Appendix A

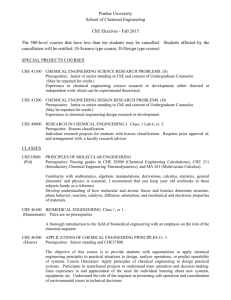

advertisement