Steam - TU Delft: Geo

advertisement

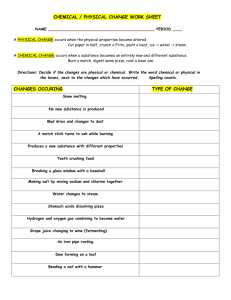

1 Wettability Alteration and Imbibition Effects in Steam Recovery from Matrix Blocks in Fractured Reservoirs SIYAVASH MOTEALLEH, BERT-RIK DE ZWART AND HANS BRUINING DIETZ LABORATORY, CENTRE OF TECHNICAL GEOSCIENCE DELFT UNIVERSITY OF TECHNOLOGY DELFT, THE NETHERLANDS Abstract Imbibition in matrix blocks is one of the most important mechanisms for oil recovery from fractured reservoirs. However, imbibition is impeded if the matrix blocks are oil-wet. The alteration of wetting from oil-wet to water-wet enhances the recovery. Contact angle measurements show that steam (high temperature) alters the wetting properties. Therefore steam injection has been suggested as an alternative for water drive. Still, the mechanism of thermally induced wetting changes remains unclear. Moreover a change in contact angle only indicates the possibility of imbibition. An imbibition test involving steam and condensed water will provide more direct evidence of the usefulness of steam drive recovery. Therefore we have conducted steam experiments at 20 bars (218 oC) in tubes filled with carbonate or sand samples. In a number of cases the carbonate samples were made oil-wet by ageing crude oil for 15 days. The porous media were filled with dead oil or with live oil. The tube was closed at one end and injection and production occurred from the same side. At the injection side one used either electrical heating or steam heating. This configuration is considered representative of a matrix block facing a fracture through which steam is blown. The experiments in the water-wet system show that an important contribution to the recovery of oil comes from imbibition. Experiments in the oil-wet system show a smaller but significant contribution due to imbibition, showing that the high temperature was able to change the wetting properties in the porous medium. Introduction Water drive recovery from fractured reservoirs (e.g. carbonate reservoirs) is low, typically a few percent, if only oil from the fractures can be recovered8. Therefore there is much interest in methods that can stimulate recovery from the matrix. Reis9 gives an overview of possible mechanisms that contribute to steam drive recovery of oil in fractured reservoirs. He concludes that thermal expansion is the main mechanism for additional oil recovery with respect to water drive. Solution gas drive is considered as a less important mechanism. However, thermal methods can also enhance imbibition because they are able to decrease the viscosity. It has also been suggested that heat can alter the wettability from oil-wet to water-wet1,2,5. Evidence that steam is indeed able to alter the wettability in carbonates from oil to water-wet is found in contact angle measurements7,11. All these experiments were conducted below 100 oC. We did not find literature on contact angle measurements in the crude oil-brine- CaCO3 system at elevated temperatures (> 100 oC). Al-Hadhrami and Blunt1 theoretically investigated the effect of wettability alteration on oil recovery in carbonate rocks. They mention wetting alteration by the application of steam or hot water as a mechanism to enhance imbibition. 13th European Symposium on Improved Oil Recovery — Budapest, Hungary, 25 - 27 April 2005 2 A few tube experiments mimicking fractured reservoir behavior have been reported in the literature. Sumnu, et al.10 reported experiments on a sand stone core filled with water, where a spacing between the core holder and the core represented the fracture. The experiments were used to validate numerical modeling. Numerical simulation for oil filled cores showed that imbibition was the most important mechanism. Tang and Kovscek5,6 conducted isothermal counter-current imbibition experiments at elevated temperatures. They attribute wettability alteration in sandstone reservoirs to fines production. However, in spite of a vast literature on wetting alteration, the mechanism for thermally induced wetting changes remains unclear5. Also there is no clear relation between contact angle measurements and imbibition. Indeed imbibition requires a change in wettability in a complex geometric configuration, whereas in contact angle measurements the configuration is much simpler. Hence an imbibition test involving steam and condensed water can provide more direct evidence of wetting alteration in steam drive recovery. Experiments In total 25 tube experiments were carried out to investigate the mechanisms contributing to steam drive recovery from matrix blocks. More specifically we want to determine the relative importance of thermal expansion, thermally induced solution gas drive and thermally enhanced imbibition (wettability effects). The distinguishing feature of the experiments is that injection and production occur at the same side of the tube. Injection and production Steam entered the tube and produced fluids left the tube at the same side. As an alternative a heating element was used to heat the injection side of the tube to 218-225 oC. In this case we used either only heating or also bypassed water in front of the injection/production side. Produced fluids were cooled by a heat exchanger and liquids were collected in a graded cylinder. Reading errors of the graded cylinder are estimated at 5% of aliquots of 10 ml in the small cylinder and less than 1% in the large cylinder. Gases were measured by a wet gas meter. The pressure regulator maintained a pressure of 20 bars, monitored by a pressure transducer, during the experiment. Porous medium properties The sand used originated from the Maas river bedding and has an average grain diameter of 90 m. The porosity of the sand has been determined by weighing and was in all cases about . The Carman-Kozeny relation estimates a sand permeability of 9.5 Darcy. We crushed carbonate rock to produce carbonate grains with size range between 100-200 m diameter. For a water-wet carbonate system we ran the experiments with carbonate outcrop samples obtained from Egypt and Mexico. The oil-wet experiment used a carbonate sample from the Qishn outcrop, which is representative of the Shu'aiba reservoir. Sample preparation First the tube was filled with crushed carbonate or sand. The sample was saturated with oil at connate water saturation. The tube (ID = 0.04 m and length is 0.26 or 0.15 m) was evacuated for 48 hours. Then the tube was mounted in a vertical position and one side of the tube was connected via tubing to a water reservoir. Due to the vacuum created the whole pore space was filled with air free (double distilled) water and the porosity could be measured. Then the tube was mounted in the setup and flushed with two or three pore volumes of oil. For oil-wet experiments the sample was allowed to age for 15 days. Connate water saturations varied between 0.2 and 0.4. After each experiment the grain pack was cleaned by flushing steam through the core for 12 hours. 3 Oil properties The oil used consists either of pure hexadecane, live oil (hexadecane + methane) or crude oil from Qarn Alam (Oman) (oil-wet system). For the live oil experiments we mixed 175 ml hexadecane with 2014 ml of methane in the two ISCO pumps. The mixture was pumped from one pump to the other at 40 bar for 24 hours. The density of hexadecane (285 K) = 770 [kg/m3] and the temperature dependent viscosity [Pa.s] is described by ln = 1803.27/T - 11.8519. For crude oil the density at 285 K is 866 [kg/m3] and the temperature dependent viscosity [Pa.s] is described by ln = -8.589 + 377.7/(T-200.9). The crude oil contains 0.84 gr asphaltene / 100 ml oil and the acid number is 0.84 mg KOH/g. Experimental results The experiments discussed below only differ with respect to the experimental parameters that were varied in our study; method of heating (steam or electrical); type of oil (live oil, dead oil or crude oil); type of medium (carbonates or sand); circulation of water in the fracture and wetting of the porous medium (oil-wet or water-wet). Sand experiments First we discuss experiments performed with sand (see Figure 1) in a 0.26 m long tube. In these experiments we used both dead and live oil and also both heating methods. We observed the lowest recovery with electric heating and dead oil. Electric heating with live oil gave a higher recovery. However with steam we found much larger recovery. All but one of the steam experiments were carried out using live oil. The dead oil steam experiment produced about the same amount of oil as the live oil experiments. The steam experiments show a large recovery variation. This recovery is not correlated to the amount of steam used in the experiments. The recovery variation possibly depends on the pressure fluctuations during the experiments. The oil production (Np) of the six live oil experiments can be expressed in terms of the standard deviation of pressure (s) during the live oil experiments as Np = 0.20 ± 0.29 + (2.64 ± 1.24)s [ml/oC]. Water-wet versus oil-wet systems To investigate the importance of wetting on imbibition processes in the matrix we used crushed carbonate and sand samples in water-wet and oil-wet conditions. Figure 2 plots the cumulative oil production versus the average temperature (oC) for experiments at water-wet conditions4. A first observation from Figure 2 is that experiments performed under identical conditions show a good reproducibility. Also all experiments reached a steady state temperature profile due to the balance between heating at the injection/ production side and heat losses from the reactor tube. After reaching a steady state temperature, the experiments were continued to observe extra oil recovery from the samples. In experiments HW_c1 and HW_c2 water, which were heated to 225 degrees, water was circulated through the injection/production side of the tube. The production only increased very slowly with increasing average temperature. A steady state average temperature was attained at 170 oC. The experiment was continued during steady state temperature conditions for more than one day during which a considerable amount of oil was produced. In contrast, the oil production for the steam experiment (steam_c) increased more steadily before it reached a steady state temperature profile. The experiment EH-c concerned an experiment where we only used electrical heating without circulating water. We observed a steady increase of cumulative production as the average temperature increased. Finally, for reasons of comparison with Figure 1 we show three equivalent experiments EH-s,1,2,3 using sand and electrical heating without circulating water. Pressure fluctuations in all these experiments were small (<0.5 bar). 13th European Symposium on Improved Oil Recovery — Budapest, Hungary, 25 - 27 April 2005 4 100 steam experiments 90 oil production (ml) 80 70 60 50 dead oil 40 E- heating life oil 30 20 E- heating dead oil 10 0 0 50 100 150 average temperature oC Figure 1. Experiments in 26 cm tube with a pore volume of 131 ml. We distinguish experiments with steam (all live oil except the one indicated (dead oil)) and electric heating experiments with live and with dead oil. Figure 2. Oil production versus average temperature for selected experiments with carbonates and sand for water-wet conditions in the 15 cm tube (PV 85 ml). The indication is as follows: steam-c means experiment circulating steam with the tube filled with crushed carbonate. HW-c1, HW-c2 are two experiments circulating water heated electrically. EH-s1,2,3 are three sand experiments using electrical heating without circulating water. EH-c is an experiment using electrical heating with crushed carbonate. Figure 3 shows experiments carried out with oil-wet conditions. The pressure fluctuations of these experiments were small (< 0.5 bar), except otherwise stated. In experiments "HW_Crudeoil" and "EH 1,2,3" we did not age for 15 days, but replaced the (aged) oil used in the previous experiment with fresh oil and performed the experiment the next day. In the steam 5 experiment (Steam_oilwet) we observe a steady increase with temperature until the average temperature reached its steady state value at 160 oC. During the next two hours an additional 5 ml of oil was produced. The pressure fluctuations in this experiment were very high (3.6 bar). The experiments "HW_oilwet 1-4" show an almost linear increase with the average temperature until the steady state temperature profile is attained. Figure 3. Oil production versus average temperature for selected experiments with crushed carbonates for oil-wet conditions. The indication is as follows: Steam_oil-wet means experiment circulating steam. HW_oilwet1-4 and HW_Crude oil concern experiments circulating water heated electrically. EH 1,2,3 are three experiments using electrical heating without circulating water. Figure 4. Comparison of experiments with oil-wet and water-wet carbonate cores plotted versus the square root of time. The oil production for “Cold water circulation” shows only very small oil production at the start of the experiment. The average temperatures at steady state conditions varied between 165 – 170 oC, because different experiments used slightly different electrical power. Experiments "HW_oilwet 1-3" show an additional production of about 10 ml during steady state temperature conditions. 13th European Symposium on Improved Oil Recovery — Budapest, Hungary, 25 - 27 April 2005 6 Experiment "HW_oilwet 4" produced only an additional 5 ml. Experiment "HW_Crudeoil" shows a higher oil production between 100 – 165 oC than experiments "HW_oilwet 1-4". Experiment "HW_Crudeoil" exhibited pressure fluctuations of 2.1 bars. Finally in experiments "EH 1,2,3" no water circulation was applied. The production is more or less linear with the temperature. Figure 4 plots the recoveries from the water-wet experiment HW_waterwet1 and the oil-wet experiments HW_oilwet1-4 versus the square root of time. All experiments show initially a large increase of the cumulative oil production followed by a slower production rate. The water-wet experiment shows initially a smaller contribution, but eventually its cumulative production exceeds the production from the oil-wet experiments. The experiment circulating cold water was performed with a carbonate sample aged with crude oil for more than 15 days. This experiment shows no oil production after an initial production of 1.4 ml. Contact angle measurements Contact angle measurements showed that “Qishn” outcrop carbonates (blocks of 0.7 × 2.5 × 2.5 cm3) made oil-wet using lauric acid became water-wet again when the temperature was raised above 60 oC. A block exposed to crude oil was shown to exhibit oil-wet behavior (contact angle 137o) as opposed to the experiment where the same block was exposed to hexadecane, which remained water-wet (~15o). The block exposed to crude oil remained oil-wet even after immersing it in a water bath of 70 oC for five days. In the current setup heating to higher temperatures was not feasible. Discussion First we discuss experiments performed with sand, shown in Figure 1. The experiments using electrical heating of dead oil are expected to only show a contribution due to thermal expansion, but it includes a contribution due to expansion of spuriously introduced trapped air. The electrical heating experiments with live oil show an additional contribution due to solution gas drive effects. In our experiment the (conducted) heating rate is larger than for normal porous media, because it is dominated by the high thermal conductivity of the iron tube. The much higher recovery shown in Figure 1 using steam heating can be attributed to imbibition effects. The experiments show large variations in recovery. The single dead-oil experiment shows about the same recovery as the recovery from the live oil experiments. It is plausible that the large variations for the live-oil steam experiments can be correlated to the pressure fluctuations. Further work on this subject has to be done. We now turn to a comparison between sand and carbonate experiments. The sand experiments EH_s1,2,3 and the carbonate experiment EH_c1, all for water-wet conditions, show about the same behavior because the oil production mechanism is dominated by the thermal expansion of the oil. The electrical heating experiments circulating water i.e. HW_c1, HW_c2 show initially less production than the experiments without circulating water. Possibly this can be attributed to trivial reasons e.g. dead volume effects. The production increase of HW_c1, HW_c2, after attainment of the steady state temperature profile, is attributed to imbibition effects. There is no clear reason why the imbibition effects in HW_c1, HW_c2 is so much delayed with respect to the imbibition effects in the Steam_c experiment. Indeed the Steam_c experiment shows similar behavior as the experiment with dead oil and steam heating shown in Figure 1. Also thermal expansion and imbibition are the main contributors to the oil recovery in the crude oil (oil-wet) experiments shown in Figure 3. The experiment HW_crude oil shows an early imbibition effect. It is tempting to relate this behavior to the fact that this experiment was only aged for 2 days as opposed to the experiments HW_oilwet1-4, which were aged for 15 days. 7 However this behavior is not shown in the experiments with (water-wet) hexadecane experiments shown in Figure 2. The experiments HW_oilwet1-4 show imbibition effects in spite of aging for 15 days. From this it is concluded that hot water (225oC) is able to change the wetting behavior of the carbonates, made oil-wet with crude oil. High temperatures are required because the contact angle measurements for crude oil show no effect on wetting below 70oC. The steam experiment shows a contribution of the imbibition much sooner than the water circulation experiments. We have no explanation for this difference between steam experiments and circulating hot-water experiments. Figure 4 shows that the water-wet experiment HW_waterwet1 has a larger contribution due to imbibition than the oil-wet experiments HW_oilwet1-4. In all curves two slopes are observed. The first slope represents initial oil production due to thermal expansion. The second slope represents imbibition effects and the slopes become proportional to the square root of time within experimental error. This is further evidence that the recovery mechanism is imbibition. However the slopes for the single water-wet experiment and the four oil-wet experiments are different. Cumulative oil production3 is proportional to the square root of the dimensionless time tD. For the oil-wet samples the slope is roughly one third of the slope in the water-wet samples. This shows that the behavior of initially oil-wet samples is different from the totally water-wet experiment. The factor relating the time to the dimensionless time3 contains both viscosity effects and relative permeability effects. If only viscosity effects would explain the difference in slopes in Figure 4 we would only expect a ratio of about 1.02, which is far too low as can be seen in Figure 4. Another explanation could be a different relative permeability behavior of the water-wet samples. However all results are obtained with Qishn outcrop samples, which should have similar relative permeability behavior for the same wetting conditions. Hence the sample has been converted from a completely oil-wet to a partially water-wet medium. The fact that we observe such a contribution due to imbibition indicates that hot water (225 oC) is able to gradually convert the sample to water-wet behavior. Experiment “Cold water circulation” in Figure 4 shows that at room temperature no wetting alteration is induced. If the initially oil-wet samples would remain oil-wet there can be no contribution to the recovery during the period that the temperature remains stationary. Hence our experiments show unambiguously that hot water can imbibe in an originally oil-wet carbonate sample. We conclude that due to heating the wettability of the samples is changed. In the field the exposure times are longer and hence the conversion to water-wetness can be expected to be more effective. Conclusions 1. Electrically heated experiments with dead oil give only a contribution due to thermal expansion. Experiments with live oil show an additional contribution due to thermally liberated solution gas. 2. For steam experiments a large additional contribution to oil production due to imbibition is observed in both sand and carbonate samples. 3. Contact angle measurements at 70 oC, showed no effect of heat treatment on the carbonate sample made oil-wet by crude oil. However, the same temperature is able to reverse the wettability of a carbonate sample made oil-wet with lauric acid. 13th European Symposium on Improved Oil Recovery — Budapest, Hungary, 25 - 27 April 2005 8 4. Hot water is able to gradually change the wetting of carbonate samples made oil-wet with crude oil. All oil-wet experiments show a contribution due to imbibition. This contribution is, however, smaller than for the water-wet samples. Acknowledgement We thank Shell(E&P) for financial support. We thank Wim Swinkels for providing outcrop samples and Rien Faber, Dan Pribnow and Arnold de Vries for many discussions and useful suggestions. Technical support was provided by Leo Vogt, Rudi Ephraim and Henk van Asten. References 1. Al-Hadhrami, H.S. and Blunt, M.J. (2001) Thermally induced wettability alteration to improve oil recovery in fractured reservoirs. SPE/DOE Improved Oil Recovery Symposium, Tulsa Oklahoma, 35 April 2000 SPE 59289. 2. Babadagli, T. (2002) Dynamics of Capillary imbibition when surfactant, polymer and hot water are used as aqueous phase for oil recovery . J. of Colloid and Interface Science 246 203-213. 3. Barenblatt, G.I., P.T.W., and Silin, D.B. (2002) The Mathematical Model of Non-equilibrium Effects in Water-Oil Displacement. SPE/DOE Thirteenth Improved Oil Recovery Symposium held in Tulsa, Oklahoma, 13-17 April, 2002 SPE 75169. 4. D.Pribnow Private communication. 5. Guo-qing Tang and Kovscek, A.R. (2002a) Experimental Study of Heavy oil Production from Diatomite by Water Imbibition at Elevated Temperatures. SPE/DOE Thirteenth Improved Oil Recovery Symposium held in Tulsa, Oklahoma, 13-17 April 2002 SPE 75132. 6. Guo-qing Tang and Kovscek, A.R. (2002b) Wettability Alteration in Diatomite Induced by HotFluid Injection. SPE Annual Technical Conference and Exhibition held in San Antonio, Texas, 29 September-2 October 2002 SPE 77461. 7. Hjelmeland, O.S. and Larrondo, L.E. (1986) Experimental Investigation of the Effects of Temperature, Pressure, and Crude Oil Composition on Interfacial Properties. SPERE 321. 8. Macaulay, R.C., Kraft, J.M., Hartemink. M., and Escovedo, B. (1995) Design of a steam pilot in a fractured carbonate reservoir-Qarn Alam Field, Oman. International Heavy Oil Symposium, Calgary, 19-21 June, 1995 SPE 30300. 9. Reis, J.C. (1990) Oil recovery mechanisms in fractured reservoirs during steam injection. seventh symposium on Enhanced Oil Recovery, Tulsa, April 22-25 1990 SPE 20204. 10. Sumnu, M.D., Brigham, W.E., Aziz, K., and Castanier, L.M. (1996) An Experimental and Numerical Study on Steam Injection in Fractured Systems. SPE/DOE Tenth Symposium on Improved Oil Recovery held in Tulsa, Oklahoma, U.S.A., 21-24 April 1996 SPE 35459. 11. Wang, W. and Gupta, A. (1995) . Investigation of the Effect of Temperature and Pressure on Wettability Using Modified Pendant Drop Method. SPE Annual Technical Conference & Exhibition held in Dallas, TX, U.S.A., 22-25 October 1995 SPE 30544.