Turnout Percentages - Factors Involved

advertisement

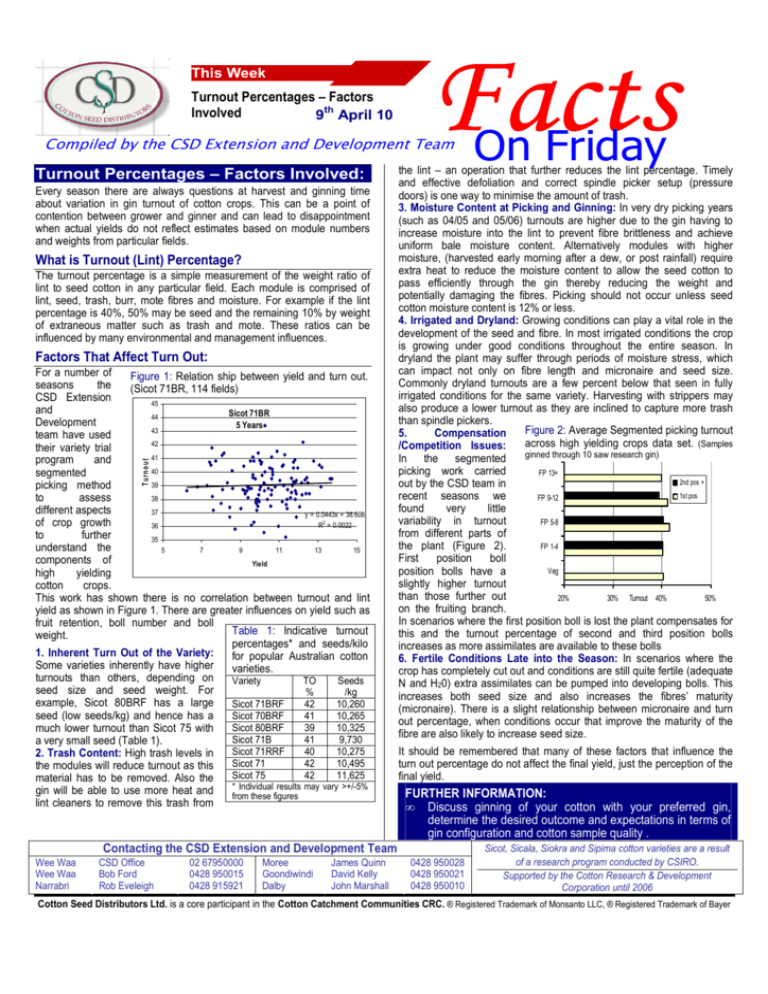

This Week Turnout Percentages – Factors Involved 9th April 10 Facts Compiled by the CSD Extension and Development Team Turnout Percentages – Factors Involved: Every season there are always questions at harvest and ginning time about variation in gin turnout of cotton crops. This can be a point of contention between grower and ginner and can lead to disappointment when actual yields do not reflect estimates based on module numbers and weights from particular fields. What is Turnout (Lint) Percentage? The turnout percentage is a simple measurement of the weight ratio of lint to seed cotton in any particular field. Each module is comprised of lint, seed, trash, burr, mote fibres and moisture. For example if the lint percentage is 40%, 50% may be seed and the remaining 10% by weight of extraneous matter such as trash and mote. These ratios can be influenced by many environmental and management influences. Factors That Affect Turn Out: T u rn o u t For a number of Figure 1: Relation ship between yield and turn out. seasons the (Sicot 71BR, 114 fields) CSD Extension 45 and Sicot 71BR 44 Development 5 Years 43 team have used 42 their variety trial 41 program and 40 segmented 39 picking method to assess 38 different aspects 37 y = 0.0443x + 38.608 of crop growth R2 = 0.0022 36 to further 35 understand the 5 7 9 11 13 15 components of Yield high yielding cotton crops. This work has shown there is no correlation between turnout and lint yield as shown in Figure 1. There are greater influences on yield such as fruit retention, boll number and boll Table 1: Indicative turnout weight. percentages* and seeds/kilo 1. Inherent Turn Out of the Variety: for popular Australian cotton Some varieties inherently have higher varieties. turnouts than others, depending on Variety TO Seeds seed size and seed weight. For % /kg example, Sicot 80BRF has a large Sicot 71BRF 42 10,260 seed (low seeds/kg) and hence has a Sicot 70BRF 41 10,265 39 10,325 much lower turnout than Sicot 75 with Sicot 80BRF Sicot 71B 41 9,730 a very small seed (Table 1). 40 10,275 2. Trash Content: High trash levels in Sicot 71RRF 42 10,495 the modules will reduce turnout as this Sicot 71 42 11,625 material has to be removed. Also the Sicot 75 Individual results may vary >+/-5% gin will be able to use more heat and *from these figures lint cleaners to remove this trash from It should be remembered that many of these factors that influence the turn out percentage do not affect the final yield, just the perception of the final yield. FURTHER INFORMATION: • Discuss ginning of your cotton with your preferred gin, determine the desired outcome and expectations in terms of gin configuration and cotton sample quality . Contacting the CSD Extension and Development Team Wee Waa Wee Waa Narrabri CSD Office Bob Ford Rob Eveleigh 02 67950000 0428 950015 0428 915921 Moree Goondiwindi Dalby James Quinn David Kelly John Marshall On Friday the lint – an operation that further reduces the lint percentage. Timely and effective defoliation and correct spindle picker setup (pressure doors) is one way to minimise the amount of trash. 3. Moisture Content at Picking and Ginning: In very dry picking years (such as 04/05 and 05/06) turnouts are higher due to the gin having to increase moisture into the lint to prevent fibre brittleness and achieve uniform bale moisture content. Alternatively modules with higher moisture, (harvested early morning after a dew, or post rainfall) require extra heat to reduce the moisture content to allow the seed cotton to pass efficiently through the gin thereby reducing the weight and potentially damaging the fibres. Picking should not occur unless seed cotton moisture content is 12% or less. 4. Irrigated and Dryland: Growing conditions can play a vital role in the development of the seed and fibre. In most irrigated conditions the crop is growing under good conditions throughout the entire season. In dryland the plant may suffer through periods of moisture stress, which can impact not only on fibre length and micronaire and seed size. Commonly dryland turnouts are a few percent below that seen in fully irrigated conditions for the same variety. Harvesting with strippers may also produce a lower turnout as they are inclined to capture more trash than spindle pickers. Figure 2: Average Segmented picking turnout 5. Compensation across high yielding crops data set. (Samples /Competition Issues: ginned through 10 saw research gin) In the segmented picking work carried FP 13+ 2nd pos + out by the CSD team in 1st pos recent seasons we FP 9-12 found very little variability in turnout FP 5-8 from different parts of FP 1-4 the plant (Figure 2). First position boll Veg position bolls have a slightly higher turnout than those further out 20% 30% Turnout 40% 50% on the fruiting branch. In scenarios where the first position boll is lost the plant compensates for this and the turnout percentage of second and third position bolls increases as more assimilates are available to these bolls 6. Fertile Conditions Late into the Season: In scenarios where the crop has completely cut out and conditions are still quite fertile (adequate N and H20) extra assimilates can be pumped into developing bolls. This increases both seed size and also increases the fibres’ maturity (micronaire). There is a slight relationship between micronaire and turn out percentage, when conditions occur that improve the maturity of the fibre are also likely to increase seed size. 0428 950028 0428 950021 0428 950010 Sicot, Sicala, Siokra and Sipima cotton varieties are a result of a research program conducted by CSIRO. Supported by the Cotton Research & Development Corporation until 2006 Cotton Seed Distributors Ltd. is a core participant in the Cotton Catchment Communities CRC. ® Registered Trademark of Monsanto LLC, ® Registered Trademark of Bayer