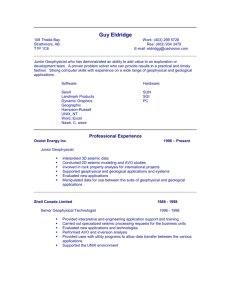

Seismic Operations

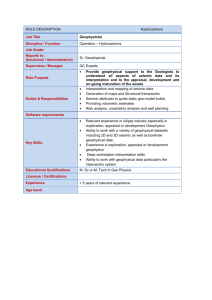

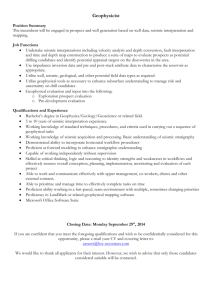

advertisement