, nonfermenting, oxidase-negative bacterium, one should use a commercial kit which differentiates: a. genus Propionibacterium from Fusobacterium . b. genus Pseudomonas from Acinetobacter . c. genus Fusobacterium from Actinomyces . d. genus Fusobacterium from Bacteroides . e. various Enterobacteriaceae .

Corresponds to task #31.

10

21. Which of the following should be added to a commercial identification kit in order to create anaerobic conditions? a. Nitrogen gas b. Water c. Mineral oil d. Plastic wrap e. Sterile cotton plugs

Corresponds to task #31.

22. A laboratory's liability for its hazardous waste ends: a. when the hazardous waste is legally removed from the premises. b. when the hazardous waste is diluted and poured down the drain. c. when the waste has been mixed with hazardous wastes from another source by another party. d. when the waste no longer exists or is recycled.

Corresponds to task #35.

23. The Resources Conversion and Recovery Act (RCRA) for hazardous waste requires: a. 60% of all medical waste to be recycled. b. medical waste to be disposed of within the state generated. c. a separate loading dock for hazardous waste. d. a cradle-to-grave tracking system. e. licensing requirements for class IV pathogens.

Corresponds to task #35.

Pharmaceutical/Medical Device/Cosmetics Specialty

Questions

24. Which of the environmental conditions listed below would be selective of a mesophilic, anaerobic heterotroph?

Temperature

Source pH Atmosphere Energy a. 10 o C b. 60 o C

7.0

3.0

N

2 air c. 60 d. 10 e. 30 o o o

C

C

C

1.0

7.0

7.0 air air

N

2

Corresponds to tasks #42 and 59. glucose sulfur glucose glucose glucose

25. According to Standard Methods for the Examination of Water and Wastewater , what is the maximum allowable time at 4°C for potable water samples that are to be plated? a. 6 hours b. 24 hours c. 30 hours d. 36 hours e. 48 hours

Corresponds to task #43.

11

26. The following units were sent to the laboratory for testing:

100 sterile samples for sterility tests

10 non-sterile samples for bioburden tests

10 non-sterile samples for pyrogen tests (in vitro)

3 extra sterile samples

The units were packaged and shipped in a cardboard box. When the packages were opened with a razor box opener, two of the nonsterile packages were found to be damaged. How can the problem BEST be solved? a. Proceed by using the two damaged units for the bioburden test and note the damage on the report. b. Use two sterile units for the bioburden test. c. Use two sterile units for the pyrogen test. d. Perform the pyrogen test on eight units only, as sterility data will provide adequate information on pyrogen safety. e. Use two of the units for both the in vitro pyrogen test and the bioburden test.

Corresponds to task #43.

27. The growth of all bacteria requires that bacteriological liquid media provide an energy source plus: a. KH

2

PO

4

, MgSO

4

, (NH

4

)

2

SO

4

, and trace elements. b. vitamins, a buffer, trace elements, and sulfur. c. a buffer, O

2

, vitamins, and a nitrogen source. d. hydrolytic products of proteins, vitamins and other growth factors, a buffer and trace elements. e. appropriate sources of C, H, N, P, and S, as well as trace elements.

Corresponds to task #43.

28. One of the problems with the USP sterility test is that the test cannot be used to detect contamination in: a. ointments and oils. b. large numbers of contaminated containers from a lot of

10,000.

c. small numbers of contaminated containers from a lot of

10,000. d. parenteral antibiotic solutions. e. monoclonal antibodies.

Corresponds to task #46.

29. What is the minimum detectable range of manual particle counts at 100 ×, according to the USP? a. 5 µm b. 10 µm c. 25 µm d. 50 µm e. 100 µm

Corresponds to task #48.

30. Which indicates the MOST toxic cellular response in an in vitro cytotoxicity assay? a. Nonconfluent cell monolayer b. Granulation c. Crenation d. Acidic shift in pH of growth medium

Corresponds to task #52.

31. The two most common gases used for plasma sterilization are: a. hydrogen peroxide and peracetic acid. b. argon and hydrogen. c. hydrogen peroxide and ethylene oxide. d. hydrogen peroxide and acetic acid.

Corresponds to task #56.

12

Food and Dairy Specialty Questions

32. The food-poisoning toxins produced by Staphylococcus aureus are: a. exotoxins. b. lethal poisons. c. endotoxins. d. heat labile. e. composed of carbohydrates.

Corresponds to task #66.

33. Saccharomyces cerevisiae var. ellipsoideus may be differentiated from Saccharomyces cerevisiae by: a. pH requirement. b. sugar fermentation. c. morphology. d. ascospore formation. e. amino acid requirements.

Corresponds to task #67.

34. Which of the following is a direct microscopic count technique? a. Smear b. Microcytic count c. Macrocytic count d. Spiral count e. Acid wash

Corresponds to task #73.

A

NSWERS

1. a 6. a 11. e 16. c 21. c 26. c 31. a

2. d

3. c

7. d 12. b 17. e 22. d 27. e 32. a

8. c 13. c 18. a 23. d 28. c 33. c

4. c 9. c 14. e 19. b 24. e 29. b 34. a

5. e 10. a 15. a 20. b 25. c 30. a

R ESOURCES

General Tasks

Cunniff, P.A., et al. (ed.).

Official methods of analysis. AOAC

International, Gaithersburg, Md.

Standard methods for the examination of water and wastewater.

American Public Health Association (APHA), Washington, D.C.

Biosafety in microbiological and biomedical laboratories.

U.S.

Department of Health and Human Services, Centers for Disease

Control and Prevention, and National Institutes of Health. U.S.

Government Printing Office, Washington, D.C.

U.S. Food and Drug Administration.

Current good manufacturing practice in manufacturing, processing, packing, or holding of drugs; general. Title 21, Code of Federal Regulations, section 210 (21 CFR

210). U.S. Government Printing Office, Washington, D.C. www.gpoaccess.gov/cfr/index/htm .

Pharmaceutical/Medical Device/Cosmetic

Tasks

Critical References

United States Pharmacopeia and National Formulary.

The

United States Pharmacopeial Convention, Inc. Rockville, Md.

Selected titles from the Association for Advancement of Medical

Instrumentation (AAMI).

Selected titles from Parenteral Drug Association Technical

Monographs .

13

Helpful References

Journals

PDA Journal of Pharmaceutical Science and Technology.

Medical Device & Diagnostic Industry.

The Microbiological Update.

Food and Dairy Tasks

Critical References

Standard methods for the examination of dairy products.

American Public Health Association, Washington, D.C.

U.S. Food and Drug Administration (FDA). 1995. Bacteriological analytical manual (BAM), 8 th ed. AOAC International, Arlington, Va.

Updates available at http://vm.cfsan.fda.gov/~ebam/bam-toc.html

.

Vanderzant, C., and D.F. Splittstoesser (ed.). Compendium of methods for the microbiological examination of foods. American

Public Health Association, Washington, D.C.

Helpful References

Dey, B.P., and C.P. Lattuda (ed.). 1998. Microbiology laboratory handbook, 3 rd ed. United States Department of Agriculture, Food

Safety and Inspection Service. U.S. Department of Agriculture,

Washington, D.C.

Journals

Food Technology.

Food Testing and Analysis.

Journal of Food Protection.

Journal of Validation Technology.

The Microbiological Update.

Internet

USP.

AAMI. http://www.usp.org. http://www.cssinfo.com/info/aami.html.

AOAC International. http://www.aoac.org.

APHA. http://www.apha.org.

FDA. http://www.fda.gov.

A

BOUT THE

R

ESOURCE

L

ISTS

The resources listed are NOT meant to be comprehensive guides to the examination. They are merely suggested references for review.

14

C ONSUMER AND I NDUSTRIAL

M ICROBIOLOGY (C & I)

T ASK L IST

General Tasks

LABORATORY INSTRUMENTS AND EQUIPMENT (19 questions)

1. Use and monitor sterilization equipment (e.g., autoclaves, ovens, ethylene oxide, radiation).

2. Use and monitor filters for sterilization of solutions.

3. Use and monitor incubation devices such as ambient air, carbon dioxide, anaerobic, and constant water temperature devices.

4. Use a pH meter or conductivity meter.

5. Use locally controlled environmental systems (e.g., biosafety cabinets, unidirectional [laminar] flow cabinets, isolators).

6. Use various types of microscopes.

7. Use colorimetric and spectrophotometric equipment.

8. Use of electronic monitoring of equipment (chart recorders, multipoint recorders) and understand electronic data trending

(storage, retrieval, auditing, electronic signature; Code of Federal

Regulations, title 21, section 11 [21 CFR 11]).

9. Calibrate and maintain laboratory equipment.

LABORATORY PREPARATIONS (9 questions)

10. Evaluate media (general, selective, and differential) for growth, isolation, and identification of bacteria and fungi.

11. Perform medium growth promotion tests.

12. Use stains, both general and for specific structures (spores, flagella, capsules).

13. Prepare solutions of known molarity, molality, and normality.

SAMPLE COLLECTION AND HANDLING (2 questions)

14. Select appropriate means of disposal for analyzed or unanalyzed samples.

15. Use appropriate documentation procedures for samples involved in legal actions (e.g., chain-of-custody documentation).

LABORATORY PROCEDURES (28 questions)

16. Understand and apply biochemical tests for bacterial identification (e.g., carbohydrate fermentations, redox reactions, catalase, coagulase, oxidase).

17. Isolate and identify coliforms.

18. Isolate and identify Pseudomonas species and common waterborne organisms.

19. Isolate and identify common fungi (e.g., Aspergillus species, yeast).

20. Perform analytical procedures for the evaluation of water and potable water.

21. Perform measurements for the growth of microorganisms (e.g., substrate utilization, plate counts, turbidity).

22. Use most-probable-number technique.

23. Perform microbial tests on disinfectants.

24. Perform identification of bacteria using biochemical, genetic, or chromatographic procedures (e.g., DNA probes, polymerase chain reaction [PCR], sequencing, fatty acid methyl esters, carbohydrate utilization).

25. Understand rapid microbiological techniques (e.g., bioluminescence, impedence, cytometry).

26. Use or detect viruses and/or mycoplasma.

27. Evaluate new test procedures or procedures that are alternative to compendial procedures.

15

LABORATORY OPERATIONS (26 questions)

28. Monitor proper handling of hazardous chemicals, radioactive materials, and biological agents.

29. Establish and maintain standard operating procedures (SOPs)

(e.g., methods, procedures, equipment maintenance, calibration, repair, replacement).

30. Develop and maintain effective laboratory quality systems (e.g., documentation, controls, trend analysis of laboratory data, proficiency testing).

31. Supervise maintenance and inventories of stock cultures and preserve biological specimens.

32. Develop and maintain laboratory safety practices.

33. Apply appropriate statistical and analytical techniques to test results.

34. Make recommendations for action based on analytical results, including failure investigation.

35. Document and maintain an ongoing training program.

36. Understand use of risk analysis for determining objectionable microorganisms and actions to take.

MANUFACTURING EQUIPMENT, FACILITIES, AND

PROCESSES (15 questions)

37. Establish and maintain environmental monitoring procedures

(e.g., of personnel; in laboratory, production areas, warehouses).

38. Evaluate clean-in-place and sterilize-in-place systems (e.g., validation procedures, monitoring procedures, troubleshooting).

39. Determine lethal rates of microorganisms (e.g., sterility assurance level, D value, F

0

value).

40. Perform and/or evaluate audits of contract manufacturers and laboratories.

41. Understand and apply good laboratory practices according to existing regulations (e.g., U.S. Food and Drug Administration

[FDA], Good Laboratory Practices [21 CFR 58], AOAC

International ISO 17025 [Guidelines for Laboratories Performing

Microbiological and Chemical Analyses of Food and

Pharmaceuticals]).

16

Pharmaceutical/Device/Cosmetic Specialty Tasks

SAMPLE COLLECTION AND HANDLING (7 questions)

42. Select appropriate methods for sample storage and transport.

43. Prepare samples for microbiological analyses (e.g., proper mixing, dilutions, dispersing, neutralization of microbial inhibitors).

44. Select appropriate sample plans, collection materials, and collection equipment.

LABORATORY PROCEDURES (22 questions)

45. Isolate and identify gram-positive organisms.

46. Isolate and identify gram-negative organisms.

47. Perform and validate tests for sterility.

48. Perform and evaluate tests for bioburden.

49. Perform tests for bacterial endotoxins ( Limulus amebocyte lysate

[LAL]).

50. Perform and validate tests for the effectiveness of preservatives.

51. Perform biocompatibility tests (e.g., cytotoxicity, mutagenicity

[Ames]).

52. Use and maintain cell culture lines for production.

53. Perform immunoassays (e.g., enzyme-linked immunosorbent assay [ELISA], precipitation, agglutination, immunofluorescence).

54. Evaluate container/closure systems.

MANUFACTURING EQUIPMENT, FACILITIES, AND

PROCESSES (17 questions)

55. Use centrifuges and/or ultracentrifuges.

56. Validate filtration equipment.

57. Use continuous culture apparatus and monitor fermentation processes.

58. Evaluate and validate manufacturing processes, fill lines, and packaging.

59. Monitor gowning techniques for manufacturing processes.

60. Validate and monitor clean rooms and controlled environments.

61. Monitor and evaluate gases used in manufacturing processes.

62. Validate and monitor water purification systems (e.g., deionized water, purified water, water for injection, biofilm control).

63. Validate sterilization and depyrogenation processes (e.g., steam, dry heat, gas, radiation).

REGULATIONS (5 questions)

64. Demonstrate knowledge of Good Manufacturing Practices (21

CFR 210, 211, and 600).

65. Demonstrate knowledge of compendial and standard methods for microbiological analysis (e.g., AOAC International, United

States Pharmacopeia and National Formula [USP-NF], and FDA

Bacteriological Analytical Manual [FDA-BAM]).

C & I Sample Questions

The sample questions included in this examination guide are actual questions from previous examinations. They have been removed from the question pool. Do not judge the content as indicative of content in current questions, but use these sample questions as templates for the format and design of questions and answers.

General Tasks

1. The most reliable way to monitor the adequacy of the sterilization cycle of an autoclave is to: a. use endospore strips. b. use tape indicators. c. allow 15 minutes at 15 pounds of pressure. d. allow 15 minutes at 121°C. e. use methylene blue strips.

Corresponds to task #1.

2. If you were preparing a sterile, heat-labile pharmaceutical solution, which one of the following pore sizes would you select for membrane filtration of the solution? a. 0.1

m b. 0.2

m c. 0.5

m d. 1.0

m

Corresponds to task #2.

3. In-line filter integrity tests should be performed: a. at the beginning of the filtration process. b. at the middle and end of the filtration process. c. at the middle of the filtration process. d. at the beginning and end of the filtration process. e. when the bulk bioburden exceeds established limits.

Corresponds to task #2.

4. Which device would give the most rapid and consistent temperature equilibration within a culture? a. Gravity incubator b. Anaerobic incubator c. Convection incubator d. Circulating water bath e. Low-temperature incubator

Corresponds to task #3.

5. A pH meter should have a compensation adjustment control for: a. light. b. color. c. magnetism. d. altitude. e. temperature.

Corresponds to task #4.

17

6. Your pH meter seems to drift excessively after calibration. What is the most likely cause? a. Improper temperature b. Voltage surges c. Slope drift d. A faulty LED e. Contaminated electrodes

Corresponds to task #4.

7. High-efficiency particulate air (HEPA) filters in laminar flow cabinets must remove what percentage of 0.3µm particles to be acceptable? a. 90.00 b. 95.00 c. 99.95 d. 99.97

Corresponds to task #5.

8. The purpose of bile salts, citrate, brilliant green, and desoxycholate is to: a. make the media differential. b. enhance the growth of enteric pathogens. c. make the media selective. d. buffer the pH of the media.

Corresponds to task #10.

9. Microorganisms which produce a clear zone around colonies on a skim milk agar plate after the plate is flooded with hydrochloric acid may be classified as: a. lipolytic. b. peptolytic. c. proteolytic. d. saccharolytic.

Corresponds to task #10.

10. The poured plates of Baird Parker staphylococcus agar have clear lumps in them. What is the most likely explanation for the clear lumps? a. The egg yolk tellurite supplement was added when the agar was too hot. b. The egg yolk tellurite was added after the agar base was too cool. c. The agar base was not melted before autoclaving d. The pH of the agar base was out of specification.

Corresponds to task #10.

11. An accurate written record that can be used to trace the possession of a sample from the moment of its collection to the completion of the analysis is known as the: a. field data sheet. b. final report. c. chain of custody. d. request for analysis.

Corresponds to task #15.

12. Coliforms are: a. strict anaerobes. b. hydrogen sulfide producers. c. lactose fermenters. d. gram positive. e. sucrose nonfermenters.

Corresponds to task #17.

13. A potable water sample for routine microbiological analysis arrives in your lab 48 hours after collection. You should: a. reject the sample and ask for another sample. b. analyze the sample. c. analyze the sample but report the results as suspect. d. analyze the sample but adjust the results based on the time factor.

Corresponds to task #20.

18

14. Water samples for microbiological evaluation that are to be shipped via overnight carrier must be packed: a. with a cold pack to keep temperatures low. b. in styrofoam or padding to prevent breakage. c. in plastic to avoid breakage. d. in insulated coolers to maintain temperature equilibrium.

Corresponds to task #20.

15. The microbial density of a suspension of a pure culture can be determined by spectrophotometry with preparation of a: a. standard curve using pour plates. b. MacFarland standard. c. most-probable-number test. d. dry-weight comparison. e. protein/cytoplasm optical density regression.

Corresponds to task #21.

16. Certain metabolites such as pyruvic, lactic, and fumaric acids are methylated prior to gas chromatography in order to: a. decrease retention time. b. decrease volatility. c. increase molecular weight. d. decrease molecular weight. e. increase retention time.

Corresponds to task #24.

17. Which reagent could be used for the dissociation of monolayers in tissue subculturing? a. DNase b. DMSO c. EDTA d. Tween 80

Corresponds to task #25.

18. Bacterial cultures can best be recovered from storage in liquid nitrogen if: a. the cell suspension is prepared from an early-stationaryphase culture. b. thawed at 37°C in a water bath. c. they were originally suspended in a mixture of skim milk and sucrose. d. they were frozen rapidly in a dry ice/ethyl Cellusolve bath.

Corresponds to task #31.

19. The main purpose of a laboratory coat is to: a. keep your clothes from being ruined. b. help assess the cleanliness of the laboratory. c. identify you as a trained professional. d. keep contamination off your clothing. e. give you access to several pockets at once.

Corresponds to task #32.

20. If a spill should occur within a biological safety cabinet (BSC), what steps would immediately be taken? a. Turn off the BSC and immediately wipe up the spill with a dry, absorbent towel. b. Turn off the BSC and wipe up the spill with a germicidal agent. c. Turn off the BSC, evacuate the laboratory, and notify company safety authorities. d. Leave the BSC on and wipe up the spill with a germicidal agent. e. Leave the BSC on and wipe up the spill with a dry, absorbent towel.

Corresponds to task #32.

19

21. RODAC plates are used for: a. air sampling. b. surface sampling. c. isolation of microbial colonies. d. water sampling. e. the phenol coefficient test.

Corresponds to task #37.

22. The D value stands for: a. disinfectant efficacy rating. b. time for a 90% population reduction. c. diffusion rate through a 0.22µm membrane filter. d. temperature change required to destroy 10 12

spores. e. differential pressure.

Corresponds to task #39.

Pharmaceutical/Medical Device/Cosmetic Specialty

Tasks

23. Which of the following describes the family Enterobacteriaceae?

a. Oxidase-positive fermenters b. Gram-positive, asporogenous, rod-shaped bacteria c. Ferment glucose with formation of acid with or without gas d. Gram-negative nonfermenters e. Motile with polar flagella

Corresponds to task #46.

24. Glassware can be rendered pyrogen free by: a. washing with a membrane-filtered 70% alcohol solution. b. heating to 200°C for not less than 1 hour. c. heating to 250°C for not less than 30 minutes. d. heating to 100

C for not less than 15 minutes.

Corresponds to task #49.

25. Bentonite, blood cells, and latex beads are components used to: a. enhance phagocytosis. b. select xenotrophic organisms. c. perform agglutination tests. d. prepare selective media. e. prepare live vaccines.

Corresponds to task #53.

26. Membrane filtration is based on the exclusion of bacteria at the surface of the membrane and: a. requires a pressure drop across the membrane. b. relies on membrane depth and tortuosity of the pores. c. the filter is constructed of materials which cannot be sterilized. d. requires a mean pore diameter greater than 0.5

m. e. is generally used with a filter aid such as diatomaceous earth.

Corresponds to task #56.

27. A rapidly growing aerobic culture requires a fermentor which has: a. large impellers. b. a powerful motor. c. high oxygen transfer. d. baffles.

Corresponds to task #57.

28. The deionized water system in your laboratory indicated low resistivity. The MOST likely cause is: a. a fouled ultrafiltration cartridge. b. an incorrect bypass valve pressure. c. a high particulate level in the feedwater. d. the ion-exchange cartridges are exhausted. e. the activated carbon cartridge requires a recharge.

Corresponds to task #62.

20

29. According to current Good Manufacturing Practices, deviations from established hold time limits may be acceptable, provided that: a. the bulk of the bioburden does not exceed established limits. b. the bioburden of the bulk solution does not exceed 10 7 CFU per cm 2 of the effective filter area. c. the established holding time has been properly validated. d. the deviation does not compromise the quality of the product and is documented and justified. e. Quality Assurance and Manufacturing has been notified and approves of the deviation.

Corresponds to task #64.

30. Staff organization, methods validation, and handling of documentation in a pharmaceutical manufacturing microbiology quality control laboratory are regulated by: a. the FDA 483 findings. b. Good Laboratory Practices. c. the Establishment Inspection Report. d. current Good Manufacturing Practices. e. ISO 9000.

Corresponds to task #64.

A

NSWERS

1. a

2. b

3. d

4. d

5. e

6. e

7. d

8. c

9. c

10. b

11. c

12. c

13. a

14. a

15. a

16. a

17. c

18. b

19. d

20. d

21. b

22. b

23. c

24. c

25. c

26. a

27. c

28. d

29. d

30. d

R ESOURCES

General Tasks

Clesceri, L. S., A. E. Greenberg, and A. D. Eaton (ed.).

Part 9000,

Microbiological examination: 9010-9060, 9212, 9215, 9221-9222,

9260. In Standard methods for the examination of water and wastewater, 20 th ed. American Public Health Association (APHA),

American Water Works Association, and Water Environment

Federation, Washington, D.C.

Cunniff, P. A., et al. (ed.).

2000. Microbiological methods. In Official methods of analysis, 17 th ed. AOAC International, Gaithersburg, Md.

Difco Manual. Difco Laboratories, Inc., and Becton Dickinson and

Co., Sparks, Md.

Environmental Protection Agency (EPA). 2001. Summary of requirements. In Managing your hazardous waste: a guide for small businesses. EPA530-K-01-005. Environmental Protection Agency,

Washington, D.C.

Laboratory safety: principles and practices. Chapters 1, 2, 19, and 22. ASM Press, Washington, D.C.

Murray, P. R., E. J. Baron, M. A. Pfaller, F. C. Tenover, and R. H.

Yolken (ed.).

1999. Chapters: Microscopy, Quality control of media, and Culture media. In Manual of clinical microbiology, 7 th ed. ASM

Press, Washington, D.C.

U.S. Food and Drug Administration. Good laboratory practice for nonclinical laboratory studies. Title 21, Code of Federal Regulations, section 58 (21 CFR 58). U.S. Government Printing Office,

Washington, D.C. www.gpoaccess.gov/cfr/index/htm .

U.S. Food and Drug Administration. Guidance for industry; electronic records; electronic signatures. 21 CFR 11. U.S.

Government Printing Office, Washington, D.C.

21

Pharmaceutical/Medical Device/Cosmetic Tasks

AOAC International.

2001. Accreditation criteria for laboratories performing microbiological and chemical analyses in food, feeds, and pharmaceutical testing. AOAC International, Gaithersburg, Md.

Association for Advancement of Medical Instrumentation

(AAMI). Selected titles, especially on sterilization. Association for

Advancement of Medical Instrumentation, Arlington, Va.

Association for Advancement of Medical Instrumentation. 2000.

Sterilization of health care products; requirements for validation and routine control; industrial moist heat sterilization. ANSI/AAMI/ISO

11134:1993. Association for Advancement of Medical

Instrumentation, Arlington, Va.

Cosmetic, Toiletry, and Fragrance Association (CTFA). CTFA microbiology guidelines. Cosmetic, Toiletry, and Fragrance

Association, Washington, D.C.

Olsen, W. P., and M. J. Groves (ed.).

1987. CIP/SIP system validation. In Aseptic pharmaceutical manufacturing. Interpharm

Press, Prairie View, Ill.

Parenteral Drug Association.

1978. Validation of steam sterilization cycles. Technical report 1. Parenteral Drug Association, Bethesda,

Md.

Pearson, F. 1985. Pyrogens, endotoxins, LAL testing, and depyrogenation. Marcel Dekker, New York, N.Y.

United States Pharmacopeial Convention. Chapters 51, 61, 71,

85, 1035, 1111, 1116, 1208, 1211, 1227, and 1231. In United States

Pharmacopeia and National Formulary. United States

Pharmacopeial Convention, Rockville, Md.

U.S. Food and Drug Administration. Current good manufacturing practice for finished pharmaceuticals.

21 CFR 211. U.S. Government

Printing Office, Washington, D.C.

U.S. Food and Drug Administration. Quality system regulation.

21

CFR 820. U.S. Government Printing Office, Washington, D.C.

U.S. Food and Drug Administration. 1995. Microbiological methods for cosmetics. In Bacteriological analytical manual (BAM),

8 th ed. AOAC International, Arlington, Va.

Internet

USP.

AAMI. http://www.usp.org. http://www.cssinfo.com/info/aami.html.

AOAC International. http://www.aoac.org.

APHA. http://www.apha.org.

CFR.

FDA-BAM. http://www.access.gpo.gov/nara/cfr. http://www.cfsan.fda.gov/~ebam/bam-toc.html.

A

BOUT THE

R

ESOURCE

L

ISTS

The resources listed are NOT meant to be comprehensive guides to the examination. They are merely suggested references for review.

22

Biological Safety Task List

DISINFECTION, DECONTAMINATION,

STERILIZATION (7 questions)

1. Understand the difference between sterilization, decontamination, and disinfection and the applicability and means of monitoring each.

2. Demonstrate knowledge of use, applicability, and potential hazards (explosive, flammable, corrosive, carcinogenic, and irritating) associated with various disinfectants and sterilants.

3. Understand how to use chemicals, steam, dry heat, irradiation, filtration, ultraviolet (UV) sources, gases, or other agents to kill or inactivate microorganisms.

WORK PRACTICES AND PROCEDURES (25 questions)

4. Understand the application of sterile (aseptic) techniques.

5. Develop, evaluate, and document exposure control procedures for biohazardous agents and materials.

6. Develop procedures and practices to prevent release of infectious aerosols from equipment.

7. Perform biosafety audit of work practices and procedures associated with large-scale operations.

8. Understand and apply monitoring techniques and equipment to determine effectiveness of exposure control measures and to investigate environmental problems.

9. Understand use and disposal of sharps.

10. Select and understand use of personal protective equipment.

11. Select and understand use of respiratory equipment.

12. Develop and implement procedures for managing biohazardous spills and releases.

13. Assure documentation of worker exposure to biohazardous materials and preparation of an incident report.

14. Develop comprehensive emergency response plan for biohazard areas.

RISK ASSESSMENT AND HAZARD IDENTIFICATION

— INFECTIOUS AGENTS AND RECOMBINANT

DNA (33 questions)

15. Demonstrate knowledge of personal risk factors associated with microbial exposure.

16. Assess the risk of occupational exposure and infection associated with handling infectious agents.

17. Demonstrate familiarity with routes of exposure, modes of transmission, and other criteria that determine the hazard category of a microorganism.

18. Assess the risk to the community from various work environments where infectious agents or sensitizing materials may be present.

19. Demonstrate understanding of microbial toxins and their potential to cause work-related illness.

20. Demonstrate the ability to recognize the characteristics of bacteria, viruses, fungi, and parasites.

21. Understand the hazard of exposure of service personnel to biological materials.

22. Understand factors that may affect susceptibility, resistance, or consequences of infection.

23. Understand the difference between risk of infection and consequences of infection.

24. Understand the risk associated with biological aerosols in the workplace, such as ventilation, indoor air quality, recirculation, and cooling towers.

25. Understand the risk associated with point source release of biological aerosols in the workplace, such as from homogenizers, cell sorters, centrifuges, fermenters, and lasers.

26. Understand the risks associated with recombinant DNA technology.

27. Demonstrate knowledge of unique biosafety conditions associated with naturally or experimentally infected animals, including nonhuman primates.

23

REGULATORY ASPECTS, STANDARDS, AND

GUIDELINES (32 questions)

28. Interpret and apply the NIH Guidelines for Research Involving

Recombinant DNA Molecules .

29. Interpret and apply OSHA Bloodborne Pathogens Standard.

30. Interpret and apply guidelines that classify biohazardous agents according to risk.

31. Interpret and apply guidelines for preventing transmission of

Mycobacterium tuberculosis in the workplace.

32. Interpret and apply regulations for packing, labeling, and shipping of infectious materials, diagnostic specimens, and medical waste.

33. Interpret and apply import and export requirements associated with biological materials.

34. Interpret and apply regulations associated with animal pathogens.

35. Interpret and apply guidelines associated with the large-scale use of microorganisms.

36. Interpret and apply the NSF International Standard/ American

National Standard on Class II laminar flow biohazard cabinetry

(NSF/ANSI 49).

37. Interpret and apply OSHA law, standards, and directives as they relate to biohazards.

38. Interpret and apply guidelines and regulations relating to infectious and medical waste.

39. Demonstrate familiarity with agencies, such as WHO, CDC, NIH,

OSHA, AAALAC, DOT, IATA, ICAO, DOD, EPA, USDA, and

FDA, and their role and relationship with biosafety.

40. Interpret and apply the CDC-NIH Biosafety in Microbiological and

Biomedical Laboratories document and other pertinent CDC publications.

41. Interpret and apply select agent regulations.

PROGRAM MANAGEMENT AND DEVELOPMENT (22 questions)

42. Understand the role and function of an institutional biosafety committee.

43. Prepare and maintain a biosafety manual.

44. Review project proposals and advise on biosafety issues.

24

45. Advise on occupational health programs for persons working with biological materials.

46. Provide and interpret biosafety resource and reference information.

47. Organize and implement institutional biosafety compliance programs and audit their effectiveness.

48. Institute, evaluate, and document biosafety training.

49. Identify biological agents and materials in your institution.

50. Develop and implement an infectious and medical waste management program.

51. Provide technical information and advice on products impacting biological safety.

52. Develop and recommend biosafety policies.

EQUIPMENT OPERATION AND CERTIFICATION (23 questions)

53. Understand the use and validation of a steam autoclave.

54. Understand the use and certification of biological safety cabinets

(BSCs).

55. Demonstrate knowledge of Class I, II, and III BSC design features, applications, and functions.

56. Understand the calibration and use of air-measuring instruments to verify the safe operation of biological safety equipment.

57. Understand the design, function, and efficiency of HEPA filters.

58. Understand the limitations in the use of equipment, such as fume hoods and clean benches, for work with biohazardous materials.

59. Understand the use and validation of sterilizers using ethylene oxide (ETO) and vaporized hydrogen peroxide.

60. Understand the equipment and chemicals used for space decontamination.

61. Understand the use and applicability of animal containment equipment.

FACILITY DESIGN (8 questions)

62. Understand the functions and indications for use of primary and secondary barriers.

63. Understand the difference and appropriateness of facility design to balance the need for hazard containment, personal product, and environmental protection.

64. Review architectural and engineering plans and advise on biosafety issues.

65. Verify that facilities as built meet minimum biosafety design criteria.

Biosafety Sample Questions

The sample questions included in this examination guide are actual questions from previous examinations. They have been removed from the question pool. Do not judge the content as indicative of content in current questions, but use these sample questions as templates for the format and design of questions and answers.

1. Which of the following definitions best describes disinfection? a. The use of antimicrobial agents on inanimate objects to destroy all non-spore-forming organisms that could pose a hazard to humans or compromise the integrity of an experiment b. Processing clean items to kill all living agents c. Application of a liquid antimicrobial chemical to living tissue to prevent infection d. Heat treatment of a liquid for the destruction of non-sporeforming organisms

Corresponds to Task #1.

2. Which one of the following disinfectants may spontaneously explode if it is stored too long in a stoppered container? a. Peracetic acid b. Beta-propiolactone c. Formaldehyde d. Sodium hypochlorite

Corresponds to Task #2.

3. The major advantage of steam sterilization over dry heat sterilization is that steam sterilization: a. can be used for the sterilization of anhydrous materials. b. kills a greater spectrum of organisms. c. is not as destructive to materials. d. sterilizes in less time.

Corresponds to Task #3.

4. Which one of the following practices would fail to provide personnel protection during the use of a biological safety cabinet? a. Locating aerosol-producing equipment at the rear of the cabinet. b. Moving all materials away from the front cabinet grille. c. Moving bulky items to one side of the cabinet. d. Performing manipulations so that work flows across the work surface from the contaminated area to the clean area.

Corresponds to Task #4.

5. Which one of the following practices best prevents worker exposure to infectious aerosols? a. Balancing the safety cups prior to placing them in the centrifuge b. Opening the centrifuge safety cups only in the biological safety cabinet c. Using a splash shield to open rubber-stoppered tubes d. Wearing a surgical mask while performing work

Corresponds to Task #5.

6. A team from a large pharmaceutical firm plans to do an audit of a production facility in which attenuated viral hepatitis A is grown in a bioreactor. Before the team can enter the work area they would each have to be: a. trained in the use of the appropriate personal protective equipment. b. evaluated for immunocompetency. c. immunized with hepatitis A vaccine, for product and personal protection. d. protected from infection with an injection of human gamma globulin.

Corresponds to Task #7.

25

7. Which of the following sampling methods is the most appropriate for determining microbial contaminants on surfaces? a. Sieve sampler b. Settling plate c. RODAC plate d. Slit-to-agar sampler

Corresponds to Task #8.

8. Which one of the following fungi is most likely to cause a laboratory-acquired infection if handled improperly? a. Aspergillus fumigatus b. Candida albicans c. Sporothrix schenckii d. Coccidioides immitis

Corresponds to Task #16.

9. The respiratory ID

50

(number of organisms required to produce infection in half of individuals exposed) for Mycobacterium tuberculosis is on the order of: a. fewer than 10. b. 100. c. 1,000. d. 10,000.

Corresponds to Task #17.

10. Exposure to Legionella pneumophila has been associated with: a. pet shops. b. gold mines. c. cooling towers. d. laundries.

Corresponds to Task #24.

11. In a rabies-free colony of laboratory dogs and cats, the most likely cause of bite-wound infection is: a. Staphylococcus aureus. b.

Bartonella henselae. c.

Pasteurella multocida. d. Mycoplasma spp.

Corresponds to Task #28.

12. The Occupational Safety and Health Administration (OSHA) requires an exposure control plan for: a. any site using biohazardous materials. b. any site using human blood or body fluids. c. any site that has research animals. d. any site that has had a spill of biohazardous materials.

Corresponds to Task #29.

13. The principal independent standard that is used for the design, manufacture, and testing of biological safety cabinets is: a. Federal Standard No. 209B. b. Centers for Disease Control and Prevention/National

Institutes of Health (CDC/NIH), Primary Containment for

Biohazards: Selection, Installation and Use of Biological

Safety Cabinets guidelines. c. National Institutes of Health (NIH) 112C. d. NSF International Standard/American National Standard

(NSF/ANSI) 49

Corresponds to Task #36.

26

14. Which one of the following combinations of containment methods best describes Biosafety Level 3? a. All work conducted in a Class II biosafety cabinet or other physical containment device, directional airflow from the corridor into the laboratory, and double-door access to the laboratory. b. Laboratory located in separate zone or building, work conducted in a Class III biological safety cabinet, and all materials decontaminated before leaving the laboratory c. Negative-pressure air environment, limited access, and hand-washing capability d. Hand-washing sink, limited laboratory access, and cultures decontaminated before disposal

Corresponds to Task #40.

15. Which one of the following agents or toxins requires registration with U.S. Department of Agriculture, Animal and Plant Health

Inspection Service (USDA, APHIS) under the Agriculture

Bioterrorism Protection Act (Title 9 CFR Part 121)? a. 5.0 mg staphylococcal enterotoxin b. A genetic element that can be expressed in vivo containing the gene encoding the Bacillus anthracis lethal factor toxin. c. 500 mg Shiga toxin d. 5 liters of E. coli O157:H7, which produces Shiga-like toxin

Corresponds to Task #41.

16. According to the National Institutes of Health (NIH) Guidelines for Research Involving Recombinant DNA Molecules , an

Institutional Biosafety Committee (IBC): a. shall consist of a minimum of 25 members of the institute. b. shall include at least two members with no affiliation to the institution. c. shall include members with expertise in plasmid methodology. d. shall include at least one physician on the committee.

Corresponds to Task #42.

17. The vaccine that must be offered to personnel working with human blood cells is: a. hepatitis A virus. b. hepatitis B virus. c. tetanus. d. malaria.

Corresponds to Task #45.

18. The best reason for preparing an outline of a biological safety training program is to: a. provide evidence of training for the Occupational Safety and

Health Administration (OSHA). b. distinguish biological safety training from programs dealing with radiation and chemicals. c. define biosafety levels. d. assure consistency in the content of the program each time it is delivered.

Corresponds to Task #48.

19. Steam autoclaving is appropriate for which of the following items? a. Nitrocellulose centrifuge tubes b. Instrument pans containing equipment soaking in bleach c. Polycarbonate petri dishes d. Reusable bronchoscopes

Corresponds to Task #53.

20. In a Class II, Type A2 biological safety cabinet: a. downward laminar flow splits 2-6 inches above work surface between front and rear grills. b. the minimum inward air flow is 75 linear feet per minute and the exhaust air is ducted. c. cabinets cannot be used with minute quantities of volatile toxic chemicals and tracer amounts of radionucleotides. d. HEPA-filtered air from the cabinet is not re-circulated to the room.

Corresponds to Task #54.

27

21. The face velocity (inward air flow) of Class I and Class II biological safety cabinets should be in the range of: a. 25-50 linear feet per minute. b. 75-100 linear feet per minute. c. 100-150 linear feet per minute. d. 150-200 linear feet per minute.

Corresponds to Task #55.

22. The dispensing of uninoculated primary rhesus monkey kidney tissue culture into sterile culture tubes is most appropriately conducted in a: a. Class I biological safety cabinet. b. Class II biological safety cabinet. c. vertical laminar flow clean bench. d. horizontal laminar flow clean bench.

Corresponds to Task #55.

23. Which one of the following is a primary containment device? a. Centrifuge rotor b. Plastic animal cage c. Clean air bench d. Horsfall cage

Corresponds to Task #62.

24. Which containment equipment item is best associated with

Biosafety Level 3? a. Class II biological safety cabinet b. Handwashing sink c. Horizontal laminar airflow clean bench d. Sharps containers

Corresponds to Task #62.

25. A Biosafety Level 3 facility should have which type of air pressurization? a. Neutral b. Positive c. Negative d. Atmospheric

Corresponds to Task #65.

A

NSWERS

1. a

2. a

3. d

4. d

5. b

6. a

7. c

8. d

9. a

10. c

11. c

12. b

13. d

14. a

15. c

16. b

17. b

18. d

19. c

20. a

21. b

22. b

23. d

24. a

25. c

28

R ESOURCES

Critical References

Dooley, S.W., Jr., K. G. Castro, M. D. Hutton, R. J. Mullan, J. A.

Polder, and D. E. Snider, Jr.

1990. Guidelines for preventing the transmission of tuberculosis in health-care settings, with special focus on HIV-related issues. Morb. Mortal. Wkly. Rep. 39 (RR-17):1 –

29.

Fleming, D. O., and D. L. Hunt (ed.). 2000. Biological safety: principles and practices, 3 rd ed. ASM Press, Washington, D.C.

National Institute for Occupational Safety and Health.

1999. TB respiratory protection program in health care facilities: administrator’s guide.

U.S. Department of Health and Human Services, Public

Health Service, Centers for Disease Control and Prevention.

National Institute for Occupational Safety and Health, Cincinnati,

Ohio.

National Institutes of Health. 2002. NIH guidelines for research involving recombinant DNA molecules. U.S. Department of Health and Human Services, National Institutes of Health. U.S. Department of Health and Human Services, Washington, D.C.

National Research Council. 1996.

Guide for the care and use of research animals. National Academy Press, Washington, D.C.

National Sanitation Foundation. 2003. NSF 49 class II (laminar flow) biosafety cabinetry. NSF/ANSI 49-02e. NSF International, Ann

Arbor, Mich.

Occupational Safety and Health Administration. 2003.

Bloodborne pathogens. Title 29, Code of Federal Regulations, section 1910.1030 (29 CFR 1910.1030). U.S. Government Printing

Office, Washington, D.C.

Occupational Safety and Health Administration, Office of Health

Compliance Assistance.

1996. Enforcement procedures and scheduling for occupational exposure to tuberculosis. CPL 02-00-

106. Occupational Safety and Health Administration, Washington,

D.C.

Richmond, J. Y., and R. W. McKinney (ed.).

1999. Biosafety in microbiological and biomedical laboratories, 4 th ed. U.S. Department of Health and Human Services, Centers for Disease Control and

Prevention, and National Institutes of Health. U.S. Government

Printing Office, Washington, D.C.

Richmond, J. Y., and R. W. McKinney (ed.). 2000. Primary containment for biohazards: selection, installation and use of biological safety cabinets, 2 nd ed. U.S. Department of Health and

Human Services, Centers for Disease Control and Prevention, and

National Institutes of Health. U.S. Government Printing Office,

Washington, D.C.

Helpful References

American Industrial Hygiene Organization. 1995. Biosafety reference manual, 2 nd ed. American Industrial Hygiene Organization,

Fairfax, Va.

World Health Organization. 2003. Laboratory biosafety manual, 2 nd ed., rev. World Health Organization, Geneva, Switzerland.

29

Internet

ABSA. http://www.absa.org.

CDC. http://www.cdc.gov.

OSHA. http://www.osha.gov.

Agency and organization abbreviations used in this section

AAALAC , Association for Assessment and Accreditation of

Laboratory Animal Care, International

ABSA , American Biological Safety Association

CDC , Centers for Disease Control and Prevention

DOD , Department of Defense

DOT , Department of Transportation

EPA , Environmental Protection Agency

FDA , U.S. Food and Drug Administration

IATA , International Air Transport Association

ICAO , International Civil Aviation Organization

NIH , National Institutes of Health

OSHA , U.S. Occupational Safety and Health Administration

USDA , U.S. Department of Agriculture

USPS , U. S. Postal Service

WHO , World Health Organization

A

BOUT THE

R

ESOURCE

L

ISTS

The resources listed are NOT meant to be comprehensive guides to the examination. They are merely suggested references for review.

30

ELIGIBILITY

Registered Microbiologist ([RM]NRM) --baccalaureate level.

The examinations offered at Registered Microbiologist level are

Consumer Products and Quality Assurance Specializing in Pharmaceutical/Medical Device/Cosmetics . It tests for factual knowledge, concepts, and laboratory skills needed in a consumer product microbiology testing laboratory.

Consumer Products and Quality Assurance Microbiology Specializing in Food and Dairy . It tests for factual knowledge, concepts, and laboratory skills needed in a consumer product microbiology testing laboratory.

There are two eligibility pathways

A minimum of a baccalaureate degree with 20 semester hours or 30 quarter hours of course work in microbiology AND one year of fulltime work experience (gained within the last three years) in a microbiology laboratory related to the specialty area in which you are seeking certification.

OR-

A minimum of a baccalaureate degree with 12 semester hours or 18 quarter hours of course work in microbiology AND seven years of fulltime work experience (gained within the last 10 years) in a microbiology laboratory related to the specialty area in which you are seeking certification.

Education

Appropriate academic courses must be completed and verified by submission of official transcripts; photocopies will not be accepted. If credit is claimed for a course not specifically listed below, or if microbiological content is not apparent from the course title, a copy of the course description verifying the course content claimed for microbiology credit must be included with the application. A description from the course catalog or another official source is sufficient. Relevant courses emphasize the study of microorganisms and may include the following:

Agriculture General microbiology Mycology

Animal or plant physiology

Applied bacteriology or microbiology

Bacteriology

Biotechnology

Cell biology

Cell physiology

Dairy

Diagnostic bacteriology or microbiology

Genetics

Immunology

Industrial

Infectious diseases

Medical microbiology

Metabolism

Microbial aerosols

Microbial genetics

Parasitology

Public health

Recombinant DNA

Rickettsiology

Sanitary engineering

Sanitation

Soil microbiology

Taxonomy

Disinfection, decontamination, or sterilization

Environmental

Epidemiology

Fermentation

Food microbiology

Microbial physiology

Microbial toxins

Microbiology

Microbiology safety or hazards

Molecular biology

Tissue culture

Virology

Water and waste

31

Academic credit will be given for workshop attendance. Up to four credit hours may be awarded for participation in a workshop sponsored by ASM, the Accreditation Council for Continuing Medical Education (ACCME), the American Society for Clinical Pathology (ASCP), the Accreditation

Council for Pharmacy Education (ACPE), or the International Association for Continuing Education and Training (IACET). One-half credit is awarded for each eight hours of participation. Candidates must submit a copy of attendance with the application.

Experience

The candidate must have experience relevant to the area in which certification is being sought. Relevant experience is experience in which a significant majority of the candidate's duties is in the area in which he/she is seeking certification. The reference form(s) must specifically document the functions associated with the candidate's position that relate to the area in which certification is being sought.

Paid student work experience in a microbiology laboratory may be considered as partial fulfillment of the work experience requirement.

Teaching and/or graduate study does not fulfill the experience requirement.

Partial credit may be given for the microbiology portion of a medical technology traineeship or other formal laboratory training program.

Conditional Registrant ---pre-baccalaureate level.

Candidates must meet the same educational requirements as Registered Microbiologist examinees. When the examination is passed, Conditional

Registrant status is granted. Conditional Registrants then have two years in which to complete the one-year, full-time laboratory work experience requirement.

Specialist Microbiologist ([SM]NRM) --baccalaureate, master's or doctoral level.

The examinations offered at Specialist Microbiologist level are

Consumer and Industrial Microbiology Specializing in Pharmaceutical/Medical Device/Cosmetics. It tests for ability to supervise the effective operation of biological procedures in a consumer product microbiology testing laboratory.

Biological Safety Microbiology. It tests pertinent knowledge and the ability to develop, implement, and manage a comprehensive biological safety program.

There are two eligibility pathways

Master's or doctoral degree with 30 semester hours or 45 quarter hours in microbiology AND four years of full-time, postbaccalaureate work experience within the past seven years in the appropriate examination specialty area.

-OR-

Bachelor's degree with 20 semester hours or 30 quarter hours of microbiology AND seven years of full-time, postbaccalaureate work experience within the past 10 years in the appropriate examination specialty area.

Education

Appropriate academic courses must be completed and verified by submission of official transcripts; photocopies will not be accepted. If credit is claimed for a course not specifically listed below, or if microbiological content is not apparent from the course title, a copy of the course description verifying the course content claimed for microbiology credit must be included with the application. A description from the course catalog or another official source is sufficient. Relevant courses emphasize the study of microorganisms and may include the following:

Agriculture General microbiology Mycology

Animal or plant physiology

Applied bacteriology or microbiology

Bacteriology

Biotechnology

Cell biology

Cell physiology

Dairy

Genetics

Immunology

Industrial

Infectious diseases

Medical microbiology

Metabolism

Microbial aerosols

Parasitology

Public health

Recombinant DNA

Rickettsiology

Sanitary engineering

Sanitation

Soil microbiology

Diagnostic bacteriology or microbiology

Disinfection, decontamination, or sterilization

Environmental

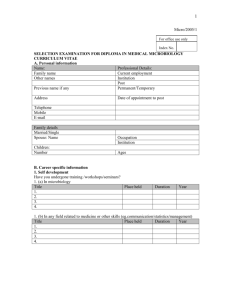

Epidemiology