Method

advertisement

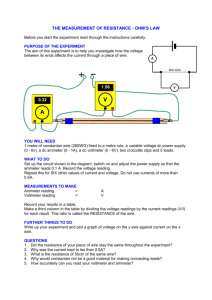

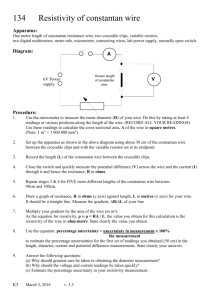

Method First of all I will get a 12V power pack and some wire. Next I will need is an ammeter and a voltmeter and a variable resistor. I will fist connect the power pack to the mains and making sure my hands are not wet, so I don't get an electric shock. Next I will connect one of the wires to the negative end of the power pack and connect the other end of the wire to a variable resistor. Afterwards I will get a second wire and connect it to the unconnected terminal of the variable resistor and add a crocodile clip to the unplug end of the second wire. This crocodile clip is to hold the wire in place and to connect it to the circuit. From the positive terminal of the power pack a wire will be connected to the terminal and also the ammeter. The fourth wire is needed to connect the unconnected terminal of the ammeter and like the second wire a crocodile clip will be added to connect the wire. Behind each end of the crocodile clipped wires they should be other wires connected to the voltmeter, making a parallel circuit. This is because in a parallel circuit the voltage is always the same in each circuit made, whereas if we connected the voltmeter in a series the voltage measured would vary depending on which side it is connected. Picture of this set up is on the diagram section. Once that is done we need to measure each wire (constantan wire) the length of 80 cm because from my preliminary experiment that was carried out 80 cm wasn't very hot and gave good readings. Below is a table with the results: Length (cm) 100 80 60 40 20 SWG 21 21 21 21 21 V/V 2 2 2 2 2 Current (amps) 0.86 2.00 2.90 3.18 6.27 Temp Cold Warm Hot Very hot Extremely hot When measuring the wire I must always keep the wire length 80-cm because the length of wire can effect the resistance and give me inaccurate results. When measuring the wire the wire must be held flat against the meter rule (We use a meter rule because it is long enough to measure 80 cm and more accurate than longer than this length) to give a fair result because if this isn't done more metal maybe measured and we won't get accurate results. The wire will then be cut to 80 cm. This 80-cm wire will be placed in between the two crocodile clip and clipped to connect it to the circuit. Turn the power on and adjust the variable resistor. We used a variable resistor for accuracy and it can measure the voltage very accurately rather than using the power pack because it isn't always accurate, making this method a fair method. The resistor will be moved left and right until the voltmeter display 1 and the voltage must be kept the same because the resistance might vary. The reading on the ammeter is the current and must be recorded three times because the result will be more accurate and because the ammeter always vary even kept at the same voltage. Wires that are tested are made out of constantan and every time a different size of wire will be used when one is finished recording. The size used will be 21, 24, 28, 30, 34, 36, 40, 42 and 44 SWG and all will be measured to 80 cm. After testing the current of each wire, each wire's diameter will be measured in order to work out each cross sectional area. This will be done using a micrometer. A wire say 21 SWG is placed in the gap of the micrometer and turns the ratchet clamping the wire until no more can be turned. The point that lines up with the dash is read off at eye level because it is more accurate than not eye level because a different size could be measured than the real one. I will measure each size of wire 5 times because in the case where different parts of the wire might be smaller than other parts, so when measuring 5 times I will measure each time in a different part of a wire, to get a average and very accurate results. Another safety precaution is that the wires maybe hot after testing so I will watch that I do not burn myself.