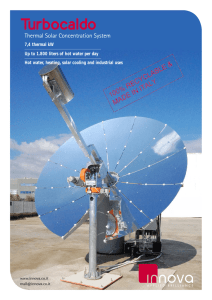

Top Cooler von BBA INNOVA erfolgreich bei Chemieunternehmen

advertisement

The Top Cooler made by BBA INNOVA is being successfully installed by chemical company Double cooling is the best! BBA INNOVA AG is based in Aarau, in Switzerland, which is not far from Basel. Our engineering services department are able to attend to numerous international customers in Europe, the USA, South America and the Far East from here. A very high concentration of chemical and pharmaceutical companies are already located in the France / Germany / Switzerland intersection area around Basel and the engineers and consultants at BBA INNOVA are frequently asked about the continuous cooling of viscous masses, which is one of the areas that the Company specialises in. Simple solutions can result in major improvements in efficiency, as shown in the following case. A Swiss subsidiary of a major chemicals company in the area around Aarau was looking for a cooling system that would easily work up to its capacity limits, together with the provision of rapid and unconventional support. BBA INNOVA was able to provide this rapid support with their unconventional Top Cooler concept. The existing cooling power was significantly increased for comparatively little expense and the throughput was also increased by up to 50 per cent. Objective: Increasing throughput rate up to 50 percent This concept was used in a product line covering up to 50 different types of product, which included different thermal capacities and hardening characteristics. The steel belt’s existing cooling and hardening processes continually resulted in production line bottlenecks occurring. The normal parameter optimisations that could be implemented for the steel cooling-belt were no longer able to provide the required result. The company’s plant manager, who cannot be named for competition-related reasons, said that: “We did not want to make a major investment in this situation, but rather to expand with another production line or procure a completely new cooling system as we were looking for a solution back in 2010 that would also accelerate the cooling process. The bottleneck occurred here and not in the upstream or downstream production stages.” The enquiry submitted to BBA Innova was also aimed at implementing options and measures that would increase the throughput rate of the existing steel cooling-belt by up to 50 per cent. The Top Cooler concept was considered to be the ideal solution after the engineers from BBA Innova had conducted an onsite inspection and surveyed the plant at the relevant facility. “It was important to measure the present cooling power as well as the possible belt speeds and especially the throughput capacity of the existing plant. It was imperative that the statics concurred”, said Hans-Jürgen Schmotzer, the sales manager at BBA Innova, “as our Top Cooler had to be installed directly on the existing steel cooling-belt”. It did not matter whether BBA Innova or another manufacturer had supplied the steel belt cooler that is currently being used. Matching Assortment of Materials This is one of the precise benefits of the Top Cooler principle: The sandwich design will result in a distinct increase in the cooling process regardless of the make of cooling belts that are presently being used. The entire system works as follows during on-going production: Moving chain sections are used in the Top Cooler to rotate the installed cooling plates at a speed synchronised to the steel conveyer underneath them. A belt that makes direct contact with the product on the lower steel belt cooler is also conducted around the cooling plates. The belt support material allows a selection of surface materials to be applied. The customer is able to choose the coating that matches the requirements relating to his products (FDA, high temperature resistant, non-stick, etc.) Convenient functionality The contact pressure applied by the Top Cooler in the cooling system’s “sandwich area” ensures better performance on its own, as the product is always in close contact with the steel belt cooler, whose controlled temperature is sprayed by water jets fitted beneath it. This results in improved heat extraction. “This combined with the cooling circuit integrated in the Top Cooler means that the existing performance can be increased by up to 50 per cent, but this depends on the product and the belt coating”, said Hans-Jürgen Schmotzer from BBA Innova. Another benefit is that the cooling element can easily be raised for cleaning, for example, before a product change takes place: “This also guarantees easy operation and great flexibility, even the operating side can be installed differently in order to comply with the customers wishes and local conditions.” Perfect fit BBA INNOVA’s Swiss customer also said: A specific Top Cooler was produced for us after the cooler specialists from BBA Innova had completed their calculations and it fits perfectly on the existing system that was made by another manufacturer and it was also designed and adapted to meet the required increase in the cooling power. The Top Cooler actually covers less than a third of the overall cooling zone, yet it provides a 50 per cent performance increase. “What we hoped to achieve with BBA Innova has actually been fully realised here. This shows that our partner from Aarau is not only completely flexible when it comes to designing systems, but also in fully implementing the contract”, said the very pleased customer’s plant manager with regard to BBA Innova’s approach to designing and manufacturing the Top Cooler, in order to jointly gain further experience in current production operations. The machine has been lent to the customer for four months with a take-back option. This does not present a problem for BBA – just the opposite in fact. BBA Innova’s chief executive officer, Wolfgang Kircher, is very pleased to have such an excellent industrial partner. After all, a certain residual risk has to be accepted from the customer’s side. Wolfgang Kircher also said: “It is only with open minded customers that you are able to produce innovations for the final start of series production and successfully position them in the market afterwards.” We would also like to point out that the relevant company has bought the Top Cooler from BBA at the previously agreed remaining purchase price in the meantime. Christof Krüger