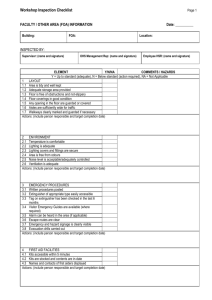

Arts checklist

advertisement

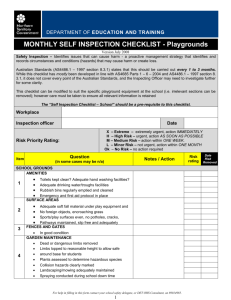

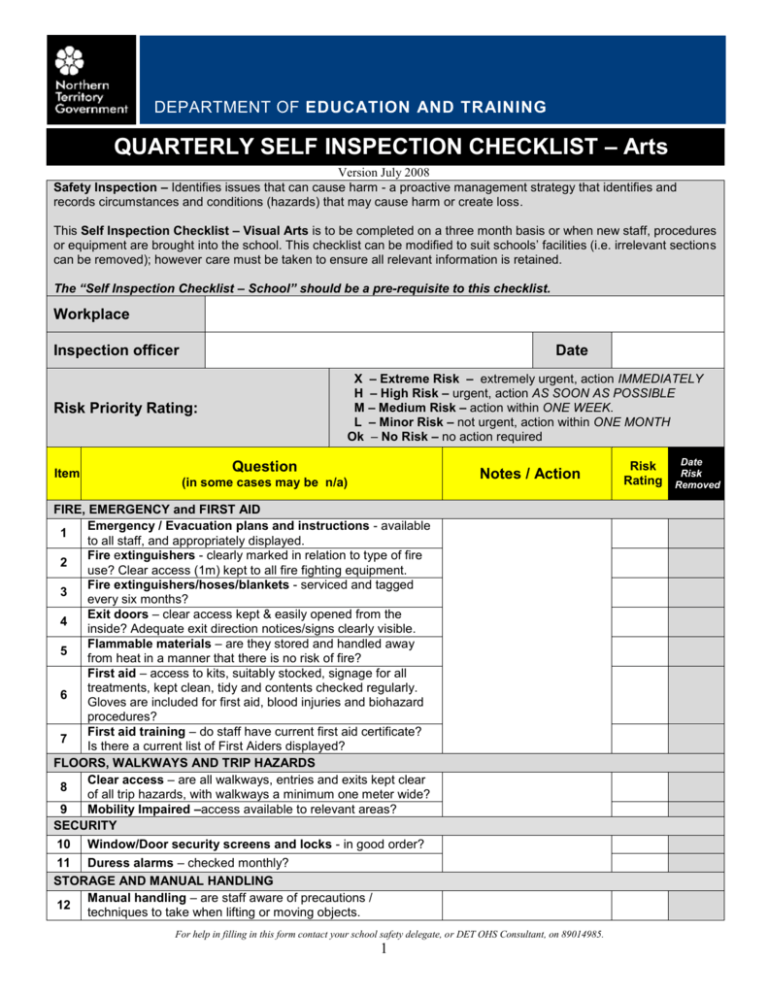

DEPARTMENT OF EDUCATION AND TRAINING QUARTERLY SELF INSPECTION CHECKLIST – Arts Version July 2008 Safety Inspection – Identifies issues that can cause harm - a proactive management strategy that identifies and records circumstances and conditions (hazards) that may cause harm or create loss. This Self Inspection Checklist – Visual Arts is to be completed on a three month basis or when new staff, procedures or equipment are brought into the school. This checklist can be modified to suit schools’ facilities (i.e. irrelevant sections can be removed); however care must be taken to ensure all relevant information is retained. The “Self Inspection Checklist – School” should be a pre-requisite to this checklist. Workplace Inspection officer Date X – Extreme Risk – extremely urgent, action IMMEDIATELY H – High Risk – urgent, action AS SOON AS POSSIBLE M – Medium Risk – action within ONE WEEK. L – Minor Risk – not urgent, action within ONE MONTH Ok – No Risk – no action required Risk Priority Rating: Item Question Notes / Action (in some cases may be n/a) FIRE, EMERGENCY and FIRST AID Emergency / Evacuation plans and instructions - available 1 to all staff, and appropriately displayed. Fire extinguishers - clearly marked in relation to type of fire 2 use? Clear access (1m) kept to all fire fighting equipment. Fire extinguishers/hoses/blankets - serviced and tagged 3 every six months? Exit doors – clear access kept & easily opened from the 4 inside? Adequate exit direction notices/signs clearly visible. Flammable materials – are they stored and handled away 5 from heat in a manner that there is no risk of fire? First aid – access to kits, suitably stocked, signage for all treatments, kept clean, tidy and contents checked regularly. 6 Gloves are included for first aid, blood injuries and biohazard procedures? First aid training – do staff have current first aid certificate? 7 Is there a current list of First Aiders displayed? FLOORS, WALKWAYS AND TRIP HAZARDS Clear access – are all walkways, entries and exits kept clear 8 of all trip hazards, with walkways a minimum one meter wide? 9 Mobility Impaired –access available to relevant areas? SECURITY 10 Window/Door security screens and locks - in good order? 11 Duress alarms – checked monthly? STORAGE AND MANUAL HANDLING Manual handling – are staff aware of precautions / 12 techniques to take when lifting or moving objects. For help in filling in this form contact your school safety delegate, or DET OHS Consultant, on 89014985. 1 Date Risk Risk Rating Removed House keeping –areas suitably clean, tidy, and free of clutter. Shelving - are free standing shelves and cupboards secured 14 to ensure stability, and are items stored at a suitable height and within shelving width? Containers – are there suitable containers used for storage, 15 and are they suitably labelled? WORKPLACE MANAGEMENT AND PRACTICES 16 Floor surfaces – kept clean, tidy and in good condition? 17 Tools - are appropriate tools supplied and used for the job? Training - are staff trained in the correct use of all equipment? 18 Are staff trained in material handling? Training - are staff/students inducted and trained in their 19 retrospective areas prior to commencement of each task? 20 Signage -adequate safety signage displayed? 21 Lighting – Is there adequate lighting? 22 Workstations/benches – are work heights appropriate? Personal Protective Equipment – Is the PPE provided, 23 inspected, maintained and stored appropriately? Housekeeping- all tools, equipment and materials stored 24 adequately? Standard Operating Procedures (SOPs) - have been 25 developed / documented for all tasks carried out, enforced and, if applicable, attached to the equipment? Extraction systems (if applicable) – is there an adequate 26 system in place, and are dust/particles disposed of regularly? 27 Steps/Ladders - are all steps/ladders maintained? SPECIFIC ARTS PRACTICES Enamelling/Jewellery– Are all staff and students aware of the safety hazards when working with kilns? Is a fume cupboard used when acid etching? PPE when etching, enamelling or firing? Fabric crafts PPE worn when working with dyes? Staff aware of which are the correct dyes to use? Staff trained in the correct method for extinguishing a wax fire? Staff aware of hazards with permanent markers, inks and aerosol? Painting Is a spray booth used when spraying or airbrushing? Are adequate respirators worn with all types of spraying? Is appropriate PPE clothing worn during spraying? Sculpture/model making Are staff aware of the hazards of hot wire Styrofoam cutters? PPE gloves, glasses and clothing where appropriate? Ceramics/Pottery – Is earth leakage protection used for all pottery wheels? Are staff aware of hazards of glaze chemicals? Has all asbestos been identified and in good condition? Appropriate signage when kiln is hot? Is the kiln area mechanically vented to outside to remove toxic fumes or heat, and turned on during kiln operation? PPE gloves, glasses, clothing and footwear? Approved PPE gloves when firing or unloading a hot kiln? Are infra red goggles used when looking into a hot kiln? 13 Lead Light work For help in filling in this form contact your school safety delegate, or DET OHS Consultant, on 89014985. 2 Are staff aware of hazards of lead working? Lead is considered a possible carcinogen and cumulative poison. Is equipment cleaned by wet sponging and not dusting? PPE respirator, clothing and eye protection? ELECTRICAL Electrical register - is one kept of all electrical items, tagged, 28 tested & updated? Electrical power boards – do they have overload cut off 29 switch? Have double adapters been removed from workplace? Electrical – are plugs, sockets, switches, extension leads kept 30 in good condition and maintained regularly? 31 Electrical - walkways clear of leads etc? CHEMICALS Chemical Register –all chemicals, solvents and enamel 32 powders clearly labelled, adequately stored and registered? MSDS – are Material Safety Data Sheets available for all 33 workplace chemicals? 34 Oily rags – are stored in steel bins with tight fitting lids? Training – is suitable training on workplace chemicals and 35 material handling given to staff and students? Disposal - are there adequate disposal protocols for waste in 36 liquid storage areas as per the MSDS? 37 Spill Control - procedures in place for chemical spills? Consequences This matrix can be used to identify the level of risk and help to prioritise any control measures. Consider the consequences and likelihood for each to the identified hazards and use the table to obtain the risk level. Further information regarding determining the level of risk can be found via the following link – http://www.det.nt.gov.au/education/policiesandfo rms/docs/self_inspection/risk_management_pro cess.pdf Likelihood Determining the Level of Risk Insignificant Minor Moderate Major Severe Very High Probability Low Medium High Extreme Extreme High Probability Low Medium High High Extreme Equal Probability Low Medium Medium High High Low Probability Low Low Medium Medium High Very Low Probability Low Low Medium Medium High This checklist should be “signed off” and registered within one month of the inspection date stated on page one Principal’s name Signature Date Comments: ………………………………………………………………………………………………………… ……………………………………………………………………………………………………………………… ……………………………………………………………………………………………………………………… ……………………………………………………………………………………………………………………… For help in filling in this form contact your school safety delegate, or DET OHS Consultant, on 89014985. 3