STGCL.SWP.31.1_Operation and Cleaning of Biological Safety

advertisement

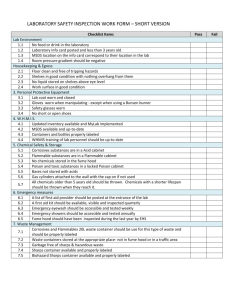

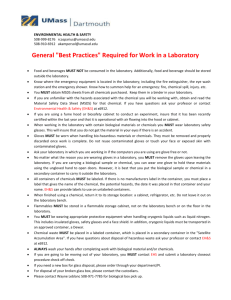

OHS026 Safe Work Procedure Faculty/Division Medicine Document number STGCL.SWP.31.1 (Replaces MED SOP 4.1) School/ Divisional Unit St George Clinical School Initial Issue date Current version 18TH March 2005 1.0 Current Version Issue date 08/03/2010 Next review date March 2012 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Safe Work Procedure for the Operation of Email Class II Biological Safety Cabinet Description: This Safe Work Procedure describes how to safely operate Class II Biological Safety Cabinet Associated risk assessment title and location: Describe the activity or process Operation of Biological Safety Cabinet Class II 1. For all work with Biological Safety Cabinets Class II, wear Long sleeved Laboratory Gown, Latex Gloves and closed footwear. 2. Turn the UV Light on (by pressing the UV button once) for 10-15 minutes to sterilize the surface of the biological safety cabinet immediately prior to use. 3. Once this time has elapsed, press the UV switch again to turn the UV light off. 4. Turn the Fan / light of the Biological Safety Cabinet on by pressing the ‘ON’ button. 5. Place all materials needed within the Biological Safety Cabinet before beginning work to minimize disruption to the of the fragile air barrier caused by arm movements in and out of the hood. 6. Manipulation of materials should be delayed approximately one minute after placing the hands/arms inside the Biological Safety Cabinet to allow the airflow in the cabinet to stabilize. 7. Do not block the front air capture grille with arms, equipment or papers. 8. All work should be performed at least 4 inches away from the edge of the grille. 9. Avoid clutter and overcrowding of the cabinet as this will disrupt the air flow. 10. Do not use the Biological Safety Cabinet for storage of items or supplies. 11. All contaminated items must be placed in a discard tray filled with final concentration of 1% Hypochlorite or other appropriate disinfectant within the hood (place pipettes in horizontal soaking trays within the hood) 12. When work is completed, remove all items from the hood. 13. Wipe the hood down with 70% (w/v) alcohol. 14. Switch the fan / light off by pressing the ‘OFF’ button. 15. Remove gloves and discard in Yellow Clinical waste bag 16. Wash hands with Microshield T and dry with paper towel prior to leaving the laboratory. List all resources required including plant, chemicals, personal protective clothing and equipment, etc Operator Biological Safety Cabinet Class II Cells, Media and consumables for cell culture work Long Sleeved Lab Gown, Latex Gloves, Paper towel, Closed Shoes 70% (w/v) ethanol Viraclean Microshield T Paper Towel Handwash station MSDS for cleaning agents / disinfectants ___________________________________________________________________________________________________________ ___________ Page 1 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List potential hazards and risk controls including specific precautions required Hazard: Infection from Biohazard Risk Control: Use Biological Safety Cabinet correctly Risk Control: Wear Long sleeved Laboratory gown, closed shoes, latex gloves Risk Control: Disinfect pipettes, tips etc before moving from the hood Risk Control: Disinfect and clean up any spillages immediately and thoroughly Risk Control: Clean cabinet on a regular basis Risk Control: Wash Hands thoroughly with Microshield T when work is completed Hazard: Chemicals used for disinfection Risk Control: Read MSDS and handle according to the MSDS List emergency shutdown instructions Switch hood off by pressing the ‘OFF’ Button List clean up and waste disposal requirements General Cleaning of Biological Safety Cabinet Class II 1. Wear protective clothing (gloves, gown, face mask, enclosed shoes) at all times. 2. Remove grill and working tray from hood. 3. Clean inside surfaces with detergent solution eg Viraclean; rinse out with water and wipe dry. 4. Decontaminate the surfaces by wiping with 70% (w/v) ethanol (Careful: Flammable liquid) using paper towel. 5. Clean tray and grille with detergent solution; rinse with water; return to hood and decontaminate by wiping with 70% (w/v) ethanol. 6. Clean the glass, inside and out, with 70% (w/v) ethanol; wipe dry. 7. Place cover on hood and turn UV light on for 10-15 minutes. 8. Sign and date cleaning log 9. Dispose of all contaminated wipes into a yellow clinical waste bag for autoclaving. Decontamination of the Biological Safety Cabinet following spill 1. Cover the spillage with neat Viraclean disinfectant and leave for 10 minutes. 2. Wipe up the spillage / disinfectant with paper towel and discard in yellow clinical waste bag. 3. Cover the area where the spillage occurred with neat Viraclean disinfectant again and leave for a further 10 minutes. 4. Wipe up the area with paper towel. 5. Remove gloves and discard in Yellow Clinical waste bag 6. Wash hands with Microshield T and dry with paper towel prior to leaving the laboratory. 7. If spillage is large and has gone through the front and rear grille, surface decontaminate all items within the hood and remove. 8. Pour neat Viraclean or other neutral disinfectant on the hood through the grilles and into the drain pan. 9. Allow at least 10 minutes contact time 10. Dry the hood surface with paper towels and discard in Biohazard bag 11. Lift out the working tray and mop up the disinfected spillage with paper towel. Discard in Biohazard Bag. 12. Pour Neat Viraclean on the spillage area again and after a further 10 minutes wipe with paper towel. Discard Paper towel in clinical waste bag. 13. Remove gloves and discard in Yellow Clinical waste bag 14. Wash hands with Microshield T and dry with paper towel prior to leaving the laboratory. ___________________________________________________________________________________________________________ ___________ Page 2 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List legislation, standards and codes of practice used in the development of the SWP Instruction Manual for Biological Safety Cabinet AS/NZS 2243.3 2002 Supervisory approval, training, and review Supervisor: Prof Michael Grimm Signature: Supervisor: Prof Beng Chong Signature: Supervisor: Prof S. Krilis Signature: Supervisor: Signature: Supervisor: Signature: Plant custodian: Prof Michael Grimm Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: PC2 Training, Training on this SWP SWP review date: March 2012 Responsibility for SWP review: Sinead O’Reilly ___________________________________________________________________________________________________________ ___________ Page 3 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007