Requirements for Catering from Mobile Units and Market Stalls

advertisement

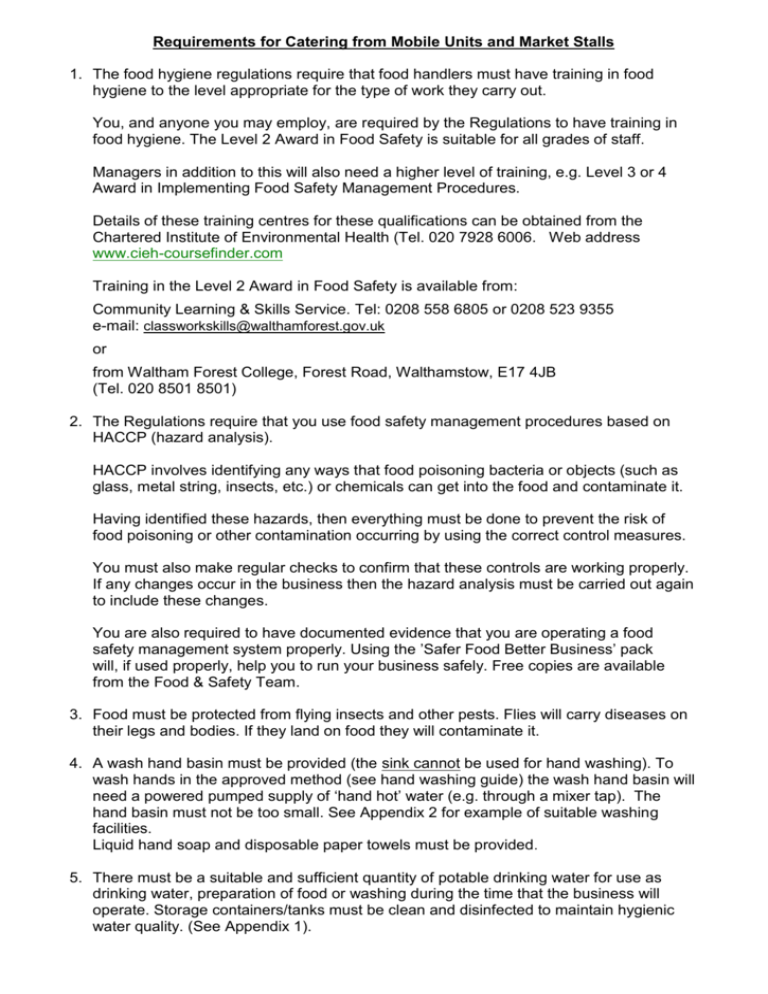

Requirements for Catering from Mobile Units and Market Stalls 1. The food hygiene regulations require that food handlers must have training in food hygiene to the level appropriate for the type of work they carry out. You, and anyone you may employ, are required by the Regulations to have training in food hygiene. The Level 2 Award in Food Safety is suitable for all grades of staff. Managers in addition to this will also need a higher level of training, e.g. Level 3 or 4 Award in Implementing Food Safety Management Procedures. Details of these training centres for these qualifications can be obtained from the Chartered Institute of Environmental Health (Tel. 020 7928 6006. Web address www.cieh-coursefinder.com Training in the Level 2 Award in Food Safety is available from: Community Learning & Skills Service. Tel: 0208 558 6805 or 0208 523 9355 e-mail: classworkskills@walthamforest.gov.uk or from Waltham Forest College, Forest Road, Walthamstow, E17 4JB (Tel. 020 8501 8501) 2. The Regulations require that you use food safety management procedures based on HACCP (hazard analysis). HACCP involves identifying any ways that food poisoning bacteria or objects (such as glass, metal string, insects, etc.) or chemicals can get into the food and contaminate it. Having identified these hazards, then everything must be done to prevent the risk of food poisoning or other contamination occurring by using the correct control measures. You must also make regular checks to confirm that these controls are working properly. If any changes occur in the business then the hazard analysis must be carried out again to include these changes. You are also required to have documented evidence that you are operating a food safety management system properly. Using the ’Safer Food Better Business’ pack will, if used properly, help you to run your business safely. Free copies are available from the Food & Safety Team. 3. Food must be protected from flying insects and other pests. Flies will carry diseases on their legs and bodies. If they land on food they will contaminate it. 4. A wash hand basin must be provided (the sink cannot be used for hand washing). To wash hands in the approved method (see hand washing guide) the wash hand basin will need a powered pumped supply of ‘hand hot’ water (e.g. through a mixer tap). The hand basin must not be too small. See Appendix 2 for example of suitable washing facilities. Liquid hand soap and disposable paper towels must be provided. 5. There must be a suitable and sufficient quantity of potable drinking water for use as drinking water, preparation of food or washing during the time that the business will operate. Storage containers/tanks must be clean and disinfected to maintain hygienic water quality. (See Appendix 1). 6. A sink (for washing equipment or food) with a supply of hot and cold water must be provided. The size must be adequate for your particular needs. 7. The work surfaces and shelves should be of a plastic laminate type or stainless steel. Avoid wooden surfaces, e.g., supporting frames of the worktops, shelving. If there is wood it should be gloss painted. 8. Preventing bacterial growth is essential to food safety. Refrigeration must be provided for storage of perishable foods. Please ensure you have sufficient capacity for your needs. 9. All cooking utensils should be plastic or stainless steel. (Avoid equipment with wooden handles). 10. Clean, washable protective clothing i.e., do not work in every day street clothes; suitable protective clothing for caterers is required to be worn by all persons working with food. 11. Adequate facilities must be provided for the storage of refuse. 12. For mobile units (not stalls): the floor must have a washable covering. Cardboard sheets must not be placed on the floor, as they create a tripping hazard and are not capable of being cleaned. The walls must have an easily washable surface. 13. Information on the proper storage of LPG cylinders is enclosed. 14. The public must be protected from injury from generators, electrical equipment, gas cylinders, BBQ’s. 15. The Health and Safety (First-Aid) Regulations 1981 requires that a first-aid box with suitable and sufficient contents be provided, i.e. The first aid box should be an easily identifiable waterproof box 20 waterproof plasters 6 triangular bandages 6 medium sterile dressings 6 safety pins 2 large sterile dressings 2 extra-large sterile dressings 2 sterile eye pads disposable gloves 16. Food must not be prepared at home unless you have registered your home with the Environmental Health Service and your kitchen meets the requirements of the Hygiene Regulations and has been inspected. 17. You must register with the Food Safety Section of the area where your mobile catering unit is to be stored overnight. The registration form is obtainable from the offices of that particular local authority. Once you have registered you may operate in any other area. 18. If the catering unit is to be kept outside your home on the road then a licence must be obtained from the Street services department (Tel: 020 8496 3000). Mobile Catering Units- Use of Butane / Propane Gas Cylinders 1. Cylinder Compartment for Storage of Gas Cylinders The butane / propane gas cylinders (whether full or empty) must not be placed in an enclosed work area, either when the unit is operating or during transit. Cylinders must not be stored or used in a horizontal position. The compartment must be large enough to carry both the cylinder in the cylinder in use, and any spare cylinder. The compartment must be both gas-tight (all joints must be sealed with mastic), and half-hour fire resisting. Access to the compartment must only be from the outside. Any pipe passing through the wall of the compartment must be protected by a rubber grommet to prevent wear on the pipe. This area must also be gas tight. The compartment must have adequate ventilation to the outside. This can be provided by having two ventilators (minimum size 3”x 2” fixed at the top and the bottom of the external wall, or door, of the compartment. An alternative is to provide a door, which is fully ventilated and is protected by a metal grill The door to the compartment must be lockable. 2. Regulators The regulator, if not attached to the gas cylinder, must be positioned outside the unit or within the cylinder compartment. It must also be easily accessible. Hose and tubing must be properly and securely attached to the regulator e.g., by a hose-clip or crimping. 3. Flexible Rubber Tubing and Hose All tubing and hose that carries LPG must me made to British Standard 3212 (this is stamped onto the hose and tubing as BS 3212). Hose carrying gas from the cylinder to the regulator must be high pressure; this is orange in colour and is stamped BS 3212/2. Tubing carrying gas from the regulator to the distribution pipework must be low-pressure tubing; this is black in colour and is stamped BS 3212/1. Hoses and tubing must be properly and securely attached to the regulator e.g., by a hose-clip or crimping. 4. Distribution Pipework This is the pipework that carries the gas inside the unit and should be of an approved material, e.g., copper piping used with copper alloy fittings. A CORGI registered gas engineer must only fit the gas installation. When installing pipework care must be taken to ensure that: the pipes are adequately supported (at intervals not exceeding 19 inches for copper piping). the pipes are protected against mechanical damage (avoid passing through walls or bulkheads unless protected by a rubber grommet). the pipes are easily accessible (to check for leaks/damage) the number of pipe connections is kept to a minimum and sharp changes in direction are avoided. the correct jointing materials are used on any pipe connections. the bore of the pipe is not restricted by bending or cutting. 5. Fixed Ventilation to the Work Area In addition to any ventilation that can be provided by an open door, serving hatch or roof-lights, fixed ventilation must be provided which is permanently open. The ventilation should consist of a non-adjustable ventilator with a minimum open area of 6 square inches. The ventilator should be positioned at a high and low level and should not be obstructed by the storage of materials within the unit. 6. Fire Precautions Fire Extinguisher A 2kg or 3kg dry powder fire extinguisher is required. This should be placed by the entrance/exit to the work area and mounted on brackets so that the handle is 3.5 feet to 4.5 feet from the floor. The fire extinguisher must be accessible at all times. It should not be placed in concealed positions, e.g., cupboards or deep recesses. A competent person should inspect the cylinder at least once a year to check that the extinguisher’s contents have not deteriorated and that the cylinder operates properly. Fire blanket Where frying is carried out then a non-asbestos fire blanket should be provided and located close to the appliance in an easily accessible position. Use this guide on LPG as a checklist to make your own checks on your unit Appendix 1 CLEANING PROCEDURE FOR WATER CONTAINERS IMPORTANT NOTE: The water that you use in your mobile food business MUST be of the same standard as laid down in the Drinking Water Standards. You must make sure that the containers used in your business are clean enough to help you to meet this requirement. This will require very regular and thorough cleaning and disinfecting of the containers. An instruction on effective cleaning of water containers is given below. For portable containers, empty the container completely. Use only mains water from the mains tap. Clean the tap thoroughly before use. Clean the outside of the container and the whole of the lid or cap to remove any dirt, grease, dust or other possible contaminant. Use hot water with an appropriate detergent for cleaning. Rinse thoroughly and empty the container after cleaning. Completely fill the container with water containing a sterilising solution and stand for the recommended contact time e.g. bleach at 1 in 100 dilution for 30 minutes. Turn the container upside down to clean the inside of the handle. Empty the solution from the container. The empty container should be turned upside down whilst stored overnight ensuring that the lip of the opening is not in contact with any surface. Fill straight from mains tap with water. Never use a hosepipe, tap-nozzle or adapter. These fittings can be very dirty inside. The above procedure must be strictly adhered to when cleaning water containers. Appendix 2 An example of basins for mobile caterers Teal portable hand washing. Tel: 0121 770 0593 www.tealwash.com/shop Requires an electical supply Does not require an electrical supply. Requires to be filled with ‘Hand hot water’ and is insulated to keep water hot ------------------------------------------------------------------------------------------------------- Burco Handwash Requires an electrical supply ------------------------------------------------------------------------------------------------------Mobile Sink Company Tel: 0121 747 1179 www.mobilesink.com Requires an electrical supply Hygiene Checklist The following points those that are looked for when hygiene inspections are carried out to determine if a business has safe management systems in place to ensure the safety of food and drink. Are all food handlers trained in food hygiene so they understand what high-risk food is, what types of food hazards can occur and how to reduce the risk/prevent food poisoning? Can the person present at the business explain what are the critical points for food safety for that business, how are the food safety hazards controlled and what monitoring (checks) is carried out to make sure the controls are working? Are the controls and monitoring of the critical points actually being carried out? Is there sufficient hot water to last for the whole period that the business operates? Is there sufficient potable drinking water to last for the whole period that the business operates? Are the containers used for storing water cleaned and disinfected as per information sheet? Is there sufficient refrigerated storage? Is the refrigerated storage operating at the correct temperature throughout the working period? If hot holding food, is the equipment operating at the correct temperature throughout the working period? Are all parts of the business clean? Are all parts of the business well maintained and in good condition? Is there sufficient equipment to prepare food and is it clean and in good condition? Are there adequate supplies of detergent and sanitisers (antibacterial cleaners)? Are separate sinks and wash hand bains provided? Are adequate materials for cleaning hands (e.g. liquid hand soap) and for drying hands (e.g. disposable paper towels)? Is suitable over clothing worn that covers the arms and chest, e.g. chef’s jacket? Is the over clothing clean? Is suitable head covering worn? Does the first aid kit have a full complement of the required contents? Requirements to Ensure Personal Hygiene Hand Washing Correct hand washing is one of the main ways of preventing cross contamination in food businesses. Rinsing hands in clean water is equally important as washing with soap and water to remove bacteria from your hands. The wash hand basin will require a powered pumped supply of ‘hand hot’ water or hot and cold water supply so that you can meet the requirements for hygienically washing hands (see guide). Water from a mixer tap that provides ‘hand hot’ water is preferable to separate hot and cold supplies. Facilities where a bowl has to be filled with hot water (e.g. from an urn) and then cold water added to obtain the right temperature to place hands in it, then emptied and refilled so that the hands can be rinsed with clean water is not an acceptable method for hand washing in a catering business. Adequate supplies of liquid hand soap must always be provided at each wash-hand basin. A suitable means of drying hands is also required at each wash-hand basin. Cotton towels for drying hands are not recommended because they quickly build up bacteria that can be transferred to each person who uses the towels. It is recommended that disposable paper towels from a dispenser be used (kitchen roll is not suitable for this). A wash hand basin must be provided for each food preparation area. Hands must only be washed in the wash hand basin; the sink(s) used for washing food or utensils must not be used. Separate sinks should be provided for the washing of food and equipment. Please read the accompanying guide to hand washing. Washing hands properly is essential to preventing cross contamination of food from bacteria present on your hands. It is the manager’s duty to make sure that everyone in the food business knows how to wash their hands properly and why it is necessary to do it in this way. It is also the manager’s duty to have adequate supervision to make sure everyone washes their hands by the proper method and at the correct time. All too often hand washing is rushed and not enough time and care is spent on doing this properly. There are 6 easy steps to washing hands properly. Over Clothing The purpose of over clothing is to protect the food from dust, dirt, fibres, hair, etc that will be found on everyday ‘street’ clothes Proper over clothing needs to be clothing that the person wears, or changes into, when they arrive at work, e.g. a ‘chef’s jacket, a T-shirt and apron. Wearing only an apron over your everyday ‘street’ clothes is not acceptable. A clean set of over clothing must be worn each day and if it becomes dirty or badly stained during the working period then it must be changed. This means that there has to be a sufficient number of clean sets of over clothing available at the business at all times. Workplace Safety All businesses are required to control health and safety risks. This includes making a risk assessment of all hazards that could cause injury or ill health to anyone working in the business or any other person who enters the premises. Where there are 5 or more employees (in the company as a whole, not just in a particular workplace) then the risk assessment must be documented. All staff must be informed of the findings of the risk assessment. Health and safety information can be obtained from: General health and safety: http://www.hse.gov.uk http://www.hse.gov.uk/workplacehealth/index.htm http://www.hse.gov.uk/smallbusinesses http://www.hse.gov.uk/catering Fire safety: http://www.fire.gov.uk/Workplace+safety http://www.communities.gov.uk/index.asp and the Health and Safety Adviceline (0845 609 6006) Other Organisations to Contact If you want to trade in a market run by a local authority you will need to obtain a licence from the market inspectors for that Council. For Waltham Forest, telephone 020 8496 3000 and ask for the Market Inspectors. If you wish to trade from a forecourt of an existing business, or on the highway or close to it you must obtain a licence from the Street Services (Tel: 020 8496 3000). If you want to trade within an industrial estate you will need to obtain the permission (in writing) from the managing agents for that estate. If you want to trade at special events, e.g. car boot sales, craft fairs, farmers markets etc. you will need the permission of the organiser. You will need to check with your insurance company which appropriate insurance(s) you require for your business, e.g. public liability insurance; employers liability insurance; road traffic insurance. The ‘Safer Food Better Business’ pack can be downloaded from http://www.food.gov.uk/business-industry/caterers/sfbb NCASS (Nationwide Caterers Association for mobile traders) Nationwide Caterers Association, Association House, 89 Mappleborough Road, Shirley, Solihull, B90 1AG. Telephone: 0121 603 2524. www.ncass.org.uk www.facebook.com/nationwidecaterersassociation