University Drug Pharmaceuticals orders its antibiotics every two

advertisement

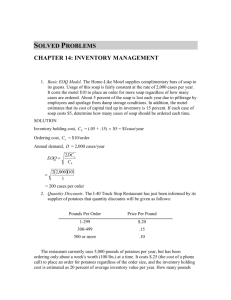

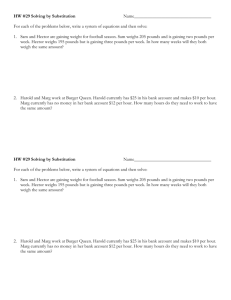

Name (print, please) _______________________________________________ ID ___________________________ Production Management 73-604 Fall 2000 Faculty of Business Administration University of Windsor Midterm Exam 2 Thursday, November 16 Instructor: Mohammed Fazle Baki Aids Permitted: Calculator, straightedge, and a one-sided formula sheet. Time available: 2 hours Instructions: This exam has 10 pages. Please be sure to put your name and student ID number on each page. Show your work. Grading: Question Marks: 1 /6 2 /6 3 /6 4 /6 5 /8 6 /4 7 /4 Total: /40 Name:_________________________________________________ ID:_________________________ Question 1: (6 points) Multiple Choice Questions 1.1 Which of the following are related to JIT? a. A philosophy of waste reduction b. Pull production c. Multi-skilled workers d. Strong supplier relations e. All of the above 1.2 Suppose we want to set up a kanban control system and want to determine the number of kanbam card sets needed. If the expected demand during lead time is 50 per hour, the safety stock is 20% of the demand during lead time, the container size is 4, and the lead time to replenish an order is 4 hours, what is the number of kanban card sets? a. 60 b. 50 c. 30 d. 20 e. 10 1.3 You have just used the Capability Index formulas to compute the two values “min[2,2.5].” Which of the following is the interpretation of these numbers? a. The true Capability index Value is 2.5 b. The mean of the production process has shifted towards the LCL c. The mean of the production process has shifted towards the UCL d. The mean has not shifted at all e. None of the above 2 Name:_________________________________________________ ID:_________________________ 1.4 Quality control charts usually have a central line and upper and lower control limit lines. Which of the following are reasons why the process that is being monitored with the chart should be investigated? a. Plots fall outside the upper or lower limit lines b. Normal behavior c. A large number of plots are on or near the central line d. No real trend in any direction e. All of the above 1.5 The costs of quality include which of the following? a. Appraisal costs b. Prevention costs c. Internal failure costs d. External failure costs e. All of the above 1.6 Which of the following is the ISO 9000 form of certification that requires that a “qualified” national or international standards or certifying agency serve as an auditor? a. First party b. Second party c. Third party d. All of the above e. None of the above 3 Name:_________________________________________________ ID:_________________________ Question 2 (6 points) A particular raw material is available to a company at three different prices, depending on the size of the order: Less than 100 pounds $40 per pound 100 pounds to 999 pounds $38 per pound More than 1,000 pounds $35 per pound The cost to place an order is $30. Annual demand is 1,200 pounds. Holding or carrying cost is 30 percent of the material price. What is the economic order quantity to buy each time? Answer: Quantity Range EOQ Cost, C 2 DS iC Feasible Less than 100 pounds $40 per pound EOQ 2(1200)(30) 77.5 (0.30)( 40) Yes 100 pounds to 999 pounds $38 per pound EOQ 2(1200)(30) 79.5 (0.30)(38) No More than 1,000 pounds $35 per pound EOQ 2(1200)(30) 82.8 (0.30)(38) No Therefore, calculate total cost at (i) Q=77.5, C=$40, (ii) Q=100, C=$38, and (iii) Q=1000, C=$35 Q C 77.5 $40 100 $38 1000 $35 D Q S iC Q 2 1200 77.5 TC (1200)( 40) 30 (0.30)( 40) $48,930 77.5 2 1200 100 TC (1200)(38) 30 (0.30)(38) $46,530 100 2 1200 1000 TC (1200)(35) 30 (0.30)(35) $47,286 1000 2 TC DC The best order size is 100 units at a cost of $38 per unit. 4 Name:_________________________________________________ ID:_________________________ Question 3 (6 points) University Drug Pharmaceuticals orders its antibiotics every two weeks (14 days) when a salesperson visits from one of the pharmaceutical companies. Tetracycline is one of its most prescribed antibiotics, with average daily demand of 2,000 capsules. The standard deviation of daily demand was derived from examining prescriptions filled over the past three months and was found to be 800 capsules. It takes five days for the order to arrive. University Drug would like to satisfy 99 percent of the prescriptions. The salesperson just arrived, and there are currently 25,000 capsules in stock. How many capsules should be ordered? Answer: We have d 2000 capsules per day, T=14 days, L=5 days, 800 capsules per day, and I 25,000 units. q M I d (T L) z T L I d (T L) z T L I 2000(14 5) z (800) 14 5 25000 We have service level = 0.99. Look for area = 0.99-0.50=0.49 in the Standard Normal Distribution table. We get z=2.33 q 2000(14 5) 2.33(800) 14 5 25000 21,125 capsules 5 Name:_________________________________________________ ID:_________________________ Question 4 (6 points) Gentle Ben’s Bar and Restaurant uses 5,000 quart bottles of an imported wine each year. The effervescent wine costs $3 per bottle and is served only in whole bottles because it loses its bubbles quickly. Ben figures that it costs $10 each time an order is placed, and holding costs are 20 percent of the purchase price. It takes three weeks for an order to arrive. Weekly demand is 100 bottles (closed two weeks per year) with a standard deviation of 30 bottles. Ben would like to use an inventory system that minimizes inventory cost and will provide a 95 percent service probability. Determine the order quantity and reorder point. Answer: Qopt 2 DS H 2(5000)10 408.25 bottles (0.20)(3) L L 30 3 52 bottles We have service level = 0.95. Look for area = 0.95-0.50=0.45 in the Standard Normal Distribution table. We get z=1.645 R d L z L 100(3) 1.645(52) 385.54 bottles 6 Name:_________________________________________________ ID:_________________________ Question 5 (8 points) An item has a setup cost of $50 and a weekly holding cost of $1.00 per unit. Currently, there is no item in the inventory. The gross requirements are as follows: Week 1 2 3 4 Gross 20 40 10 30 Requirements a) What should the lot sizes be using economic order quantity (EOQ) and the least unit cost (LUC)? Answer: Lot-sizing technique: EOQ From the 4-week data, annual demand, D=(20+40+10+30)(52/4)=1300 units. Annual holding cost per unit = $1.00(52) = $52.00 2DS 2(1300)(50) 50 units. H 52 Hence, order 50 units whenever the net requirement is negative. Lot-sizing technique: LUC EOQ Order at Week 1 3 Upto Week 1 2 3 4 3 4 Order size 20 60 70 100 10 40 Cumulative Inventory 0 40 60 150 0 30 Carrying cost 0 40 60 150 0 30 Ordering cost 50 50 50 50 50 50 Unit cost 2.50 1.50 1.57 2.00 5.00 2.00 The above worksheet shows that if an order is placed in Week 1, the unit cost is minimum if the order is placed for Weeks 1 and 2. If order is placed in Week 3, the unit cost is minimum if the order is placed for Weeks 3 and 4. Hence, 2 orders are placed; one in Week 1 of size 60 and the other in Week 3 of size 40. Lot-sizing technique: EOQ Lot-sizing technique: LUC Week 1 2 3 4 Week 1 2 3 4 Gross Requirement 20 40 10 30 Gross Requirement 20 40 10 30 Beginning Inventory 0 30 40 30 Beginning Inventory 0 40 0 30 Net Requirements 20 10 0 0 Net Requirements 20 0 10 0 Planned Order receipt 50 50 0 0 Planned Order receipt 60 0 40 0 Ending inventory 30 40 30 0 Ending inventory 40 0 30 0 b) What is the total cost associated with each lot-sizing technique? Answer: EOQ: Cost = ordering cost+holding cost = (50(2))+ (30(1)+40(1)+30(1)+0(1))=$200 LUC: Cost = ordering cost+holding cost = (50(2))+ (30(1)+40(1)+30(1)+0(1))=$170 7 Name:_________________________________________________ ID:_________________________ Question 6 (4 points) The following matrix contains the costs (in dollars) associated with assigning Jobs A, B, C, D, and E to Machines 1, 2, 3, 4, and 5. Assign jobs to machines to minimize costs. Jobs A B C D E 1 6 5 7 4 5 Machines 3 12 10 13 16 17 2 11 12 14 15 13 Answer: 8 4 3 7 8 7 11 5 10 9 12 9 12 Name:_________________________________________________ ID:_________________________ Question 7 (4 points) a) Schedule the following 3 jobs through two machines in sequence to minimize the completion time of the last job processed using Johnson’s rule: Operations Time Job A B C Machine 1 10 7 5 Machine 2 8 3 6 Answer: Minimum operation time is 3 units for Job B on Machine 2. Since the minimum occurs on Machine 2, schedule Job B in the end. Among the remaining jobs A and C, the minimum operation time is 5 units for Job C on Machine 1. Since the minimum occurs on Machine 1, schedule job C in the beginning. The remaining job, Job A is scheduled after Job C and before Job B. Hence, the sequence is C, A, B on both machines. b) For the schedule in Part a, what is the completion time of the last job processed? Answer: Job C A B Start, Process, End Times Machine 1 Machine 2 0,5,5 5,6,11 5,10,15 15,8,23 15,6,21 23,3,26 Hence, the last job processed (Job B) is completed at time 26. 9